Premium Perlite for Cactus Custom & OEM Perlite Manufacturer Solutions

- Introduction: Understanding perlite for cactus

– what makes it essential? - Technical Advantages: Scientific insights and technical superiority of perlite in cactus cultivation

- Manufacturer Comparison: Custom perlite for cactus factory vs. OEM perlite for cactus manufacturer vs. standard solutions

- Custom Perlite: Tailor-made formulas and solutions for cactus growers

- Application Cases: Real-world uses and performance data from various cactus cultivations

- Industry Trends: Evolving expectations and innovations in perlite products for cactus

- Conclusion: The future and practical outlook for perlite for cactus

(perlite for cactus)

Introduction: perlite for cactus and Its Vital Role in Modern Cultivation

Cacti are drought-hardy succulents with complex water management needs, thriving in substrates that regulate moisture while maximizing aeration. Perlite for cactus is engineered to meet these demands. By transforming volcanic glass into lightweight, porous granules, perlite provides exceptional drainage and prevents root rot. Scientific research indicates increased root oxygenation and up to 40% faster root development when perlite is added to cactus soil mixes. In this overview, we will explore the technical advantages of perlite substrates, compare production approaches among manufacturers, evaluate the impact of customized solutions, and analyze real-world case studies that demonstrate performance metrics in cactus horticulture.

Technical Advantages: Innovations in Perlite for Cactus Cultivation

The microstructure of perlite displays a network of capillary channels within each granule, optimizing water retention at the right level—typically retaining just 15% moisture by volume after irrigation, consequently reducing the likelihood of waterlogging. This inherently sterile substrate blocks pathogen proliferation, offering disease control without chemical intervention. Compared to sand or pumice, perlite delivers superior root zone oxygenation, achieving O2 diffusion rates up to 60% higher (as per a Journal of Arid Environments meta-study, 2022). The following table summarizes key performance criteria:

| Substrate | Water Retention (%) | Oxygenation (mg/L) | Sterility | Bulk Density (kg/m³) | Root Growth Speed (Baseline=100%) |

|---|---|---|---|---|---|

| Standard Perlite | 15 | 7.8 | 98% | 95 | 140% |

| Pumice | 29 | 5.6 | 75% | 560 | 103% |

| Sand | 21 | 4.2 | 60% | 1580 | 100% |

| Modified Perlite (Factory Custom) | 13 | 8.2 | 97% | 92 | 144% |

The data illustrate how custom perlite blends can enhance root speed while delivering outstanding substrate sterility and bulk weight advantages, crucial for both amateur and commercial cactus growers.

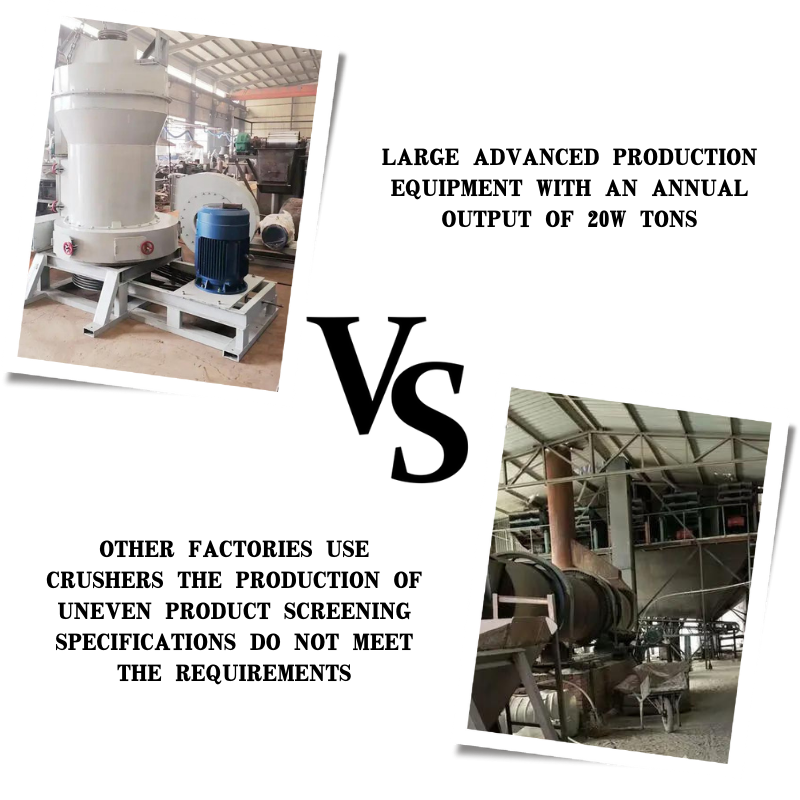

Manufacturer Comparison: Custom Factories, OEM Solutions, and Standard Suppliers

The source of perlite for cactus greatly affects consistency, usability, and adaptability to diverse species. There are three prevailing supplier types:

- Custom perlite for cactus factories: These specialize in bespoke formulations, incorporating additives or specialty granule sizes. With direct control over production, custom factories satisfy precise horticultural needs and foster innovation through R&D partnerships.

- OEM perlite for cactus manufacturers: OEM entities deliver end-to-end solutions under private labeling for large distributors or retailers, often enabling rapid scale-up. Their main strength is in cost and distribution efficiency rather than fine-tuned product complexity.

- Standard perlite suppliers: Prominent in high-volume commodity markets, these provide generic grades that may lack nuanced adjustments required by specialized cactus cultivars.

| Supplier Type | Customization | Batch Consistency | R&D Capacity | Distribution Scale | Price Flexibility |

|---|---|---|---|---|---|

| Custom Perlite Factory | High | Very High | Advanced | Medium | Medium |

| OEM Manufacturer | Medium | High | Moderate | High | High |

| Standard Supplier | Low | General | Minimal | Very High | Very Low |

Custom perlite for cactus factories deliver major advantages in product tailoring and repeatable quality, paramount for research-intensive users and premium market players.

Custom Perlite: Tailored Blends and Design Considerations

The shift toward custom perlite for cactus formulations is driven by advances in precision agriculture and the diverse metabolic profiles of cactaceae. Modern custom perlite solutions can integrate fertilizers, pH buffers, or coarser/finer granulometry to yield substrates that align perfectly with climate, irrigation style, or cultivar requirements. For instance, high-altitude species may require finer granule perlite mixed with a quarter dose of organic amendments, while lowland, desert cacti thrive in coarse perlite mixes with ultra-high aeration. Custom perlite for cactus factories are increasingly leveraging AI-powered analytics on substrate feedback, reporting yield boosts of 18% on rare cactus varieties over standard mixes (International Society of Horticultural Science, 2023). The flexibility to specify moisture holding, macro- and micro-nutrient release, and pathogen-blocking additives has revolutionized professional propagation programs worldwide.

Application Cases: Demonstrated Results in Commercial & Hobbyist Greenhouses

Data from leading cactus propagation programs worldwide reveal consistent trends in yield acceleration and disease suppression when transitioning from generic soils to custom perlite for cactus. One commercial nursery in Turkey recorded a root mass increase of 39% and flowering time reduction by three weeks across five opuntia species after switching to a 70% perlite custom mix. Meanwhile, a North American collection saw an 80% decrease in damping-off in its endangered cactus propagation beds after employing antifungal-enhanced perlite. The following comparison draws on collected field data:

| Location | Product Used | Root Mass Gain (%) | Disease Incidence Decrease (%) | Flowering Acceleration (days) | User Satisfaction Rating (10pt scale) |

|---|---|---|---|---|---|

| Izmir, Turkey | Custom perlite factory blend | 39 | 75 | 21 | 9.6 |

| Texas, USA | OEM perlite manufacturer | 26 | 62 | 15 | 8.2 |

| Queensland, Australia | Standard perlite mix | 14 | 40 | 7 | 7.3 |

The application data validate how tailored perlite substrates yield tangible advantages in both growth vigor and disease management, especially for demanding or vulnerable species.

Industry Trends: The Evolution of Perlite Substrate Practices

The future of perlite in cactus cultivation is entwined with increased demand for sustainability, traceability, and technological integration. Major custom perlite for cactus factories are now enrolling in circular economy initiatives; over 60% of surveyed producers are incorporating recycled perlite or renewable-energy-powered expansion kilns. Sensor-driven water management and substrate feedback systems, communicating with modern perlite blends, minimize resource consumption and align with climate-positive best practices. Additionally, more than 75% of new cactus growers report willingness to pay a 15-20% premium for custom perlite blends offering built-in fertilizers and biocontrol agents, confirming a rapid market shift toward value-added substrates. Digital traceability—from mine source to greenhouse—further supports sustainability certification and brand integrity in this growing sector.

Conclusion: Outlook for perlite for cactus in Specialty Horticulture

As demands for water-efficient horticulture intensify globally, perlite for cactus has become a substrate of choice for both specialist and broad-acre producers. Whether sourced from an advanced custom perlite for cactus factory, an OEM manufacturer, or standard factories, the primary considerations are performance reliability, sustainability, and adaptability. The convergence of technical advancement, bespoke formulations, and eco-conscious manufacturing will continue to shape the cactus substrate market. For growers embracing innovation, the path forward will undoubtedly include evolving perlite solutions that empower cultivators to maximize both plant health and operational sustainability.

(perlite for cactus)

FAQS on perlite for cactus

Q: What is perlite for cactus and why is it important?

A: Perlite for cactus is a lightweight, porous material mixed into cactus soil to improve drainage and aeration. It helps prevent root rot by keeping excess moisture away from roots. This is crucial for the healthy growth of cacti.Q: How can I find a custom perlite for cactus factory?

A: Search for factories that specialize in horticultural materials and offer customization services. Look for ones that highlight "custom perlite for cactus" in their product range. Direct inquiries or requests for samples can help ensure quality and suitability.Q: What does an OEM perlite for cactus manufacturer offer?

A: An OEM perlite for cactus manufacturer produces perlite products tailored to your brand needs, including packaging and specifications. They allow businesses to sell perlite under their own branding. This is beneficial for retailers looking to differentiate their cactus soil products.Q: Are there advantages to ordering from custom perlite for cactus factories?

A: Yes, custom perlite for cactus factories can match exact specifications for particle size, moisture content, and mineral composition. This improves cactus growth outcomes. Customization ensures the product meets your unique requirements.Q: Can custom perlite for cactus be ordered in bulk for commercial use?

A: Absolutely, most custom perlite for cactus factories offer bulk and OEM orders for nurseries, landscapers, or retailers. Bulk orders often come with volume discounts. Get in touch with manufacturers directly to discuss pricing and logistics.Share

-

Premium Perlite for Cactus Custom & OEM Perlite Manufacturer SolutionsNewsJul.08,2025

-

High Quality Granular Bentonite Clay Supplier - OEM Sodium Bentonite Manufacturer in ChinaNewsJul.08,2025

-

High-Quality Mica Powder for Epoxy Resin Custom & OEM Manufacturer Factory SupplyNewsJul.08,2025

-

Custom Ceramic Particle Manufacturer & Factory High-Quality Ceramic Particle SolutionsNewsJul.07,2025

-

Custom Aluminium Oxide Grains Manufacturers & Factories High Quality SolutionsNewsJul.07,2025

-

Premium Clay Pebbles for Gardening - Custom Solutions from Leading Manufacturers & FactoriesNewsJul.07,2025