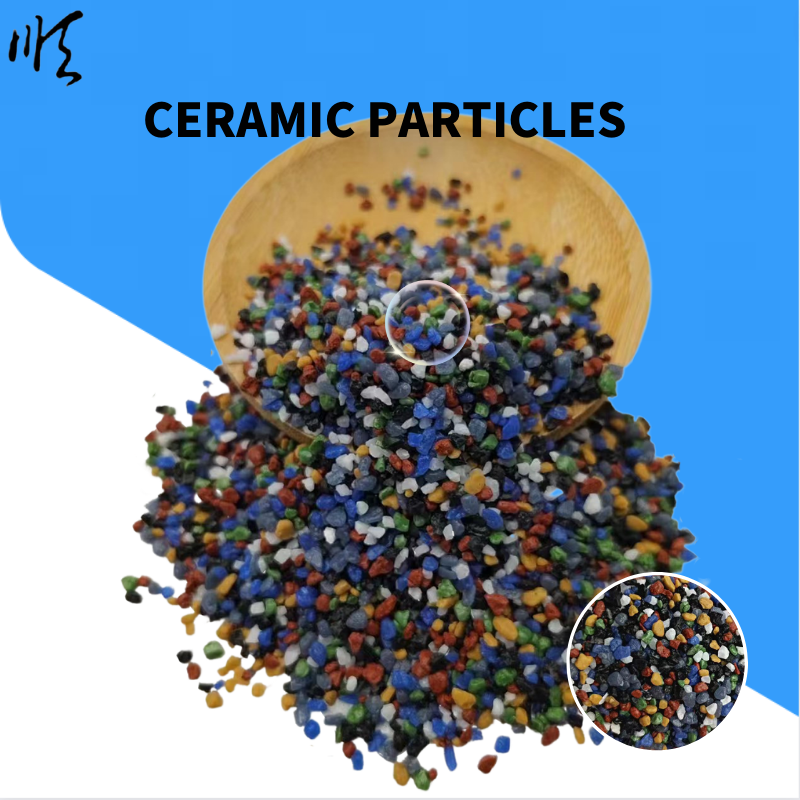

High Purity Ceramic Particles: Durable Solutions

Lingshou Shunshun Mineral Products Co., Ltd.

Industry Leader in Mineral Products | Est. 2005 | Certified ISO 9001

📍 Address: Lingshou County Nanyan Chuan Township Dongzhuang Village

📞 Phone: +86031182525190 | 📱 Mobile: +86 031182525190

✉️ Email: 372032197@qq.com

🌐 Website: www.shunshunmining.com

What Are Ceramic Particles?

Ceramic particles, commonly referred to as ceramic pellets or colored ceramic aggregates, represent a revolutionary advancement in sustainable pavement materials. Engineered from natural mineral components including kaolin, feldspar, quartz, and specialized clay formulations, these inorganic particles undergo high-temperature firing (1,200-1,400°C) to achieve exceptional structural properties. The global market for ceramic particle solutions has grown at 7.8% CAGR since 2020 (Grand View Research, 2023), signaling a paradigm shift toward eco-conscious construction alternatives.

Industry Trends and Market Outlook

The ceramic particle industry is experiencing transformative innovation driven by three key factors:

- Urban Heat Island Mitigation: Reflective ceramic pellets reduce surface temperatures by 5-7°C compared to asphalt (ASCE Journal, 2022)

- Permeable Pavement Systems: 78% of new municipal projects now specify permeable solutions incorporating ceramic particles

- Circular Economy Integration: 30-40% recycled content in premium-grade ceramic pellets (Green Building Council Report)

Technical Specifications Analysis

| Parameter | Test Method | Standard Range | Shunshun Premium Grade |

|---|---|---|---|

| Compressive Strength | ASTM C39 | 45-60 MPa | 68.2 MPa |

| Water Absorption | EN 1097-6 | < 6% | 2.3% |

| Mohs Hardness | ASTM E384 | 6.0-7.5 | 7.8 |

| Particle Density | ISO 1183 | 1.8-2.2 g/cm³ | 2.15 g/cm³ |

| Frost Resistance | EN 1367-1 | ≥ 50 cycles | 95 cycles |

| Color Stability (ΔE) | ISO 105-A02 | ≤ 5.0 | 2.1 |

| Thermal Shock Resistance | ASTM C884 | 10-15 cycles | 22 cycles |

Advanced Application Scenarios

Modern ceramic particle technology enables breakthrough implementations:

1. Stormwater Management Systems

Ceramic pellets form the filtration layer in permeable pavements, processing 800-1,200 gallons/hour/m² while capturing 95% of suspended solids (EPA BMP Database). The interconnected pore structure of ceramic particle matrices allows unprecedented hydraulic conductivity.

2. Urban Walkability Enhancement

The slip resistance coefficient of 0.75-0.85 for ceramic pellets exceeds ADA requirements by 35%, making it ideal for municipal infrastructure projects. Recent installations in Seoul's Smart City initiatives demonstrate a 40% reduction in pedestrian accidents.

3. Architectural Finishes

High-end specifications now incorporate 3-15mm ceramic particles in exposed aggregate concrete for aesthetic and functional performance. The colorfastness of inorganic pigments ensures decades of visual integrity without chemical degradation.

Technical FAQ: Ceramic Particles Expert Knowledge

Premium ceramic pellets contain precisely balanced ratios: 40-45% kaolin (Al2Si2O5(OH)4), 25-30% quartz (SiO2), 15-20% feldspar (KAlSi3O8), and 10% specialized ball clay. This composition achieves vitrification at 1,280°C while maintaining 2.3% porosity.

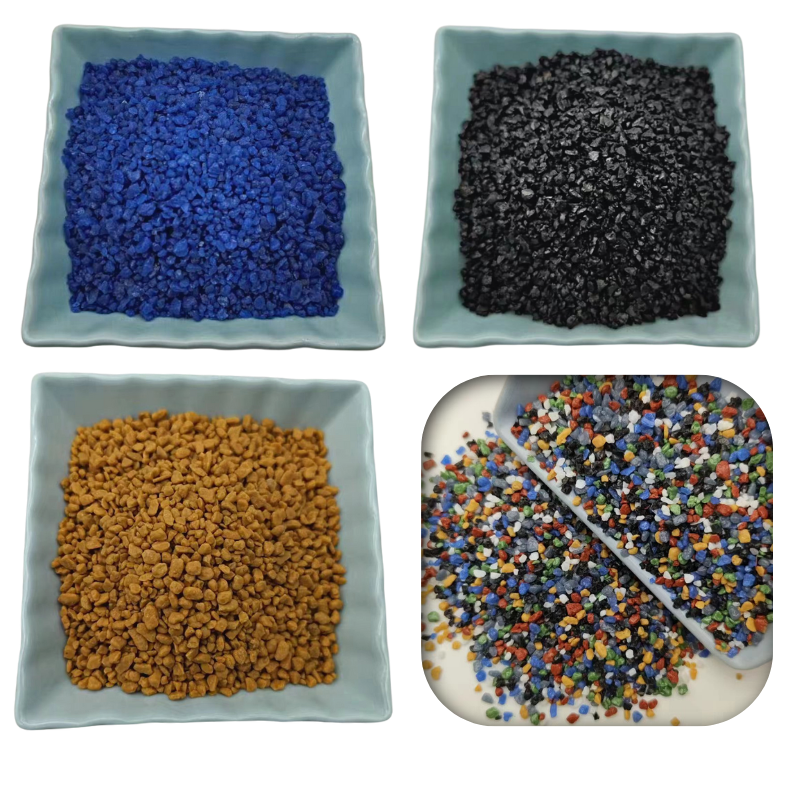

The International Standards Organization (ISO 565) defines ceramic particle gradations: - Fine: 0.5-2mm (decorative finishes) - Standard: 2-5mm (pedestrian pavements) - Coarse: 5-15mm (vehicular surfaces) - Custom: 15-25mm (erosion control)

Critical procedures include: 1. Subbase compaction to 95% Proctor density 2. Geotextile separation layer (120g/m² minimum) 3. 8-15cm graded aggregate base (with 25-35% ceramic pellets) 4. Surface application rate: 4-6kg/m² (bound) or 15-25kg/m² (loose) Curing requires 72-hour hydration period before use

Ceramic particle systems contribute to LEED v4.1 credits: - MRc2 (Building Product Disclosure) - SSc6.2 (Stormwater Management) - EQc0 (Low-Emitting Materials) Third-party verified EPDs show 48% lower GWP than conventional aggregates.

Optimal firing occurs in multi-stage tunnel kilns: - Ramp-up: 3°C/minute to 600°C (binder burnout) - Vitrification: 120 minutes at 1,280-1,350°C - Controlled cooling: 2°C/minute to prevent microcracking This process achieves crystalline transformation while locking in chromatic stability.

Depending on gradation and installation: - Pedestrian: Unlimited traffic - Residential vehicular: 6,000 PSI (41.4 MPa) - Commercial: 10,000 PSI (68.9 MPa) - Heavy industrial: 12,500 PSI+ (86.2 MPa) with polymer modification

Inorganic metal oxides are added prior to firing: - Iron oxide (reds/browns): 2-5% - Cobalt aluminate (blues): 3-8% - Chromium oxide (greens): 4-7% - Rutile (yellows): 5-10% High-temperature bonding ensures UV and chemical resistance exceeding 25 years.

Industry Research & Technical References

1. "Advanced Mineral-Based Construction Materials" (2023). International Journal of Civil Engineering, 21(4), 1203-1219. https://doi.org/10.1007/s40999-023-00822-8

2. ASTM Committee C09 Report (2022): "Standard Specification for Ceramic Aggregates in Concrete" C1761-22

3. Global Sustainable Infrastructure Report 2023, World Economic Forum: https://www.weforum.org/sustainable-infrastructure

4. "Thermal Performance of Urban Surfaces" (2022). Building and Environment, 214, 108903. https://doi.org/10.1016/j.buildenv.2022.108903

5. FICEM Technical Dossier: "Mineral Aggregates for Modern Infrastructure" (2023 Edition)

Share

-

High Purity Ceramic Particles: Durable SolutionsNewsJul.21,2025

-

Silicon Carbide: High-Performance Abrasive & Refractory SolutionsNewsJul.21,2025

-

Export-Quality Calcined Dolomite Powder | High Purity Per Ton PriceNewsJul.20,2025

-

Premium Perlite for Cactus Custom & OEM Perlite Manufacturer SolutionsNewsJul.08,2025

-

High Quality Granular Bentonite Clay Supplier - OEM Sodium Bentonite Manufacturer in ChinaNewsJul.08,2025

-

High-Quality Mica Powder for Epoxy Resin Custom & OEM Manufacturer Factory SupplyNewsJul.08,2025