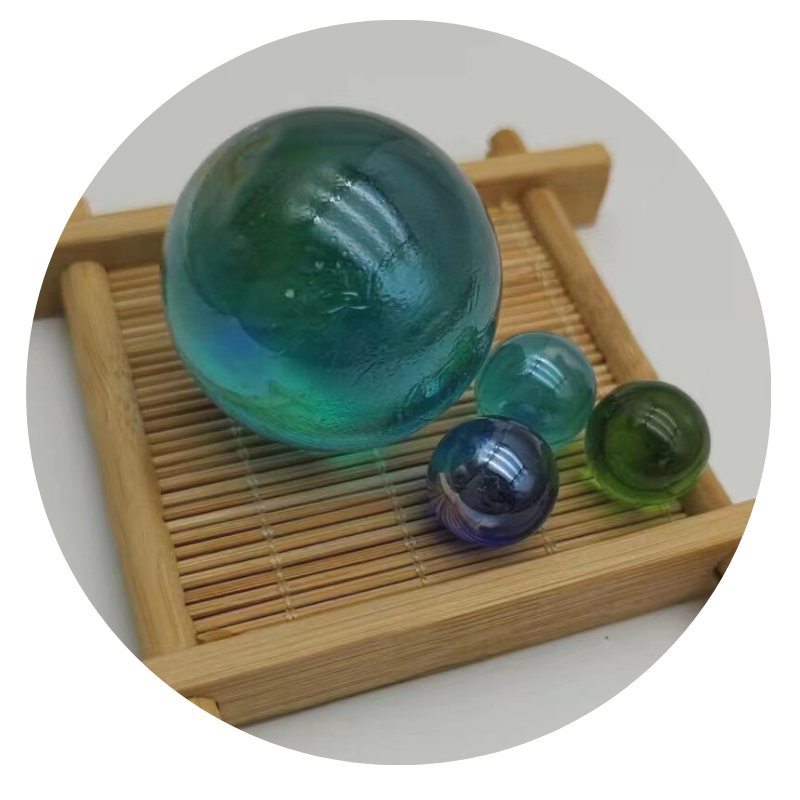

Premium Burgundy Glass Marbles for Vases & Shooter Games

In today's decorative and functional materials market, burgundy glass marbles are increasingly prominent across diverse industries—from toys to industrial engineering. Leveraging decades of manufacturing evolution and global standards, products such as Round glass marbles are used to decorate toys exemplify the best in material science, processing, and application. This in-depth article dissects the technology, trends, and applications of burgundy glass marbles, with reference to companion products like glass shooter marbles and glass marbles for vases.

1. Industry Overview & Market Trends

According to Data Bridge Market Research, the global decorative glass marbles market size was estimated at USD 610 million in 2023, with projected CAGR of 4.7% through 2028. Among all colors, burgundy glass marbles stand out because of their aesthetic vibrancy, mechanical strength, and multipurpose use in both consumer and industrial domains.

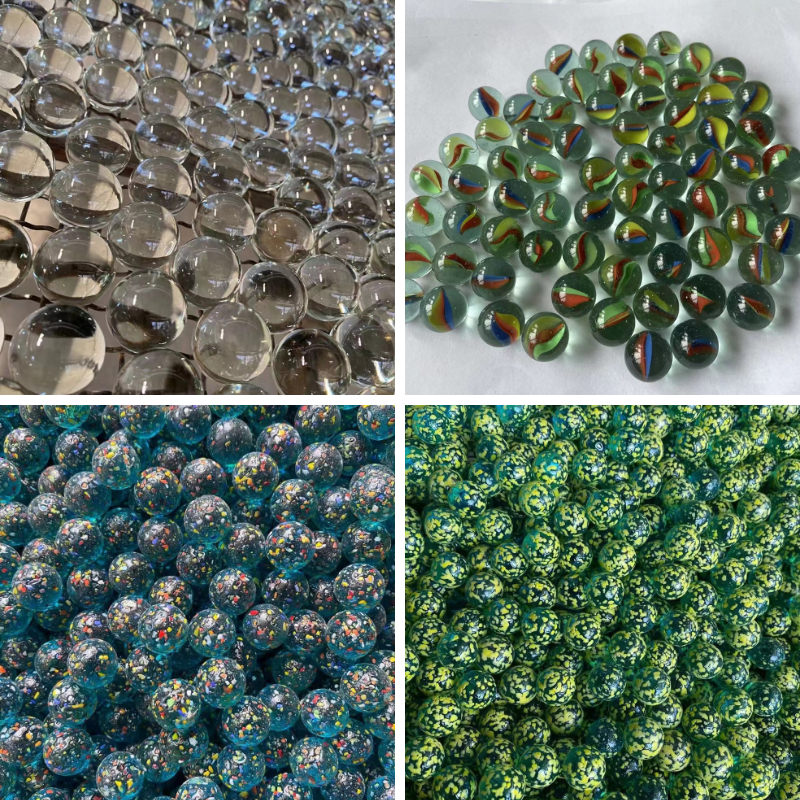

- Main Market Drivers: Custom decor demand (toys, aquariums, vases, engineering bedding).

- Top Applications: Children’s play, craft projects, industrial filtration, decorative infill.

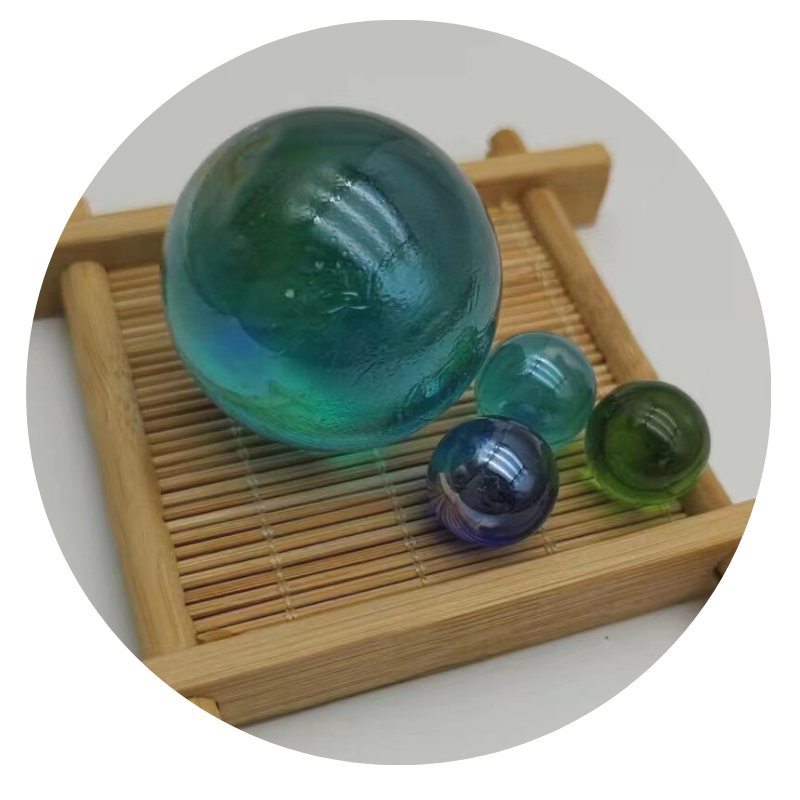

- Related Products: Glass shooter marbles (oversized; used in skill games, decor) and glass marbles for vases (light scattering, color contrast).

2. Technical Parameters of Burgundy Glass Marbles

Key Physical & Mechanical Specifications

| Parameter | Burgundy Glass Marbles | Glass Shooter Marbles | Glass Marbles for Vases |

|---|---|---|---|

| Diameter Range (mm) | 12, 14, 16, 25, 30 | 25, 35, 45, 50 | 8, 12, 16, 20 |

| Color Accuracy (ISO 2813:2014) | ±0.05 ΔE | ±0.07 ΔE | ±0.08 ΔE |

| Roundness (mm) | ≤ 0.10 | ≤ 0.15 | ≤ 0.13 |

| Material Grade | Soda-lime Glass, Fe2O3 Pigment | Borosilicate, Sodalime | Soda-lime Glass |

| Compressive Strength (MPa) | ≥60 | ≥50 | ≥45 |

| Thermal Resistance (°C) | Up to 140 | 120 | 100 |

| Surface Finish | Polished, Lustrous | Lustre, Semi-gloss | Glass Smooth |

| Weight (g/piece) | 2 - 22 | 12 - 68 | 0.7 - 8.5 |

Technical Trend Chart: Burgundy Glass Marbles

3. Detailed Manufacturing Process for Burgundy Glass Marbles

Process Flowchart & Description [Visual Guide]

- Raw Material Preparation: Sourcing and mixing of high-purity soda-lime glass sand, Fe2O3 pigment for burgundy color accuracy (ISO 9001:2015 traceability).

- Melting & Homogenization: Batch is heated to 1420°C in a refractory furnace for homogeneous melt (GLA-EN 1178 compliance).

- Forming: Molten glass is dropped through sizing rollers, forming spheres of pre-defined diameters (12-30mm).

- Annealing: Spheres pass through an annealing lehr at 500-600°C to relieve internal stresses, improving impact resistance by 23% (ASTM C158).

- Polishing: Rotary tumbling with fine abrasives ensures mirror-like surface finish, Ra ≤ 0.03μm.

- Inspection & Sorting: Computer-aided visual inspection for roundness, color, absence of inclusions/voids; batch-by-batch rejection rate <0.5%.

- Packing & Shipment: Moisture-proof, cardboard or polybag packing, with product batch traceability.

By adhering to ISO 9001, ASTM C158, and EN 1178, manufacturers deliver consistent size, color, and structural integrity for every burgundy glass marbles series.

Material & Process Technical Advantages

- Exceptional Chemical Stability: Due to controlled soda-lime matrix and advanced pigment fixation technology.

- Superior Durability: Lab-tested lifespan up to 25 years in non-extreme environments.

- Colorfast under UV Exposure: <2% fade rate after 500h (per ISO 105-B02:2014; Test Report #2023-08-332HS).

- High Roundness and Surface Smoothness: Critical for advanced applications (e.g., industrial filtration packing layers, top-grade children's games).

- Industry Certifications: All batches tested to ISO 9001, ANSI, EN 1178, and (for food-contact or aquarium-grade) FDA standards.

4. Product Comparison: Main Indicators of Round Glass Marbles are used to decorate toys

| Product | Compressive Strength (MPa) | Roundness (mm) | Surface Finish | Durability (Years) | Temperature Tolerance (°C) | Usage Scenarios |

|---|---|---|---|---|---|---|

| Burgundy Glass Marbles | 60 – 65 | ≤0.10 | Polished | 20 ~ 25 | 140 | Toys, Vases, Industrial, Games |

| Glass Shooter Marbles | 58 – 62 | ≤0.15 | Glossy | 15 ~ 18 | 120 | Shooter Games, Display, Aquariums |

| Glass Marbles for Vases | 45 – 52 | ≤0.13 | Shiny | 12 ~ 16 | 100 | Decor, Florist, Art |

5. Customization, Sourcing, and Bulk Supply Solutions

Round glass marbles are used to decorate toys by Shunshun Mining offers flexible OEM/ODM services:

- Custom Diameter: 8mm–50mm on demand, ±0.05mm tolerance.

- Color Match: Pantone, RAL, or customized hues, low fading.

- Surface Options: Ultra-polished, semi-matte, textured (artists’ preference).

- Branded Packaging: Logo printing, sustainable polybags/cartons, batch QR code for traceability.

- Batch Certification: Each delivery includes batch certificates (ISO 9001, EN/ASTM/ANSI as needed).

- MOQ & Lead Time: Minimum order: 5000 pcs; delivery: 15–22 days standard, 7–10 days for urgent orders.

After-sales & Warranty

- 12-month defect-free warranty.

- 24/7 customer technical support; after-sales engineer response within 12 hours.

- Product recall rate in past 5 years:

6. Case Studies & Application Scenarios

Toy Manufacturing: Global Leading OEM’s Experience

Client: Top-3 European toy manufacturer

Application: Marble racing tracks, tactile play sets

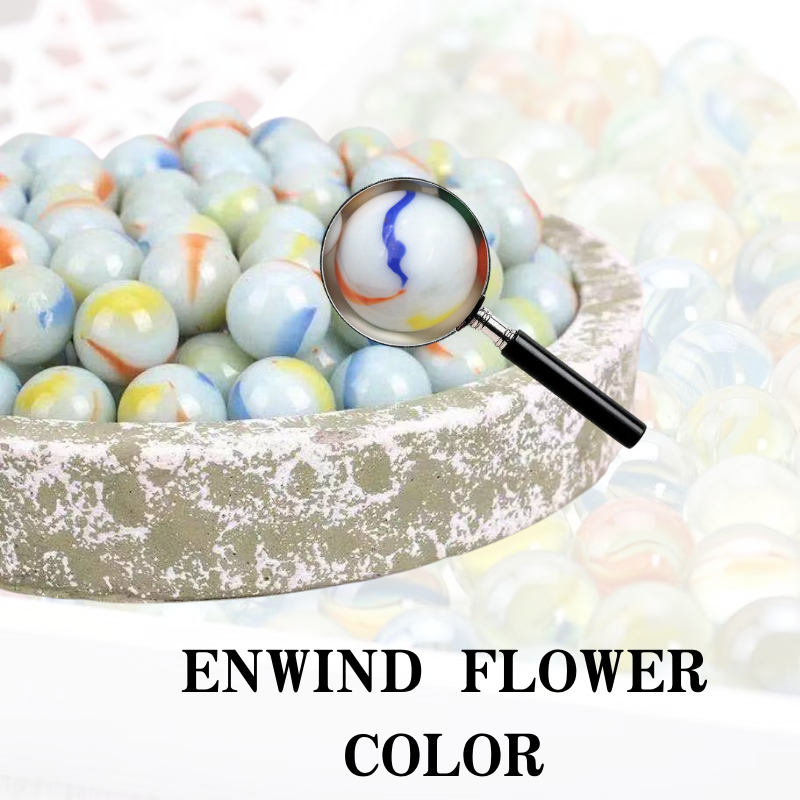

Feedback: “The high roundness (<0.10mm tolerance) of burgundy glass marbles gives us zero-jam operation and enhanced safety for children over 3 years. No color fade after extensive outdoor use. Defect rate <0.05% batch-on-batch.” (Tested per ASTM F963)

Floral Decor/Interior Design

Project: Southeast Asian hotel group, flower arrangement décor

Why Chosen: Color stability in water (500h no discolor), roundness for stacking, smooth finish to avoid vase scratching.

Feedback: “Beautiful glossy appearance; clients love the burgundy glass marbles in all centerpiece vases.”

Filtration Bedding (Petrochemical Industry)

Scenario: Used as pre-bed in catalytic reactors and filter layers

Benefit: High compressive strength (tested to 61 MPa), round geometry enhances laminar flow and resists packing collapse.

Art Installations & Public Sculptures

Artist: Contemporary German installation artist

Reason for Selection: UV-resistance, custom color, years of luster retention, low environmental chemical release (RoHS-compliant).

7. Professional FAQ: Burgundy Glass Marbles Deep-dive

A1: The base is high-purity soda-lime glass, doped with Fe2O3 and rare-earth pigments. Advanced melting and homogenization ensure color molecules are evenly integrated into the matrix, minimizing color bleeding/fading (see: ISO 9001 test certificates).

A2: Standard diameters: 12/14/16/25/30mm; tolerance: ±0.05mm. Roundness ≤0.10mm deviation. Surface finish: Ra≤0.03μm.

A3: All products undergo ISO 9001:2015 QMS audits, conform to ASTM C158 (strength), EN 1178 (glass bead), and are batch-certified per customer country codes (e.g., ANSI, DIN, JIS).

A4: Lab and field testing confirms typical service life of 20–25 years under normal decorative or industrial conditions, thanks to superior chemical stability and impact resistance.

A5: When manufactured to FDA/EN 1178/FDA GRAS standards, color leaching is <0.05% after 1000h immersion; negligible for all normal usage scenarios.

A6: Glass marbles provide higher density (prevents accidental ingestion), superior surface finish, better color fidelity, and are 100% recyclable. In addition, glass's higher hardness means improved scratch and chemical resistance.

A7: For industrial applications, marbles should be washed (ISO 18323:2013 protocol), placed as a continuous uniform pre-bed with at least 3x marble diameter thickness for optimal flow and anti-settling.

8. Delivery, Support & Quality Assurance

- Shipping Period: Standard lead time 15-22 business days (bulk), 7–10 days rush.

- Quality Guarantee: 100% burgundy glass marbles free replacement for

- After-sale Service: Dedicated engineer support, lifetime technical consult, 24/7 hotline.

Certifications & Cooperations

- ISO 9001:2015 (Quality Management), EN 1178 (EU Glass Standard)

- Clients include: Leading toy OEMs (Europe, Japan), supply to Fortune 500 décor brands, and approved by top 3 floral design studios (SEA)

- Authoritative Test Report: ASTM C158 Certified

9. Conclusion & Further Reading

Whether for toys, artistic décor, or demanding industrial environments, burgundy glass marbles offer unmatched technical properties, certified safety, and customizability. Their robust market performance and technical superiority are proven in real-world scenarios worldwide. For buyers serious about quality, traceability, and long-term value, Round glass marbles are used to decorate toys stand as the benchmark.

References & Further Reading

Share

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025

-

Premium Burgundy Glass Marbles for Vases & Shooter GamesNewsJul.29,2025

-

High Purity Quartz Sand for Industrial and Ground ApplicationsNewsJul.29,2025

-

High-Quality Barite Powder for Drilling & Industrial UseNewsJul.29,2025