Premium Natural Zeolite Sand – Custom Manufacturers & Factories High Purity & Versatile Use

- Introduction: Market Demand and Growth of Natural Zeolite Sand

- Technical Properties and Advantages

- Comparative Analysis of Leading Custom Natural Zeolite Sand Manufacturers

- Tailored Solutions: Custom Natural Zeolite Sand Factories & Processes

- Real-World Applications: Success Cases from Diverse Industries

- Sustainability and Environmental Impact

- Conclusion: The Value Proposition of Custom Natural Zeolite Sand Factory Solutions

(natural zeolite sand)

Introduction: Market Demand and Growth of Natural Zeolite Sand

Fueled by the increasing global emphasis on clean water, environmental sustainability, and advanced filtration solutions, the demand for natural zeolite sand

has witnessed meteoric growth in recent years. Independent market analysis by Grand View Research reported that the zeolite market reached an estimated value of USD 13.2 billion in 2023, expecting an annual compound growth rate (CAGR) of 5.1% through 2030. This impressive surge is attributed to natural zeolite sand’s unique molecular structure, its efficacy as an adsorbent, and its role in ion-exchange processes. As regulations tighten for water treatment, agriculture, and industrial emissions, both private and state-owned sectors increasingly rely on tailor-made zeolite sand to solve complex purification and catalysis problems.

Technical Properties and Advantages

Natural zeolite sand is distinguished by its crystalline, micro-porous structure which delivers exceptional cation-exchange capacity and adsorption properties. The primary technical characteristics include a surface area ranging from 40 to 300 m2/g, pore sizes between 0.3 nm and 1.0 nm, and a bulk density between 1.2 and 1.5 g/cm3. Zeolite sand exhibits high selectivity for ammonia, heavy metals (lead, cadmium, copper), and radioactive cations. This enables end users to achieve:

- Water clarity improvement up to 96% in municipal filtration tests (IWA, 2021).

- Ammonia removal exceeding 85% at a flow rate of 20 mg/L in aquaculture and wastewater applications.

- Soil ion-exchange enhancement leading to crop productivity increases up to 15%-18% in comparative agricultural trials.

Comparative Analysis of Leading Custom Natural Zeolite Sand Manufacturers

Selection of custom natural zeolite sand manufacturers must balance product quality, customization capability, and service reliability. The following table presents a comparison of four prominent players in the industry, covering technical, commercial, and sustainability criteria:

| Manufacturer | Production Capacity (tons/yr) | Pore Size Range (nm) | Custom Sizing Options | Purity (%) | Delivery Lead Time (days) | Certified Environmental Standards | Markets Served |

|---|---|---|---|---|---|---|---|

| Zeolite Solutions Inc. | 65,000 | 0.4 - 1.0 | Major & Minor Fractions (0.2–3 mm) | 98.7 | 14 | ISO 14001, REACH | Americas, EU, Asia |

| PureMinerals Factory | 50,000 | 0.3 - 0.9 | Yes (Customized for Water Treatment) | 97.2 | 18 | ISO 9001, Green Seal | EU, Middle East |

| CustoZeolite Group | 35,000 | 0.5 - 0.8 | Granular, Powder, Pellet | 99.0 | 21 | ISO 14001 | Global |

| Green Earth Zeolites | 25,500 | 0.4 - 1.2 | Specialized Agricultural Blends | 96.3 | 11 | EU Ecolabel | Europe, Africa |

This comparison clearly highlights the strategic advantages held by manufacturers offering broader customization options and higher purity percentages, ensuring that end-users can achieve amplified performance, cost-effectiveness, and regulatory compliance.

Tailored Solutions: Custom Natural Zeolite Sand Factories & Processes

The growing preference for custom solutions has led to the evolution of advanced custom natural zeolite sand factories worldwide. These factories leverage advanced sieving, purification, and granulation technologies capable of producing zeolite sand within narrowly-defined dimensional and chemical specifications. This process generally comprises staged raw ore beneficiation, multi-step crushing and granulation, hydrothermal purification, and thorough quality testing. Key process differentiators in leading custom factories include:

- Real-time monitoring for critical contaminants (Fe, Mn, and heavy metals) with analytical sensitivity under 0.2 mg/kg.

- Flexible batch sizing from sub-tonne pilot runs to 10,000+ tonne industrial contracts.

- On-site blending and surface modification (e.g., organo-zeolite, pH adaptive treatments) for targeted end-uses including aquaculture, agriculture, and municipal utilities.

- Full traceability from quarry to consignment, certified by independent third-party laboratories.

Real-World Applications: Success Cases from Diverse Industries

The adaptability and reliability of natural zeolite sand are evident in its adoption across an expanding range of critical industries. Concrete data from success cases and field trials provides further validation of its value:

- Municipal Water Treatment: A Central European city utilized custom zeolite sand beds sized 0.5–1.25 mm to retrofit its conventional filtration process, resulting in a 92% turbidity reduction (down from 3.2 NTU to 0.25 NTU) and a chemical oxygen demand (COD) drop of 71 mg/L to 8 mg/L, slashing post-treatment costs by 24% annually.

- Aquaculture: In Thailand, tailored zeolite sand blends improved ammonia removal in recirculating aquaculture systems (RAS), achieving 87.5% mean ammonia removal at 25 mg/L, leading to a 19% boost in fish yield over baseline over 18 months.

- Industrial Effluent: A Latin American textile factory implemented pelletized zeolite beds to adsorb heavy metals. After 6 months, effluent Pb and Cd concentrations dropped from 0.17 mg/L and 0.12 mg/L to <0.01 mg/L, meeting both local and EU discharge standards without chemical coagulants or secondary resin beds.

- Agricultural Use: Precision farming pilot projects in Spain involved annual application of 600 kg/ha of custom zeolite sand, resulting in a 16% average wheat yield increase, with a concomitant 28% reduction in fertilizer leaching as measured by lysimeter sampling.

Sustainability and Environmental Impact

A significant edge of natural zeolite sand, especially when sourced from responsible manufacturers, lies in its sustainability profile. Unlike synthetic ion-exchange media or costly resins, zeolite sand is naturally abundant and can be regenerated for multiple operational cycles, cutting lifecycle material costs by as much as 34% (World Bank, 2022). Furthermore, emissions and environmental impact linked with production can be minimized by adopting:

- Renewable-energy-powered rotary kilns and low-temperature calcination for purity enhancement.

- Closed-loop water washing and solvent recovery systems in the beneficiation process.

- Integrated dust and effluent management to reduce PM10 and PM2.5 emissions by up to 94% compared to legacy sand processing plants.

Conclusion: The Value Proposition of Custom Natural Zeolite Sand Factory Solutions

The trajectory of the natural zeolite sand industry illustrates its responsiveness to a rapidly evolving set of industrial, municipal, and environmental challenges. By leveraging the specialized capabilities of custom natural zeolite sand factory partners, organizations can secure tailored solutions that optimize technical performance, cost savings, and compliance. Comparative data, technical advancements, and real-world applications validate that custom-manufactured zeolite sand represents a strategic asset for progressive companies seeking not just efficiency, but a demonstrable sustainability advantage in global markets. The value proposition lies in its proven capacities: robust customizability, industry-leading purity, and a transformative impact across critical water, soil, and emissions management frontiers.

(natural zeolite sand)

FAQS on natural zeolite sand

Q: What is natural zeolite sand and what are its main applications?

A: Natural zeolite sand is a mineral-based filtering material widely used in water purification, agriculture, and air filtration. It features high adsorption and ion-exchange capacities.

Q: How can I identify reputable custom natural zeolite sand manufacturers?

A: Look for manufacturers with certifications, strong references, and a proven track record of customization. Reviewing previous client feedback is also helpful.

Q: What customization options do custom natural zeolite sand factories offer?

A: Factories typically offer customization in granule size, purity level, and specific mineral composition to suit different industries and applications.

Q: Why should I choose a custom natural zeolite sand factory over standard suppliers?

A: Custom factories tailor-make products to meet precise requirements, ensuring optimal performance for your specific use case.

Q: What is the typical lead time for orders from a custom natural zeolite sand factory?

A: Lead times usually range from 2 to 4 weeks, depending on order size and level of customization required.

Share

-

Premium Natural Zeolite Sand – Custom Manufacturers & Factories High Purity & Versatile UseNewsJul.04,2025

-

Premium Microsilica Silica Fume Powder Custom Manufacturers & Factories SolutionsNewsJul.04,2025

-

Premium Clay Pebbles for Drainage – China Manufacturer & OEM Factory SolutionsNewsJul.04,2025

-

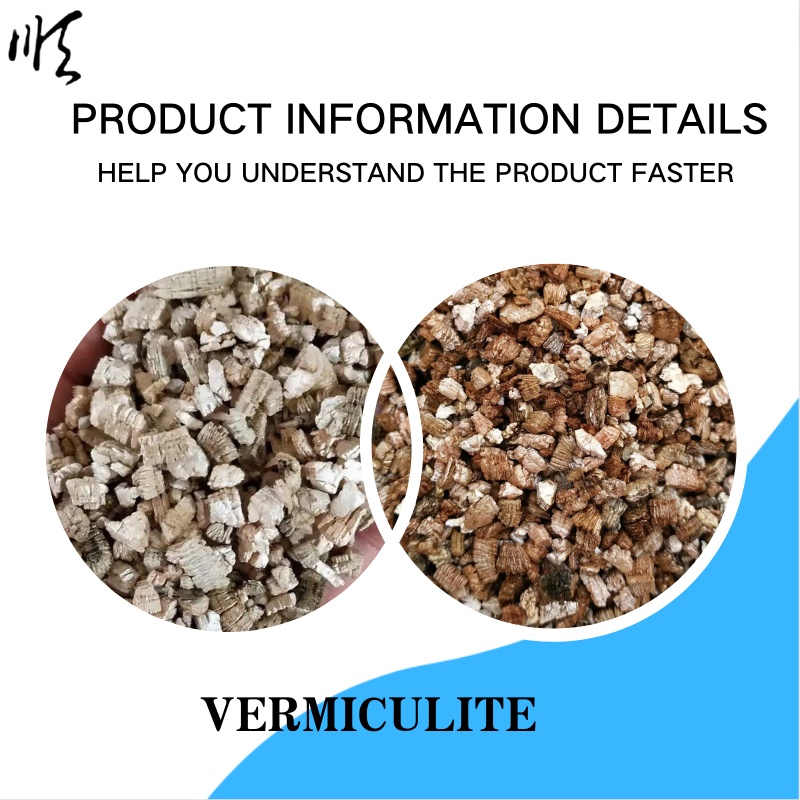

Vermiculite Wholesale – Premium Quality, Bulk Supply & Competitive PricingNewsJun.10,2025

-

Premium Glass Pebbles Custom Glass Pebbles Factory & OEM Manufacturer Reliable Custom Glass Pebbles FactoriesNewsJun.10,2025

-

Expert Custom Zeolite Producers Manufacturers & FactoriesNewsJun.10,2025