- china white glass beads manufacturers******Exploring the Landscape of China’s White Glass Beads Manufacturers The global market for decorative materials continues to thrive, and among these materials, glass beads stand out for their versatility and aesthetic appeal. Specifically, white glass beads, produced predominantly by manufacturers in China, have garnered significant attention due to their unique properties and wide range of applications. This article explores the landscape of white glass bead manufacturing in China, highlighting the production processes, applications, and the competitive edge these manufacturers possess in the international market. Understanding White Glass Beads White glass beads are small, spherical beads made from high-quality glass. They are known for their brilliant luster, smooth surface, and uniform size. These beads are primarily used in jewelry making, craft projects, embroidery, and as decorative elements in various products. Moreover, their reflective properties make them popular in the automotive, construction, and fashion industries, where they are often used for safety signs, road markings, and decorative accessories. The Manufacturing Process The production of white glass beads involves a carefully controlled process. It typically begins with the selection of raw materials, which include silica sand, soda lime, and various coloring agents. The glass-making process includes melting these materials in a furnace at high temperatures, followed by molding them into spherical shapes. Once formed, the beads undergo a process known as annealing, which involves cooling the glass slowly to relieve internal stresses and enhance durability. Quality control is paramount in the production of glass beads. Manufacturers in China have established rigorous testing protocols to ensure that each batch of beads meets international standards. This commitment to quality has made Chinese white glass beads a preferred choice for many industries globally. The Competitive Edge of Chinese Manufacturers China has emerged as a leading hub for glass bead production, thanks to several key factors. Firstly, the country has access to abundant raw materials, which lowers production costs and improves profitability. Secondly, the manufacturing sector in China benefits from well-established supply chains, allowing for the efficient sourcing of components and the rapid delivery of finished products. Additionally, Chinese manufacturers have invested heavily in modern technology and manufacturing techniques. Many factories utilize automated machinery, which not only increases production efficiency but also enhances the consistency and quality of the final products. Furthermore, the ability to produce large quantities of white glass beads means that manufacturers can meet the growing demand from both domestic and international markets. china white glass beads manufacturers Applications of White Glass Beads White glass beads have a diverse range of applications. In the fashion industry, they are utilized in costume jewelry, adding a touch of elegance to clothing items and accessories. They are also popular in crafting, where DIY enthusiasts use them to create unique designs and artistic expressions. In the industrial domain, white glass beads play a vital role in road safety applications. They are incorporated into road marking paints to enhance nighttime visibility, ensuring the safety of drivers. Additionally, these beads are used in reflective safety garments, contributing to worker safety in various industries. Moreover, the demand for white glass beads in decorative arts and home decor continues to grow. Designers leverage their aesthetic appeal to create eye-catching products that attract consumers looking for something unique and stylish. Challenges and Future Prospects Despite their success, manufacturers of white glass beads in China face challenges such as increasing raw material costs, environmental regulations, and competition from manufacturers in other countries. However, many companies are adapting by adopting sustainable practices, including recycling glass and reducing waste, thus appealing to environmentally-conscious consumers. Looking ahead, the future of white glass bead manufacturing in China appears promising. With the continued innovation in product design and manufacturing techniques, combined with a growing global demand for decorative materials, Chinese manufacturers are well-positioned to maintain their leadership in this vibrant industry. Conclusion China’s white glass beads manufacturers play an integral role in the global decorative material market. Their ability to produce high-quality, aesthetically appealing beads at competitive prices has made them indispensable to various industries worldwide. As these manufacturers continue to evolve and adapt to changing market dynamics, they will undoubtedly remain a vital force in the world of glass bead production for years to come.>

- china white glass beads manufacturers******Exploring the Landscape of China’s White Glass Beads Manufacturers The global market for decorative materials continues to thrive, and among these materials, glass beads stand out for their versatility and aesthetic appeal. Specifically, white glass beads, produced predominantly by manufacturers in China, have garnered significant attention due to their unique properties and wide range of applications. This article explores the landscape of white glass bead manufacturing in China, highlighting the production processes, applications, and the competitive edge these manufacturers possess in the international market. Understanding White Glass Beads White glass beads are small, spherical beads made from high-quality glass. They are known for their brilliant luster, smooth surface, and uniform size. These beads are primarily used in jewelry making, craft projects, embroidery, and as decorative elements in various products. Moreover, their reflective properties make them popular in the automotive, construction, and fashion industries, where they are often used for safety signs, road markings, and decorative accessories. The Manufacturing Process The production of white glass beads involves a carefully controlled process. It typically begins with the selection of raw materials, which include silica sand, soda lime, and various coloring agents. The glass-making process includes melting these materials in a furnace at high temperatures, followed by molding them into spherical shapes. Once formed, the beads undergo a process known as annealing, which involves cooling the glass slowly to relieve internal stresses and enhance durability. Quality control is paramount in the production of glass beads. Manufacturers in China have established rigorous testing protocols to ensure that each batch of beads meets international standards. This commitment to quality has made Chinese white glass beads a preferred choice for many industries globally. The Competitive Edge of Chinese Manufacturers China has emerged as a leading hub for glass bead production, thanks to several key factors. Firstly, the country has access to abundant raw materials, which lowers production costs and improves profitability. Secondly, the manufacturing sector in China benefits from well-established supply chains, allowing for the efficient sourcing of components and the rapid delivery of finished products. Additionally, Chinese manufacturers have invested heavily in modern technology and manufacturing techniques. Many factories utilize automated machinery, which not only increases production efficiency but also enhances the consistency and quality of the final products. Furthermore, the ability to produce large quantities of white glass beads means that manufacturers can meet the growing demand from both domestic and international markets. china white glass beads manufacturers Applications of White Glass Beads White glass beads have a diverse range of applications. In the fashion industry, they are utilized in costume jewelry, adding a touch of elegance to clothing items and accessories. They are also popular in crafting, where DIY enthusiasts use them to create unique designs and artistic expressions. In the industrial domain, white glass beads play a vital role in road safety applications. They are incorporated into road marking paints to enhance nighttime visibility, ensuring the safety of drivers. Additionally, these beads are used in reflective safety garments, contributing to worker safety in various industries. Moreover, the demand for white glass beads in decorative arts and home decor continues to grow. Designers leverage their aesthetic appeal to create eye-catching products that attract consumers looking for something unique and stylish. Challenges and Future Prospects Despite their success, manufacturers of white glass beads in China face challenges such as increasing raw material costs, environmental regulations, and competition from manufacturers in other countries. However, many companies are adapting by adopting sustainable practices, including recycling glass and reducing waste, thus appealing to environmentally-conscious consumers. Looking ahead, the future of white glass bead manufacturing in China appears promising. With the continued innovation in product design and manufacturing techniques, combined with a growing global demand for decorative materials, Chinese manufacturers are well-positioned to maintain their leadership in this vibrant industry. Conclusion China’s white glass beads manufacturers play an integral role in the global decorative material market. Their ability to produce high-quality, aesthetically appealing beads at competitive prices has made them indispensable to various industries worldwide. As these manufacturers continue to evolve and adapt to changing market dynamics, they will undoubtedly remain a vital force in the world of glass bead production for years to come._china pigment pigment

china white glass beads manufacturers******Exploring the Landscape of China’s White Glass Beads Manufacturers The global market for decorative materials continues to thrive, and among these materials, glass beads stand out for their versatility and aesthetic appeal. Specifically, white glass beads, produced predominantly by manufacturers in China, have garnered significant attention due to their unique properties and wide range of applications. This article explores the landscape of white glass bead manufacturing in China, highlighting the production processes, applications, and the competitive edge these manufacturers possess in the international market. Understanding White Glass Beads White glass beads are small, spherical beads made from high-quality glass. They are known for their brilliant luster, smooth surface, and uniform size. These beads are primarily used in jewelry making, craft projects, embroidery, and as decorative elements in various products. Moreover, their reflective properties make them popular in the automotive, construction, and fashion industries, where they are often used for safety signs, road markings, and decorative accessories. The Manufacturing Process The production of white glass beads involves a carefully controlled process. It typically begins with the selection of raw materials, which include silica sand, soda lime, and various coloring agents. The glass-making process includes melting these materials in a furnace at high temperatures, followed by molding them into spherical shapes. Once formed, the beads undergo a process known as annealing, which involves cooling the glass slowly to relieve internal stresses and enhance durability. Quality control is paramount in the production of glass beads. Manufacturers in China have established rigorous testing protocols to ensure that each batch of beads meets international standards. This commitment to quality has made Chinese white glass beads a preferred choice for many industries globally. The Competitive Edge of Chinese Manufacturers China has emerged as a leading hub for glass bead production, thanks to several key factors. Firstly, the country has access to abundant raw materials, which lowers production costs and improves profitability. Secondly, the manufacturing sector in China benefits from well-established supply chains, allowing for the efficient sourcing of components and the rapid delivery of finished products. Additionally, Chinese manufacturers have invested heavily in modern technology and manufacturing techniques. Many factories utilize automated machinery, which not only increases production efficiency but also enhances the consistency and quality of the final products. Furthermore, the ability to produce large quantities of white glass beads means that manufacturers can meet the growing demand from both domestic and international markets. china white glass beads manufacturers Applications of White Glass Beads White glass beads have a diverse range of applications. In the fashion industry, they are utilized in costume jewelry, adding a touch of elegance to clothing items and accessories. They are also popular in crafting, where DIY enthusiasts use them to create unique designs and artistic expressions. In the industrial domain, white glass beads play a vital role in road safety applications. They are incorporated into road marking paints to enhance nighttime visibility, ensuring the safety of drivers. Additionally, these beads are used in reflective safety garments, contributing to worker safety in various industries. Moreover, the demand for white glass beads in decorative arts and home decor continues to grow. Designers leverage their aesthetic appeal to create eye-catching products that attract consumers looking for something unique and stylish. Challenges and Future Prospects Despite their success, manufacturers of white glass beads in China face challenges such as increasing raw material costs, environmental regulations, and competition from manufacturers in other countries. However, many companies are adapting by adopting sustainable practices, including recycling glass and reducing waste, thus appealing to environmentally-conscious consumers. Looking ahead, the future of white glass bead manufacturing in China appears promising. With the continued innovation in product design and manufacturing techniques, combined with a growing global demand for decorative materials, Chinese manufacturers are well-positioned to maintain their leadership in this vibrant industry. Conclusion China’s white glass beads manufacturers play an integral role in the global decorative material market. Their ability to produce high-quality, aesthetically appealing beads at competitive prices has made them indispensable to various industries worldwide. As these manufacturers continue to evolve and adapt to changing market dynamics, they will undoubtedly remain a vital force in the world of glass bead production for years to come._china pigment pigment

Top Manufacturers of OEM Pebbles for Indoor and Outdoor Plant Decorations

The Benefits of OEM Pebbles for Plants A Comprehensive Overview When it comes to enhancing the beaut...

Read Morechina white glass beads manufacturers******Exploring the Landscape of China’s White Glass Beads Manufacturers The global market for decorative materials continues to thrive, and among these materials, glass beads stand out for their versatility and aesthetic appeal. Specifically, white glass beads, produced predominantly by manufacturers in China, have garnered significant attention due to their unique properties and wide range of applications. This article explores the landscape of white glass bead manufacturing in China, highlighting the production processes, applications, and the competitive edge these manufacturers possess in the international market. Understanding White Glass Beads White glass beads are small, spherical beads made from high-quality glass. They are known for their brilliant luster, smooth surface, and uniform size. These beads are primarily used in jewelry making, craft projects, embroidery, and as decorative elements in various products. Moreover, their reflective properties make them popular in the automotive, construction, and fashion industries, where they are often used for safety signs, road markings, and decorative accessories. The Manufacturing Process The production of white glass beads involves a carefully controlled process. It typically begins with the selection of raw materials, which include silica sand, soda lime, and various coloring agents. The glass-making process includes melting these materials in a furnace at high temperatures, followed by molding them into spherical shapes. Once formed, the beads undergo a process known as annealing, which involves cooling the glass slowly to relieve internal stresses and enhance durability. Quality control is paramount in the production of glass beads. Manufacturers in China have established rigorous testing protocols to ensure that each batch of beads meets international standards. This commitment to quality has made Chinese white glass beads a preferred choice for many industries globally. The Competitive Edge of Chinese Manufacturers China has emerged as a leading hub for glass bead production, thanks to several key factors. Firstly, the country has access to abundant raw materials, which lowers production costs and improves profitability. Secondly, the manufacturing sector in China benefits from well-established supply chains, allowing for the efficient sourcing of components and the rapid delivery of finished products. Additionally, Chinese manufacturers have invested heavily in modern technology and manufacturing techniques. Many factories utilize automated machinery, which not only increases production efficiency but also enhances the consistency and quality of the final products. Furthermore, the ability to produce large quantities of white glass beads means that manufacturers can meet the growing demand from both domestic and international markets. china white glass beads manufacturers Applications of White Glass Beads White glass beads have a diverse range of applications. In the fashion industry, they are utilized in costume jewelry, adding a touch of elegance to clothing items and accessories. They are also popular in crafting, where DIY enthusiasts use them to create unique designs and artistic expressions. In the industrial domain, white glass beads play a vital role in road safety applications. They are incorporated into road marking paints to enhance nighttime visibility, ensuring the safety of drivers. Additionally, these beads are used in reflective safety garments, contributing to worker safety in various industries. Moreover, the demand for white glass beads in decorative arts and home decor continues to grow. Designers leverage their aesthetic appeal to create eye-catching products that attract consumers looking for something unique and stylish. Challenges and Future Prospects Despite their success, manufacturers of white glass beads in China face challenges such as increasing raw material costs, environmental regulations, and competition from manufacturers in other countries. However, many companies are adapting by adopting sustainable practices, including recycling glass and reducing waste, thus appealing to environmentally-conscious consumers. Looking ahead, the future of white glass bead manufacturing in China appears promising. With the continued innovation in product design and manufacturing techniques, combined with a growing global demand for decorative materials, Chinese manufacturers are well-positioned to maintain their leadership in this vibrant industry. Conclusion China’s white glass beads manufacturers play an integral role in the global decorative material market. Their ability to produce high-quality, aesthetically appealing beads at competitive prices has made them indispensable to various industries worldwide. As these manufacturers continue to evolve and adapt to changing market dynamics, they will undoubtedly remain a vital force in the world of glass bead production for years to come._china pigment pigment2025-08-17 13:02Read(589)In conclusion, the rise of custom ultra fine fly ash factories represents a significant leap forward in sustainable construction. By providing high-quality, tailored materials that reduce environmental impacts and enhance project performance, these factories are poised to play a pivotal role in the future of the construction sector. As the industry continues to embrace sustainable innovations, the integration of custom ultra fine fly ash into building practices will undoubtedly become a cornerstone of modern construction, reflecting a commitment to both quality and environmental stewardship.

...

Read Morechina white glass beads manufacturers******Exploring the Landscape of China’s White Glass Beads Manufacturers The global market for decorative materials continues to thrive, and among these materials, glass beads stand out for their versatility and aesthetic appeal. Specifically, white glass beads, produced predominantly by manufacturers in China, have garnered significant attention due to their unique properties and wide range of applications. This article explores the landscape of white glass bead manufacturing in China, highlighting the production processes, applications, and the competitive edge these manufacturers possess in the international market. Understanding White Glass Beads White glass beads are small, spherical beads made from high-quality glass. They are known for their brilliant luster, smooth surface, and uniform size. These beads are primarily used in jewelry making, craft projects, embroidery, and as decorative elements in various products. Moreover, their reflective properties make them popular in the automotive, construction, and fashion industries, where they are often used for safety signs, road markings, and decorative accessories. The Manufacturing Process The production of white glass beads involves a carefully controlled process. It typically begins with the selection of raw materials, which include silica sand, soda lime, and various coloring agents. The glass-making process includes melting these materials in a furnace at high temperatures, followed by molding them into spherical shapes. Once formed, the beads undergo a process known as annealing, which involves cooling the glass slowly to relieve internal stresses and enhance durability. Quality control is paramount in the production of glass beads. Manufacturers in China have established rigorous testing protocols to ensure that each batch of beads meets international standards. This commitment to quality has made Chinese white glass beads a preferred choice for many industries globally. The Competitive Edge of Chinese Manufacturers China has emerged as a leading hub for glass bead production, thanks to several key factors. Firstly, the country has access to abundant raw materials, which lowers production costs and improves profitability. Secondly, the manufacturing sector in China benefits from well-established supply chains, allowing for the efficient sourcing of components and the rapid delivery of finished products. Additionally, Chinese manufacturers have invested heavily in modern technology and manufacturing techniques. Many factories utilize automated machinery, which not only increases production efficiency but also enhances the consistency and quality of the final products. Furthermore, the ability to produce large quantities of white glass beads means that manufacturers can meet the growing demand from both domestic and international markets. china white glass beads manufacturers Applications of White Glass Beads White glass beads have a diverse range of applications. In the fashion industry, they are utilized in costume jewelry, adding a touch of elegance to clothing items and accessories. They are also popular in crafting, where DIY enthusiasts use them to create unique designs and artistic expressions. In the industrial domain, white glass beads play a vital role in road safety applications. They are incorporated into road marking paints to enhance nighttime visibility, ensuring the safety of drivers. Additionally, these beads are used in reflective safety garments, contributing to worker safety in various industries. Moreover, the demand for white glass beads in decorative arts and home decor continues to grow. Designers leverage their aesthetic appeal to create eye-catching products that attract consumers looking for something unique and stylish. Challenges and Future Prospects Despite their success, manufacturers of white glass beads in China face challenges such as increasing raw material costs, environmental regulations, and competition from manufacturers in other countries. However, many companies are adapting by adopting sustainable practices, including recycling glass and reducing waste, thus appealing to environmentally-conscious consumers. Looking ahead, the future of white glass bead manufacturing in China appears promising. With the continued innovation in product design and manufacturing techniques, combined with a growing global demand for decorative materials, Chinese manufacturers are well-positioned to maintain their leadership in this vibrant industry. Conclusion China’s white glass beads manufacturers play an integral role in the global decorative material market. Their ability to produce high-quality, aesthetically appealing beads at competitive prices has made them indispensable to various industries worldwide. As these manufacturers continue to evolve and adapt to changing market dynamics, they will undoubtedly remain a vital force in the world of glass bead production for years to come._china pigment pigment2025-08-17 12:49Read(1163)2. Crafts and Art Supplies Artisans and DIY enthusiasts often seek custom mica for crafting. Mica flakes can be used in resin art, greeting cards, and various artistic projects. By providing custom sizes and colors, manufacturers cater to the creative community, allowing them to explore endless possibilities.

...

Read Morechina white glass beads manufacturers******Exploring the Landscape of China’s White Glass Beads Manufacturers The global market for decorative materials continues to thrive, and among these materials, glass beads stand out for their versatility and aesthetic appeal. Specifically, white glass beads, produced predominantly by manufacturers in China, have garnered significant attention due to their unique properties and wide range of applications. This article explores the landscape of white glass bead manufacturing in China, highlighting the production processes, applications, and the competitive edge these manufacturers possess in the international market. Understanding White Glass Beads White glass beads are small, spherical beads made from high-quality glass. They are known for their brilliant luster, smooth surface, and uniform size. These beads are primarily used in jewelry making, craft projects, embroidery, and as decorative elements in various products. Moreover, their reflective properties make them popular in the automotive, construction, and fashion industries, where they are often used for safety signs, road markings, and decorative accessories. The Manufacturing Process The production of white glass beads involves a carefully controlled process. It typically begins with the selection of raw materials, which include silica sand, soda lime, and various coloring agents. The glass-making process includes melting these materials in a furnace at high temperatures, followed by molding them into spherical shapes. Once formed, the beads undergo a process known as annealing, which involves cooling the glass slowly to relieve internal stresses and enhance durability. Quality control is paramount in the production of glass beads. Manufacturers in China have established rigorous testing protocols to ensure that each batch of beads meets international standards. This commitment to quality has made Chinese white glass beads a preferred choice for many industries globally. The Competitive Edge of Chinese Manufacturers China has emerged as a leading hub for glass bead production, thanks to several key factors. Firstly, the country has access to abundant raw materials, which lowers production costs and improves profitability. Secondly, the manufacturing sector in China benefits from well-established supply chains, allowing for the efficient sourcing of components and the rapid delivery of finished products. Additionally, Chinese manufacturers have invested heavily in modern technology and manufacturing techniques. Many factories utilize automated machinery, which not only increases production efficiency but also enhances the consistency and quality of the final products. Furthermore, the ability to produce large quantities of white glass beads means that manufacturers can meet the growing demand from both domestic and international markets. china white glass beads manufacturers Applications of White Glass Beads White glass beads have a diverse range of applications. In the fashion industry, they are utilized in costume jewelry, adding a touch of elegance to clothing items and accessories. They are also popular in crafting, where DIY enthusiasts use them to create unique designs and artistic expressions. In the industrial domain, white glass beads play a vital role in road safety applications. They are incorporated into road marking paints to enhance nighttime visibility, ensuring the safety of drivers. Additionally, these beads are used in reflective safety garments, contributing to worker safety in various industries. Moreover, the demand for white glass beads in decorative arts and home decor continues to grow. Designers leverage their aesthetic appeal to create eye-catching products that attract consumers looking for something unique and stylish. Challenges and Future Prospects Despite their success, manufacturers of white glass beads in China face challenges such as increasing raw material costs, environmental regulations, and competition from manufacturers in other countries. However, many companies are adapting by adopting sustainable practices, including recycling glass and reducing waste, thus appealing to environmentally-conscious consumers. Looking ahead, the future of white glass bead manufacturing in China appears promising. With the continued innovation in product design and manufacturing techniques, combined with a growing global demand for decorative materials, Chinese manufacturers are well-positioned to maintain their leadership in this vibrant industry. Conclusion China’s white glass beads manufacturers play an integral role in the global decorative material market. Their ability to produce high-quality, aesthetically appealing beads at competitive prices has made them indispensable to various industries worldwide. As these manufacturers continue to evolve and adapt to changing market dynamics, they will undoubtedly remain a vital force in the world of glass bead production for years to come._china pigment pigment2025-08-17 12:44Read(1631)china metallic mica factory

The Emergence of China’s Metallic Mica Industry Trends and Innovations Introduction China has long b...

Read Morechina white glass beads manufacturers******Exploring the Landscape of China’s White Glass Beads Manufacturers The global market for decorative materials continues to thrive, and among these materials, glass beads stand out for their versatility and aesthetic appeal. Specifically, white glass beads, produced predominantly by manufacturers in China, have garnered significant attention due to their unique properties and wide range of applications. This article explores the landscape of white glass bead manufacturing in China, highlighting the production processes, applications, and the competitive edge these manufacturers possess in the international market. Understanding White Glass Beads White glass beads are small, spherical beads made from high-quality glass. They are known for their brilliant luster, smooth surface, and uniform size. These beads are primarily used in jewelry making, craft projects, embroidery, and as decorative elements in various products. Moreover, their reflective properties make them popular in the automotive, construction, and fashion industries, where they are often used for safety signs, road markings, and decorative accessories. The Manufacturing Process The production of white glass beads involves a carefully controlled process. It typically begins with the selection of raw materials, which include silica sand, soda lime, and various coloring agents. The glass-making process includes melting these materials in a furnace at high temperatures, followed by molding them into spherical shapes. Once formed, the beads undergo a process known as annealing, which involves cooling the glass slowly to relieve internal stresses and enhance durability. Quality control is paramount in the production of glass beads. Manufacturers in China have established rigorous testing protocols to ensure that each batch of beads meets international standards. This commitment to quality has made Chinese white glass beads a preferred choice for many industries globally. The Competitive Edge of Chinese Manufacturers China has emerged as a leading hub for glass bead production, thanks to several key factors. Firstly, the country has access to abundant raw materials, which lowers production costs and improves profitability. Secondly, the manufacturing sector in China benefits from well-established supply chains, allowing for the efficient sourcing of components and the rapid delivery of finished products. Additionally, Chinese manufacturers have invested heavily in modern technology and manufacturing techniques. Many factories utilize automated machinery, which not only increases production efficiency but also enhances the consistency and quality of the final products. Furthermore, the ability to produce large quantities of white glass beads means that manufacturers can meet the growing demand from both domestic and international markets. china white glass beads manufacturers Applications of White Glass Beads White glass beads have a diverse range of applications. In the fashion industry, they are utilized in costume jewelry, adding a touch of elegance to clothing items and accessories. They are also popular in crafting, where DIY enthusiasts use them to create unique designs and artistic expressions. In the industrial domain, white glass beads play a vital role in road safety applications. They are incorporated into road marking paints to enhance nighttime visibility, ensuring the safety of drivers. Additionally, these beads are used in reflective safety garments, contributing to worker safety in various industries. Moreover, the demand for white glass beads in decorative arts and home decor continues to grow. Designers leverage their aesthetic appeal to create eye-catching products that attract consumers looking for something unique and stylish. Challenges and Future Prospects Despite their success, manufacturers of white glass beads in China face challenges such as increasing raw material costs, environmental regulations, and competition from manufacturers in other countries. However, many companies are adapting by adopting sustainable practices, including recycling glass and reducing waste, thus appealing to environmentally-conscious consumers. Looking ahead, the future of white glass bead manufacturing in China appears promising. With the continued innovation in product design and manufacturing techniques, combined with a growing global demand for decorative materials, Chinese manufacturers are well-positioned to maintain their leadership in this vibrant industry. Conclusion China’s white glass beads manufacturers play an integral role in the global decorative material market. Their ability to produce high-quality, aesthetically appealing beads at competitive prices has made them indispensable to various industries worldwide. As these manufacturers continue to evolve and adapt to changing market dynamics, they will undoubtedly remain a vital force in the world of glass bead production for years to come._china pigment pigment2025-08-17 12:13Read(2555)red bentonite clay

The Versatile Applications of Red Bentonitic Clay Red bentonite clay, a naturally occurring volcanic...

Read Morechina white glass beads manufacturers******Exploring the Landscape of China’s White Glass Beads Manufacturers The global market for decorative materials continues to thrive, and among these materials, glass beads stand out for their versatility and aesthetic appeal. Specifically, white glass beads, produced predominantly by manufacturers in China, have garnered significant attention due to their unique properties and wide range of applications. This article explores the landscape of white glass bead manufacturing in China, highlighting the production processes, applications, and the competitive edge these manufacturers possess in the international market. Understanding White Glass Beads White glass beads are small, spherical beads made from high-quality glass. They are known for their brilliant luster, smooth surface, and uniform size. These beads are primarily used in jewelry making, craft projects, embroidery, and as decorative elements in various products. Moreover, their reflective properties make them popular in the automotive, construction, and fashion industries, where they are often used for safety signs, road markings, and decorative accessories. The Manufacturing Process The production of white glass beads involves a carefully controlled process. It typically begins with the selection of raw materials, which include silica sand, soda lime, and various coloring agents. The glass-making process includes melting these materials in a furnace at high temperatures, followed by molding them into spherical shapes. Once formed, the beads undergo a process known as annealing, which involves cooling the glass slowly to relieve internal stresses and enhance durability. Quality control is paramount in the production of glass beads. Manufacturers in China have established rigorous testing protocols to ensure that each batch of beads meets international standards. This commitment to quality has made Chinese white glass beads a preferred choice for many industries globally. The Competitive Edge of Chinese Manufacturers China has emerged as a leading hub for glass bead production, thanks to several key factors. Firstly, the country has access to abundant raw materials, which lowers production costs and improves profitability. Secondly, the manufacturing sector in China benefits from well-established supply chains, allowing for the efficient sourcing of components and the rapid delivery of finished products. Additionally, Chinese manufacturers have invested heavily in modern technology and manufacturing techniques. Many factories utilize automated machinery, which not only increases production efficiency but also enhances the consistency and quality of the final products. Furthermore, the ability to produce large quantities of white glass beads means that manufacturers can meet the growing demand from both domestic and international markets. china white glass beads manufacturers Applications of White Glass Beads White glass beads have a diverse range of applications. In the fashion industry, they are utilized in costume jewelry, adding a touch of elegance to clothing items and accessories. They are also popular in crafting, where DIY enthusiasts use them to create unique designs and artistic expressions. In the industrial domain, white glass beads play a vital role in road safety applications. They are incorporated into road marking paints to enhance nighttime visibility, ensuring the safety of drivers. Additionally, these beads are used in reflective safety garments, contributing to worker safety in various industries. Moreover, the demand for white glass beads in decorative arts and home decor continues to grow. Designers leverage their aesthetic appeal to create eye-catching products that attract consumers looking for something unique and stylish. Challenges and Future Prospects Despite their success, manufacturers of white glass beads in China face challenges such as increasing raw material costs, environmental regulations, and competition from manufacturers in other countries. However, many companies are adapting by adopting sustainable practices, including recycling glass and reducing waste, thus appealing to environmentally-conscious consumers. Looking ahead, the future of white glass bead manufacturing in China appears promising. With the continued innovation in product design and manufacturing techniques, combined with a growing global demand for decorative materials, Chinese manufacturers are well-positioned to maintain their leadership in this vibrant industry. Conclusion China’s white glass beads manufacturers play an integral role in the global decorative material market. Their ability to produce high-quality, aesthetically appealing beads at competitive prices has made them indispensable to various industries worldwide. As these manufacturers continue to evolve and adapt to changing market dynamics, they will undoubtedly remain a vital force in the world of glass bead production for years to come._china pigment pigment2025-08-17 11:53Read(2091)chinese barite

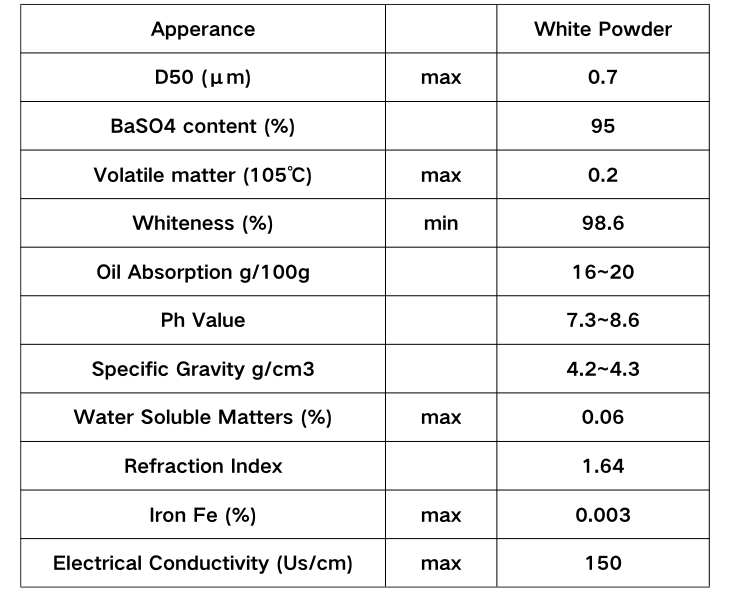

Chinese barite, a mineral known for its vast applications and superior quality, stands as an essenti...

Read Morechina white glass beads manufacturers******Exploring the Landscape of China’s White Glass Beads Manufacturers The global market for decorative materials continues to thrive, and among these materials, glass beads stand out for their versatility and aesthetic appeal. Specifically, white glass beads, produced predominantly by manufacturers in China, have garnered significant attention due to their unique properties and wide range of applications. This article explores the landscape of white glass bead manufacturing in China, highlighting the production processes, applications, and the competitive edge these manufacturers possess in the international market. Understanding White Glass Beads White glass beads are small, spherical beads made from high-quality glass. They are known for their brilliant luster, smooth surface, and uniform size. These beads are primarily used in jewelry making, craft projects, embroidery, and as decorative elements in various products. Moreover, their reflective properties make them popular in the automotive, construction, and fashion industries, where they are often used for safety signs, road markings, and decorative accessories. The Manufacturing Process The production of white glass beads involves a carefully controlled process. It typically begins with the selection of raw materials, which include silica sand, soda lime, and various coloring agents. The glass-making process includes melting these materials in a furnace at high temperatures, followed by molding them into spherical shapes. Once formed, the beads undergo a process known as annealing, which involves cooling the glass slowly to relieve internal stresses and enhance durability. Quality control is paramount in the production of glass beads. Manufacturers in China have established rigorous testing protocols to ensure that each batch of beads meets international standards. This commitment to quality has made Chinese white glass beads a preferred choice for many industries globally. The Competitive Edge of Chinese Manufacturers China has emerged as a leading hub for glass bead production, thanks to several key factors. Firstly, the country has access to abundant raw materials, which lowers production costs and improves profitability. Secondly, the manufacturing sector in China benefits from well-established supply chains, allowing for the efficient sourcing of components and the rapid delivery of finished products. Additionally, Chinese manufacturers have invested heavily in modern technology and manufacturing techniques. Many factories utilize automated machinery, which not only increases production efficiency but also enhances the consistency and quality of the final products. Furthermore, the ability to produce large quantities of white glass beads means that manufacturers can meet the growing demand from both domestic and international markets. china white glass beads manufacturers Applications of White Glass Beads White glass beads have a diverse range of applications. In the fashion industry, they are utilized in costume jewelry, adding a touch of elegance to clothing items and accessories. They are also popular in crafting, where DIY enthusiasts use them to create unique designs and artistic expressions. In the industrial domain, white glass beads play a vital role in road safety applications. They are incorporated into road marking paints to enhance nighttime visibility, ensuring the safety of drivers. Additionally, these beads are used in reflective safety garments, contributing to worker safety in various industries. Moreover, the demand for white glass beads in decorative arts and home decor continues to grow. Designers leverage their aesthetic appeal to create eye-catching products that attract consumers looking for something unique and stylish. Challenges and Future Prospects Despite their success, manufacturers of white glass beads in China face challenges such as increasing raw material costs, environmental regulations, and competition from manufacturers in other countries. However, many companies are adapting by adopting sustainable practices, including recycling glass and reducing waste, thus appealing to environmentally-conscious consumers. Looking ahead, the future of white glass bead manufacturing in China appears promising. With the continued innovation in product design and manufacturing techniques, combined with a growing global demand for decorative materials, Chinese manufacturers are well-positioned to maintain their leadership in this vibrant industry. Conclusion China’s white glass beads manufacturers play an integral role in the global decorative material market. Their ability to produce high-quality, aesthetically appealing beads at competitive prices has made them indispensable to various industries worldwide. As these manufacturers continue to evolve and adapt to changing market dynamics, they will undoubtedly remain a vital force in the world of glass bead production for years to come._china pigment pigment2025-08-17 11:29Read(712)The Growing Demand for Bulk Activated Carbon

...

Read Morechina white glass beads manufacturers******Exploring the Landscape of China’s White Glass Beads Manufacturers The global market for decorative materials continues to thrive, and among these materials, glass beads stand out for their versatility and aesthetic appeal. Specifically, white glass beads, produced predominantly by manufacturers in China, have garnered significant attention due to their unique properties and wide range of applications. This article explores the landscape of white glass bead manufacturing in China, highlighting the production processes, applications, and the competitive edge these manufacturers possess in the international market. Understanding White Glass Beads White glass beads are small, spherical beads made from high-quality glass. They are known for their brilliant luster, smooth surface, and uniform size. These beads are primarily used in jewelry making, craft projects, embroidery, and as decorative elements in various products. Moreover, their reflective properties make them popular in the automotive, construction, and fashion industries, where they are often used for safety signs, road markings, and decorative accessories. The Manufacturing Process The production of white glass beads involves a carefully controlled process. It typically begins with the selection of raw materials, which include silica sand, soda lime, and various coloring agents. The glass-making process includes melting these materials in a furnace at high temperatures, followed by molding them into spherical shapes. Once formed, the beads undergo a process known as annealing, which involves cooling the glass slowly to relieve internal stresses and enhance durability. Quality control is paramount in the production of glass beads. Manufacturers in China have established rigorous testing protocols to ensure that each batch of beads meets international standards. This commitment to quality has made Chinese white glass beads a preferred choice for many industries globally. The Competitive Edge of Chinese Manufacturers China has emerged as a leading hub for glass bead production, thanks to several key factors. Firstly, the country has access to abundant raw materials, which lowers production costs and improves profitability. Secondly, the manufacturing sector in China benefits from well-established supply chains, allowing for the efficient sourcing of components and the rapid delivery of finished products. Additionally, Chinese manufacturers have invested heavily in modern technology and manufacturing techniques. Many factories utilize automated machinery, which not only increases production efficiency but also enhances the consistency and quality of the final products. Furthermore, the ability to produce large quantities of white glass beads means that manufacturers can meet the growing demand from both domestic and international markets. china white glass beads manufacturers Applications of White Glass Beads White glass beads have a diverse range of applications. In the fashion industry, they are utilized in costume jewelry, adding a touch of elegance to clothing items and accessories. They are also popular in crafting, where DIY enthusiasts use them to create unique designs and artistic expressions. In the industrial domain, white glass beads play a vital role in road safety applications. They are incorporated into road marking paints to enhance nighttime visibility, ensuring the safety of drivers. Additionally, these beads are used in reflective safety garments, contributing to worker safety in various industries. Moreover, the demand for white glass beads in decorative arts and home decor continues to grow. Designers leverage their aesthetic appeal to create eye-catching products that attract consumers looking for something unique and stylish. Challenges and Future Prospects Despite their success, manufacturers of white glass beads in China face challenges such as increasing raw material costs, environmental regulations, and competition from manufacturers in other countries. However, many companies are adapting by adopting sustainable practices, including recycling glass and reducing waste, thus appealing to environmentally-conscious consumers. Looking ahead, the future of white glass bead manufacturing in China appears promising. With the continued innovation in product design and manufacturing techniques, combined with a growing global demand for decorative materials, Chinese manufacturers are well-positioned to maintain their leadership in this vibrant industry. Conclusion China’s white glass beads manufacturers play an integral role in the global decorative material market. Their ability to produce high-quality, aesthetically appealing beads at competitive prices has made them indispensable to various industries worldwide. As these manufacturers continue to evolve and adapt to changing market dynamics, they will undoubtedly remain a vital force in the world of glass bead production for years to come._china pigment pigment2025-08-17 11:22Read(2430)alumina aluminum oxide

Understanding Alumina The Foundation of Aluminum Oxide Alumina, chemically known as aluminum oxide (...

Read Morechina white glass beads manufacturers******Exploring the Landscape of China’s White Glass Beads Manufacturers The global market for decorative materials continues to thrive, and among these materials, glass beads stand out for their versatility and aesthetic appeal. Specifically, white glass beads, produced predominantly by manufacturers in China, have garnered significant attention due to their unique properties and wide range of applications. This article explores the landscape of white glass bead manufacturing in China, highlighting the production processes, applications, and the competitive edge these manufacturers possess in the international market. Understanding White Glass Beads White glass beads are small, spherical beads made from high-quality glass. They are known for their brilliant luster, smooth surface, and uniform size. These beads are primarily used in jewelry making, craft projects, embroidery, and as decorative elements in various products. Moreover, their reflective properties make them popular in the automotive, construction, and fashion industries, where they are often used for safety signs, road markings, and decorative accessories. The Manufacturing Process The production of white glass beads involves a carefully controlled process. It typically begins with the selection of raw materials, which include silica sand, soda lime, and various coloring agents. The glass-making process includes melting these materials in a furnace at high temperatures, followed by molding them into spherical shapes. Once formed, the beads undergo a process known as annealing, which involves cooling the glass slowly to relieve internal stresses and enhance durability. Quality control is paramount in the production of glass beads. Manufacturers in China have established rigorous testing protocols to ensure that each batch of beads meets international standards. This commitment to quality has made Chinese white glass beads a preferred choice for many industries globally. The Competitive Edge of Chinese Manufacturers China has emerged as a leading hub for glass bead production, thanks to several key factors. Firstly, the country has access to abundant raw materials, which lowers production costs and improves profitability. Secondly, the manufacturing sector in China benefits from well-established supply chains, allowing for the efficient sourcing of components and the rapid delivery of finished products. Additionally, Chinese manufacturers have invested heavily in modern technology and manufacturing techniques. Many factories utilize automated machinery, which not only increases production efficiency but also enhances the consistency and quality of the final products. Furthermore, the ability to produce large quantities of white glass beads means that manufacturers can meet the growing demand from both domestic and international markets. china white glass beads manufacturers Applications of White Glass Beads White glass beads have a diverse range of applications. In the fashion industry, they are utilized in costume jewelry, adding a touch of elegance to clothing items and accessories. They are also popular in crafting, where DIY enthusiasts use them to create unique designs and artistic expressions. In the industrial domain, white glass beads play a vital role in road safety applications. They are incorporated into road marking paints to enhance nighttime visibility, ensuring the safety of drivers. Additionally, these beads are used in reflective safety garments, contributing to worker safety in various industries. Moreover, the demand for white glass beads in decorative arts and home decor continues to grow. Designers leverage their aesthetic appeal to create eye-catching products that attract consumers looking for something unique and stylish. Challenges and Future Prospects Despite their success, manufacturers of white glass beads in China face challenges such as increasing raw material costs, environmental regulations, and competition from manufacturers in other countries. However, many companies are adapting by adopting sustainable practices, including recycling glass and reducing waste, thus appealing to environmentally-conscious consumers. Looking ahead, the future of white glass bead manufacturing in China appears promising. With the continued innovation in product design and manufacturing techniques, combined with a growing global demand for decorative materials, Chinese manufacturers are well-positioned to maintain their leadership in this vibrant industry. Conclusion China’s white glass beads manufacturers play an integral role in the global decorative material market. Their ability to produce high-quality, aesthetically appealing beads at competitive prices has made them indispensable to various industries worldwide. As these manufacturers continue to evolve and adapt to changing market dynamics, they will undoubtedly remain a vital force in the world of glass bead production for years to come._china pigment pigment2025-08-17 11:22Read(786)Top Manufacturers of Customized High-Quality Calcium Bentonite Clay Products for Various Application

Understanding the Role and Benefits of Custom Calcium Bentonite Clay Manufacturers Calcium bentonite...

Read Morechina white glass beads manufacturers******Exploring the Landscape of China’s White Glass Beads Manufacturers The global market for decorative materials continues to thrive, and among these materials, glass beads stand out for their versatility and aesthetic appeal. Specifically, white glass beads, produced predominantly by manufacturers in China, have garnered significant attention due to their unique properties and wide range of applications. This article explores the landscape of white glass bead manufacturing in China, highlighting the production processes, applications, and the competitive edge these manufacturers possess in the international market. Understanding White Glass Beads White glass beads are small, spherical beads made from high-quality glass. They are known for their brilliant luster, smooth surface, and uniform size. These beads are primarily used in jewelry making, craft projects, embroidery, and as decorative elements in various products. Moreover, their reflective properties make them popular in the automotive, construction, and fashion industries, where they are often used for safety signs, road markings, and decorative accessories. The Manufacturing Process The production of white glass beads involves a carefully controlled process. It typically begins with the selection of raw materials, which include silica sand, soda lime, and various coloring agents. The glass-making process includes melting these materials in a furnace at high temperatures, followed by molding them into spherical shapes. Once formed, the beads undergo a process known as annealing, which involves cooling the glass slowly to relieve internal stresses and enhance durability. Quality control is paramount in the production of glass beads. Manufacturers in China have established rigorous testing protocols to ensure that each batch of beads meets international standards. This commitment to quality has made Chinese white glass beads a preferred choice for many industries globally. The Competitive Edge of Chinese Manufacturers China has emerged as a leading hub for glass bead production, thanks to several key factors. Firstly, the country has access to abundant raw materials, which lowers production costs and improves profitability. Secondly, the manufacturing sector in China benefits from well-established supply chains, allowing for the efficient sourcing of components and the rapid delivery of finished products. Additionally, Chinese manufacturers have invested heavily in modern technology and manufacturing techniques. Many factories utilize automated machinery, which not only increases production efficiency but also enhances the consistency and quality of the final products. Furthermore, the ability to produce large quantities of white glass beads means that manufacturers can meet the growing demand from both domestic and international markets. china white glass beads manufacturers Applications of White Glass Beads White glass beads have a diverse range of applications. In the fashion industry, they are utilized in costume jewelry, adding a touch of elegance to clothing items and accessories. They are also popular in crafting, where DIY enthusiasts use them to create unique designs and artistic expressions. In the industrial domain, white glass beads play a vital role in road safety applications. They are incorporated into road marking paints to enhance nighttime visibility, ensuring the safety of drivers. Additionally, these beads are used in reflective safety garments, contributing to worker safety in various industries. Moreover, the demand for white glass beads in decorative arts and home decor continues to grow. Designers leverage their aesthetic appeal to create eye-catching products that attract consumers looking for something unique and stylish. Challenges and Future Prospects Despite their success, manufacturers of white glass beads in China face challenges such as increasing raw material costs, environmental regulations, and competition from manufacturers in other countries. However, many companies are adapting by adopting sustainable practices, including recycling glass and reducing waste, thus appealing to environmentally-conscious consumers. Looking ahead, the future of white glass bead manufacturing in China appears promising. With the continued innovation in product design and manufacturing techniques, combined with a growing global demand for decorative materials, Chinese manufacturers are well-positioned to maintain their leadership in this vibrant industry. Conclusion China’s white glass beads manufacturers play an integral role in the global decorative material market. Their ability to produce high-quality, aesthetically appealing beads at competitive prices has made them indispensable to various industries worldwide. As these manufacturers continue to evolve and adapt to changing market dynamics, they will undoubtedly remain a vital force in the world of glass bead production for years to come._china pigment pigment2025-08-17 11:05Read(1272)all natural calcium bentonite clay

The Wonders of All-Natural Calcium Bentonite Clay In recent years, the world of natural health and w...

Read Morechina white glass beads manufacturers******Exploring the Landscape of China’s White Glass Beads Manufacturers The global market for decorative materials continues to thrive, and among these materials, glass beads stand out for their versatility and aesthetic appeal. Specifically, white glass beads, produced predominantly by manufacturers in China, have garnered significant attention due to their unique properties and wide range of applications. This article explores the landscape of white glass bead manufacturing in China, highlighting the production processes, applications, and the competitive edge these manufacturers possess in the international market. Understanding White Glass Beads White glass beads are small, spherical beads made from high-quality glass. They are known for their brilliant luster, smooth surface, and uniform size. These beads are primarily used in jewelry making, craft projects, embroidery, and as decorative elements in various products. Moreover, their reflective properties make them popular in the automotive, construction, and fashion industries, where they are often used for safety signs, road markings, and decorative accessories. The Manufacturing Process The production of white glass beads involves a carefully controlled process. It typically begins with the selection of raw materials, which include silica sand, soda lime, and various coloring agents. The glass-making process includes melting these materials in a furnace at high temperatures, followed by molding them into spherical shapes. Once formed, the beads undergo a process known as annealing, which involves cooling the glass slowly to relieve internal stresses and enhance durability. Quality control is paramount in the production of glass beads. Manufacturers in China have established rigorous testing protocols to ensure that each batch of beads meets international standards. This commitment to quality has made Chinese white glass beads a preferred choice for many industries globally. The Competitive Edge of Chinese Manufacturers China has emerged as a leading hub for glass bead production, thanks to several key factors. Firstly, the country has access to abundant raw materials, which lowers production costs and improves profitability. Secondly, the manufacturing sector in China benefits from well-established supply chains, allowing for the efficient sourcing of components and the rapid delivery of finished products. Additionally, Chinese manufacturers have invested heavily in modern technology and manufacturing techniques. Many factories utilize automated machinery, which not only increases production efficiency but also enhances the consistency and quality of the final products. Furthermore, the ability to produce large quantities of white glass beads means that manufacturers can meet the growing demand from both domestic and international markets. china white glass beads manufacturers Applications of White Glass Beads White glass beads have a diverse range of applications. In the fashion industry, they are utilized in costume jewelry, adding a touch of elegance to clothing items and accessories. They are also popular in crafting, where DIY enthusiasts use them to create unique designs and artistic expressions. In the industrial domain, white glass beads play a vital role in road safety applications. They are incorporated into road marking paints to enhance nighttime visibility, ensuring the safety of drivers. Additionally, these beads are used in reflective safety garments, contributing to worker safety in various industries. Moreover, the demand for white glass beads in decorative arts and home decor continues to grow. Designers leverage their aesthetic appeal to create eye-catching products that attract consumers looking for something unique and stylish. Challenges and Future Prospects Despite their success, manufacturers of white glass beads in China face challenges such as increasing raw material costs, environmental regulations, and competition from manufacturers in other countries. However, many companies are adapting by adopting sustainable practices, including recycling glass and reducing waste, thus appealing to environmentally-conscious consumers. Looking ahead, the future of white glass bead manufacturing in China appears promising. With the continued innovation in product design and manufacturing techniques, combined with a growing global demand for decorative materials, Chinese manufacturers are well-positioned to maintain their leadership in this vibrant industry. Conclusion China’s white glass beads manufacturers play an integral role in the global decorative material market. Their ability to produce high-quality, aesthetically appealing beads at competitive prices has made them indispensable to various industries worldwide. As these manufacturers continue to evolve and adapt to changing market dynamics, they will undoubtedly remain a vital force in the world of glass bead production for years to come._china pigment pigment2025-08-17 10:58Read(1069)