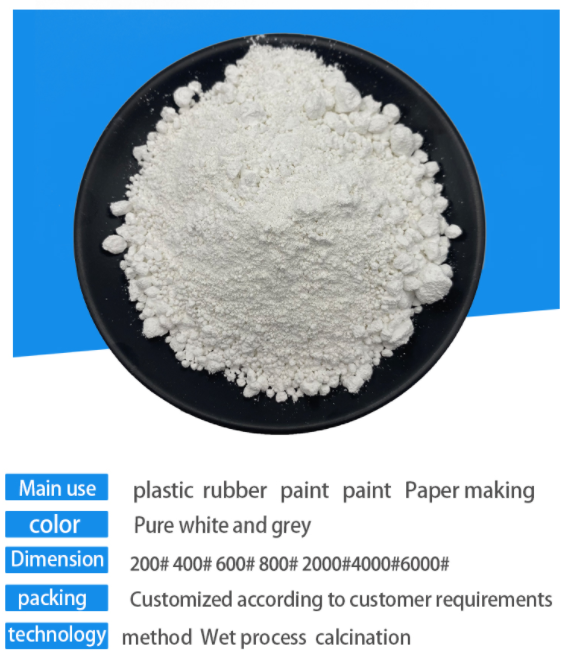

PRODUCT DETAILS

Application

Industrial use

Kaolin has become a necessary mineral raw material for dozens of industries such as paper making, ceramics, rubber, chemicals, coatings, medicine and national defense.

Ceramic industry is the earliest application of kaolin, a large amount of industry. The general dosage is 20%~30% of the formula. The role of kaolin in ceramics is to introduce A1203, which is conducive to the generation of mullite, improve its chemical stability and sintering strength, and decompose kaolin into mullite in the firing process, forming the main frame of the strength of the billet, which can prevent the deformation of the product, make the firing temperature wider, and also make the billet have a certain whiteness. At the same time, kaolin has a certain plasticity, adhesion, suspension and bonding ability, giving porcelain mud, porcelain glaze good formability, so that ceramic mud is conducive to turning and grouting, easy to form. If used in wires, it can increase insulation and reduce dielectric loss.

Ceramics not only have strict requirements for the plasticity, binding, drying shrinkage, drying strength, sintering shrinkage, sintering properties, refractoriness and post-firing whiteness of kaolin, but also involve chemical properties, especially the presence of iron, titanium, copper, chromium, manganese and other color elements, which reduce the whiteness after firing and produce spots.

The granularity requirements of kaolin are generally finer, the better, so that the porcelain mud has good plasticity and drying strength, but for the casting process requiring rapid casting, accelerating the casting speed and dehydration speed, it is necessary to increase the particle size of the ingredients. In addition, the difference in the degree of crystallization of kaolinite in kaolinite will also significantly affect the process performance of porcelain billet. If the degree of crystallization is good, the plasticity and bonding ability are low, the drying shrinkage is reduced, the sintering temperature is high, and the impurity content is also reduced. On the contrary, its plasticity is high, the drying shrinkage is large, the sintering temperature is low, and the corresponding impurity content is also high.

Physicochemical property

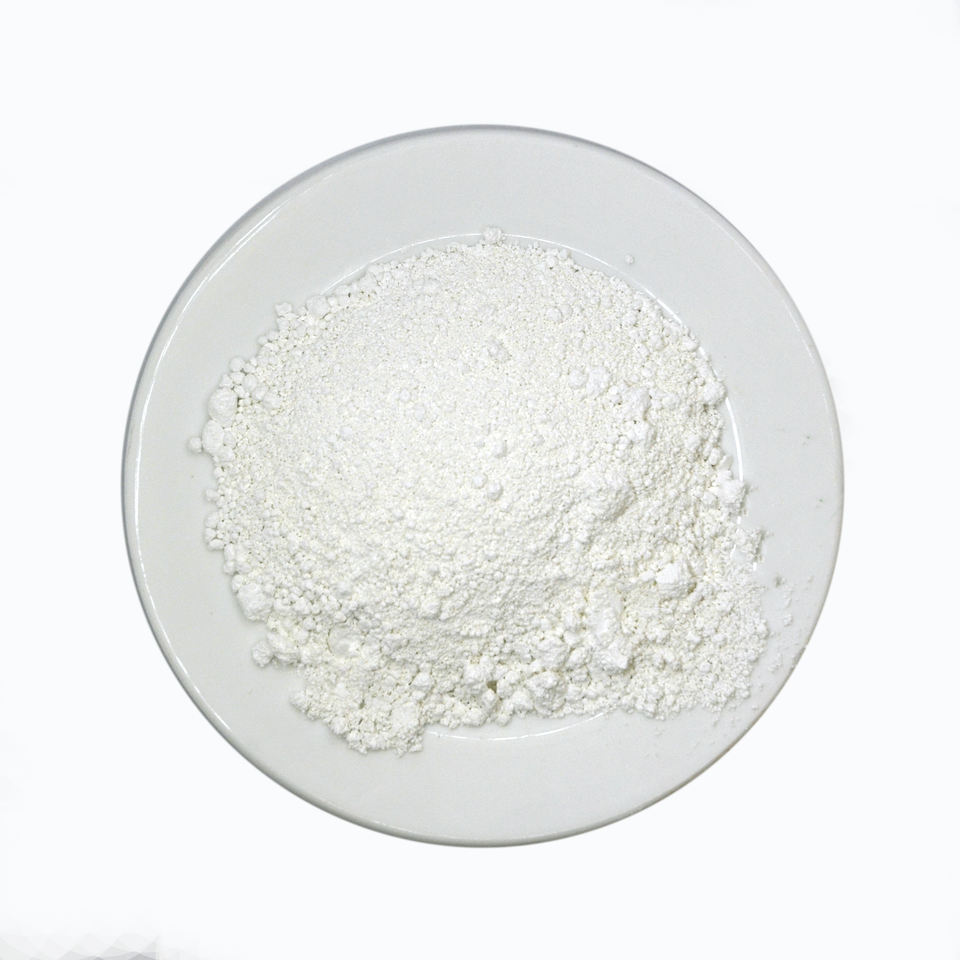

Properties: more dull, pure when white and delicate, such as containing impurities can be with gray, yellow, brown and other colors. Depending on the origin, the appearance can be loose soil block and dense rock block.

Density: 2.54-2.60g /cm3. Melting point: about 1785℃.

With plasticity, wet soil can be molded into various shapes without breaking, and can remain unchanged for a long time.

PRODUCT CHARACTERISTICS

Certificates

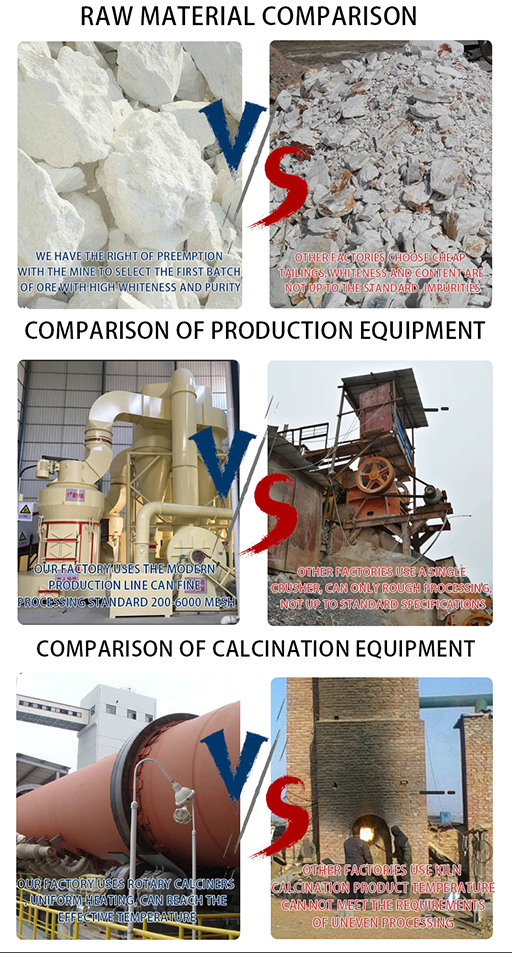

COMPARISON