Custom Glow in the Dark Beads High-Quality Custom Manufacturers

- The Science Behind Modern Luminescent Beads

- Top Custom Glow in the Dark Beads Manufacturers Compared

- Tailoring Beads to Unique Requirements: Customization Options

- Technical Specifications That Enhance Performance

- Real-World Applications Across Industries

- Quality Assurance and Sustainability Practices

- Implementing Custom Glow Bead Solutions

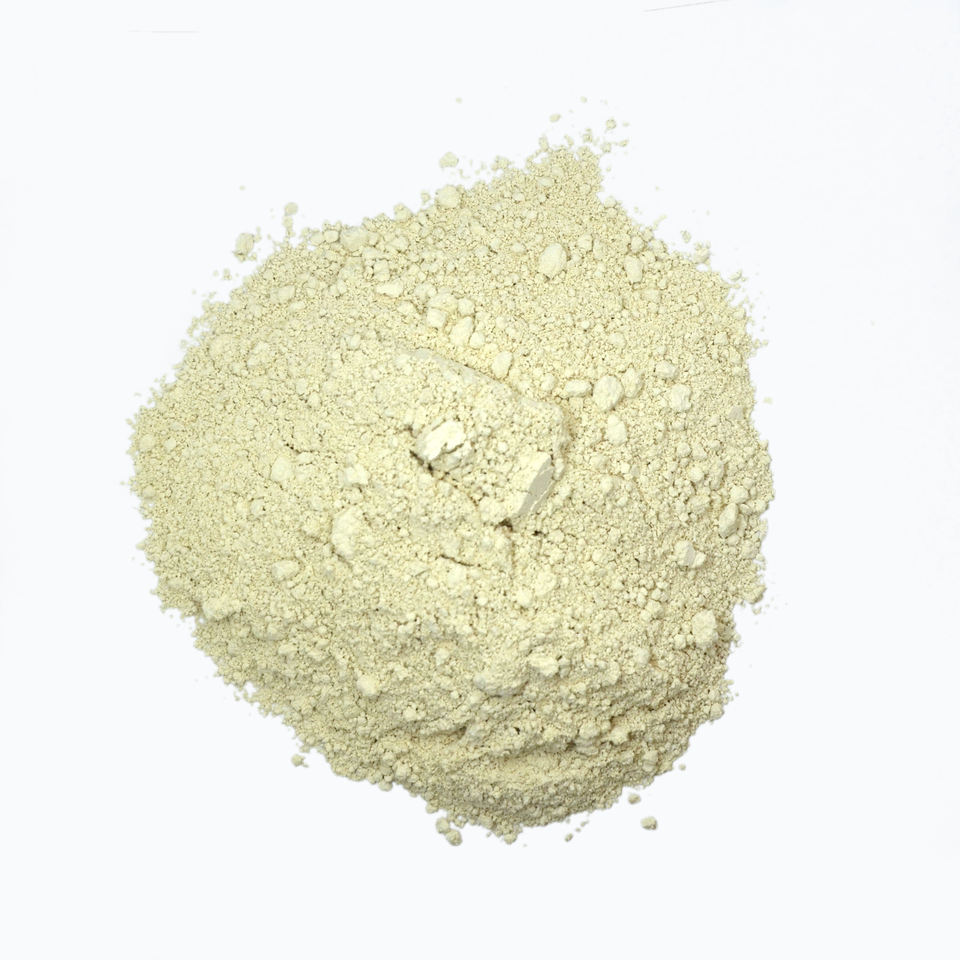

(glow in the dark beads)

Unveiling the Science of Glow in the Dark Beads

Modern glow in the dark beads

utilize advanced strontium aluminate photoluminescence, a significant upgrade from earlier zinc sulfide formulations. When exposed to natural or artificial light for just 15-30 minutes, these beads absorb photons and re-emit light for 8-12 hours in darkness. This phosphorescent material provides 10 times brighter luminosity and lasts 10 times longer than first-generation alternatives. Factories manipulate crystalline structures at molecular level to achieve precise glow characteristics including:

- Variable afterglow duration (from 1 to 14 hours)

- Multiple emission wavelengths (blue-green to red-orange spectrums)

- Temperature resistance from -30°C to 180°C

- UV stability maintaining 85% glow efficiency after 5 years

Manufacturers precisely control particle size distributions during production to ensure uniform light emission. Beads sized between 50-500 microns achieve optimal surface-area-to-volume ratios for maximum brightness.

Custom Glow in the Dark Beads Manufacturers: Capabilities Compared

| Manufacturer | Production Capacity | Material Quality | Customization Options | Lead Time |

|---|---|---|---|---|

| Luminova Specialists | 20 tons/month | Grade A (99.7% pure) | Shape, color, glow duration | 10-15 days |

| NoctiTech Manufacturing | 45 tons/month | Industrial Grade (95% pure) | Color, size, encapsulation | 5-7 days |

| GlowCore International | 70 tons/month | Military Grade (99.9% pure) | Full chemical composition | 21-28 days |

Leading factories invest in automated quality control systems with spectrophotometers measuring glow intensity within ±1.5% accuracy. Top-tier manufacturers hold ISO 9001:2015 and REACH compliance certifications, with production facilities featuring Class 7 cleanrooms to prevent particulate contamination.

Engineering Bespoke Luminescent Solutions

Custom glow in the dark beads factories provide comprehensive modification services:

- Color Spectrum Adjustments: Precise doping with europium (red) or dysprosium (blue) during synthesis

- Surface Treatments: Hydrophobic coatings, anti-static layers, UV protectants

- Size Grading: From 5-micron powders to 10mm macrobeads

- Encapsulation: Polymer resin infusion strengthens beads against physical damage

For specialized applications, manufacturers can modify decay rates to create specific afterglow profiles. Safety-certified formulations eliminate heavy metals while achieving 75 cd/m² initial brightness, exceeding OSHA visibility requirements.

Performance Specifications and Material Advancements

Technical parameters that define premium glow beads include:

- Luminance: 100-350 mcd/m² after 10 minutes charge

- Persistence: >0.3 mcd/m² maintained after 10 hours

- Thermal Stability: Withstand 250°F without deformation

- Chemical Resistance: pH stability between 3-11

Breakthrough phosphor formulations demonstrate 15% improved charging efficiency under low-light conditions compared to standard options. Manufacturers utilize proprietary crystal lattice engineering to reduce electron trap depths, enabling rapid charging from ambient room light.

Commercial and Industrial Implementation Cases

Safety equipment manufacturers incorporate 200-400 micron beads into:

- Emergency exit path markings lasting through 8-hour night shifts

- Aviation industry dashboard components maintaining visibility at 30,000ft

- Maritime safety vests with 10-year seawater resistance

Consumer applications leverage custom properties for brand differentiation. Novelty producers utilize color-shifting beads that transition from green to blue emission over decay cycles. Sports equipment companies embed customized glow patterns directly into fishing lines and camping gear fabrics.

Quality Verification and Environmental Certifications

Reputable factories implement rigorous testing protocols:

- Batch-sample photometric analysis documenting decay curves

- Accelerated aging simulations predicting 10-year performance

- Toxicological screening exceeding EU Directive 67/548/EEC

Environmentally-conscious manufacturers utilize closed-loop water systems that reduce consumption by 80% and convert production byproducts into safe mineral compounds. Certification to ISO 14001 standards demonstrates commitment to sustainable manufacturing practices throughout the supply chain.

Custom Glow in the Dark Beads: Implementation Strategy

Optimizing custom bead integration requires technical coordination between designers and factories:

- Specify required luminosity decay profile with performance benchmarks

- Select base material grade matching environmental exposure factors

- Coordinate manufacturing trials with spectrophotometer verification

- Validate final production batches against reference standards

Leading manufacturers provide technical support throughout product development cycles. The most advanced factories offer material certification documentation detailing composition and performance characteristics essential for compliance-critical applications.

(glow in the dark beads)

FAQS on glow in the dark beads

Q: What are glow in the dark beads used for?

A: Glow in the dark beads absorb and emit light, ideal for safety gear or creative crafts. They are made from phosphorescent materials like strontium aluminate. Many industries use them for visibility in low-light conditions.

Q: How do I find reliable custom glow in the dark beads manufacturers?

A: Search online directories like Alibaba for custom glow in the dark beads manufacturers with certifications. Check reviews and request samples to assess quality. Reputable manufacturers offer customization in size, color, and glow intensity.

Q: What advantages do custom glow in the dark beads factories provide?

A: Custom glow in the dark beads factories handle end-to-end production for bulk orders. They ensure cost-efficiency and quality control in shaping and coating processes. Many factories support custom designs, such as logo embedding or unique glow durations.

Q: How can a custom glow in the dark beads factory customize products?

A: A custom glow in the dark beads factory can tailor beads to your needs, like specific shapes or glow times. They use molds and pigments for personalization in large batches. Always confirm details like material safety standards before ordering.

Q: What should I check when selecting custom glow in the dark beads manufacturers?

A: Verify certifications and past projects from custom glow in the dark beads manufacturers. Test sample beads for brightness and durability. Ensure they follow international standards, such as RoHS compliance, for safe usage.

Share

-

High-Quality Mineral Sepiolite for Industrial Use – Sepiolite Powder SupplierNewsJul.26,2025

-

High-Quality Natural Zeolite: Eco-Friendly Solutions with Nanosized & Synthetic OptionsNewsJul.25,2025

-

High Purity Quartz Sand for Industrial and Ground ApplicationsNewsJul.24,2025

-

High-Quality Zeolite Powder for Industrial & Agricultural UseNewsJul.23,2025

-

Premium Cultured Stone Ledgestone for Lasting Elegance OutdoorsNewsJul.22,2025

-

High Purity Ceramic Particles: Durable SolutionsNewsJul.21,2025