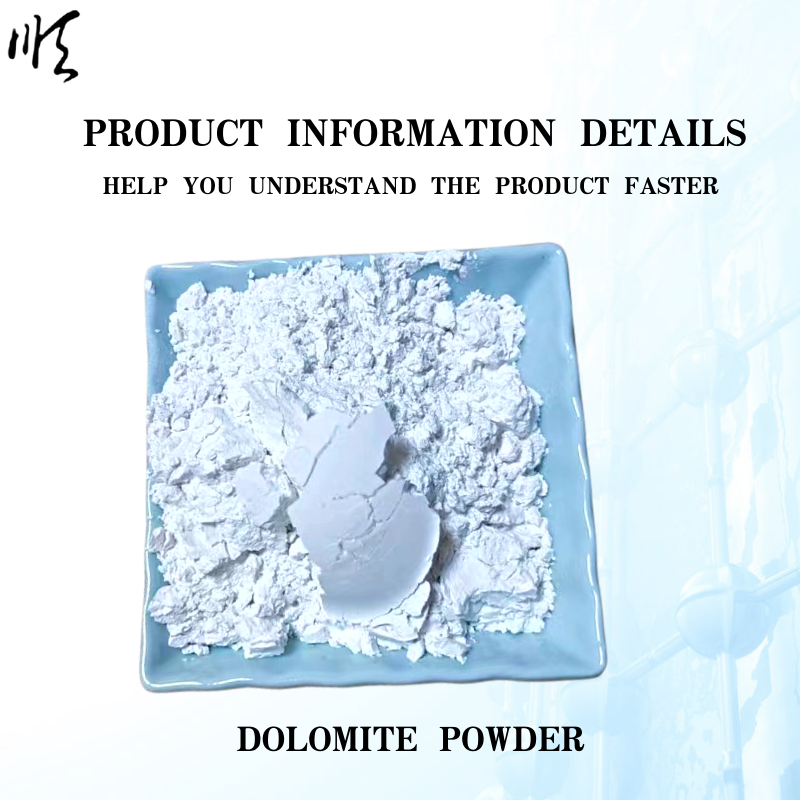

Superior Dolomite Powder: Micronized & Fine Dust

Understanding High-Purity Dolomite Powder in Industrial Applications

In the realm of industrial minerals, dolomite powder stands as a cornerstone material, essential across a vast array of sectors from metallurgy to agriculture. This naturally occurring mineral, primarily calcium magnesium carbonate (CaMg(CO₃)₂), undergoes meticulous processing to achieve the high purity and specific particle sizes required for its diverse applications. Its unique chemical composition and physical properties, particularly after calcination or micronization, make it indispensable for processes demanding stable pH, refractory qualities, or specific mineral additions. The global demand for high-quality dolomite powder continues to surge, driven by advancements in steelmaking technologies, increasing agricultural productivity needs, and an expanding construction sector, underscoring its pivotal role in modern industrial development and supply chains.

The Advanced Manufacturing Process of Calcined Dolomite Powder

The production of high-purity dolomite powder, especially the calcined variant, is a sophisticated multi-stage process ensuring optimal performance for industrial use. It begins with the careful quarrying of raw dolomite ore, selected for its mineralogical purity. The extracted ore then undergoes primary crushing to reduce it to manageable sizes, followed by secondary crushing and grinding in mills to achieve finer particles. A critical step for calcined dolomite powder is the calcination process, where the ground dolomite is heated in rotary kilns at precisely controlled high temperatures (typically 900-1100°C). This thermal treatment drives off carbon dioxide, converting the calcium magnesium carbonate into a mixture of calcium oxide (CaO) and magnesium oxide (MgO), enhancing its reactivity and properties as burnt dolomite. Post-calcination, the material is further pulverized and classified to produce a finely dispersed micronized dolomite powder, meeting stringent industry standards such as ISO 9001 for quality management and consistent product specifications, ensuring its suitability for demanding applications.

Essential Technical Parameters and Specifications of Dolomite Powder

Understanding the technical parameters of dolomite powder is crucial for B2B procurement, ensuring the material meets specific application requirements. Key specifications include chemical composition, particularly the percentages of CaO and MgO, which directly influence its reactivity and effectiveness as a flux or pH modifier. Particle size distribution, often measured in microns (e.g., as micronized dolomite powder), is vital for controlling dispersion, reactivity, and flow characteristics in various industrial processes. Other critical parameters are bulk density, moisture content, whiteness index, and specific surface area. These specifications dictate its performance in sectors like steelmaking, where precise flux properties are needed, or in the glass industry, where high purity ensures optical clarity. Manufacturers adhere to rigorous testing protocols to provide consistent product quality, enabling clients to optimize their processes and achieve superior end-product performance.

| Parameter | Typical Range/Value | Relevance/Application Impact |

|---|---|---|

| CaO Content | 55% - 60% | Key basicity for fluxing in steel; cementitious properties. |

| MgO Content | 35% - 40% | Refractory properties; glass melt viscosity. |

| SiO₂ Content | < 1.5% | Impurity level; affects reactivity and end-product quality. Lower is better. |

| Particle Size (D90) | 10 - 75 microns (customizable) | Influences reactivity, flowability, and dispersion in slurries/mixes. |

| Whiteness Index | > 90% (L value) | Important for applications like paint fillers, paper, plastics. |

| Bulk Density | 0.9 - 1.3 g/cm³ | Impacts transport, storage, and volumetric dosing in processes. |

Diverse Application Scenarios and Industry Use Cases

The versatility of dolomite powder allows for its extensive use across numerous industrial sectors. In metallurgy, particularly in steelmaking, calcined dolomite powder serves as an indispensable fluxing agent, removing impurities and protecting refractory linings due to its basicity and high melting point. The glass industry utilizes it as a source of magnesia and calcia, improving glass durability, chemical resistance, and workability. In agriculture, fine dolomite dust is applied as a soil conditioner to neutralize acidic soils, supply essential magnesium and calcium, and enhance crop yield. The construction sector benefits from dolomite powder as a filler in concrete, asphalt, and building materials, improving strength, density, and fire resistance. Furthermore, it finds applications in environmental treatment (e.g., flue gas desulfurization, wastewater neutralization), chemical production, and as a filler in paints, plastics, and rubber, demonstrating its broad utility and crucial role in industrial processes.

Technical Advantages and Performance Benefits

High-purity dolomite powder offers a spectrum of technical advantages that translate directly into performance benefits for industrial clients. Its inherent chemical stability and buffering capacity make it an ideal pH regulator in diverse chemical processes and environmental applications. For high-temperature uses, such as in refractories or steel ladles, its excellent thermal stability and basicity ensure extended service life for linings and efficient impurity removal, contributing to significant energy savings and reduced operational costs. The fine particle size of micronized dolomite powder facilitates homogeneous mixing and dispersion, critical for consistent product quality in polymers, paints, and rubber. Furthermore, its natural abundance and relatively low processing costs, coupled with its non-toxic nature, position dolomite powder as an economically viable and environmentally sound solution compared to many synthetic alternatives. These attributes collectively enhance process efficiency, improve product quality, and contribute to overall cost-effectiveness for industrial operations.

Industry Trends and Market Dynamics for Dolomite Powder

The market for dolomite powder is experiencing robust growth, driven by several key industry trends. The burgeoning infrastructure and construction sectors globally continue to demand significant volumes of dolomite dust for cement, concrete, and asphalt applications. Simultaneously, the steel industry's ongoing expansion, particularly in emerging economies, solidifies dolomite powder's role as a crucial flux. There is also an increasing emphasis on sustainable agricultural practices, leading to higher demand for dolomite as a natural soil amendment. Furthermore, advancements in specialized applications, such as high-performance ceramics and environmental remediation technologies, are creating new niches for ultra-fine and high-purity micronized dolomite powder. Manufacturers are responding to these trends by investing in advanced processing technologies to meet stringent quality requirements and offer customized solutions, ensuring a resilient and expanding market for this fundamental industrial mineral.

Customized Solutions and Unwavering Supply Chain Reliability

Recognizing that each industrial application has unique requirements, leading suppliers offer highly customized dolomite powder solutions. This includes tailoring particle size distributions, chemical purity levels, and even specific surface treatments to optimize performance for a client's particular process. Whether a client requires ultrafine micronized dolomite powder for specialized coatings or coarse dolomite dust for large-scale agricultural projects, experienced manufacturers can meet these diverse needs. Beyond product customization, robust supply chain management is paramount. This involves strategic sourcing of raw materials, efficient production scheduling, and flexible logistics to ensure on-time delivery. Our commitment to reliable supply chain operations, coupled with decades of service in the industrial minerals sector, allows us to forge enduring partnerships and consistently meet the evolving demands of our global clientele, ensuring uninterrupted operations for our B2B partners.

Quality Assurance, Certifications, and Customer Trust

Maintaining the highest standards of quality is non-negotiable for industrial dolomite powder. Reputable manufacturers adhere strictly to international quality management systems, notably ISO 9001, ensuring every batch of dolomite powder meets predefined specifications. This commitment is underpinned by rigorous internal quality control measures, including comprehensive chemical analysis, particle size verification, and impurity testing at every stage of the manufacturing process. Independent third-party certifications and consistent testing data provide further assurance of product integrity and reliability. Furthermore, transparency in delivery cycles and comprehensive quality assurance protocols build significant trust with B2B clients. We provide clear delivery schedules, robust product warranties, and dedicated customer support to address any inquiries, reflecting our unwavering commitment to client satisfaction and long-term partnership in the supply of high-purity industrial minerals.

Frequently Asked Questions (FAQ) about Dolomite Powder

- What is the primary difference between raw and calcined dolomite powder?

Raw dolomite powder is simply ground dolomite rock. Calcined dolomite powder has been heat-treated to remove carbon dioxide, converting it into a more reactive mixture of calcium oxide (CaO) and magnesium oxide (MgO), suitable for applications like steel fluxing and pH adjustment. - How does micronized dolomite powder benefit specific applications?

Micronized dolomite powder, with its extremely fine particle size, offers enhanced surface area and reactivity. This makes it ideal for applications requiring superior dispersion, such as in polymers, paints, and rubber, improving rheological properties and filler efficiency. - What are the typical storage requirements for dolomite powder?

Dolomite powder should be stored in a dry environment, ideally in sealed bags or bulk container111s, to prevent moisture absorption, which can lead to caking and reduced reactivity. Proper storage ensures product integrity and prolonged shelf life. - Can dolomite powder be customized for specific industrial needs?

Yes, reputable suppliers offer custom solutions, including specific particle size ranges (e.g., coarser dolomite dust or finer micronized grades), purity levels, and even packaging formats to align with diverse client operational and application requirements. - What industries are the largest consumers of dolomite powder?

The largest consumers include the steel industry (as a flux and refractory material), glass manufacturing, agriculture (as a soil amendment), and the construction sector (as a filler in building materials).

Conclusion: The Indispensable Role of High-Quality Dolomite Powder

High-purity dolomite powder, especially its calcined and micronized dolomite powder variants, is an indispensable industrial mineral critical to the efficiency and quality of products across numerous global industries. From the fundamental processes of steelmaking and agriculture to the intricate formulations in chemicals and advanced materials, its unique properties provide unparalleled value. As industries continue to evolve with demands for higher purity, consistent quality, and sustainable solutions, the importance of reliable sourcing and expert manufacturing of dolomite powder becomes ever more pronounced. Partnering with a supplier committed to stringent quality control, technical expertise, and tailored solutions ensures that industrial clients can confidently meet their operational challenges and achieve superior outcomes.

References

- Smith, J. A. (2022). "Industrial Minerals: Production, Properties, and Applications." Geological Society Publishing.

- Mineral Resources Program. (2023). "Dolomite Statistics and Information." U.S. Geological Survey.

- International Organization for Standardization. (ISO 9001). "Quality management systems — Requirements."

- White, R. L. (2021). "The Role of Alkaline Earth Minerals in Sustainable Agriculture." Journal of Agricultural Science.

- Chen, H. (2020). "Advanced Materials for High-Temperature Industrial Processes." Materials Science and Engineering Journal.

Share

-

Premium Mica Crystals: Natural Beauty & Unique ShineNewsAug.13,2025

-

Superior Dolomite Powder: Micronized & Fine DustNewsAug.12,2025

-

Vibrant Dyed Gravel: Colorful Stone for Landscaping & DecorNewsAug.11,2025

-

Premium Ceramsite for Plants & Hydroponics - Ideal Growing MediaNewsAug.10,2025

-

Premium Mineral Sepiolite Powder: Versatile Adsorbent & FillerNewsAug.09,2025

-

Premium Talcum Powder - Smoothness & Purity GuaranteedNewsAug.08,2025