- silica fume fly ash factories******The Role of Silica Fume and Fly Ash in Modern Construction In recent years, the construction industry has recognized the importance of sustainable building materials that not only enhance the strength and durability of concrete but also minimize the environmental impact. Among these materials, silica fume and fly ash have emerged as key components in the production of high-performance concrete. Their utilization in factories has revolutionized conventional construction practices, leading to significant benefits. The Role of Silica Fume and Fly Ash in Modern Construction On the other hand, fly ash is a by-product of coal combustion in power plants. It contains silica, alumina, and iron, which, like silica fume, can react with calcium hydroxide in the presence of water to form additional cementitious compounds. The incorporation of fly ash in concrete not only improves workability and reduces water demand but also lowers the carbon footprint of concrete production. By replacing a portion of traditional Portland cement with fly ash, factories can significantly reduce greenhouse gas emissions. silica fume fly ash factories The combination of silica fume and fly ash in concrete formulations is particularly advantageous. When used together, they create a synergistic effect that enhances the overall performance of concrete. Factories that produce concrete with these materials are better equipped to meet the increasing demand for sustainable construction solutions. Furthermore, the use of industrial by-products like silica fume and fly ash contributes to the circular economy, where waste materials are repurposed, reducing the need for virgin resources. Another critical aspect of using silica fume and fly ash in concrete production is their economic benefits. Although the initial cost of these materials may be higher than that of conventional cement, the long-term advantages, including reduced maintenance costs and increased lifespan of structures, can lead to significant savings. Factories that implement these materials also benefit from compliance with sustainability certifications and green building standards, which can enhance their marketability and competitiveness. In conclusion, the integration of silica fume and fly ash into concrete production processes represents a significant advancement in the construction industry. Their use not only improves the mechanical properties and sustainability of concrete but also supports the broader goals of environmental stewardship and resource efficiency. As factories continue to adopt these innovative materials, the construction sector moves closer to achieving its objectives of durability, sustainability, and reduced environmental impact. The future of construction lies in the responsible use of such materials, paving the way for more resilient and eco-friendly infrastructure.>

- silica fume fly ash factories******The Role of Silica Fume and Fly Ash in Modern Construction In recent years, the construction industry has recognized the importance of sustainable building materials that not only enhance the strength and durability of concrete but also minimize the environmental impact. Among these materials, silica fume and fly ash have emerged as key components in the production of high-performance concrete. Their utilization in factories has revolutionized conventional construction practices, leading to significant benefits. The Role of Silica Fume and Fly Ash in Modern Construction On the other hand, fly ash is a by-product of coal combustion in power plants. It contains silica, alumina, and iron, which, like silica fume, can react with calcium hydroxide in the presence of water to form additional cementitious compounds. The incorporation of fly ash in concrete not only improves workability and reduces water demand but also lowers the carbon footprint of concrete production. By replacing a portion of traditional Portland cement with fly ash, factories can significantly reduce greenhouse gas emissions. silica fume fly ash factories The combination of silica fume and fly ash in concrete formulations is particularly advantageous. When used together, they create a synergistic effect that enhances the overall performance of concrete. Factories that produce concrete with these materials are better equipped to meet the increasing demand for sustainable construction solutions. Furthermore, the use of industrial by-products like silica fume and fly ash contributes to the circular economy, where waste materials are repurposed, reducing the need for virgin resources. Another critical aspect of using silica fume and fly ash in concrete production is their economic benefits. Although the initial cost of these materials may be higher than that of conventional cement, the long-term advantages, including reduced maintenance costs and increased lifespan of structures, can lead to significant savings. Factories that implement these materials also benefit from compliance with sustainability certifications and green building standards, which can enhance their marketability and competitiveness. In conclusion, the integration of silica fume and fly ash into concrete production processes represents a significant advancement in the construction industry. Their use not only improves the mechanical properties and sustainability of concrete but also supports the broader goals of environmental stewardship and resource efficiency. As factories continue to adopt these innovative materials, the construction sector moves closer to achieving its objectives of durability, sustainability, and reduced environmental impact. The future of construction lies in the responsible use of such materials, paving the way for more resilient and eco-friendly infrastructure._rutile titanium dioxide price

silica fume fly ash factories******The Role of Silica Fume and Fly Ash in Modern Construction In recent years, the construction industry has recognized the importance of sustainable building materials that not only enhance the strength and durability of concrete but also minimize the environmental impact. Among these materials, silica fume and fly ash have emerged as key components in the production of high-performance concrete. Their utilization in factories has revolutionized conventional construction practices, leading to significant benefits. The Role of Silica Fume and Fly Ash in Modern Construction On the other hand, fly ash is a by-product of coal combustion in power plants. It contains silica, alumina, and iron, which, like silica fume, can react with calcium hydroxide in the presence of water to form additional cementitious compounds. The incorporation of fly ash in concrete not only improves workability and reduces water demand but also lowers the carbon footprint of concrete production. By replacing a portion of traditional Portland cement with fly ash, factories can significantly reduce greenhouse gas emissions. silica fume fly ash factories The combination of silica fume and fly ash in concrete formulations is particularly advantageous. When used together, they create a synergistic effect that enhances the overall performance of concrete. Factories that produce concrete with these materials are better equipped to meet the increasing demand for sustainable construction solutions. Furthermore, the use of industrial by-products like silica fume and fly ash contributes to the circular economy, where waste materials are repurposed, reducing the need for virgin resources. Another critical aspect of using silica fume and fly ash in concrete production is their economic benefits. Although the initial cost of these materials may be higher than that of conventional cement, the long-term advantages, including reduced maintenance costs and increased lifespan of structures, can lead to significant savings. Factories that implement these materials also benefit from compliance with sustainability certifications and green building standards, which can enhance their marketability and competitiveness. In conclusion, the integration of silica fume and fly ash into concrete production processes represents a significant advancement in the construction industry. Their use not only improves the mechanical properties and sustainability of concrete but also supports the broader goals of environmental stewardship and resource efficiency. As factories continue to adopt these innovative materials, the construction sector moves closer to achieving its objectives of durability, sustainability, and reduced environmental impact. The future of construction lies in the responsible use of such materials, paving the way for more resilient and eco-friendly infrastructure._rutile titanium dioxide price

Мікавы парашок для вытворчасці бальзама для вуснаў і касметычных сродкаў

Мікайны парадак у вытворчасці бальзама для губ У апошнія гады, попыт на натуральныя і бяспечныя камп...

Read Moresilica fume fly ash factories******The Role of Silica Fume and Fly Ash in Modern Construction In recent years, the construction industry has recognized the importance of sustainable building materials that not only enhance the strength and durability of concrete but also minimize the environmental impact. Among these materials, silica fume and fly ash have emerged as key components in the production of high-performance concrete. Their utilization in factories has revolutionized conventional construction practices, leading to significant benefits. The Role of Silica Fume and Fly Ash in Modern Construction On the other hand, fly ash is a by-product of coal combustion in power plants. It contains silica, alumina, and iron, which, like silica fume, can react with calcium hydroxide in the presence of water to form additional cementitious compounds. The incorporation of fly ash in concrete not only improves workability and reduces water demand but also lowers the carbon footprint of concrete production. By replacing a portion of traditional Portland cement with fly ash, factories can significantly reduce greenhouse gas emissions. silica fume fly ash factories The combination of silica fume and fly ash in concrete formulations is particularly advantageous. When used together, they create a synergistic effect that enhances the overall performance of concrete. Factories that produce concrete with these materials are better equipped to meet the increasing demand for sustainable construction solutions. Furthermore, the use of industrial by-products like silica fume and fly ash contributes to the circular economy, where waste materials are repurposed, reducing the need for virgin resources. Another critical aspect of using silica fume and fly ash in concrete production is their economic benefits. Although the initial cost of these materials may be higher than that of conventional cement, the long-term advantages, including reduced maintenance costs and increased lifespan of structures, can lead to significant savings. Factories that implement these materials also benefit from compliance with sustainability certifications and green building standards, which can enhance their marketability and competitiveness. In conclusion, the integration of silica fume and fly ash into concrete production processes represents a significant advancement in the construction industry. Their use not only improves the mechanical properties and sustainability of concrete but also supports the broader goals of environmental stewardship and resource efficiency. As factories continue to adopt these innovative materials, the construction sector moves closer to achieving its objectives of durability, sustainability, and reduced environmental impact. The future of construction lies in the responsible use of such materials, paving the way for more resilient and eco-friendly infrastructure._rutile titanium dioxide price2025-08-18 00:34Read(2784)Exploring the Production Processes and Environmental Impact of Titanium Dioxide Manufacturing Facili

The Role of Titanium Dioxide Factories in Modern Industry Titanium dioxide (TiO2) is a widely used c...

Read Moresilica fume fly ash factories******The Role of Silica Fume and Fly Ash in Modern Construction In recent years, the construction industry has recognized the importance of sustainable building materials that not only enhance the strength and durability of concrete but also minimize the environmental impact. Among these materials, silica fume and fly ash have emerged as key components in the production of high-performance concrete. Their utilization in factories has revolutionized conventional construction practices, leading to significant benefits. The Role of Silica Fume and Fly Ash in Modern Construction On the other hand, fly ash is a by-product of coal combustion in power plants. It contains silica, alumina, and iron, which, like silica fume, can react with calcium hydroxide in the presence of water to form additional cementitious compounds. The incorporation of fly ash in concrete not only improves workability and reduces water demand but also lowers the carbon footprint of concrete production. By replacing a portion of traditional Portland cement with fly ash, factories can significantly reduce greenhouse gas emissions. silica fume fly ash factories The combination of silica fume and fly ash in concrete formulations is particularly advantageous. When used together, they create a synergistic effect that enhances the overall performance of concrete. Factories that produce concrete with these materials are better equipped to meet the increasing demand for sustainable construction solutions. Furthermore, the use of industrial by-products like silica fume and fly ash contributes to the circular economy, where waste materials are repurposed, reducing the need for virgin resources. Another critical aspect of using silica fume and fly ash in concrete production is their economic benefits. Although the initial cost of these materials may be higher than that of conventional cement, the long-term advantages, including reduced maintenance costs and increased lifespan of structures, can lead to significant savings. Factories that implement these materials also benefit from compliance with sustainability certifications and green building standards, which can enhance their marketability and competitiveness. In conclusion, the integration of silica fume and fly ash into concrete production processes represents a significant advancement in the construction industry. Their use not only improves the mechanical properties and sustainability of concrete but also supports the broader goals of environmental stewardship and resource efficiency. As factories continue to adopt these innovative materials, the construction sector moves closer to achieving its objectives of durability, sustainability, and reduced environmental impact. The future of construction lies in the responsible use of such materials, paving the way for more resilient and eco-friendly infrastructure._rutile titanium dioxide price2025-08-18 00:12Read(1058)iridescent mica powder factory

The Enchantment of Iridescent Mica Powder A Glossy Revolution from the Factory to Your Products In t...

Read Moresilica fume fly ash factories******The Role of Silica Fume and Fly Ash in Modern Construction In recent years, the construction industry has recognized the importance of sustainable building materials that not only enhance the strength and durability of concrete but also minimize the environmental impact. Among these materials, silica fume and fly ash have emerged as key components in the production of high-performance concrete. Their utilization in factories has revolutionized conventional construction practices, leading to significant benefits. The Role of Silica Fume and Fly Ash in Modern Construction On the other hand, fly ash is a by-product of coal combustion in power plants. It contains silica, alumina, and iron, which, like silica fume, can react with calcium hydroxide in the presence of water to form additional cementitious compounds. The incorporation of fly ash in concrete not only improves workability and reduces water demand but also lowers the carbon footprint of concrete production. By replacing a portion of traditional Portland cement with fly ash, factories can significantly reduce greenhouse gas emissions. silica fume fly ash factories The combination of silica fume and fly ash in concrete formulations is particularly advantageous. When used together, they create a synergistic effect that enhances the overall performance of concrete. Factories that produce concrete with these materials are better equipped to meet the increasing demand for sustainable construction solutions. Furthermore, the use of industrial by-products like silica fume and fly ash contributes to the circular economy, where waste materials are repurposed, reducing the need for virgin resources. Another critical aspect of using silica fume and fly ash in concrete production is their economic benefits. Although the initial cost of these materials may be higher than that of conventional cement, the long-term advantages, including reduced maintenance costs and increased lifespan of structures, can lead to significant savings. Factories that implement these materials also benefit from compliance with sustainability certifications and green building standards, which can enhance their marketability and competitiveness. In conclusion, the integration of silica fume and fly ash into concrete production processes represents a significant advancement in the construction industry. Their use not only improves the mechanical properties and sustainability of concrete but also supports the broader goals of environmental stewardship and resource efficiency. As factories continue to adopt these innovative materials, the construction sector moves closer to achieving its objectives of durability, sustainability, and reduced environmental impact. The future of construction lies in the responsible use of such materials, paving the way for more resilient and eco-friendly infrastructure._rutile titanium dioxide price2025-08-18 00:12Read(1564)Custom-Made Granular Activated Carbon Production Facility

The Role of Custom Granular Activated Carbon Factories in Environmental Protection In recent years,...

Read Moresilica fume fly ash factories******The Role of Silica Fume and Fly Ash in Modern Construction In recent years, the construction industry has recognized the importance of sustainable building materials that not only enhance the strength and durability of concrete but also minimize the environmental impact. Among these materials, silica fume and fly ash have emerged as key components in the production of high-performance concrete. Their utilization in factories has revolutionized conventional construction practices, leading to significant benefits. The Role of Silica Fume and Fly Ash in Modern Construction On the other hand, fly ash is a by-product of coal combustion in power plants. It contains silica, alumina, and iron, which, like silica fume, can react with calcium hydroxide in the presence of water to form additional cementitious compounds. The incorporation of fly ash in concrete not only improves workability and reduces water demand but also lowers the carbon footprint of concrete production. By replacing a portion of traditional Portland cement with fly ash, factories can significantly reduce greenhouse gas emissions. silica fume fly ash factories The combination of silica fume and fly ash in concrete formulations is particularly advantageous. When used together, they create a synergistic effect that enhances the overall performance of concrete. Factories that produce concrete with these materials are better equipped to meet the increasing demand for sustainable construction solutions. Furthermore, the use of industrial by-products like silica fume and fly ash contributes to the circular economy, where waste materials are repurposed, reducing the need for virgin resources. Another critical aspect of using silica fume and fly ash in concrete production is their economic benefits. Although the initial cost of these materials may be higher than that of conventional cement, the long-term advantages, including reduced maintenance costs and increased lifespan of structures, can lead to significant savings. Factories that implement these materials also benefit from compliance with sustainability certifications and green building standards, which can enhance their marketability and competitiveness. In conclusion, the integration of silica fume and fly ash into concrete production processes represents a significant advancement in the construction industry. Their use not only improves the mechanical properties and sustainability of concrete but also supports the broader goals of environmental stewardship and resource efficiency. As factories continue to adopt these innovative materials, the construction sector moves closer to achieving its objectives of durability, sustainability, and reduced environmental impact. The future of construction lies in the responsible use of such materials, paving the way for more resilient and eco-friendly infrastructure._rutile titanium dioxide price2025-08-17 23:58Read(2160)vermiculite wholesale

Understanding Vermiculite A Guide to Wholesale Purchasing Vermiculite is a natural mineral that has...

Read Moresilica fume fly ash factories******The Role of Silica Fume and Fly Ash in Modern Construction In recent years, the construction industry has recognized the importance of sustainable building materials that not only enhance the strength and durability of concrete but also minimize the environmental impact. Among these materials, silica fume and fly ash have emerged as key components in the production of high-performance concrete. Their utilization in factories has revolutionized conventional construction practices, leading to significant benefits. The Role of Silica Fume and Fly Ash in Modern Construction On the other hand, fly ash is a by-product of coal combustion in power plants. It contains silica, alumina, and iron, which, like silica fume, can react with calcium hydroxide in the presence of water to form additional cementitious compounds. The incorporation of fly ash in concrete not only improves workability and reduces water demand but also lowers the carbon footprint of concrete production. By replacing a portion of traditional Portland cement with fly ash, factories can significantly reduce greenhouse gas emissions. silica fume fly ash factories The combination of silica fume and fly ash in concrete formulations is particularly advantageous. When used together, they create a synergistic effect that enhances the overall performance of concrete. Factories that produce concrete with these materials are better equipped to meet the increasing demand for sustainable construction solutions. Furthermore, the use of industrial by-products like silica fume and fly ash contributes to the circular economy, where waste materials are repurposed, reducing the need for virgin resources. Another critical aspect of using silica fume and fly ash in concrete production is their economic benefits. Although the initial cost of these materials may be higher than that of conventional cement, the long-term advantages, including reduced maintenance costs and increased lifespan of structures, can lead to significant savings. Factories that implement these materials also benefit from compliance with sustainability certifications and green building standards, which can enhance their marketability and competitiveness. In conclusion, the integration of silica fume and fly ash into concrete production processes represents a significant advancement in the construction industry. Their use not only improves the mechanical properties and sustainability of concrete but also supports the broader goals of environmental stewardship and resource efficiency. As factories continue to adopt these innovative materials, the construction sector moves closer to achieving its objectives of durability, sustainability, and reduced environmental impact. The future of construction lies in the responsible use of such materials, paving the way for more resilient and eco-friendly infrastructure._rutile titanium dioxide price2025-08-17 23:54Read(2427)custom bulk perlite manufacturer

Custom Bulk Perlite Manufacturer Meeting Diverse Agricultural and Industrial Needs Perlite, a natura...

Read Moresilica fume fly ash factories******The Role of Silica Fume and Fly Ash in Modern Construction In recent years, the construction industry has recognized the importance of sustainable building materials that not only enhance the strength and durability of concrete but also minimize the environmental impact. Among these materials, silica fume and fly ash have emerged as key components in the production of high-performance concrete. Their utilization in factories has revolutionized conventional construction practices, leading to significant benefits. The Role of Silica Fume and Fly Ash in Modern Construction On the other hand, fly ash is a by-product of coal combustion in power plants. It contains silica, alumina, and iron, which, like silica fume, can react with calcium hydroxide in the presence of water to form additional cementitious compounds. The incorporation of fly ash in concrete not only improves workability and reduces water demand but also lowers the carbon footprint of concrete production. By replacing a portion of traditional Portland cement with fly ash, factories can significantly reduce greenhouse gas emissions. silica fume fly ash factories The combination of silica fume and fly ash in concrete formulations is particularly advantageous. When used together, they create a synergistic effect that enhances the overall performance of concrete. Factories that produce concrete with these materials are better equipped to meet the increasing demand for sustainable construction solutions. Furthermore, the use of industrial by-products like silica fume and fly ash contributes to the circular economy, where waste materials are repurposed, reducing the need for virgin resources. Another critical aspect of using silica fume and fly ash in concrete production is their economic benefits. Although the initial cost of these materials may be higher than that of conventional cement, the long-term advantages, including reduced maintenance costs and increased lifespan of structures, can lead to significant savings. Factories that implement these materials also benefit from compliance with sustainability certifications and green building standards, which can enhance their marketability and competitiveness. In conclusion, the integration of silica fume and fly ash into concrete production processes represents a significant advancement in the construction industry. Their use not only improves the mechanical properties and sustainability of concrete but also supports the broader goals of environmental stewardship and resource efficiency. As factories continue to adopt these innovative materials, the construction sector moves closer to achieving its objectives of durability, sustainability, and reduced environmental impact. The future of construction lies in the responsible use of such materials, paving the way for more resilient and eco-friendly infrastructure._rutile titanium dioxide price2025-08-17 23:36Read(1123)Custom Tiny Glass Beads Manufacturer for OEM Solutions and High-Quality Products

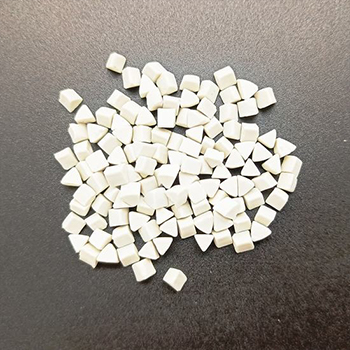

The Emergence of OEM Tiny Glass Beads Manufacturers A Comprehensive Overview In the fast-evolving la...

Read Moresilica fume fly ash factories******The Role of Silica Fume and Fly Ash in Modern Construction In recent years, the construction industry has recognized the importance of sustainable building materials that not only enhance the strength and durability of concrete but also minimize the environmental impact. Among these materials, silica fume and fly ash have emerged as key components in the production of high-performance concrete. Their utilization in factories has revolutionized conventional construction practices, leading to significant benefits. The Role of Silica Fume and Fly Ash in Modern Construction On the other hand, fly ash is a by-product of coal combustion in power plants. It contains silica, alumina, and iron, which, like silica fume, can react with calcium hydroxide in the presence of water to form additional cementitious compounds. The incorporation of fly ash in concrete not only improves workability and reduces water demand but also lowers the carbon footprint of concrete production. By replacing a portion of traditional Portland cement with fly ash, factories can significantly reduce greenhouse gas emissions. silica fume fly ash factories The combination of silica fume and fly ash in concrete formulations is particularly advantageous. When used together, they create a synergistic effect that enhances the overall performance of concrete. Factories that produce concrete with these materials are better equipped to meet the increasing demand for sustainable construction solutions. Furthermore, the use of industrial by-products like silica fume and fly ash contributes to the circular economy, where waste materials are repurposed, reducing the need for virgin resources. Another critical aspect of using silica fume and fly ash in concrete production is their economic benefits. Although the initial cost of these materials may be higher than that of conventional cement, the long-term advantages, including reduced maintenance costs and increased lifespan of structures, can lead to significant savings. Factories that implement these materials also benefit from compliance with sustainability certifications and green building standards, which can enhance their marketability and competitiveness. In conclusion, the integration of silica fume and fly ash into concrete production processes represents a significant advancement in the construction industry. Their use not only improves the mechanical properties and sustainability of concrete but also supports the broader goals of environmental stewardship and resource efficiency. As factories continue to adopt these innovative materials, the construction sector moves closer to achieving its objectives of durability, sustainability, and reduced environmental impact. The future of construction lies in the responsible use of such materials, paving the way for more resilient and eco-friendly infrastructure._rutile titanium dioxide price2025-08-17 22:45Read(2518)Understanding Iron Oxide Black 330 Properties, Uses, and Significance

...

Read Moresilica fume fly ash factories******The Role of Silica Fume and Fly Ash in Modern Construction In recent years, the construction industry has recognized the importance of sustainable building materials that not only enhance the strength and durability of concrete but also minimize the environmental impact. Among these materials, silica fume and fly ash have emerged as key components in the production of high-performance concrete. Their utilization in factories has revolutionized conventional construction practices, leading to significant benefits. The Role of Silica Fume and Fly Ash in Modern Construction On the other hand, fly ash is a by-product of coal combustion in power plants. It contains silica, alumina, and iron, which, like silica fume, can react with calcium hydroxide in the presence of water to form additional cementitious compounds. The incorporation of fly ash in concrete not only improves workability and reduces water demand but also lowers the carbon footprint of concrete production. By replacing a portion of traditional Portland cement with fly ash, factories can significantly reduce greenhouse gas emissions. silica fume fly ash factories The combination of silica fume and fly ash in concrete formulations is particularly advantageous. When used together, they create a synergistic effect that enhances the overall performance of concrete. Factories that produce concrete with these materials are better equipped to meet the increasing demand for sustainable construction solutions. Furthermore, the use of industrial by-products like silica fume and fly ash contributes to the circular economy, where waste materials are repurposed, reducing the need for virgin resources. Another critical aspect of using silica fume and fly ash in concrete production is their economic benefits. Although the initial cost of these materials may be higher than that of conventional cement, the long-term advantages, including reduced maintenance costs and increased lifespan of structures, can lead to significant savings. Factories that implement these materials also benefit from compliance with sustainability certifications and green building standards, which can enhance their marketability and competitiveness. In conclusion, the integration of silica fume and fly ash into concrete production processes represents a significant advancement in the construction industry. Their use not only improves the mechanical properties and sustainability of concrete but also supports the broader goals of environmental stewardship and resource efficiency. As factories continue to adopt these innovative materials, the construction sector moves closer to achieving its objectives of durability, sustainability, and reduced environmental impact. The future of construction lies in the responsible use of such materials, paving the way for more resilient and eco-friendly infrastructure._rutile titanium dioxide price2025-08-17 22:18Read(378)High-Quality OEM Pigment Red Manufacturers _ Custom Pigment Solutions

The Importance of OEM Pigment Red Factories in the Color Manufacturing Industry In the world of colo...

Read Moresilica fume fly ash factories******The Role of Silica Fume and Fly Ash in Modern Construction In recent years, the construction industry has recognized the importance of sustainable building materials that not only enhance the strength and durability of concrete but also minimize the environmental impact. Among these materials, silica fume and fly ash have emerged as key components in the production of high-performance concrete. Their utilization in factories has revolutionized conventional construction practices, leading to significant benefits. The Role of Silica Fume and Fly Ash in Modern Construction On the other hand, fly ash is a by-product of coal combustion in power plants. It contains silica, alumina, and iron, which, like silica fume, can react with calcium hydroxide in the presence of water to form additional cementitious compounds. The incorporation of fly ash in concrete not only improves workability and reduces water demand but also lowers the carbon footprint of concrete production. By replacing a portion of traditional Portland cement with fly ash, factories can significantly reduce greenhouse gas emissions. silica fume fly ash factories The combination of silica fume and fly ash in concrete formulations is particularly advantageous. When used together, they create a synergistic effect that enhances the overall performance of concrete. Factories that produce concrete with these materials are better equipped to meet the increasing demand for sustainable construction solutions. Furthermore, the use of industrial by-products like silica fume and fly ash contributes to the circular economy, where waste materials are repurposed, reducing the need for virgin resources. Another critical aspect of using silica fume and fly ash in concrete production is their economic benefits. Although the initial cost of these materials may be higher than that of conventional cement, the long-term advantages, including reduced maintenance costs and increased lifespan of structures, can lead to significant savings. Factories that implement these materials also benefit from compliance with sustainability certifications and green building standards, which can enhance their marketability and competitiveness. In conclusion, the integration of silica fume and fly ash into concrete production processes represents a significant advancement in the construction industry. Their use not only improves the mechanical properties and sustainability of concrete but also supports the broader goals of environmental stewardship and resource efficiency. As factories continue to adopt these innovative materials, the construction sector moves closer to achieving its objectives of durability, sustainability, and reduced environmental impact. The future of construction lies in the responsible use of such materials, paving the way for more resilient and eco-friendly infrastructure._rutile titanium dioxide price2025-08-17 22:10Read(2750)Custom Fly Ash Pellets Manufacturing Solutions for Enhanced Performance and Sustainability

Custom Fly Ash Pellets Factories Revolutionizing Waste Management and Construction In recent years,...

Read Moresilica fume fly ash factories******The Role of Silica Fume and Fly Ash in Modern Construction In recent years, the construction industry has recognized the importance of sustainable building materials that not only enhance the strength and durability of concrete but also minimize the environmental impact. Among these materials, silica fume and fly ash have emerged as key components in the production of high-performance concrete. Their utilization in factories has revolutionized conventional construction practices, leading to significant benefits. The Role of Silica Fume and Fly Ash in Modern Construction On the other hand, fly ash is a by-product of coal combustion in power plants. It contains silica, alumina, and iron, which, like silica fume, can react with calcium hydroxide in the presence of water to form additional cementitious compounds. The incorporation of fly ash in concrete not only improves workability and reduces water demand but also lowers the carbon footprint of concrete production. By replacing a portion of traditional Portland cement with fly ash, factories can significantly reduce greenhouse gas emissions. silica fume fly ash factories The combination of silica fume and fly ash in concrete formulations is particularly advantageous. When used together, they create a synergistic effect that enhances the overall performance of concrete. Factories that produce concrete with these materials are better equipped to meet the increasing demand for sustainable construction solutions. Furthermore, the use of industrial by-products like silica fume and fly ash contributes to the circular economy, where waste materials are repurposed, reducing the need for virgin resources. Another critical aspect of using silica fume and fly ash in concrete production is their economic benefits. Although the initial cost of these materials may be higher than that of conventional cement, the long-term advantages, including reduced maintenance costs and increased lifespan of structures, can lead to significant savings. Factories that implement these materials also benefit from compliance with sustainability certifications and green building standards, which can enhance their marketability and competitiveness. In conclusion, the integration of silica fume and fly ash into concrete production processes represents a significant advancement in the construction industry. Their use not only improves the mechanical properties and sustainability of concrete but also supports the broader goals of environmental stewardship and resource efficiency. As factories continue to adopt these innovative materials, the construction sector moves closer to achieving its objectives of durability, sustainability, and reduced environmental impact. The future of construction lies in the responsible use of such materials, paving the way for more resilient and eco-friendly infrastructure._rutile titanium dioxide price2025-08-17 21:56Read(800)