- china cinder block fly ash factory******The Rise of China’s Cinder Block and Fly Ash Manufacturing Industry In recent years, the construction industry has seen a significant transformation worldwide, driven by the need for more sustainable materials and efficient building practices. Among the notable developments in this sector is the rising prominence of cinder block and fly ash production in China. As one of the leading manufacturers of construction materials, China has embraced innovative technologies and environmental sustainability practices to enhance its cinder block production. This article explores the evolution of the cinder block and fly ash manufacturing industry in China, its significance, and the future prospects of this burgeoning field. Cinder blocks, also known as concrete masonry units (CMUs), are essential components of modern construction. They are utilized due to their durability, thermal performance, and versatility in various building applications. The traditional production of cinder blocks involves a mixture of cement, sand, and aggregates. However, the introduction of fly ash as a key ingredient has revolutionized this process. Fly ash is a byproduct of coal combustion in power plants and offers several environmental benefits when recycled into construction materials. The Rise of China’s Cinder Block and Fly Ash Manufacturing Industry The manufacturing process of cinder blocks with fly ash involves blending the ash with cement and water, allowing for a chemical reaction that improves the strength and durability of the final product. This method not only reduces the quantity of cement needed—often responsible for a large portion of global CO2 emissions—but also improves the physical characteristics of the blocks, making them highly competitive in the market. china cinder block fly ash factory In China, numerous factories have emerged that specialize in the production of fly ash-based cinder blocks. These facilities are often equipped with advanced technology, allowing for efficient production processes and consistent quality control. The implementation of automated manufacturing systems and robotics has streamlined operations, thereby increasing efficiency and reducing labor costs. Factories are now able to produce thousands of blocks per hour, meeting the rising demand from the booming construction sector. Moreover, the Chinese government has introduced various regulations and incentives aimed at promoting the use of sustainable construction materials. Policies supporting the development of eco-friendly building practices have fostered a favorable environment for cinder block and fly ash manufacturers. As a result, there has been a significant increase in the market share of fly ash-based products in construction projects across the country. The environmental benefits associated with using fly ash in cinder blocks are substantial. By diverting fly ash from landfills and incorporating it into construction materials, manufacturers help to alleviate some of the environmental issues linked with coal power generation. Additionally, cinder blocks made with fly ash offer improved thermal insulation properties, leading to energy savings in buildings and contributing to overall sustainability. Looking ahead, the future of the cinder block and fly ash manufacturing industry in China appears to be promising. With an increasing focus on green building practices and sustainability, the demand for eco-friendly construction materials is projected to rise. Furthermore, as new technologies emerge and further innovations are made in recycling methods, the potential for fly ash in construction will expand, opening new avenues for research and development. In conclusion, the cinder block and fly ash manufacturing industry in China is at the forefront of a pivotal shift towards sustainable construction practices. By integrating waste materials into practical applications, China not only addresses environmental concerns but also fosters economic growth within the construction industry. As the world continues to grapple with the challenges of climate change and resource depletion, the advancements made in this sector serve as a model for other countries seeking to build greener and more sustainable futures.>

- china cinder block fly ash factory******The Rise of China’s Cinder Block and Fly Ash Manufacturing Industry In recent years, the construction industry has seen a significant transformation worldwide, driven by the need for more sustainable materials and efficient building practices. Among the notable developments in this sector is the rising prominence of cinder block and fly ash production in China. As one of the leading manufacturers of construction materials, China has embraced innovative technologies and environmental sustainability practices to enhance its cinder block production. This article explores the evolution of the cinder block and fly ash manufacturing industry in China, its significance, and the future prospects of this burgeoning field. Cinder blocks, also known as concrete masonry units (CMUs), are essential components of modern construction. They are utilized due to their durability, thermal performance, and versatility in various building applications. The traditional production of cinder blocks involves a mixture of cement, sand, and aggregates. However, the introduction of fly ash as a key ingredient has revolutionized this process. Fly ash is a byproduct of coal combustion in power plants and offers several environmental benefits when recycled into construction materials. The Rise of China’s Cinder Block and Fly Ash Manufacturing Industry The manufacturing process of cinder blocks with fly ash involves blending the ash with cement and water, allowing for a chemical reaction that improves the strength and durability of the final product. This method not only reduces the quantity of cement needed—often responsible for a large portion of global CO2 emissions—but also improves the physical characteristics of the blocks, making them highly competitive in the market. china cinder block fly ash factory In China, numerous factories have emerged that specialize in the production of fly ash-based cinder blocks. These facilities are often equipped with advanced technology, allowing for efficient production processes and consistent quality control. The implementation of automated manufacturing systems and robotics has streamlined operations, thereby increasing efficiency and reducing labor costs. Factories are now able to produce thousands of blocks per hour, meeting the rising demand from the booming construction sector. Moreover, the Chinese government has introduced various regulations and incentives aimed at promoting the use of sustainable construction materials. Policies supporting the development of eco-friendly building practices have fostered a favorable environment for cinder block and fly ash manufacturers. As a result, there has been a significant increase in the market share of fly ash-based products in construction projects across the country. The environmental benefits associated with using fly ash in cinder blocks are substantial. By diverting fly ash from landfills and incorporating it into construction materials, manufacturers help to alleviate some of the environmental issues linked with coal power generation. Additionally, cinder blocks made with fly ash offer improved thermal insulation properties, leading to energy savings in buildings and contributing to overall sustainability. Looking ahead, the future of the cinder block and fly ash manufacturing industry in China appears to be promising. With an increasing focus on green building practices and sustainability, the demand for eco-friendly construction materials is projected to rise. Furthermore, as new technologies emerge and further innovations are made in recycling methods, the potential for fly ash in construction will expand, opening new avenues for research and development. In conclusion, the cinder block and fly ash manufacturing industry in China is at the forefront of a pivotal shift towards sustainable construction practices. By integrating waste materials into practical applications, China not only addresses environmental concerns but also fosters economic growth within the construction industry. As the world continues to grapple with the challenges of climate change and resource depletion, the advancements made in this sector serve as a model for other countries seeking to build greener and more sustainable futures._oem silver mica powder

china cinder block fly ash factory******The Rise of China’s Cinder Block and Fly Ash Manufacturing Industry In recent years, the construction industry has seen a significant transformation worldwide, driven by the need for more sustainable materials and efficient building practices. Among the notable developments in this sector is the rising prominence of cinder block and fly ash production in China. As one of the leading manufacturers of construction materials, China has embraced innovative technologies and environmental sustainability practices to enhance its cinder block production. This article explores the evolution of the cinder block and fly ash manufacturing industry in China, its significance, and the future prospects of this burgeoning field. Cinder blocks, also known as concrete masonry units (CMUs), are essential components of modern construction. They are utilized due to their durability, thermal performance, and versatility in various building applications. The traditional production of cinder blocks involves a mixture of cement, sand, and aggregates. However, the introduction of fly ash as a key ingredient has revolutionized this process. Fly ash is a byproduct of coal combustion in power plants and offers several environmental benefits when recycled into construction materials. The Rise of China’s Cinder Block and Fly Ash Manufacturing Industry The manufacturing process of cinder blocks with fly ash involves blending the ash with cement and water, allowing for a chemical reaction that improves the strength and durability of the final product. This method not only reduces the quantity of cement needed—often responsible for a large portion of global CO2 emissions—but also improves the physical characteristics of the blocks, making them highly competitive in the market. china cinder block fly ash factory In China, numerous factories have emerged that specialize in the production of fly ash-based cinder blocks. These facilities are often equipped with advanced technology, allowing for efficient production processes and consistent quality control. The implementation of automated manufacturing systems and robotics has streamlined operations, thereby increasing efficiency and reducing labor costs. Factories are now able to produce thousands of blocks per hour, meeting the rising demand from the booming construction sector. Moreover, the Chinese government has introduced various regulations and incentives aimed at promoting the use of sustainable construction materials. Policies supporting the development of eco-friendly building practices have fostered a favorable environment for cinder block and fly ash manufacturers. As a result, there has been a significant increase in the market share of fly ash-based products in construction projects across the country. The environmental benefits associated with using fly ash in cinder blocks are substantial. By diverting fly ash from landfills and incorporating it into construction materials, manufacturers help to alleviate some of the environmental issues linked with coal power generation. Additionally, cinder blocks made with fly ash offer improved thermal insulation properties, leading to energy savings in buildings and contributing to overall sustainability. Looking ahead, the future of the cinder block and fly ash manufacturing industry in China appears to be promising. With an increasing focus on green building practices and sustainability, the demand for eco-friendly construction materials is projected to rise. Furthermore, as new technologies emerge and further innovations are made in recycling methods, the potential for fly ash in construction will expand, opening new avenues for research and development. In conclusion, the cinder block and fly ash manufacturing industry in China is at the forefront of a pivotal shift towards sustainable construction practices. By integrating waste materials into practical applications, China not only addresses environmental concerns but also fosters economic growth within the construction industry. As the world continues to grapple with the challenges of climate change and resource depletion, the advancements made in this sector serve as a model for other countries seeking to build greener and more sustainable futures._oem silver mica powder

선인장 제조사의 옴진주암

OEM 퍼라이트, 선인장을 위한 최적의 선택 선인장은 그 독특한 생태와 아름다움 덕분에 많은 사람들에게 사랑받고 있는 식물입니다. 하지만 제대로 된 환경에서 자생할 수 있도록 도와...

Read Morechina cinder block fly ash factory******The Rise of China’s Cinder Block and Fly Ash Manufacturing Industry In recent years, the construction industry has seen a significant transformation worldwide, driven by the need for more sustainable materials and efficient building practices. Among the notable developments in this sector is the rising prominence of cinder block and fly ash production in China. As one of the leading manufacturers of construction materials, China has embraced innovative technologies and environmental sustainability practices to enhance its cinder block production. This article explores the evolution of the cinder block and fly ash manufacturing industry in China, its significance, and the future prospects of this burgeoning field. Cinder blocks, also known as concrete masonry units (CMUs), are essential components of modern construction. They are utilized due to their durability, thermal performance, and versatility in various building applications. The traditional production of cinder blocks involves a mixture of cement, sand, and aggregates. However, the introduction of fly ash as a key ingredient has revolutionized this process. Fly ash is a byproduct of coal combustion in power plants and offers several environmental benefits when recycled into construction materials. The Rise of China’s Cinder Block and Fly Ash Manufacturing Industry The manufacturing process of cinder blocks with fly ash involves blending the ash with cement and water, allowing for a chemical reaction that improves the strength and durability of the final product. This method not only reduces the quantity of cement needed—often responsible for a large portion of global CO2 emissions—but also improves the physical characteristics of the blocks, making them highly competitive in the market. china cinder block fly ash factory In China, numerous factories have emerged that specialize in the production of fly ash-based cinder blocks. These facilities are often equipped with advanced technology, allowing for efficient production processes and consistent quality control. The implementation of automated manufacturing systems and robotics has streamlined operations, thereby increasing efficiency and reducing labor costs. Factories are now able to produce thousands of blocks per hour, meeting the rising demand from the booming construction sector. Moreover, the Chinese government has introduced various regulations and incentives aimed at promoting the use of sustainable construction materials. Policies supporting the development of eco-friendly building practices have fostered a favorable environment for cinder block and fly ash manufacturers. As a result, there has been a significant increase in the market share of fly ash-based products in construction projects across the country. The environmental benefits associated with using fly ash in cinder blocks are substantial. By diverting fly ash from landfills and incorporating it into construction materials, manufacturers help to alleviate some of the environmental issues linked with coal power generation. Additionally, cinder blocks made with fly ash offer improved thermal insulation properties, leading to energy savings in buildings and contributing to overall sustainability. Looking ahead, the future of the cinder block and fly ash manufacturing industry in China appears to be promising. With an increasing focus on green building practices and sustainability, the demand for eco-friendly construction materials is projected to rise. Furthermore, as new technologies emerge and further innovations are made in recycling methods, the potential for fly ash in construction will expand, opening new avenues for research and development. In conclusion, the cinder block and fly ash manufacturing industry in China is at the forefront of a pivotal shift towards sustainable construction practices. By integrating waste materials into practical applications, China not only addresses environmental concerns but also fosters economic growth within the construction industry. As the world continues to grapple with the challenges of climate change and resource depletion, the advancements made in this sector serve as a model for other countries seeking to build greener and more sustainable futures._oem silver mica powder2025-08-17 08:13Read(2319)Limestone Powder Producers Specializing in High-Quality Calcium Carbonate Products

The Role of Calcium Carbonate Limestone Powder Manufacturers in Industry Calcium carbonate, a chemic...

Read Morechina cinder block fly ash factory******The Rise of China’s Cinder Block and Fly Ash Manufacturing Industry In recent years, the construction industry has seen a significant transformation worldwide, driven by the need for more sustainable materials and efficient building practices. Among the notable developments in this sector is the rising prominence of cinder block and fly ash production in China. As one of the leading manufacturers of construction materials, China has embraced innovative technologies and environmental sustainability practices to enhance its cinder block production. This article explores the evolution of the cinder block and fly ash manufacturing industry in China, its significance, and the future prospects of this burgeoning field. Cinder blocks, also known as concrete masonry units (CMUs), are essential components of modern construction. They are utilized due to their durability, thermal performance, and versatility in various building applications. The traditional production of cinder blocks involves a mixture of cement, sand, and aggregates. However, the introduction of fly ash as a key ingredient has revolutionized this process. Fly ash is a byproduct of coal combustion in power plants and offers several environmental benefits when recycled into construction materials. The Rise of China’s Cinder Block and Fly Ash Manufacturing Industry The manufacturing process of cinder blocks with fly ash involves blending the ash with cement and water, allowing for a chemical reaction that improves the strength and durability of the final product. This method not only reduces the quantity of cement needed—often responsible for a large portion of global CO2 emissions—but also improves the physical characteristics of the blocks, making them highly competitive in the market. china cinder block fly ash factory In China, numerous factories have emerged that specialize in the production of fly ash-based cinder blocks. These facilities are often equipped with advanced technology, allowing for efficient production processes and consistent quality control. The implementation of automated manufacturing systems and robotics has streamlined operations, thereby increasing efficiency and reducing labor costs. Factories are now able to produce thousands of blocks per hour, meeting the rising demand from the booming construction sector. Moreover, the Chinese government has introduced various regulations and incentives aimed at promoting the use of sustainable construction materials. Policies supporting the development of eco-friendly building practices have fostered a favorable environment for cinder block and fly ash manufacturers. As a result, there has been a significant increase in the market share of fly ash-based products in construction projects across the country. The environmental benefits associated with using fly ash in cinder blocks are substantial. By diverting fly ash from landfills and incorporating it into construction materials, manufacturers help to alleviate some of the environmental issues linked with coal power generation. Additionally, cinder blocks made with fly ash offer improved thermal insulation properties, leading to energy savings in buildings and contributing to overall sustainability. Looking ahead, the future of the cinder block and fly ash manufacturing industry in China appears to be promising. With an increasing focus on green building practices and sustainability, the demand for eco-friendly construction materials is projected to rise. Furthermore, as new technologies emerge and further innovations are made in recycling methods, the potential for fly ash in construction will expand, opening new avenues for research and development. In conclusion, the cinder block and fly ash manufacturing industry in China is at the forefront of a pivotal shift towards sustainable construction practices. By integrating waste materials into practical applications, China not only addresses environmental concerns but also fosters economic growth within the construction industry. As the world continues to grapple with the challenges of climate change and resource depletion, the advancements made in this sector serve as a model for other countries seeking to build greener and more sustainable futures._oem silver mica powder2025-08-17 08:02Read(2831)china ceramsite for plants factories

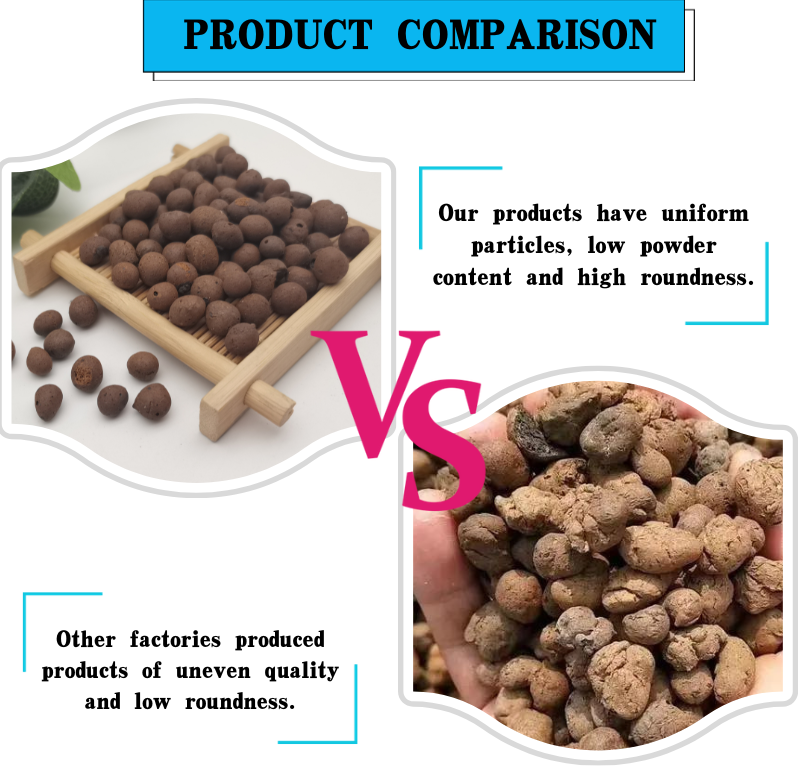

Ceramsite A Game Changer for Plant Growth in China Ceramsite, a lightweight aggregate made from expa...

Read Morechina cinder block fly ash factory******The Rise of China’s Cinder Block and Fly Ash Manufacturing Industry In recent years, the construction industry has seen a significant transformation worldwide, driven by the need for more sustainable materials and efficient building practices. Among the notable developments in this sector is the rising prominence of cinder block and fly ash production in China. As one of the leading manufacturers of construction materials, China has embraced innovative technologies and environmental sustainability practices to enhance its cinder block production. This article explores the evolution of the cinder block and fly ash manufacturing industry in China, its significance, and the future prospects of this burgeoning field. Cinder blocks, also known as concrete masonry units (CMUs), are essential components of modern construction. They are utilized due to their durability, thermal performance, and versatility in various building applications. The traditional production of cinder blocks involves a mixture of cement, sand, and aggregates. However, the introduction of fly ash as a key ingredient has revolutionized this process. Fly ash is a byproduct of coal combustion in power plants and offers several environmental benefits when recycled into construction materials. The Rise of China’s Cinder Block and Fly Ash Manufacturing Industry The manufacturing process of cinder blocks with fly ash involves blending the ash with cement and water, allowing for a chemical reaction that improves the strength and durability of the final product. This method not only reduces the quantity of cement needed—often responsible for a large portion of global CO2 emissions—but also improves the physical characteristics of the blocks, making them highly competitive in the market. china cinder block fly ash factory In China, numerous factories have emerged that specialize in the production of fly ash-based cinder blocks. These facilities are often equipped with advanced technology, allowing for efficient production processes and consistent quality control. The implementation of automated manufacturing systems and robotics has streamlined operations, thereby increasing efficiency and reducing labor costs. Factories are now able to produce thousands of blocks per hour, meeting the rising demand from the booming construction sector. Moreover, the Chinese government has introduced various regulations and incentives aimed at promoting the use of sustainable construction materials. Policies supporting the development of eco-friendly building practices have fostered a favorable environment for cinder block and fly ash manufacturers. As a result, there has been a significant increase in the market share of fly ash-based products in construction projects across the country. The environmental benefits associated with using fly ash in cinder blocks are substantial. By diverting fly ash from landfills and incorporating it into construction materials, manufacturers help to alleviate some of the environmental issues linked with coal power generation. Additionally, cinder blocks made with fly ash offer improved thermal insulation properties, leading to energy savings in buildings and contributing to overall sustainability. Looking ahead, the future of the cinder block and fly ash manufacturing industry in China appears to be promising. With an increasing focus on green building practices and sustainability, the demand for eco-friendly construction materials is projected to rise. Furthermore, as new technologies emerge and further innovations are made in recycling methods, the potential for fly ash in construction will expand, opening new avenues for research and development. In conclusion, the cinder block and fly ash manufacturing industry in China is at the forefront of a pivotal shift towards sustainable construction practices. By integrating waste materials into practical applications, China not only addresses environmental concerns but also fosters economic growth within the construction industry. As the world continues to grapple with the challenges of climate change and resource depletion, the advancements made in this sector serve as a model for other countries seeking to build greener and more sustainable futures._oem silver mica powder2025-08-17 07:37Read(1384)Leading Manufacturers of High-Quality Silica Fume in China for Construction and Industrial Applicati

The Significance of Silica Fume in the Construction Industry A Focus on China’s Leading Companies In...

Read Morechina cinder block fly ash factory******The Rise of China’s Cinder Block and Fly Ash Manufacturing Industry In recent years, the construction industry has seen a significant transformation worldwide, driven by the need for more sustainable materials and efficient building practices. Among the notable developments in this sector is the rising prominence of cinder block and fly ash production in China. As one of the leading manufacturers of construction materials, China has embraced innovative technologies and environmental sustainability practices to enhance its cinder block production. This article explores the evolution of the cinder block and fly ash manufacturing industry in China, its significance, and the future prospects of this burgeoning field. Cinder blocks, also known as concrete masonry units (CMUs), are essential components of modern construction. They are utilized due to their durability, thermal performance, and versatility in various building applications. The traditional production of cinder blocks involves a mixture of cement, sand, and aggregates. However, the introduction of fly ash as a key ingredient has revolutionized this process. Fly ash is a byproduct of coal combustion in power plants and offers several environmental benefits when recycled into construction materials. The Rise of China’s Cinder Block and Fly Ash Manufacturing Industry The manufacturing process of cinder blocks with fly ash involves blending the ash with cement and water, allowing for a chemical reaction that improves the strength and durability of the final product. This method not only reduces the quantity of cement needed—often responsible for a large portion of global CO2 emissions—but also improves the physical characteristics of the blocks, making them highly competitive in the market. china cinder block fly ash factory In China, numerous factories have emerged that specialize in the production of fly ash-based cinder blocks. These facilities are often equipped with advanced technology, allowing for efficient production processes and consistent quality control. The implementation of automated manufacturing systems and robotics has streamlined operations, thereby increasing efficiency and reducing labor costs. Factories are now able to produce thousands of blocks per hour, meeting the rising demand from the booming construction sector. Moreover, the Chinese government has introduced various regulations and incentives aimed at promoting the use of sustainable construction materials. Policies supporting the development of eco-friendly building practices have fostered a favorable environment for cinder block and fly ash manufacturers. As a result, there has been a significant increase in the market share of fly ash-based products in construction projects across the country. The environmental benefits associated with using fly ash in cinder blocks are substantial. By diverting fly ash from landfills and incorporating it into construction materials, manufacturers help to alleviate some of the environmental issues linked with coal power generation. Additionally, cinder blocks made with fly ash offer improved thermal insulation properties, leading to energy savings in buildings and contributing to overall sustainability. Looking ahead, the future of the cinder block and fly ash manufacturing industry in China appears to be promising. With an increasing focus on green building practices and sustainability, the demand for eco-friendly construction materials is projected to rise. Furthermore, as new technologies emerge and further innovations are made in recycling methods, the potential for fly ash in construction will expand, opening new avenues for research and development. In conclusion, the cinder block and fly ash manufacturing industry in China is at the forefront of a pivotal shift towards sustainable construction practices. By integrating waste materials into practical applications, China not only addresses environmental concerns but also fosters economic growth within the construction industry. As the world continues to grapple with the challenges of climate change and resource depletion, the advancements made in this sector serve as a model for other countries seeking to build greener and more sustainable futures._oem silver mica powder2025-08-17 07:30Read(853)खरानीका लागि परलाइटको प्रयोग र यसको फाइदाहरु

पेरलाइट र क्याक्टसको उगासँगको सम्बन्ध क्याक्टस, विशेष गरी सूखे स्थानमा उब्जने र कम पानीमा बाँच्न सक्...

Read Morechina cinder block fly ash factory******The Rise of China’s Cinder Block and Fly Ash Manufacturing Industry In recent years, the construction industry has seen a significant transformation worldwide, driven by the need for more sustainable materials and efficient building practices. Among the notable developments in this sector is the rising prominence of cinder block and fly ash production in China. As one of the leading manufacturers of construction materials, China has embraced innovative technologies and environmental sustainability practices to enhance its cinder block production. This article explores the evolution of the cinder block and fly ash manufacturing industry in China, its significance, and the future prospects of this burgeoning field. Cinder blocks, also known as concrete masonry units (CMUs), are essential components of modern construction. They are utilized due to their durability, thermal performance, and versatility in various building applications. The traditional production of cinder blocks involves a mixture of cement, sand, and aggregates. However, the introduction of fly ash as a key ingredient has revolutionized this process. Fly ash is a byproduct of coal combustion in power plants and offers several environmental benefits when recycled into construction materials. The Rise of China’s Cinder Block and Fly Ash Manufacturing Industry The manufacturing process of cinder blocks with fly ash involves blending the ash with cement and water, allowing for a chemical reaction that improves the strength and durability of the final product. This method not only reduces the quantity of cement needed—often responsible for a large portion of global CO2 emissions—but also improves the physical characteristics of the blocks, making them highly competitive in the market. china cinder block fly ash factory In China, numerous factories have emerged that specialize in the production of fly ash-based cinder blocks. These facilities are often equipped with advanced technology, allowing for efficient production processes and consistent quality control. The implementation of automated manufacturing systems and robotics has streamlined operations, thereby increasing efficiency and reducing labor costs. Factories are now able to produce thousands of blocks per hour, meeting the rising demand from the booming construction sector. Moreover, the Chinese government has introduced various regulations and incentives aimed at promoting the use of sustainable construction materials. Policies supporting the development of eco-friendly building practices have fostered a favorable environment for cinder block and fly ash manufacturers. As a result, there has been a significant increase in the market share of fly ash-based products in construction projects across the country. The environmental benefits associated with using fly ash in cinder blocks are substantial. By diverting fly ash from landfills and incorporating it into construction materials, manufacturers help to alleviate some of the environmental issues linked with coal power generation. Additionally, cinder blocks made with fly ash offer improved thermal insulation properties, leading to energy savings in buildings and contributing to overall sustainability. Looking ahead, the future of the cinder block and fly ash manufacturing industry in China appears to be promising. With an increasing focus on green building practices and sustainability, the demand for eco-friendly construction materials is projected to rise. Furthermore, as new technologies emerge and further innovations are made in recycling methods, the potential for fly ash in construction will expand, opening new avenues for research and development. In conclusion, the cinder block and fly ash manufacturing industry in China is at the forefront of a pivotal shift towards sustainable construction practices. By integrating waste materials into practical applications, China not only addresses environmental concerns but also fosters economic growth within the construction industry. As the world continues to grapple with the challenges of climate change and resource depletion, the advancements made in this sector serve as a model for other countries seeking to build greener and more sustainable futures._oem silver mica powder2025-08-17 07:22Read(610)China's Leading Manufacturers of Magnetic Iron Powder for Diverse Applications

The Rise of China’s Iron Powder Magnetic Manufacturers In recent years, the demand for iron powder m...

Read Morechina cinder block fly ash factory******The Rise of China’s Cinder Block and Fly Ash Manufacturing Industry In recent years, the construction industry has seen a significant transformation worldwide, driven by the need for more sustainable materials and efficient building practices. Among the notable developments in this sector is the rising prominence of cinder block and fly ash production in China. As one of the leading manufacturers of construction materials, China has embraced innovative technologies and environmental sustainability practices to enhance its cinder block production. This article explores the evolution of the cinder block and fly ash manufacturing industry in China, its significance, and the future prospects of this burgeoning field. Cinder blocks, also known as concrete masonry units (CMUs), are essential components of modern construction. They are utilized due to their durability, thermal performance, and versatility in various building applications. The traditional production of cinder blocks involves a mixture of cement, sand, and aggregates. However, the introduction of fly ash as a key ingredient has revolutionized this process. Fly ash is a byproduct of coal combustion in power plants and offers several environmental benefits when recycled into construction materials. The Rise of China’s Cinder Block and Fly Ash Manufacturing Industry The manufacturing process of cinder blocks with fly ash involves blending the ash with cement and water, allowing for a chemical reaction that improves the strength and durability of the final product. This method not only reduces the quantity of cement needed—often responsible for a large portion of global CO2 emissions—but also improves the physical characteristics of the blocks, making them highly competitive in the market. china cinder block fly ash factory In China, numerous factories have emerged that specialize in the production of fly ash-based cinder blocks. These facilities are often equipped with advanced technology, allowing for efficient production processes and consistent quality control. The implementation of automated manufacturing systems and robotics has streamlined operations, thereby increasing efficiency and reducing labor costs. Factories are now able to produce thousands of blocks per hour, meeting the rising demand from the booming construction sector. Moreover, the Chinese government has introduced various regulations and incentives aimed at promoting the use of sustainable construction materials. Policies supporting the development of eco-friendly building practices have fostered a favorable environment for cinder block and fly ash manufacturers. As a result, there has been a significant increase in the market share of fly ash-based products in construction projects across the country. The environmental benefits associated with using fly ash in cinder blocks are substantial. By diverting fly ash from landfills and incorporating it into construction materials, manufacturers help to alleviate some of the environmental issues linked with coal power generation. Additionally, cinder blocks made with fly ash offer improved thermal insulation properties, leading to energy savings in buildings and contributing to overall sustainability. Looking ahead, the future of the cinder block and fly ash manufacturing industry in China appears to be promising. With an increasing focus on green building practices and sustainability, the demand for eco-friendly construction materials is projected to rise. Furthermore, as new technologies emerge and further innovations are made in recycling methods, the potential for fly ash in construction will expand, opening new avenues for research and development. In conclusion, the cinder block and fly ash manufacturing industry in China is at the forefront of a pivotal shift towards sustainable construction practices. By integrating waste materials into practical applications, China not only addresses environmental concerns but also fosters economic growth within the construction industry. As the world continues to grapple with the challenges of climate change and resource depletion, the advancements made in this sector serve as a model for other countries seeking to build greener and more sustainable futures._oem silver mica powder2025-08-17 07:22Read(2131)In conclusion, calcium bentonite is a versatile and valuable natural resource with a wide range of applications. From agriculture to industrial uses and health benefits, this clay exhibits unique properties that make it indispensable in various fields. Its role in promoting sustainable practices and environmental care further underscores its importance in our modern world. As research continues to uncover more about its potential, calcium bentonite is poised to remain a prominent and beneficial component across numerous industries for years to come.

...

Read Morechina cinder block fly ash factory******The Rise of China’s Cinder Block and Fly Ash Manufacturing Industry In recent years, the construction industry has seen a significant transformation worldwide, driven by the need for more sustainable materials and efficient building practices. Among the notable developments in this sector is the rising prominence of cinder block and fly ash production in China. As one of the leading manufacturers of construction materials, China has embraced innovative technologies and environmental sustainability practices to enhance its cinder block production. This article explores the evolution of the cinder block and fly ash manufacturing industry in China, its significance, and the future prospects of this burgeoning field. Cinder blocks, also known as concrete masonry units (CMUs), are essential components of modern construction. They are utilized due to their durability, thermal performance, and versatility in various building applications. The traditional production of cinder blocks involves a mixture of cement, sand, and aggregates. However, the introduction of fly ash as a key ingredient has revolutionized this process. Fly ash is a byproduct of coal combustion in power plants and offers several environmental benefits when recycled into construction materials. The Rise of China’s Cinder Block and Fly Ash Manufacturing Industry The manufacturing process of cinder blocks with fly ash involves blending the ash with cement and water, allowing for a chemical reaction that improves the strength and durability of the final product. This method not only reduces the quantity of cement needed—often responsible for a large portion of global CO2 emissions—but also improves the physical characteristics of the blocks, making them highly competitive in the market. china cinder block fly ash factory In China, numerous factories have emerged that specialize in the production of fly ash-based cinder blocks. These facilities are often equipped with advanced technology, allowing for efficient production processes and consistent quality control. The implementation of automated manufacturing systems and robotics has streamlined operations, thereby increasing efficiency and reducing labor costs. Factories are now able to produce thousands of blocks per hour, meeting the rising demand from the booming construction sector. Moreover, the Chinese government has introduced various regulations and incentives aimed at promoting the use of sustainable construction materials. Policies supporting the development of eco-friendly building practices have fostered a favorable environment for cinder block and fly ash manufacturers. As a result, there has been a significant increase in the market share of fly ash-based products in construction projects across the country. The environmental benefits associated with using fly ash in cinder blocks are substantial. By diverting fly ash from landfills and incorporating it into construction materials, manufacturers help to alleviate some of the environmental issues linked with coal power generation. Additionally, cinder blocks made with fly ash offer improved thermal insulation properties, leading to energy savings in buildings and contributing to overall sustainability. Looking ahead, the future of the cinder block and fly ash manufacturing industry in China appears to be promising. With an increasing focus on green building practices and sustainability, the demand for eco-friendly construction materials is projected to rise. Furthermore, as new technologies emerge and further innovations are made in recycling methods, the potential for fly ash in construction will expand, opening new avenues for research and development. In conclusion, the cinder block and fly ash manufacturing industry in China is at the forefront of a pivotal shift towards sustainable construction practices. By integrating waste materials into practical applications, China not only addresses environmental concerns but also fosters economic growth within the construction industry. As the world continues to grapple with the challenges of climate change and resource depletion, the advancements made in this sector serve as a model for other countries seeking to build greener and more sustainable futures._oem silver mica powder2025-08-17 07:21Read(1177)Leading Manufacturers of Zeolite Pellets for Various Industrial Applications

An Overview of Zeolite Pellet Manufacturers Zeolites, a group of crystalline aluminosilicate mineral...

Read Morechina cinder block fly ash factory******The Rise of China’s Cinder Block and Fly Ash Manufacturing Industry In recent years, the construction industry has seen a significant transformation worldwide, driven by the need for more sustainable materials and efficient building practices. Among the notable developments in this sector is the rising prominence of cinder block and fly ash production in China. As one of the leading manufacturers of construction materials, China has embraced innovative technologies and environmental sustainability practices to enhance its cinder block production. This article explores the evolution of the cinder block and fly ash manufacturing industry in China, its significance, and the future prospects of this burgeoning field. Cinder blocks, also known as concrete masonry units (CMUs), are essential components of modern construction. They are utilized due to their durability, thermal performance, and versatility in various building applications. The traditional production of cinder blocks involves a mixture of cement, sand, and aggregates. However, the introduction of fly ash as a key ingredient has revolutionized this process. Fly ash is a byproduct of coal combustion in power plants and offers several environmental benefits when recycled into construction materials. The Rise of China’s Cinder Block and Fly Ash Manufacturing Industry The manufacturing process of cinder blocks with fly ash involves blending the ash with cement and water, allowing for a chemical reaction that improves the strength and durability of the final product. This method not only reduces the quantity of cement needed—often responsible for a large portion of global CO2 emissions—but also improves the physical characteristics of the blocks, making them highly competitive in the market. china cinder block fly ash factory In China, numerous factories have emerged that specialize in the production of fly ash-based cinder blocks. These facilities are often equipped with advanced technology, allowing for efficient production processes and consistent quality control. The implementation of automated manufacturing systems and robotics has streamlined operations, thereby increasing efficiency and reducing labor costs. Factories are now able to produce thousands of blocks per hour, meeting the rising demand from the booming construction sector. Moreover, the Chinese government has introduced various regulations and incentives aimed at promoting the use of sustainable construction materials. Policies supporting the development of eco-friendly building practices have fostered a favorable environment for cinder block and fly ash manufacturers. As a result, there has been a significant increase in the market share of fly ash-based products in construction projects across the country. The environmental benefits associated with using fly ash in cinder blocks are substantial. By diverting fly ash from landfills and incorporating it into construction materials, manufacturers help to alleviate some of the environmental issues linked with coal power generation. Additionally, cinder blocks made with fly ash offer improved thermal insulation properties, leading to energy savings in buildings and contributing to overall sustainability. Looking ahead, the future of the cinder block and fly ash manufacturing industry in China appears to be promising. With an increasing focus on green building practices and sustainability, the demand for eco-friendly construction materials is projected to rise. Furthermore, as new technologies emerge and further innovations are made in recycling methods, the potential for fly ash in construction will expand, opening new avenues for research and development. In conclusion, the cinder block and fly ash manufacturing industry in China is at the forefront of a pivotal shift towards sustainable construction practices. By integrating waste materials into practical applications, China not only addresses environmental concerns but also fosters economic growth within the construction industry. As the world continues to grapple with the challenges of climate change and resource depletion, the advancements made in this sector serve as a model for other countries seeking to build greener and more sustainable futures._oem silver mica powder2025-08-17 06:43Read(1596)Pabrika ng OEM Perlite para sa Lupa sa Hardin sa Pilipinas

OEM Perlite sa Mga Tagagawa ng Lupa ng Hardin Ang perlite ay isang natural na materyal na ginagamit...

Read Morechina cinder block fly ash factory******The Rise of China’s Cinder Block and Fly Ash Manufacturing Industry In recent years, the construction industry has seen a significant transformation worldwide, driven by the need for more sustainable materials and efficient building practices. Among the notable developments in this sector is the rising prominence of cinder block and fly ash production in China. As one of the leading manufacturers of construction materials, China has embraced innovative technologies and environmental sustainability practices to enhance its cinder block production. This article explores the evolution of the cinder block and fly ash manufacturing industry in China, its significance, and the future prospects of this burgeoning field. Cinder blocks, also known as concrete masonry units (CMUs), are essential components of modern construction. They are utilized due to their durability, thermal performance, and versatility in various building applications. The traditional production of cinder blocks involves a mixture of cement, sand, and aggregates. However, the introduction of fly ash as a key ingredient has revolutionized this process. Fly ash is a byproduct of coal combustion in power plants and offers several environmental benefits when recycled into construction materials. The Rise of China’s Cinder Block and Fly Ash Manufacturing Industry The manufacturing process of cinder blocks with fly ash involves blending the ash with cement and water, allowing for a chemical reaction that improves the strength and durability of the final product. This method not only reduces the quantity of cement needed—often responsible for a large portion of global CO2 emissions—but also improves the physical characteristics of the blocks, making them highly competitive in the market. china cinder block fly ash factory In China, numerous factories have emerged that specialize in the production of fly ash-based cinder blocks. These facilities are often equipped with advanced technology, allowing for efficient production processes and consistent quality control. The implementation of automated manufacturing systems and robotics has streamlined operations, thereby increasing efficiency and reducing labor costs. Factories are now able to produce thousands of blocks per hour, meeting the rising demand from the booming construction sector. Moreover, the Chinese government has introduced various regulations and incentives aimed at promoting the use of sustainable construction materials. Policies supporting the development of eco-friendly building practices have fostered a favorable environment for cinder block and fly ash manufacturers. As a result, there has been a significant increase in the market share of fly ash-based products in construction projects across the country. The environmental benefits associated with using fly ash in cinder blocks are substantial. By diverting fly ash from landfills and incorporating it into construction materials, manufacturers help to alleviate some of the environmental issues linked with coal power generation. Additionally, cinder blocks made with fly ash offer improved thermal insulation properties, leading to energy savings in buildings and contributing to overall sustainability. Looking ahead, the future of the cinder block and fly ash manufacturing industry in China appears to be promising. With an increasing focus on green building practices and sustainability, the demand for eco-friendly construction materials is projected to rise. Furthermore, as new technologies emerge and further innovations are made in recycling methods, the potential for fly ash in construction will expand, opening new avenues for research and development. In conclusion, the cinder block and fly ash manufacturing industry in China is at the forefront of a pivotal shift towards sustainable construction practices. By integrating waste materials into practical applications, China not only addresses environmental concerns but also fosters economic growth within the construction industry. As the world continues to grapple with the challenges of climate change and resource depletion, the advancements made in this sector serve as a model for other countries seeking to build greener and more sustainable futures._oem silver mica powder2025-08-17 06:42Read(2473)lava rock factories

The Fascinating World of Lava Rock Factories Lava rock, a porous and lightweight material formed fro...

Read Morechina cinder block fly ash factory******The Rise of China’s Cinder Block and Fly Ash Manufacturing Industry In recent years, the construction industry has seen a significant transformation worldwide, driven by the need for more sustainable materials and efficient building practices. Among the notable developments in this sector is the rising prominence of cinder block and fly ash production in China. As one of the leading manufacturers of construction materials, China has embraced innovative technologies and environmental sustainability practices to enhance its cinder block production. This article explores the evolution of the cinder block and fly ash manufacturing industry in China, its significance, and the future prospects of this burgeoning field. Cinder blocks, also known as concrete masonry units (CMUs), are essential components of modern construction. They are utilized due to their durability, thermal performance, and versatility in various building applications. The traditional production of cinder blocks involves a mixture of cement, sand, and aggregates. However, the introduction of fly ash as a key ingredient has revolutionized this process. Fly ash is a byproduct of coal combustion in power plants and offers several environmental benefits when recycled into construction materials. The Rise of China’s Cinder Block and Fly Ash Manufacturing Industry The manufacturing process of cinder blocks with fly ash involves blending the ash with cement and water, allowing for a chemical reaction that improves the strength and durability of the final product. This method not only reduces the quantity of cement needed—often responsible for a large portion of global CO2 emissions—but also improves the physical characteristics of the blocks, making them highly competitive in the market. china cinder block fly ash factory In China, numerous factories have emerged that specialize in the production of fly ash-based cinder blocks. These facilities are often equipped with advanced technology, allowing for efficient production processes and consistent quality control. The implementation of automated manufacturing systems and robotics has streamlined operations, thereby increasing efficiency and reducing labor costs. Factories are now able to produce thousands of blocks per hour, meeting the rising demand from the booming construction sector. Moreover, the Chinese government has introduced various regulations and incentives aimed at promoting the use of sustainable construction materials. Policies supporting the development of eco-friendly building practices have fostered a favorable environment for cinder block and fly ash manufacturers. As a result, there has been a significant increase in the market share of fly ash-based products in construction projects across the country. The environmental benefits associated with using fly ash in cinder blocks are substantial. By diverting fly ash from landfills and incorporating it into construction materials, manufacturers help to alleviate some of the environmental issues linked with coal power generation. Additionally, cinder blocks made with fly ash offer improved thermal insulation properties, leading to energy savings in buildings and contributing to overall sustainability. Looking ahead, the future of the cinder block and fly ash manufacturing industry in China appears to be promising. With an increasing focus on green building practices and sustainability, the demand for eco-friendly construction materials is projected to rise. Furthermore, as new technologies emerge and further innovations are made in recycling methods, the potential for fly ash in construction will expand, opening new avenues for research and development. In conclusion, the cinder block and fly ash manufacturing industry in China is at the forefront of a pivotal shift towards sustainable construction practices. By integrating waste materials into practical applications, China not only addresses environmental concerns but also fosters economic growth within the construction industry. As the world continues to grapple with the challenges of climate change and resource depletion, the advancements made in this sector serve as a model for other countries seeking to build greener and more sustainable futures._oem silver mica powder2025-08-17 05:48Read(1855)