- oem pumice or perlite factories******The Role of OEM Pumice and Perlite Factories in Modern Industries In today's fast-paced industrial landscape, the demand for high-quality raw materials has led to the rise of Original Equipment Manufacturer (OEM) pumice and perlite factories. These factories play a crucial role in providing essential products that cater to diverse sectors, including construction, horticulture, and environmental management. Understanding the significance of OEM pumice and perlite production is vital for numerous industries seeking reliable materials and innovative solutions. What are Pumice and Perlite? Pumice is a lightweight volcanic rock that forms when lava cools quickly with trapped gases, resulting in a porous texture. Its unique properties make it an excellent natural abrasive, as well as a lightweight aggregate in construction materials. Pumice is commonly used in concrete, lightweight blocks, and as a soil amendment in agriculture. Perlite, on the other hand, is a form of volcanic glass that expands when heated. The expansion process gives perlite its desirable lightweight and insulating properties. It is widely utilized in horticulture as a soil component to improve aeration and drainage, and in construction as an insulating material due to its fire-resistant capabilities. The Importance of OEM Factories OEM factories specialize in producing products that are tailored to their clients' specifications. This customization offers businesses the advantage of obtaining materials that meet precise industry standards and requirements. In the context of pumice and perlite, OEM factories are vital for several reasons 1. Quality Assurance OEM factories adhere to strict quality control measures, ensuring that the pumice and perlite produced meet international quality standards. This commitment to quality is critical for industries where the performance of materials directly impacts the end product's integrity. 2. Customization Different industries have varied requirements for pumice and perlite. OEM factories can tailor the texture, size, and chemical composition of these materials to meet specific needs, allowing for greater flexibility in application. oem pumice or perlite factories 3. Innovation Collaboration with OEM factories encourages innovation in product development. By working closely with manufacturers, companies can leverage cutting-edge processing techniques and formulations that enhance the performance characteristics of pumice and perlite. 4. Sustainability Many OEM factories are increasingly focusing on sustainable practices, utilizing eco-friendly extraction and production methods. This commitment not only benefits the environment but also aligns with the growing demand for sustainable products in various sectors. Applications of Pumice and Perlite The applications of pumice and perlite are vast, showcasing their versatility. In construction, pumice is prominently used in lightweight concrete and aggregates, which help reduce the overall weight of structures while maintaining strength. Perlite serves as an excellent insulation material, effectively retaining heat and reducing energy costs. In horticulture, perlite is a favorite among gardeners and farmers. Its ability to improve drainage and aeration makes it an essential component in potting mixes, while its inert nature ensures that it does not alter the chemical properties of the soil. Moreover, pumice is used in filtration systems, providing an efficient medium for removing impurities from water. Its unique structure enhances its effectiveness in various environmental applications, including soil remediation and erosion control. Conclusion OEM pumice and perlite factories represent a critical component of the supply chain for multiple industries. Their commitment to quality, customization, and sustainability ensures that businesses receive the materials necessary for success. As industries continue to evolve, the role of these factories will only grow, ultimately contributing to advancements in construction, horticulture, and environmental management. In a world increasingly focused on efficiency and sustainability, the demand for OEM pumice and perlite is poised to remain strong, reflecting a future where innovation drives growth across sectors.>

- oem pumice or perlite factories******The Role of OEM Pumice and Perlite Factories in Modern Industries In today's fast-paced industrial landscape, the demand for high-quality raw materials has led to the rise of Original Equipment Manufacturer (OEM) pumice and perlite factories. These factories play a crucial role in providing essential products that cater to diverse sectors, including construction, horticulture, and environmental management. Understanding the significance of OEM pumice and perlite production is vital for numerous industries seeking reliable materials and innovative solutions. What are Pumice and Perlite? Pumice is a lightweight volcanic rock that forms when lava cools quickly with trapped gases, resulting in a porous texture. Its unique properties make it an excellent natural abrasive, as well as a lightweight aggregate in construction materials. Pumice is commonly used in concrete, lightweight blocks, and as a soil amendment in agriculture. Perlite, on the other hand, is a form of volcanic glass that expands when heated. The expansion process gives perlite its desirable lightweight and insulating properties. It is widely utilized in horticulture as a soil component to improve aeration and drainage, and in construction as an insulating material due to its fire-resistant capabilities. The Importance of OEM Factories OEM factories specialize in producing products that are tailored to their clients' specifications. This customization offers businesses the advantage of obtaining materials that meet precise industry standards and requirements. In the context of pumice and perlite, OEM factories are vital for several reasons 1. Quality Assurance OEM factories adhere to strict quality control measures, ensuring that the pumice and perlite produced meet international quality standards. This commitment to quality is critical for industries where the performance of materials directly impacts the end product's integrity. 2. Customization Different industries have varied requirements for pumice and perlite. OEM factories can tailor the texture, size, and chemical composition of these materials to meet specific needs, allowing for greater flexibility in application. oem pumice or perlite factories 3. Innovation Collaboration with OEM factories encourages innovation in product development. By working closely with manufacturers, companies can leverage cutting-edge processing techniques and formulations that enhance the performance characteristics of pumice and perlite. 4. Sustainability Many OEM factories are increasingly focusing on sustainable practices, utilizing eco-friendly extraction and production methods. This commitment not only benefits the environment but also aligns with the growing demand for sustainable products in various sectors. Applications of Pumice and Perlite The applications of pumice and perlite are vast, showcasing their versatility. In construction, pumice is prominently used in lightweight concrete and aggregates, which help reduce the overall weight of structures while maintaining strength. Perlite serves as an excellent insulation material, effectively retaining heat and reducing energy costs. In horticulture, perlite is a favorite among gardeners and farmers. Its ability to improve drainage and aeration makes it an essential component in potting mixes, while its inert nature ensures that it does not alter the chemical properties of the soil. Moreover, pumice is used in filtration systems, providing an efficient medium for removing impurities from water. Its unique structure enhances its effectiveness in various environmental applications, including soil remediation and erosion control. Conclusion OEM pumice and perlite factories represent a critical component of the supply chain for multiple industries. Their commitment to quality, customization, and sustainability ensures that businesses receive the materials necessary for success. As industries continue to evolve, the role of these factories will only grow, ultimately contributing to advancements in construction, horticulture, and environmental management. In a world increasingly focused on efficiency and sustainability, the demand for OEM pumice and perlite is poised to remain strong, reflecting a future where innovation drives growth across sectors._custom mica powder pigment factories

oem pumice or perlite factories******The Role of OEM Pumice and Perlite Factories in Modern Industries In today's fast-paced industrial landscape, the demand for high-quality raw materials has led to the rise of Original Equipment Manufacturer (OEM) pumice and perlite factories. These factories play a crucial role in providing essential products that cater to diverse sectors, including construction, horticulture, and environmental management. Understanding the significance of OEM pumice and perlite production is vital for numerous industries seeking reliable materials and innovative solutions. What are Pumice and Perlite? Pumice is a lightweight volcanic rock that forms when lava cools quickly with trapped gases, resulting in a porous texture. Its unique properties make it an excellent natural abrasive, as well as a lightweight aggregate in construction materials. Pumice is commonly used in concrete, lightweight blocks, and as a soil amendment in agriculture. Perlite, on the other hand, is a form of volcanic glass that expands when heated. The expansion process gives perlite its desirable lightweight and insulating properties. It is widely utilized in horticulture as a soil component to improve aeration and drainage, and in construction as an insulating material due to its fire-resistant capabilities. The Importance of OEM Factories OEM factories specialize in producing products that are tailored to their clients' specifications. This customization offers businesses the advantage of obtaining materials that meet precise industry standards and requirements. In the context of pumice and perlite, OEM factories are vital for several reasons 1. Quality Assurance OEM factories adhere to strict quality control measures, ensuring that the pumice and perlite produced meet international quality standards. This commitment to quality is critical for industries where the performance of materials directly impacts the end product's integrity. 2. Customization Different industries have varied requirements for pumice and perlite. OEM factories can tailor the texture, size, and chemical composition of these materials to meet specific needs, allowing for greater flexibility in application. oem pumice or perlite factories 3. Innovation Collaboration with OEM factories encourages innovation in product development. By working closely with manufacturers, companies can leverage cutting-edge processing techniques and formulations that enhance the performance characteristics of pumice and perlite. 4. Sustainability Many OEM factories are increasingly focusing on sustainable practices, utilizing eco-friendly extraction and production methods. This commitment not only benefits the environment but also aligns with the growing demand for sustainable products in various sectors. Applications of Pumice and Perlite The applications of pumice and perlite are vast, showcasing their versatility. In construction, pumice is prominently used in lightweight concrete and aggregates, which help reduce the overall weight of structures while maintaining strength. Perlite serves as an excellent insulation material, effectively retaining heat and reducing energy costs. In horticulture, perlite is a favorite among gardeners and farmers. Its ability to improve drainage and aeration makes it an essential component in potting mixes, while its inert nature ensures that it does not alter the chemical properties of the soil. Moreover, pumice is used in filtration systems, providing an efficient medium for removing impurities from water. Its unique structure enhances its effectiveness in various environmental applications, including soil remediation and erosion control. Conclusion OEM pumice and perlite factories represent a critical component of the supply chain for multiple industries. Their commitment to quality, customization, and sustainability ensures that businesses receive the materials necessary for success. As industries continue to evolve, the role of these factories will only grow, ultimately contributing to advancements in construction, horticulture, and environmental management. In a world increasingly focused on efficiency and sustainability, the demand for OEM pumice and perlite is poised to remain strong, reflecting a future where innovation drives growth across sectors._custom mica powder pigment factories

oem white aluminium oxide powder

The Versatility and Applications of OEM White Aluminium Oxide Powder Aluminium oxide powder, particu...

Read Moreoem pumice or perlite factories******The Role of OEM Pumice and Perlite Factories in Modern Industries In today's fast-paced industrial landscape, the demand for high-quality raw materials has led to the rise of Original Equipment Manufacturer (OEM) pumice and perlite factories. These factories play a crucial role in providing essential products that cater to diverse sectors, including construction, horticulture, and environmental management. Understanding the significance of OEM pumice and perlite production is vital for numerous industries seeking reliable materials and innovative solutions. What are Pumice and Perlite? Pumice is a lightweight volcanic rock that forms when lava cools quickly with trapped gases, resulting in a porous texture. Its unique properties make it an excellent natural abrasive, as well as a lightweight aggregate in construction materials. Pumice is commonly used in concrete, lightweight blocks, and as a soil amendment in agriculture. Perlite, on the other hand, is a form of volcanic glass that expands when heated. The expansion process gives perlite its desirable lightweight and insulating properties. It is widely utilized in horticulture as a soil component to improve aeration and drainage, and in construction as an insulating material due to its fire-resistant capabilities. The Importance of OEM Factories OEM factories specialize in producing products that are tailored to their clients' specifications. This customization offers businesses the advantage of obtaining materials that meet precise industry standards and requirements. In the context of pumice and perlite, OEM factories are vital for several reasons 1. Quality Assurance OEM factories adhere to strict quality control measures, ensuring that the pumice and perlite produced meet international quality standards. This commitment to quality is critical for industries where the performance of materials directly impacts the end product's integrity. 2. Customization Different industries have varied requirements for pumice and perlite. OEM factories can tailor the texture, size, and chemical composition of these materials to meet specific needs, allowing for greater flexibility in application. oem pumice or perlite factories 3. Innovation Collaboration with OEM factories encourages innovation in product development. By working closely with manufacturers, companies can leverage cutting-edge processing techniques and formulations that enhance the performance characteristics of pumice and perlite. 4. Sustainability Many OEM factories are increasingly focusing on sustainable practices, utilizing eco-friendly extraction and production methods. This commitment not only benefits the environment but also aligns with the growing demand for sustainable products in various sectors. Applications of Pumice and Perlite The applications of pumice and perlite are vast, showcasing their versatility. In construction, pumice is prominently used in lightweight concrete and aggregates, which help reduce the overall weight of structures while maintaining strength. Perlite serves as an excellent insulation material, effectively retaining heat and reducing energy costs. In horticulture, perlite is a favorite among gardeners and farmers. Its ability to improve drainage and aeration makes it an essential component in potting mixes, while its inert nature ensures that it does not alter the chemical properties of the soil. Moreover, pumice is used in filtration systems, providing an efficient medium for removing impurities from water. Its unique structure enhances its effectiveness in various environmental applications, including soil remediation and erosion control. Conclusion OEM pumice and perlite factories represent a critical component of the supply chain for multiple industries. Their commitment to quality, customization, and sustainability ensures that businesses receive the materials necessary for success. As industries continue to evolve, the role of these factories will only grow, ultimately contributing to advancements in construction, horticulture, and environmental management. In a world increasingly focused on efficiency and sustainability, the demand for OEM pumice and perlite is poised to remain strong, reflecting a future where innovation drives growth across sectors._custom mica powder pigment factories2025-08-18 03:55Read(135)Custom Pellet Activated Carbon Manufacturer A Comprehensive Guide

Exploring the World of Custom Pelletized Activated Carbon Manufacturers In the realm of industrial...

Read Moreoem pumice or perlite factories******The Role of OEM Pumice and Perlite Factories in Modern Industries In today's fast-paced industrial landscape, the demand for high-quality raw materials has led to the rise of Original Equipment Manufacturer (OEM) pumice and perlite factories. These factories play a crucial role in providing essential products that cater to diverse sectors, including construction, horticulture, and environmental management. Understanding the significance of OEM pumice and perlite production is vital for numerous industries seeking reliable materials and innovative solutions. What are Pumice and Perlite? Pumice is a lightweight volcanic rock that forms when lava cools quickly with trapped gases, resulting in a porous texture. Its unique properties make it an excellent natural abrasive, as well as a lightweight aggregate in construction materials. Pumice is commonly used in concrete, lightweight blocks, and as a soil amendment in agriculture. Perlite, on the other hand, is a form of volcanic glass that expands when heated. The expansion process gives perlite its desirable lightweight and insulating properties. It is widely utilized in horticulture as a soil component to improve aeration and drainage, and in construction as an insulating material due to its fire-resistant capabilities. The Importance of OEM Factories OEM factories specialize in producing products that are tailored to their clients' specifications. This customization offers businesses the advantage of obtaining materials that meet precise industry standards and requirements. In the context of pumice and perlite, OEM factories are vital for several reasons 1. Quality Assurance OEM factories adhere to strict quality control measures, ensuring that the pumice and perlite produced meet international quality standards. This commitment to quality is critical for industries where the performance of materials directly impacts the end product's integrity. 2. Customization Different industries have varied requirements for pumice and perlite. OEM factories can tailor the texture, size, and chemical composition of these materials to meet specific needs, allowing for greater flexibility in application. oem pumice or perlite factories 3. Innovation Collaboration with OEM factories encourages innovation in product development. By working closely with manufacturers, companies can leverage cutting-edge processing techniques and formulations that enhance the performance characteristics of pumice and perlite. 4. Sustainability Many OEM factories are increasingly focusing on sustainable practices, utilizing eco-friendly extraction and production methods. This commitment not only benefits the environment but also aligns with the growing demand for sustainable products in various sectors. Applications of Pumice and Perlite The applications of pumice and perlite are vast, showcasing their versatility. In construction, pumice is prominently used in lightweight concrete and aggregates, which help reduce the overall weight of structures while maintaining strength. Perlite serves as an excellent insulation material, effectively retaining heat and reducing energy costs. In horticulture, perlite is a favorite among gardeners and farmers. Its ability to improve drainage and aeration makes it an essential component in potting mixes, while its inert nature ensures that it does not alter the chemical properties of the soil. Moreover, pumice is used in filtration systems, providing an efficient medium for removing impurities from water. Its unique structure enhances its effectiveness in various environmental applications, including soil remediation and erosion control. Conclusion OEM pumice and perlite factories represent a critical component of the supply chain for multiple industries. Their commitment to quality, customization, and sustainability ensures that businesses receive the materials necessary for success. As industries continue to evolve, the role of these factories will only grow, ultimately contributing to advancements in construction, horticulture, and environmental management. In a world increasingly focused on efficiency and sustainability, the demand for OEM pumice and perlite is poised to remain strong, reflecting a future where innovation drives growth across sectors._custom mica powder pigment factories2025-08-18 03:49Read(728)OEM rutile titanium dioxide pricing trends and market analysis for manufacturers and suppliers

The Trends and Pricing of OEM Rutile Titanium Dioxide Rutile titanium dioxide (TiO2) is a vital whit...

Read Moreoem pumice or perlite factories******The Role of OEM Pumice and Perlite Factories in Modern Industries In today's fast-paced industrial landscape, the demand for high-quality raw materials has led to the rise of Original Equipment Manufacturer (OEM) pumice and perlite factories. These factories play a crucial role in providing essential products that cater to diverse sectors, including construction, horticulture, and environmental management. Understanding the significance of OEM pumice and perlite production is vital for numerous industries seeking reliable materials and innovative solutions. What are Pumice and Perlite? Pumice is a lightweight volcanic rock that forms when lava cools quickly with trapped gases, resulting in a porous texture. Its unique properties make it an excellent natural abrasive, as well as a lightweight aggregate in construction materials. Pumice is commonly used in concrete, lightweight blocks, and as a soil amendment in agriculture. Perlite, on the other hand, is a form of volcanic glass that expands when heated. The expansion process gives perlite its desirable lightweight and insulating properties. It is widely utilized in horticulture as a soil component to improve aeration and drainage, and in construction as an insulating material due to its fire-resistant capabilities. The Importance of OEM Factories OEM factories specialize in producing products that are tailored to their clients' specifications. This customization offers businesses the advantage of obtaining materials that meet precise industry standards and requirements. In the context of pumice and perlite, OEM factories are vital for several reasons 1. Quality Assurance OEM factories adhere to strict quality control measures, ensuring that the pumice and perlite produced meet international quality standards. This commitment to quality is critical for industries where the performance of materials directly impacts the end product's integrity. 2. Customization Different industries have varied requirements for pumice and perlite. OEM factories can tailor the texture, size, and chemical composition of these materials to meet specific needs, allowing for greater flexibility in application. oem pumice or perlite factories 3. Innovation Collaboration with OEM factories encourages innovation in product development. By working closely with manufacturers, companies can leverage cutting-edge processing techniques and formulations that enhance the performance characteristics of pumice and perlite. 4. Sustainability Many OEM factories are increasingly focusing on sustainable practices, utilizing eco-friendly extraction and production methods. This commitment not only benefits the environment but also aligns with the growing demand for sustainable products in various sectors. Applications of Pumice and Perlite The applications of pumice and perlite are vast, showcasing their versatility. In construction, pumice is prominently used in lightweight concrete and aggregates, which help reduce the overall weight of structures while maintaining strength. Perlite serves as an excellent insulation material, effectively retaining heat and reducing energy costs. In horticulture, perlite is a favorite among gardeners and farmers. Its ability to improve drainage and aeration makes it an essential component in potting mixes, while its inert nature ensures that it does not alter the chemical properties of the soil. Moreover, pumice is used in filtration systems, providing an efficient medium for removing impurities from water. Its unique structure enhances its effectiveness in various environmental applications, including soil remediation and erosion control. Conclusion OEM pumice and perlite factories represent a critical component of the supply chain for multiple industries. Their commitment to quality, customization, and sustainability ensures that businesses receive the materials necessary for success. As industries continue to evolve, the role of these factories will only grow, ultimately contributing to advancements in construction, horticulture, and environmental management. In a world increasingly focused on efficiency and sustainability, the demand for OEM pumice and perlite is poised to remain strong, reflecting a future where innovation drives growth across sectors._custom mica powder pigment factories2025-08-18 03:33Read(640)- Backstage Prabal Gurung Fall/Winter 2020 show. Luca Cannonieri / Gorunway" title='Backstage Prabal Gurung Fall/Winter 2020 show. Luca Cannonieri / Gorunway'>Backstage Prabal Gurung Fall/Winter 2020 show. Luca Cannonieri / Gorunway

...

Read Moreoem pumice or perlite factories******The Role of OEM Pumice and Perlite Factories in Modern Industries In today's fast-paced industrial landscape, the demand for high-quality raw materials has led to the rise of Original Equipment Manufacturer (OEM) pumice and perlite factories. These factories play a crucial role in providing essential products that cater to diverse sectors, including construction, horticulture, and environmental management. Understanding the significance of OEM pumice and perlite production is vital for numerous industries seeking reliable materials and innovative solutions. What are Pumice and Perlite? Pumice is a lightweight volcanic rock that forms when lava cools quickly with trapped gases, resulting in a porous texture. Its unique properties make it an excellent natural abrasive, as well as a lightweight aggregate in construction materials. Pumice is commonly used in concrete, lightweight blocks, and as a soil amendment in agriculture. Perlite, on the other hand, is a form of volcanic glass that expands when heated. The expansion process gives perlite its desirable lightweight and insulating properties. It is widely utilized in horticulture as a soil component to improve aeration and drainage, and in construction as an insulating material due to its fire-resistant capabilities. The Importance of OEM Factories OEM factories specialize in producing products that are tailored to their clients' specifications. This customization offers businesses the advantage of obtaining materials that meet precise industry standards and requirements. In the context of pumice and perlite, OEM factories are vital for several reasons 1. Quality Assurance OEM factories adhere to strict quality control measures, ensuring that the pumice and perlite produced meet international quality standards. This commitment to quality is critical for industries where the performance of materials directly impacts the end product's integrity. 2. Customization Different industries have varied requirements for pumice and perlite. OEM factories can tailor the texture, size, and chemical composition of these materials to meet specific needs, allowing for greater flexibility in application. oem pumice or perlite factories 3. Innovation Collaboration with OEM factories encourages innovation in product development. By working closely with manufacturers, companies can leverage cutting-edge processing techniques and formulations that enhance the performance characteristics of pumice and perlite. 4. Sustainability Many OEM factories are increasingly focusing on sustainable practices, utilizing eco-friendly extraction and production methods. This commitment not only benefits the environment but also aligns with the growing demand for sustainable products in various sectors. Applications of Pumice and Perlite The applications of pumice and perlite are vast, showcasing their versatility. In construction, pumice is prominently used in lightweight concrete and aggregates, which help reduce the overall weight of structures while maintaining strength. Perlite serves as an excellent insulation material, effectively retaining heat and reducing energy costs. In horticulture, perlite is a favorite among gardeners and farmers. Its ability to improve drainage and aeration makes it an essential component in potting mixes, while its inert nature ensures that it does not alter the chemical properties of the soil. Moreover, pumice is used in filtration systems, providing an efficient medium for removing impurities from water. Its unique structure enhances its effectiveness in various environmental applications, including soil remediation and erosion control. Conclusion OEM pumice and perlite factories represent a critical component of the supply chain for multiple industries. Their commitment to quality, customization, and sustainability ensures that businesses receive the materials necessary for success. As industries continue to evolve, the role of these factories will only grow, ultimately contributing to advancements in construction, horticulture, and environmental management. In a world increasingly focused on efficiency and sustainability, the demand for OEM pumice and perlite is poised to remain strong, reflecting a future where innovation drives growth across sectors._custom mica powder pigment factories2025-08-18 02:56Read(2408) OEM पिग्मेन्ट रेड उत्पादकका लागि शीर्षक सिर्जना गर्नुहोस्

ओईएम पिग्मेंट रेड निर्माता एउटा समर्पित उद्योग ओईएम (असली उपकरण निर्माता) पिग्मेंट रेड उत्पादकहरूको...

Read Moreoem pumice or perlite factories******The Role of OEM Pumice and Perlite Factories in Modern Industries In today's fast-paced industrial landscape, the demand for high-quality raw materials has led to the rise of Original Equipment Manufacturer (OEM) pumice and perlite factories. These factories play a crucial role in providing essential products that cater to diverse sectors, including construction, horticulture, and environmental management. Understanding the significance of OEM pumice and perlite production is vital for numerous industries seeking reliable materials and innovative solutions. What are Pumice and Perlite? Pumice is a lightweight volcanic rock that forms when lava cools quickly with trapped gases, resulting in a porous texture. Its unique properties make it an excellent natural abrasive, as well as a lightweight aggregate in construction materials. Pumice is commonly used in concrete, lightweight blocks, and as a soil amendment in agriculture. Perlite, on the other hand, is a form of volcanic glass that expands when heated. The expansion process gives perlite its desirable lightweight and insulating properties. It is widely utilized in horticulture as a soil component to improve aeration and drainage, and in construction as an insulating material due to its fire-resistant capabilities. The Importance of OEM Factories OEM factories specialize in producing products that are tailored to their clients' specifications. This customization offers businesses the advantage of obtaining materials that meet precise industry standards and requirements. In the context of pumice and perlite, OEM factories are vital for several reasons 1. Quality Assurance OEM factories adhere to strict quality control measures, ensuring that the pumice and perlite produced meet international quality standards. This commitment to quality is critical for industries where the performance of materials directly impacts the end product's integrity. 2. Customization Different industries have varied requirements for pumice and perlite. OEM factories can tailor the texture, size, and chemical composition of these materials to meet specific needs, allowing for greater flexibility in application. oem pumice or perlite factories 3. Innovation Collaboration with OEM factories encourages innovation in product development. By working closely with manufacturers, companies can leverage cutting-edge processing techniques and formulations that enhance the performance characteristics of pumice and perlite. 4. Sustainability Many OEM factories are increasingly focusing on sustainable practices, utilizing eco-friendly extraction and production methods. This commitment not only benefits the environment but also aligns with the growing demand for sustainable products in various sectors. Applications of Pumice and Perlite The applications of pumice and perlite are vast, showcasing their versatility. In construction, pumice is prominently used in lightweight concrete and aggregates, which help reduce the overall weight of structures while maintaining strength. Perlite serves as an excellent insulation material, effectively retaining heat and reducing energy costs. In horticulture, perlite is a favorite among gardeners and farmers. Its ability to improve drainage and aeration makes it an essential component in potting mixes, while its inert nature ensures that it does not alter the chemical properties of the soil. Moreover, pumice is used in filtration systems, providing an efficient medium for removing impurities from water. Its unique structure enhances its effectiveness in various environmental applications, including soil remediation and erosion control. Conclusion OEM pumice and perlite factories represent a critical component of the supply chain for multiple industries. Their commitment to quality, customization, and sustainability ensures that businesses receive the materials necessary for success. As industries continue to evolve, the role of these factories will only grow, ultimately contributing to advancements in construction, horticulture, and environmental management. In a world increasingly focused on efficiency and sustainability, the demand for OEM pumice and perlite is poised to remain strong, reflecting a future where innovation drives growth across sectors._custom mica powder pigment factories2025-08-18 02:25Read(1918)//skinpharm.com/cdn/shop/articles/skinpharm02.09xhtp_27_new_1400x.jpg?v=1686022075 1400w,

...

Read Moreoem pumice or perlite factories******The Role of OEM Pumice and Perlite Factories in Modern Industries In today's fast-paced industrial landscape, the demand for high-quality raw materials has led to the rise of Original Equipment Manufacturer (OEM) pumice and perlite factories. These factories play a crucial role in providing essential products that cater to diverse sectors, including construction, horticulture, and environmental management. Understanding the significance of OEM pumice and perlite production is vital for numerous industries seeking reliable materials and innovative solutions. What are Pumice and Perlite? Pumice is a lightweight volcanic rock that forms when lava cools quickly with trapped gases, resulting in a porous texture. Its unique properties make it an excellent natural abrasive, as well as a lightweight aggregate in construction materials. Pumice is commonly used in concrete, lightweight blocks, and as a soil amendment in agriculture. Perlite, on the other hand, is a form of volcanic glass that expands when heated. The expansion process gives perlite its desirable lightweight and insulating properties. It is widely utilized in horticulture as a soil component to improve aeration and drainage, and in construction as an insulating material due to its fire-resistant capabilities. The Importance of OEM Factories OEM factories specialize in producing products that are tailored to their clients' specifications. This customization offers businesses the advantage of obtaining materials that meet precise industry standards and requirements. In the context of pumice and perlite, OEM factories are vital for several reasons 1. Quality Assurance OEM factories adhere to strict quality control measures, ensuring that the pumice and perlite produced meet international quality standards. This commitment to quality is critical for industries where the performance of materials directly impacts the end product's integrity. 2. Customization Different industries have varied requirements for pumice and perlite. OEM factories can tailor the texture, size, and chemical composition of these materials to meet specific needs, allowing for greater flexibility in application. oem pumice or perlite factories 3. Innovation Collaboration with OEM factories encourages innovation in product development. By working closely with manufacturers, companies can leverage cutting-edge processing techniques and formulations that enhance the performance characteristics of pumice and perlite. 4. Sustainability Many OEM factories are increasingly focusing on sustainable practices, utilizing eco-friendly extraction and production methods. This commitment not only benefits the environment but also aligns with the growing demand for sustainable products in various sectors. Applications of Pumice and Perlite The applications of pumice and perlite are vast, showcasing their versatility. In construction, pumice is prominently used in lightweight concrete and aggregates, which help reduce the overall weight of structures while maintaining strength. Perlite serves as an excellent insulation material, effectively retaining heat and reducing energy costs. In horticulture, perlite is a favorite among gardeners and farmers. Its ability to improve drainage and aeration makes it an essential component in potting mixes, while its inert nature ensures that it does not alter the chemical properties of the soil. Moreover, pumice is used in filtration systems, providing an efficient medium for removing impurities from water. Its unique structure enhances its effectiveness in various environmental applications, including soil remediation and erosion control. Conclusion OEM pumice and perlite factories represent a critical component of the supply chain for multiple industries. Their commitment to quality, customization, and sustainability ensures that businesses receive the materials necessary for success. As industries continue to evolve, the role of these factories will only grow, ultimately contributing to advancements in construction, horticulture, and environmental management. In a world increasingly focused on efficiency and sustainability, the demand for OEM pumice and perlite is poised to remain strong, reflecting a future where innovation drives growth across sectors._custom mica powder pigment factories2025-08-18 02:04Read(620)...

Read Moreoem pumice or perlite factories******The Role of OEM Pumice and Perlite Factories in Modern Industries In today's fast-paced industrial landscape, the demand for high-quality raw materials has led to the rise of Original Equipment Manufacturer (OEM) pumice and perlite factories. These factories play a crucial role in providing essential products that cater to diverse sectors, including construction, horticulture, and environmental management. Understanding the significance of OEM pumice and perlite production is vital for numerous industries seeking reliable materials and innovative solutions. What are Pumice and Perlite? Pumice is a lightweight volcanic rock that forms when lava cools quickly with trapped gases, resulting in a porous texture. Its unique properties make it an excellent natural abrasive, as well as a lightweight aggregate in construction materials. Pumice is commonly used in concrete, lightweight blocks, and as a soil amendment in agriculture. Perlite, on the other hand, is a form of volcanic glass that expands when heated. The expansion process gives perlite its desirable lightweight and insulating properties. It is widely utilized in horticulture as a soil component to improve aeration and drainage, and in construction as an insulating material due to its fire-resistant capabilities. The Importance of OEM Factories OEM factories specialize in producing products that are tailored to their clients' specifications. This customization offers businesses the advantage of obtaining materials that meet precise industry standards and requirements. In the context of pumice and perlite, OEM factories are vital for several reasons 1. Quality Assurance OEM factories adhere to strict quality control measures, ensuring that the pumice and perlite produced meet international quality standards. This commitment to quality is critical for industries where the performance of materials directly impacts the end product's integrity. 2. Customization Different industries have varied requirements for pumice and perlite. OEM factories can tailor the texture, size, and chemical composition of these materials to meet specific needs, allowing for greater flexibility in application. oem pumice or perlite factories 3. Innovation Collaboration with OEM factories encourages innovation in product development. By working closely with manufacturers, companies can leverage cutting-edge processing techniques and formulations that enhance the performance characteristics of pumice and perlite. 4. Sustainability Many OEM factories are increasingly focusing on sustainable practices, utilizing eco-friendly extraction and production methods. This commitment not only benefits the environment but also aligns with the growing demand for sustainable products in various sectors. Applications of Pumice and Perlite The applications of pumice and perlite are vast, showcasing their versatility. In construction, pumice is prominently used in lightweight concrete and aggregates, which help reduce the overall weight of structures while maintaining strength. Perlite serves as an excellent insulation material, effectively retaining heat and reducing energy costs. In horticulture, perlite is a favorite among gardeners and farmers. Its ability to improve drainage and aeration makes it an essential component in potting mixes, while its inert nature ensures that it does not alter the chemical properties of the soil. Moreover, pumice is used in filtration systems, providing an efficient medium for removing impurities from water. Its unique structure enhances its effectiveness in various environmental applications, including soil remediation and erosion control. Conclusion OEM pumice and perlite factories represent a critical component of the supply chain for multiple industries. Their commitment to quality, customization, and sustainability ensures that businesses receive the materials necessary for success. As industries continue to evolve, the role of these factories will only grow, ultimately contributing to advancements in construction, horticulture, and environmental management. In a world increasingly focused on efficiency and sustainability, the demand for OEM pumice and perlite is poised to remain strong, reflecting a future where innovation drives growth across sectors._custom mica powder pigment factories2025-08-18 01:44Read(2610)

You may feel surprised to learn that activated carbon appears in many products we use around the home. Toothpaste represents a prime example as activated carbon toothpaste proves an excellent whitener. Adding a tiny amount of finely ground-down activated charcoal to your toothpaste gives it antiviral and antibacterial properties.

...

Volcanic Stone Grill Experience

The Art of Volcanic Stone Barbecue Barbecue enthusiasts around the world are always in search of ne...

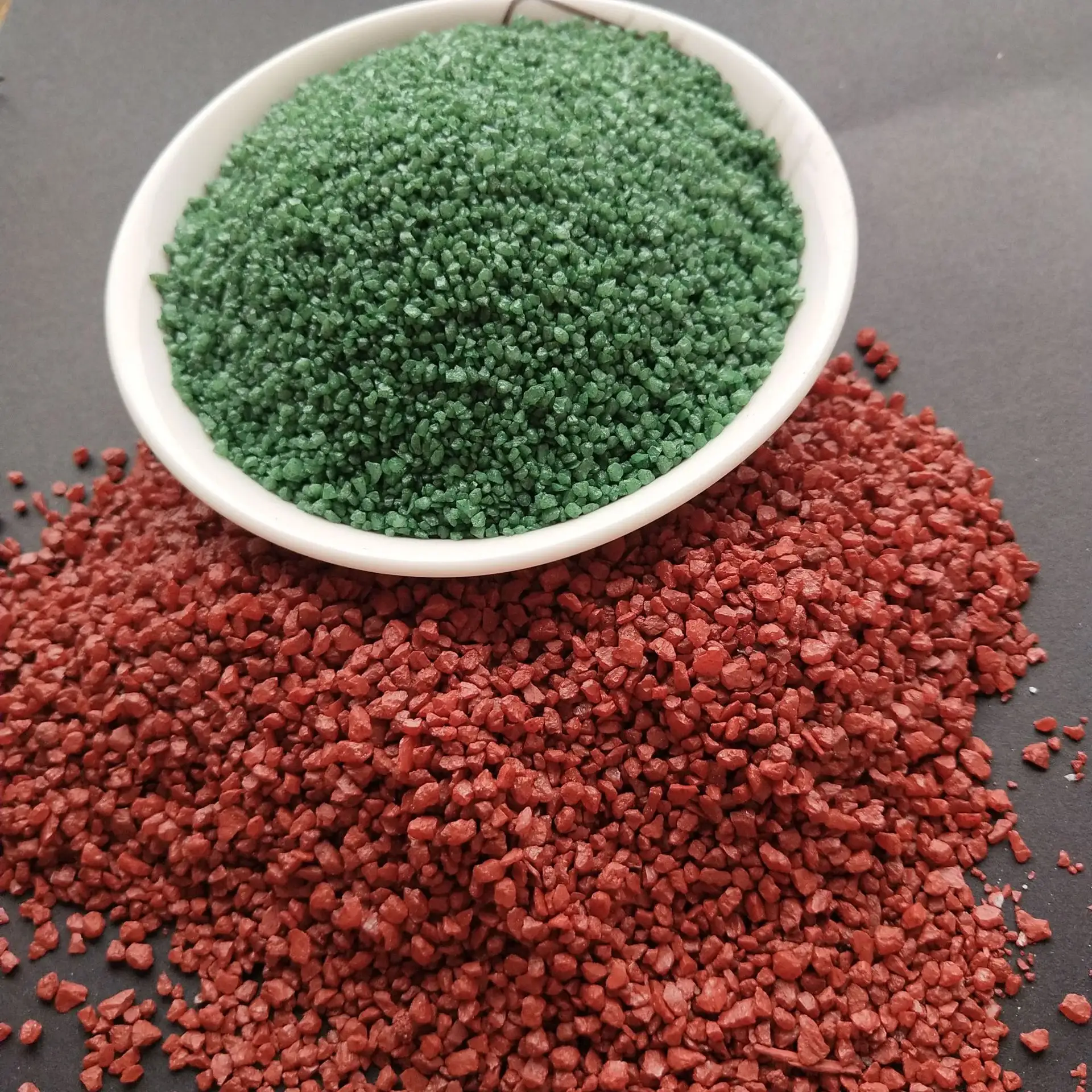

dry quartz sand

Understanding Dry Quartz Sand Properties and Applications Quartz sand, predominantly composed of sil...