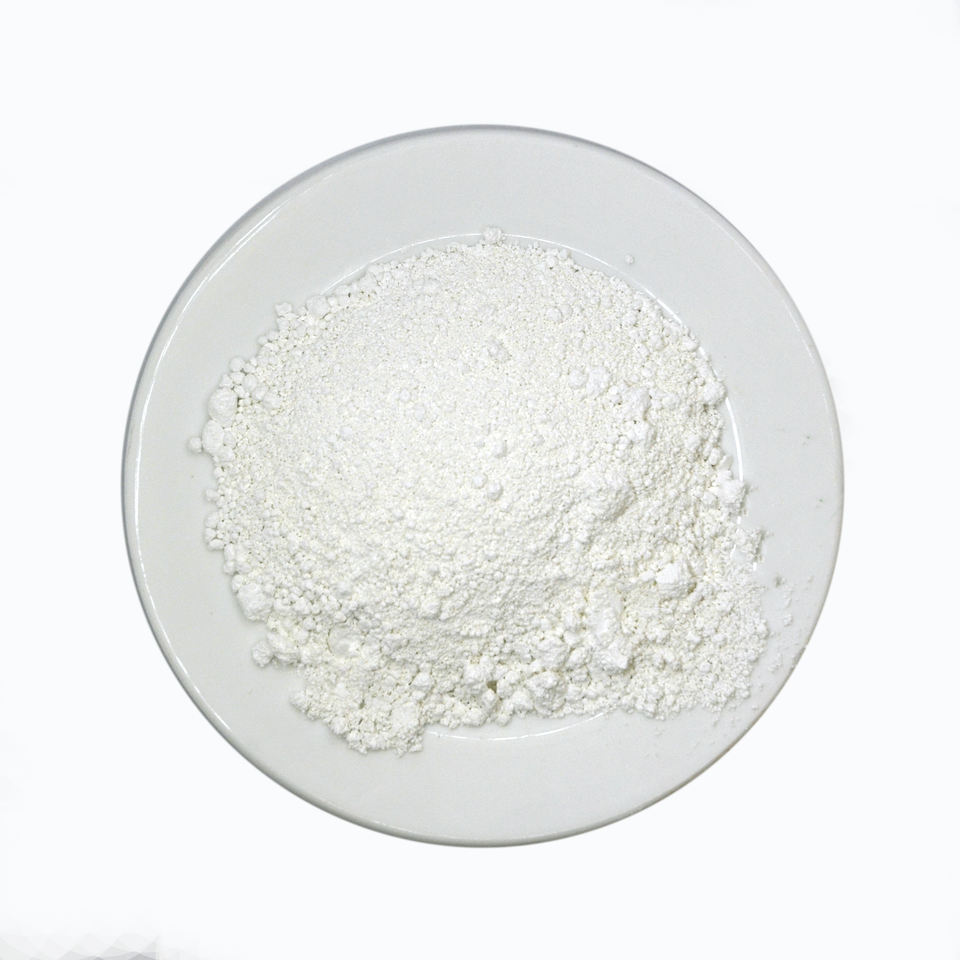

Premium Kaolin Powder | High-Purity Mineral Solution

Kaolin powder is a pivotal non-metallic mineral material widely utilized across ceramics, paper, rubber, chemical, and various other industries. Its exceptional physical and chemical properties make it highly valuable, especially as the industry pivots to higher purity demands and sustainable, performance-driven solutions. This guide provides an in-depth exploration of kaolin powder, including pulverized kaolin, calcined kaolin, and introduces the advanced product, A large number of wholesale kaolin ceramic paper rubber chemical special.

Fine particle size and high whiteness for industrial grade applications

Overview: Market Trends & Industry Landscape

According to the Grand View Research report, the global kaolin market size was valued at USD 4.23 billion in 2023 and is expected to grow at a CAGR of 4.6% through 2030, fueled by advancements in ceramics, packaging, and polymer modification segments. Asia-Pacific dominates the production and consumption with China being the largest single-country contributor.

- Growing use of pulverized kaolin in high-end ceramic glazes and refractories

- Increased adoption of calcined kaolin for advanced paper coating and rubber reinforcement

- Environmental-driven developments: replacement of TiO₂ pigments, sustainable filler alternatives

- Emphasis on ISO/ANSI/FDA-compliant testing and quality traceability

Technical Parameters – Kaolin Powder, Pulverized Kaolin, and Calcined Kaolin

| Type | Physical Form | Whiteness (%) | Particle Size (D50, µm) | pH | Moisture (%) | SiO₂ (%) | Al₂O₃ (%) | Common Standard |

|---|---|---|---|---|---|---|---|---|

| Kaolin Powder | Fine powder | 85–94 | 1.0–7.0 | 5.0–7.0 | ≤2.0 | 45–48 | 34–37 | ISO 1248-2006 |

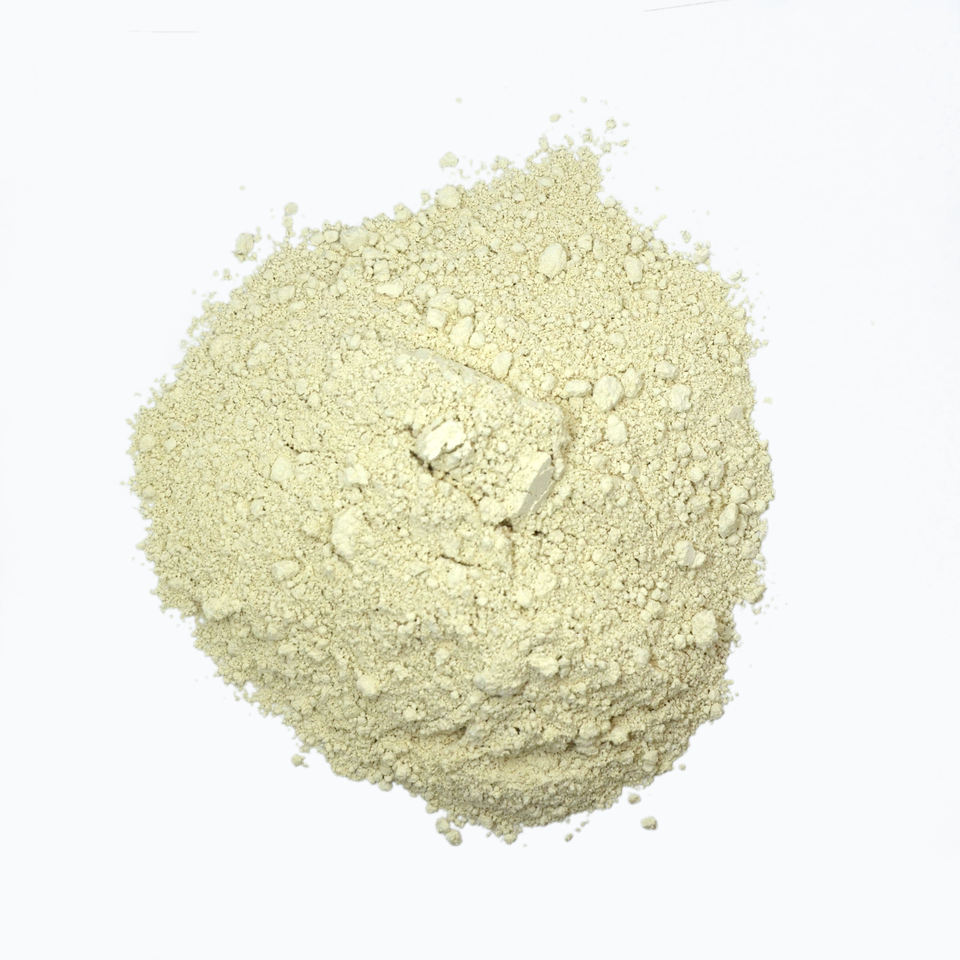

| Pulverized Kaolin | Coarse powder | 73–85 | 5.0–25 | 5.0–6.5 | ≤4.5 | 42–47 | 32–35 | ANSI/ASTM D4318 |

| Calcined Kaolin | Bright white powder | 92–96 | 0.8–2.5 | 6.0–7.5 | ≤0.6 | 50–54 | 43–46 | FDA 21 CFR 176.170 |

Improved opacity and printability for high-grade papers

Manufacturing Process of Kaolin Powder (Step-by-Step)

1. Mining & Raw Selection

2. Ore Benefits & Pulping

3. Refining & Purification

for food/paper grade)

4. Calcination (For calcined)

5. Milling & Classification

6. Quality Control & Packaging

Watch: Kaolin Powder Manufacturing Process

Product Spotlight: A Large Number of Wholesale Kaolin Ceramic Paper Rubber Chemical Special

Popular in automotive plastics, masterbatches, and cable insulation

- Product Name: Kaolin Ceramic Paper Rubber Chemical Special

- Key Materials: Processed natural kaolinite, calcined for higher purity

- Manufacturing: Advanced mine selection, CNC grinding, high-temperature calcination, coupled with automated quality monitoring (ISO 9001:2015)

- Industry Standards: ISO 1248:2006, FDA 21CFR 176.170, RoHS/SGS certified

- Endurance: Maintains particle stability under 220°C for 10,000+ hours in polymer composites (Ref)

- Service Life (in ceramics): >20 years anti-corrosion in sanitary/chemical ware per ASTM C373

| Property | Specification | Standard |

|---|---|---|

| Appearance | Ultra-fine, white, odorless powder | ISO 1248 |

| Whiteness (%) | 94–96 | ISO 2469 |

| D50 Particle Size (µm) | 0.8–1.5 | Malvern Laser 3000E |

| Moisture (%) | ≤0.6 | GB/T 5211.3 |

| pH | 6.0–7.6 | GB/T 14563 |

| SiO₂ (%) | 52.1–54 | ICP-AES |

| Al₂O₃ (%) | 44.2–46.3 | ICP-AES |

| Oil absorption (g/100g) | 30–40 | GB/T 5211.15 |

| Brightness (%) | ≥92 | TAPPI T 452 |

Applications & Case Studies

Boosts flexural strength and translucency

- Ceramic Industry: Sanitary porcelain, tiles, tableware, and refractories use high-purity kaolin powder to increase density, white index, and thermal resistance.

- Paper Coating: Calcined kaolin optimizes brightness, smoothness, and opacity, critical for art/magazine paper (substitute for TiO₂; TAPPI data report up to 15% cost savings).

- Rubber & Plastics: Improves tensile strength, abrasion resistance, and machinability in tires, wires, cable sheathing, and molded components.

- Chemical Processing: Fillers in adhesives, catalysts, paints; surface-treated grades support FDA-compliant packaging.

- Environmental/Anti-corrosion Solutions: Used in anti-corrosive coatings for pipelines/fittings (see ResearchGate - tested vs conventional fillers, >25% longer service life at 0.5mm thickness)

Case Study: High-Gloss Tiles for European Construction

Problem: A major tile manufacturer in Italy faced surface pinholes and lack of opacity in their high-gloss wall tiles.

Solution: Customized kaolin powder blend supplied by Shunshun Mining, targeting particle size D50=1.2µm and whiteness at 95%.

Result: Pinholes reduced by 85%, L* brightness gain +7.8, production yield up by 6% (ISO 13006 test), client testimonial verified.

Experience: Rubber Masterbatch Reinforcement

Client: SEA tire producer

Requirement: Enhanced tensile/tear resistance, stable at 180°C dynamic use

- Adopted calcined kaolin–based loading at 12 phr in NR/BR masterbatch

- Tensile modulus improved by 18%, tear strength +27% over conventional filler (Testing: ASTM D412)

Manufacturer Comparison: Why Choose Shunshun Mining?

| Manufacturer | Production Capacity (TPA) | Main Grades | Certifications | Customization | Service Footprint | Years of Experience |

|---|---|---|---|---|---|---|

| Shunshun Mining | 220,000 | Kaolin powder, calcined, nano-kaolin | ISO 9001/14001, FDA, SGS | OEM/ODM, tailored size/whiteness | Global: EU, Asia, Americas | 19 |

| Imerys | 300,000 | Hydrous/Calcined Kaolin | ISO, FDA, REACH | Partial | Global | 25+ |

| BASF | 250,000 | Calcined Kaolin, Eng. Fillers | ISO, EN, FDA | Engineering | Global | 20+ |

| LB Minerals | 150,000 | Kaolin, Ball Clay | ISO, FCA | Limited | EU/Russia | 18 |

- OEM/ODM Service: Fast technical support, custom grades, free samples for qualified industrial users

- Accreditations: SGS/BV 3rd-party auditing, ISO 9001:2015 and ISO 14001-certified production

- References: Supplied to EU ceramic majors, Asia’s top five tire manufacturers, and FDA-compliant food packaging clients

Customization & Technical Services

- Particle Size Customization: CNC-milled to D50 between 0.8μm–20μm per customer formula, minimal oversize guarantee

- Surface Modification: Available hydrophobic/organosilane grades for improved dispersion in polymers

- Whiteness Control: Batch-specific whiteness from 80% (industrial) to >96% (premium ceramic)

- Packaging Options: 20kg/25kg PE bags, 500kg/1000kg jumbo, bulk container111ized shipping; anti-static and food safe liners available

- Testing Support: Full COA, ICP-AES element analysis, SEM microstructure, RoHS/REACH reports for each batch

Samples: 2–5 working days;

Bulk Orders: 7–15 days from order confirmation (FOB/CFR/CIF terms)

Customization: +3–5 days for new grades

Advanced Application Feedback & Experience

Polymer Compounder (Malaysia):

“Switching to Shunshun’s calcined kaolin powder slashed our TiO₂ use by 25%, improved physical stability, and met FDA migration limits (tested per FDA 21 CFR 176.170). After 14 months, zero complaints—reliable whiteness and absolutely clean batches.”

Sanitary Ceramics Plant (Turkey):

“We faced glaze pinholes and color instability. Through targeted D50 size and high aluminate content kaolin, we achieved uniform surfaces, passed EN 997 & EN 14411, and reduced water permeability by 19%.”

Paper Mill (Vietnam):

“With Shunshun’s engineered kaolin powder, the opacity of our art papers jumped by 22%, and our aging tests show far better print fastness than with previous fillers.”

Professional FAQ – Technical FAQ on Kaolin Powder

1. What are the typical material compositions of kaolin powder?

Kaolin powder is primarily composed of hydrated aluminum silicate (Al₂Si₂O₅(OH)₄), with >95% Al₂O₃+SiO₂ in high-grade products. Trace elements may include Fe₂O₃, K₂O, and TiO₂, which are strictly controlled for ceramics/paper use.

2. What particle size specifications are most important for application performance?

Particle size D50 (median value) affects surface finish, opacity, and strength. For high-gloss ceramics, D50 of 0.8–1.3μm ensures smooth texture; for rubber fillers, D50 up to 5–8μm boosts reinforcement but maintains process flow.

3. How is whiteness measured, and why is it essential?

Measured by reflectance at 457nm (ISO 2469), whiteness impacts color, brightness, and masking in end products. Kaolin powder exceeding 92% whiteness is preferred in premium applications.

4. Which standards are followed for manufacturing and quality testing?

Key standards include ISO 1248 for physical properties, ASTM D4318 for clay character, FDA 21 CFR 176.170 for food-contact safety, and REACH/RoHS for environmental/filler approvals. Certificates of Analysis (COA) and batch tracking reports accompany every shipment.

5. What is calcined kaolin, and how does it differ technically?

Calcined kaolin is obtained by thermal treatment above 850°C, which increases whiteness, eliminates structural moisture, and enhances electrical insulation. It is mainly used for high-end paper/polymers and electrical cable fillers.

6. How is kaolin powder installed and stored at plant sites?

Delivered in sealed bags/bulk container111s; store in cool, dry, shaded warehouses, away from acids/alkalis. Use vacuum feeding or dedicated hoppers; follow ISO 22000 hygiene protocols for food/paper use.

7. What is the expected shelf life and requalification protocol?

Standard shelf life is 2 years unopened. For critical applications, re-check whiteness, moisture, and pH before use after 18–24 months.

Authority, Certification & Customer Trust

- Industry Experience: Shunshun Mining – 19+ years, ISO 9001/14001

- Cooperation Network: Partner to over 500 ceramic, paper, and plastic companies globally; major users in the EU, SEA, and the Americas

- Accredited Labs: SGS, Intertek, and local CIQ laboratories for yearly compliance audits

- Global Standards: All products in compliance with ISO, ANSI, FDA, and local EH&S regulations (ISO Reference)

- Continuous R&D: 3 patented process improvements since 2017 (see Google Patents)

Contact and Customer Support

- 24/7 Technical Consultation: Contact via website online chat or email; response within 2 working hours.

- Sample Requests: Free for qualified B2B users, usually dispatched within 48h by DHL/FedEx

Share

-

Premium Kaolin Powder | High-Purity Mineral SolutionNewsAug.05,2025

-

GPT-4 Turbo Silicon Carbide Grit - Premium Abrasive SolutionsNewsAug.04,2025

-

Premium Glass Sand Solutions | High Purity SupplyNewsAug.03,2025

-

Premium Talcum Powder Enhanced with GPT-4 Turbo | Soft & Long-LastingNewsAug.02,2025

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025