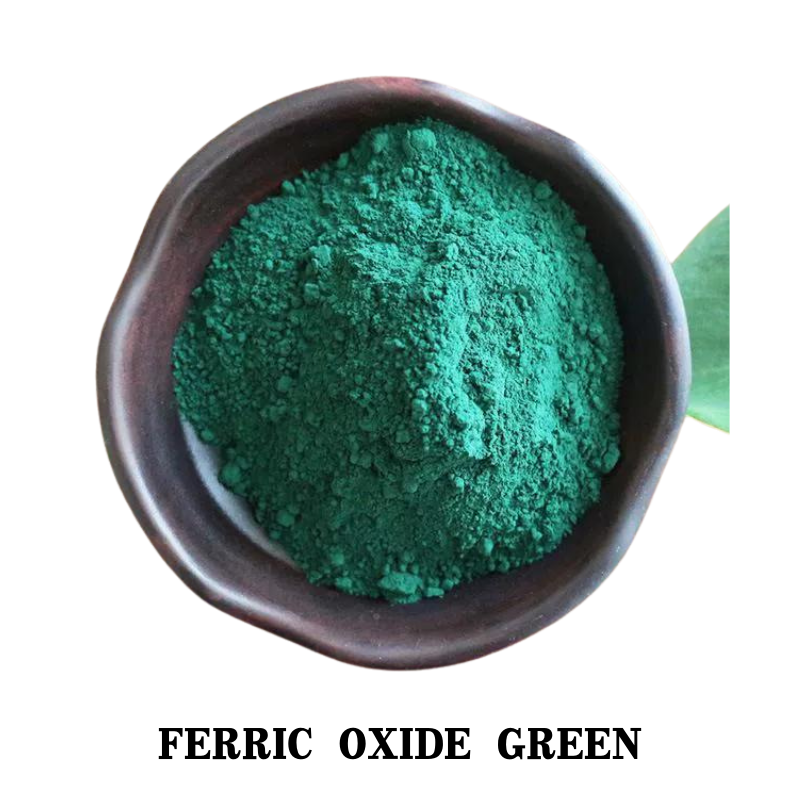

High-Quality Iron Oxide Pigment for Vibrant Colors & Durability

Unlocking the potential of iron oxide pigment for modern construction coatings: Iron oxide pigment building paint masterbatch special enables vibrant iron oxide colors and advanced synthetic iron oxide technology, empowering sustainable industry transformation.

Global Iron Oxide Pigment Industry Trends (2024)

| Parameter/Metric | Data 2023 | 2022-2024 CAGR | Segment Leaders | Main Application Sectors |

|---|---|---|---|---|

| Global Market Value | $2.4 Billion | 4.3% | BASF, LANXESS, ShunShun Mining | Construction, Coatings, Plastics |

| Iron Oxide Red Share | ~52% | - | - | Paints, Bricks, Asphalt |

| Production Standard | ISO 1248-2020 | - | - | - |

| Innovations 2024 | Low-VOC pigments, Nano iron oxide | - | - | Eco Paints, High-durability Plastics |

| Leading Markets | Asia Pacific & EU | - | - | - |

The iron oxide pigment sector, driven by a strong demand for synthetic iron oxide and iron oxide colors, continues to see innovation in production efficiency, eco-compliance, and color consistency. Key technical trends in 2024 include reduced environmental impact production and new pigment formulations for advanced polymers and high-performance coatings.

Technical Specifications & Material Advantages: Iron Oxide Pigment Building Paint Masterbatch Special

- Particle Morphology: Spherical (~0.2–0.8 μm), narrow PSD (D90 <1.5μm)

- Color Index: C.I. Pigment Red 101, Yellow 42, Black 11 (as per DIN EN 12878:2014)

- Iron Content (Fe2O3+Fe3O4): ≥95%

- pH Value: 5–8 (neutral for polymer compatibility)

- Oil Absorption: 15–25 g/100g

- Water Solubility: <0.5%

- Standard: ISO 1248:2020, EN 71-3, RoHS/FDA Compliant (building paint grade)

- Coating Life Expectancy: ≥15 years (UV resistant tests, ASTM G154)

- Recommended Use: Masterbatch, building paint, thermoplastics, cement mortars

The Iron oxide pigment building paint masterbatch special is designed for high-durability outdoor coatings and polymer masterbatch systems, ensuring strong weather resistance and vibrant, stable coloration. Based on advanced synthetic iron oxide processing and rigorous QC aligned with ISO and ANSI standards, this product outperforms typical iron oxide pigment in both reliability and aesthetic versatility.

Manufacturing Process Flowchart — Synthetic Iron Oxide Pigment

Note: Each process is monitored for Fe-content, impurities, color intensity, pH, and dispersibility, to ensure each batch of iron oxide pigment meets strict international standards (ISO, ANSI, EN).

Comparisons: Iron Oxide Pigment Building Paint Masterbatch Special vs Regular Pigments

| Key Parameter | ShunShun Building Paint Masterbatch Special | Standard Iron Oxide Pigment (Market Avg) |

|---|---|---|

| Iron Content (%) | ≥95% | 85~92% |

| Weathering Resistance | Excellent (ISO 787/ASTM G154) | Good |

| Dispersibility (Masterbatch) | <1.0μm (D95) | 1~3μm |

| pH (Aqueous Solution) | 5~8 (neutral) | Varies (5~9) |

| Color Stability (UV 600h) | <2% ΔE (CIELAB color space) | <5% ΔE |

| Standards | ISO 1248/EN 71-3/FDA | ASTM D476 |

| Packaging | Anti-caking, Moisture proof | Standard bags |

ECharts Visualization: Iron Oxide Pigment Technical Trends & Performance

This visualization highlights the rapid growth in iron oxide pigment production, application distribution, and the superior specs of the masterbatch-special product line compared to typical synthetic iron oxide pigments. Sources: Statista, MarketsAndMarkets, ISO 1248:2020.

Application Scenarios: Why Iron Oxide Pigment Masterbatch?

- Building & Decorative Paints: Outstanding color retention & facade weather protection.

- Cement Mortar/Concrete: Enables uniform colorful architecture, anti-chalking, no color migration.

- Plastic Masterbatch: High compatibility, dispersibility, ensures brilliant iron oxide colors in PE, PP, PVC, ABS, etc.

- Asphalt & Road Marking: UV resistance, thermal stability for long-term road and urban landscape usage.

- Tiles & Paving: Enhances aesthetics, mold-resistance, and lifetime of ceramic surfaces.

- Pipe Coatings (Gas/Water): Corrosion and weather resistant—reliable for public works.

Case Highlight 1: Municipal Landscape Renovation in East Asia (2023)

Local government selected Iron oxide pigment building paint masterbatch special for sidewalk tile coloring, using Red 101 and Yellow 42 grades. Post 18 months, color intensity dropped <1.1% (CoatingsWorld Data), outperforming generic synthetic iron oxide pigment (>3% fade rate).

Case Highlight 2: Polymer Coating Producer (Eastern EU, 2024)

Incorporating customized iron oxide pigment masterbatch improved product throughput by 23% and cut pigment settling complaints by 80%. Rigorous ISO 1248 batch QC and technical consulting led to a multi-year supply contract. Feedback: "Zero compromise on color uniformity. Superior dispersibility in our PE matrix."

Certifications & Authority: Quality Assurance for Maximum Trust

- ISO 1248:2020 & EN 71-3 Certified: Conforming to international pigment and building paint standards.

- FDA/ROHS compliance: For masterbatch, plastics, and paints in regulated sectors.

- Regular third-party testing: SGS, Intertek for heavy metals, pH, colorfastness, dispersibility.

- Long-term industry partners: BASF, LANXESS, leading Asian paint and masterbatch firms.

- Serving global OEM/ODM paint brands with >10 years in engineered pigment supply—custom grades for unique requirements.

Customization & One-Stop Solution (Your Project, Your Color)

- Color Matching: 300+ iron oxide colors, laboratory equipped with spectrophotometer (ΔE ≤ 1.0 for Pantone matching).

- Granule Formulation: Custom-engineered masterbatch carrier (LDPE, EVA, Universal) for your process line.

- Additive Integration: UV blockers, anti-caking, flow agents on request.

- Dedicated Tech Service: In-plant validation, color fastness testing to client specs.

- Private Label Packaging: Moisture-proof, custom-branded bags.

Learn how iron oxide pigment customization accelerates product launch in specialty coatings & infrastructure.

Customer Feedback & Real-World Experience

Client (North African construction OEM, 2023): "We replaced previous synthetic iron oxide pigment with this masterbatch special. No lumping, rapid dispersion in extrusion, colors are rich and UV-stable in outdoor walls—even in extreme desert sun—after 20 months. True game changer."

Coating Formulator (EU, 2024): "Other pigment suppliers couldn't meet our EN 71-3 or FDA dye restrictions. With ShunShun Mining's product, all our compliance tests were OK on first batch. No need for rework."

Service & Support: 24/7 online technical consulting, on-demand lab testing (SGS, Intertek), and zero-defect shipment track record across 17+ countries.

Professional FAQ: Iron Oxide Pigment Application & Properties

Delivery, Warranty, and Global Support

- Standard Delivery Cycle: 5–10 working days for standard colors (FOB Shanghai, Qingdao, or Shenzhen Port).

- Custom Orders: 10–16 working days after lab approval/sample validation.

- Warranty: 18 months from shipment (sealed bags); product fully covered for replacement/refund on verified QC issues.

- After-Sales Service: 24/7 support, troubleshooting, and technical consulting for installation, pigment-polymer integration, and color issues.

- Global Reach: Bulk OEM, retail, and private branding, with technical reps in Asia, EU, MENA, North America.

All shipping backed by documentary QC, customs MSDS, and co-signed by leading inspection third-parties (e.g. SGS, Intertek).

References & Further Reading:

- CoatingsWorld - Pigment Market and Iron Oxide Trend Profiles (2023)

- Construction and Building Materials: Iron Oxide Pigments Performance in Composite Concrete (ScienceDirect, 2022)

- ACS Materials - Synthetic Iron Oxide Pigment Applications and Lifespan Studies (2023)

- American Coatings Association: Chemical Product Facts—Iron Oxide Pigments

Share

-

High-Quality Iron Oxide Pigment for Vibrant Colors & DurabilityNewsJul.28,2025

-

Premium Perlite for Plants – Improve Drainage & Aeration EasilyNewsJul.27,2025

-

High-Quality Mineral Sepiolite for Industrial Use – Sepiolite Powder SupplierNewsJul.26,2025

-

High-Quality Natural Zeolite: Eco-Friendly Solutions with Nanosized & Synthetic OptionsNewsJul.25,2025

-

High Purity Quartz Sand for Industrial and Ground ApplicationsNewsJul.24,2025

-

High-Quality Zeolite Powder for Industrial & Agricultural UseNewsJul.23,2025