Use of Silica Fume in Cement Production for Enhanced Strength and Durability

The Role of Silica Fume in Cement Manufacturing

In the domain of construction materials, the search for innovations that enhance the durability and strength of concrete is ever-present. One such innovation is the incorporation of silica fume in cement manufacturing. Silica fume, also known as microsilica, is a byproduct of the silicon and ferrosilicon alloy production process. Its unique properties make it an important ingredient in the production of high-performance concrete and advanced cement products.

Understanding Silica Fume

Silica fume consists of tiny spherical particles with a diameter of around 1/100th that of a human hair. This fine dust is primarily composed of silicon dioxide (SiO2), boasting a silica content of about 85% to 95%. Due to its remarkably high specific surface area, which can be up to 30 times larger than that of cement, silica fume is known for its pozzolanic properties. When mixed with cement, it reacts with calcium hydroxide, a byproduct of cement hydration, to form additional calcium silicate hydrate (C-S-H), the primary binding compound that gives concrete its strength.

Enhancing Concrete Properties

The inclusion of silica fume in cement offers several benefits that contribute to enhanced concrete performance

1. Improved Strength Silica fume significantly increases the compressive and flexural strength of concrete. By filling the voids between the cement particles, it creates a denser microstructure, thereby enhancing the overall strength and durability.

2. Reduced Permeability The fine particles of silica fume help to reduce the permeability of concrete, making it less susceptible to water and chemical infiltration. This property is crucial for structures exposed to harsh environmental conditions, such as bridges and offshore structures, where moisture can lead to corrosion and degradation.

3. Increased Durability Concrete containing silica fume exhibits improved resistance to aggressive chemicals and alkali-silica reactions. This makes it an ideal choice for applications that require long-lasting and resilient materials.

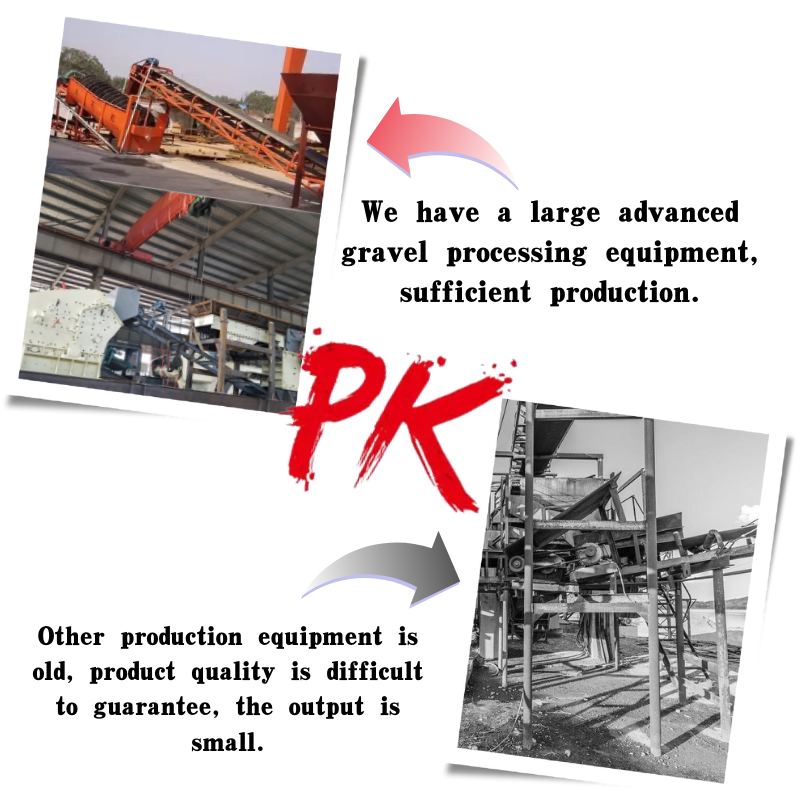

silica fume in cement manufacturer

4. Enhanced Workability Although silica fume can initially complicate the workability of concrete due to its absorbent nature, the use of superplasticizers can mitigate this issue. These additives allow for easier mixing and placement, ensuring that the beneficial properties of silica fume can be harnessed without compromising the workability of the concrete.

5. Sustainable Construction Practices The use of silica fume contributes to sustainable building practices by reducing the need for Portland cement. An increase in the proportion of silica fume can lower the overall carbon footprint of concrete production, aligning with the growing emphasis on green building materials.

Incorporating Silica Fume in Cement Manufacturing

To achieve optimal results when incorporating silica fume into cement, careful consideration of the mixing ratios and methodologies is essential. Typically, silica fume is added in proportions ranging from 5% to 15% by weight of cement, depending on the desired application and performance characteristics.

Cement manufacturers are increasingly recognizing the value of silica fume as an integral component of their products. By producing blended cements that contain silica fume, they can cater to the demands of modern construction projects, leveraging enhanced performance characteristics while maintaining cost-effectiveness.

Challenges and Considerations

While silica fume brings many advantages to cement manufacturing, there are challenges associated with its use. The handling of silica fume requires strict adherence to safety protocols due to its fine particulate nature, which can pose health hazards if inhaled. Additionally, the variability in the quality and characteristics of silica fume sourced from different suppliers necessitates rigorous quality control measures to ensure consistent performance in concrete.

Conclusion

Silica fume has emerged as a game-changer in the cement manufacturing industry, offering remarkable improvements in concrete strength, durability, and sustainability. As technology continues to advance and the construction industry evolves, the integration of silica fume into cement formulations will likely play a crucial role in producing high-performance concrete suitable for the challenges of the modern world. With ongoing research and development, silica fume stands to redefine the standards of what concrete can achieve, paving the way for future innovations in construction materials.

Share

-

Vermiculite Wholesale – Premium Quality, Bulk Supply & Competitive PricingNewsJun.10,2025

-

Premium Glass Pebbles Custom Glass Pebbles Factory & OEM Manufacturer Reliable Custom Glass Pebbles FactoriesNewsJun.10,2025

-

Expert Custom Zeolite Producers Manufacturers & FactoriesNewsJun.10,2025

-

Custom Glow in the Dark Beads High-Quality Custom ManufacturersNewsJun.10,2025

-

China Ceramsite Balls Factory - Lightweight & Durable Media Solutions ManufacturerNewsJun.09,2025

-

Custom Matte Mica Powder Manufacturers High Quality & AffordableNewsJun.09,2025