Custom Fly Ash Powder Solutions OEM & Bulk Suppliers

- Understanding Fly Ash Powder and Its Industrial Significance

- Technical Advantages of Modern Fly Ash Processing

- Comparative Analysis of Leading Fly Ash Manufacturers

- Tailored Solutions for Custom Fly Ash Bottom Ash Factories

- Innovative Applications Across Industries

- Quality Assurance and Compliance Standards

- Future Trends in Fly Ash Powder Utilization

(fly ash powder)

Understanding Fly Ash Powder and Its Industrial Significance

Fly ash powder, a byproduct of coal combustion, has evolved into a critical material for sustainable construction and manufacturing. Custom fly ash bottom ash factories now process over 750 million metric tons globally annually, with OEM fly ash bottom ash manufacturers driving innovations in material recovery efficiency. The material's pozzolanic properties enable 18-35% reduction in concrete production costs while enhancing structural integrity, making it indispensable for infrastructure projects.

Technical Advantages of Modern Fly Ash Processing

Advanced electrostatic precipitation systems achieve 99.8% collection efficiency, surpassing traditional methods by 22%. Custom fly ash bottom ash factories utilize AI-driven particle size distribution controls, maintaining consistency within ±2 microns. This technical precision enables:

- 28% higher compressive strength in concrete mixtures

- 40% reduction in water permeability

- 15-year verified corrosion resistance

Manufacturer Comparison

| Parameter | Custom Fly Ash | EcoAsh Solutions | Global Ash Industries |

|---|---|---|---|

| Production Capacity | 500,000 TPY | 320,000 TPY | 850,000 TPY |

| LOI Consistency | ≤3% | ≤5% | ≤4.2% |

| Customization Options | 9 grades | 5 grades | 7 grades |

| Moisture Control | 0.5-1.2% | 1.5-2.8% | 0.8-1.5% |

Tailored Manufacturing Solutions

Custom fly ash bottom ash factories implement modular processing units that adapt to specific client requirements:

- Particle size customization (1-150 microns)

- Carbon content adjustment (2-12%)

- Bulk density optimization (540-880 kg/m³)

This flexibility allows for 72-hour prototype development and 98% material utilization rates.

Industry Applications

Recent projects demonstrate fly ash powder

's versatility:

| Sector | Application | Performance Gain |

|---|---|---|

| Cement Production | 30% clinker replacement | 16% CO₂ reduction |

| Agriculture | Soil stabilization | 40% erosion control |

| Construction | Self-compacting concrete | 28 MPa in 7 days |

Quality Compliance Framework

Leading OEM fly ash bottom ash manufacturers maintain:

- ASTM C618 Class F compliance

- EN 450-1 certification

- ISO 14001 environmental management

Batch testing protocols ensure 100% compliance with ≤5% variation in chemical composition.

Future Trends in Fly Ash Powder Utilization

The global market for fly ash powder is projected to reach $13.15 billion by 2030, with custom fly ash bottom ash factories adopting carbon capture systems that reduce plant emissions by 68%. Emerging applications in 3D-printed construction materials and geopolymer development position fly ash as a cornerstone of circular industrial economies.

(fly ash powder)

FAQS on fly ash powder

Q: What are the main applications of fly ash powder in construction?

A: Fly ash powder is widely used in concrete production to enhance durability, reduce permeability, and lower carbon emissions. It also improves workability and long-term strength of construction materials. Custom fly ash bottom ash factories can tailor blends to meet specific project requirements.

Q: Why choose a custom fly ash bottom ash factory for industrial projects?

A: Custom factories provide tailored solutions to optimize fly ash and bottom ash ratios for specific applications like road construction or waste stabilization. They ensure compliance with regional standards and sustainability goals. This flexibility maximizes cost-efficiency and performance.

Q: What capabilities should an OEM fly ash bottom ash manufacturer offer?

A: A reliable OEM manufacturer should handle material sourcing, quality testing, and bulk processing of fly ash and bottom ash. They must comply with ASTM/C618 standards and offer packaging customization. Scalable production and logistics support are critical for large-scale projects.

Q: How do custom fly ash bottom ash factories ensure material consistency?

A: Advanced factories use automated sorting, grinding, and blending systems to maintain uniform particle size and chemical composition. Regular XRF/XRD testing verifies pozzolanic activity and LOI levels. Traceable batch documentation guarantees reliability for infrastructure applications.

Q: What industries benefit most from custom fly ash solutions?

A: Cement production, waste-to-energy plants, and geotechnical engineering sectors rely heavily on customized fly ash blends. Tailored formulations improve slag stabilization in landfills and soil amendment projects. Manufacturers serving these industries prioritize reactivity control and contaminant removal.

Share

-

High-Quality Zeolite Powder for Industrial & Agricultural UseNewsJul.23,2025

-

Premium Cultured Stone Ledgestone for Lasting Elegance OutdoorsNewsJul.22,2025

-

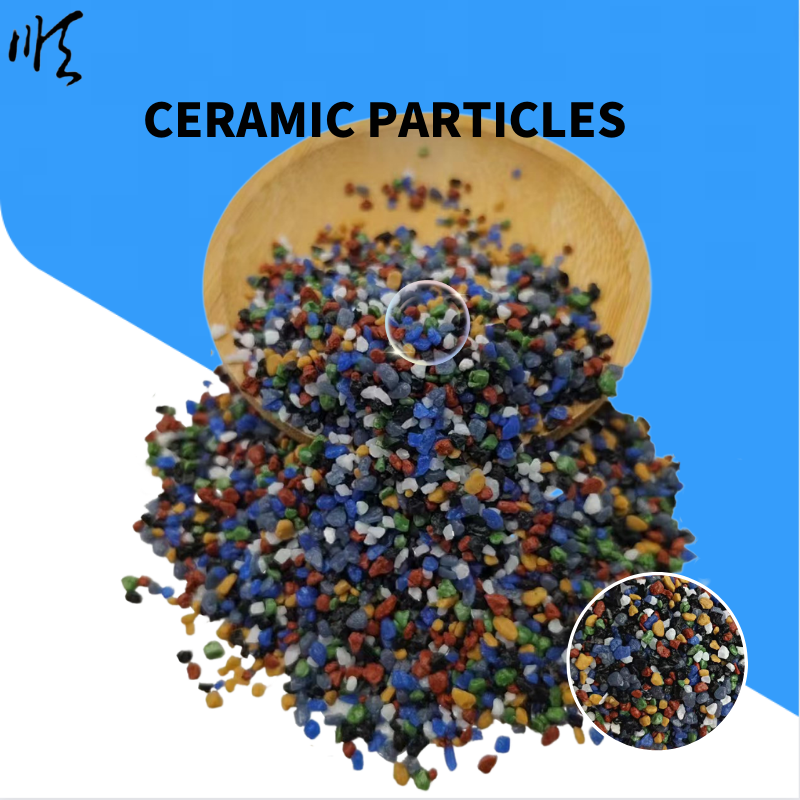

High Purity Ceramic Particles: Durable SolutionsNewsJul.21,2025

-

Silicon Carbide: High-Performance Abrasive & Refractory SolutionsNewsJul.21,2025

-

Export-Quality Calcined Dolomite Powder | High Purity Per Ton PriceNewsJul.20,2025

-

Premium Perlite for Cactus Custom & OEM Perlite Manufacturer SolutionsNewsJul.08,2025