- Limestone Powder Suppliers for Construction and Industrial Applications******Understanding Crushed Limestone Powder A Key Ingredient in Various Industries Crushed limestone powder has become an essential material across multiple industries, primarily due to its versatility and fundamental properties . Manufactured through the crushing of limestone, a sedimentary rock primarily composed of calcium carbonate, this fine powder offers a range of applications that contribute to construction, agriculture, and environmental management. One of the primary uses of crushed limestone powder is in the construction industry. It serves as a key ingredient in cement production, which is fundamental to creating concrete. The high calcium content in limestone provides the necessary chemical reaction when mixed with water and other materials, resulting in a durable and strong building material. Furthermore, crushed limestone powder is utilized as a base material for roads, highways, and foundations, providing stability and support. Its natural properties enhance drainage capabilities, making it an excellent choice for landscaping projects and erosion control. In agriculture, crushed limestone powder plays a crucial role in soil management. It is often used to amend acidic soils, improving pH levels for optimal crop growth. By adding calcium to the soil, it promotes the healthy development of plants and helps to enhance nutrient availability, ultimately leading to improved yields. Additionally, farmers utilize limestone powder as a feed supplement for livestock, ensuring adequate calcium intake for the animals’ bone health and productivity. crushed limestone powder manufacturer Another significant application of crushed limestone powder is in environmental management. It is frequently employed in water treatment processes, where it acts as a neutralizing agent for acidic waters, helping to restore ecological balance in aquatic systems. Moreover, limestone powder assists in the reduction of greenhouse gas emissions, as it can be used in flue gas desulfurization systems. This process captures sulfur dioxide produced from industrial processes, converting it into a solid waste product through a chemical reaction, thus minimizing air pollution. As awareness of sustainable practices increases, the demand for crushed limestone powder continues to grow. Manufacturers are now focused on optimizing their production processes to enhance efficiency while minimizing environmental impact. Utilizing advanced technologies, they aim to produce high-quality limestone powder that meets the stringent requirements of various sectors. In conclusion, crushed limestone powder is a vital ingredient that underpins numerous industries, enhancing construction practices, agricultural productivity, and environmental sustainability. Its multifaceted applications and essential properties make it an indispensable material that contributes significantly to economic growth and ecological balance. As the industries evolve, the importance of this natural resource is likely to expand, underscoring the need for responsible sourcing and innovative manufacturing methods.>

- Limestone Powder Suppliers for Construction and Industrial Applications******Understanding Crushed Limestone Powder A Key Ingredient in Various Industries Crushed limestone powder has become an essential material across multiple industries, primarily due to its versatility and fundamental properties . Manufactured through the crushing of limestone, a sedimentary rock primarily composed of calcium carbonate, this fine powder offers a range of applications that contribute to construction, agriculture, and environmental management. One of the primary uses of crushed limestone powder is in the construction industry. It serves as a key ingredient in cement production, which is fundamental to creating concrete. The high calcium content in limestone provides the necessary chemical reaction when mixed with water and other materials, resulting in a durable and strong building material. Furthermore, crushed limestone powder is utilized as a base material for roads, highways, and foundations, providing stability and support. Its natural properties enhance drainage capabilities, making it an excellent choice for landscaping projects and erosion control. In agriculture, crushed limestone powder plays a crucial role in soil management. It is often used to amend acidic soils, improving pH levels for optimal crop growth. By adding calcium to the soil, it promotes the healthy development of plants and helps to enhance nutrient availability, ultimately leading to improved yields. Additionally, farmers utilize limestone powder as a feed supplement for livestock, ensuring adequate calcium intake for the animals’ bone health and productivity. crushed limestone powder manufacturer Another significant application of crushed limestone powder is in environmental management. It is frequently employed in water treatment processes, where it acts as a neutralizing agent for acidic waters, helping to restore ecological balance in aquatic systems. Moreover, limestone powder assists in the reduction of greenhouse gas emissions, as it can be used in flue gas desulfurization systems. This process captures sulfur dioxide produced from industrial processes, converting it into a solid waste product through a chemical reaction, thus minimizing air pollution. As awareness of sustainable practices increases, the demand for crushed limestone powder continues to grow. Manufacturers are now focused on optimizing their production processes to enhance efficiency while minimizing environmental impact. Utilizing advanced technologies, they aim to produce high-quality limestone powder that meets the stringent requirements of various sectors. In conclusion, crushed limestone powder is a vital ingredient that underpins numerous industries, enhancing construction practices, agricultural productivity, and environmental sustainability. Its multifaceted applications and essential properties make it an indispensable material that contributes significantly to economic growth and ecological balance. As the industries evolve, the importance of this natural resource is likely to expand, underscoring the need for responsible sourcing and innovative manufacturing methods._china pumice stone manufacturer

Limestone Powder Suppliers for Construction and Industrial Applications******Understanding Crushed Limestone Powder A Key Ingredient in Various Industries Crushed limestone powder has become an essential material across multiple industries, primarily due to its versatility and fundamental properties . Manufactured through the crushing of limestone, a sedimentary rock primarily composed of calcium carbonate, this fine powder offers a range of applications that contribute to construction, agriculture, and environmental management. One of the primary uses of crushed limestone powder is in the construction industry. It serves as a key ingredient in cement production, which is fundamental to creating concrete. The high calcium content in limestone provides the necessary chemical reaction when mixed with water and other materials, resulting in a durable and strong building material. Furthermore, crushed limestone powder is utilized as a base material for roads, highways, and foundations, providing stability and support. Its natural properties enhance drainage capabilities, making it an excellent choice for landscaping projects and erosion control. In agriculture, crushed limestone powder plays a crucial role in soil management. It is often used to amend acidic soils, improving pH levels for optimal crop growth. By adding calcium to the soil, it promotes the healthy development of plants and helps to enhance nutrient availability, ultimately leading to improved yields. Additionally, farmers utilize limestone powder as a feed supplement for livestock, ensuring adequate calcium intake for the animals’ bone health and productivity. crushed limestone powder manufacturer Another significant application of crushed limestone powder is in environmental management. It is frequently employed in water treatment processes, where it acts as a neutralizing agent for acidic waters, helping to restore ecological balance in aquatic systems. Moreover, limestone powder assists in the reduction of greenhouse gas emissions, as it can be used in flue gas desulfurization systems. This process captures sulfur dioxide produced from industrial processes, converting it into a solid waste product through a chemical reaction, thus minimizing air pollution. As awareness of sustainable practices increases, the demand for crushed limestone powder continues to grow. Manufacturers are now focused on optimizing their production processes to enhance efficiency while minimizing environmental impact. Utilizing advanced technologies, they aim to produce high-quality limestone powder that meets the stringent requirements of various sectors. In conclusion, crushed limestone powder is a vital ingredient that underpins numerous industries, enhancing construction practices, agricultural productivity, and environmental sustainability. Its multifaceted applications and essential properties make it an indispensable material that contributes significantly to economic growth and ecological balance. As the industries evolve, the importance of this natural resource is likely to expand, underscoring the need for responsible sourcing and innovative manufacturing methods._china pumice stone manufacturer

grey sand

Exploring the Beauty of Grey Sand Nature's Unique Palette When we think of sandy beaches, vivid imag...

Read MoreLimestone Powder Suppliers for Construction and Industrial Applications******Understanding Crushed Limestone Powder A Key Ingredient in Various Industries Crushed limestone powder has become an essential material across multiple industries, primarily due to its versatility and fundamental properties . Manufactured through the crushing of limestone, a sedimentary rock primarily composed of calcium carbonate, this fine powder offers a range of applications that contribute to construction, agriculture, and environmental management. One of the primary uses of crushed limestone powder is in the construction industry. It serves as a key ingredient in cement production, which is fundamental to creating concrete. The high calcium content in limestone provides the necessary chemical reaction when mixed with water and other materials, resulting in a durable and strong building material. Furthermore, crushed limestone powder is utilized as a base material for roads, highways, and foundations, providing stability and support. Its natural properties enhance drainage capabilities, making it an excellent choice for landscaping projects and erosion control. In agriculture, crushed limestone powder plays a crucial role in soil management. It is often used to amend acidic soils, improving pH levels for optimal crop growth. By adding calcium to the soil, it promotes the healthy development of plants and helps to enhance nutrient availability, ultimately leading to improved yields. Additionally, farmers utilize limestone powder as a feed supplement for livestock, ensuring adequate calcium intake for the animals’ bone health and productivity. crushed limestone powder manufacturer Another significant application of crushed limestone powder is in environmental management. It is frequently employed in water treatment processes, where it acts as a neutralizing agent for acidic waters, helping to restore ecological balance in aquatic systems. Moreover, limestone powder assists in the reduction of greenhouse gas emissions, as it can be used in flue gas desulfurization systems. This process captures sulfur dioxide produced from industrial processes, converting it into a solid waste product through a chemical reaction, thus minimizing air pollution. As awareness of sustainable practices increases, the demand for crushed limestone powder continues to grow. Manufacturers are now focused on optimizing their production processes to enhance efficiency while minimizing environmental impact. Utilizing advanced technologies, they aim to produce high-quality limestone powder that meets the stringent requirements of various sectors. In conclusion, crushed limestone powder is a vital ingredient that underpins numerous industries, enhancing construction practices, agricultural productivity, and environmental sustainability. Its multifaceted applications and essential properties make it an indispensable material that contributes significantly to economic growth and ecological balance. As the industries evolve, the importance of this natural resource is likely to expand, underscoring the need for responsible sourcing and innovative manufacturing methods._china pumice stone manufacturer2025-08-17 12:55Read(2126)...

Read MoreLimestone Powder Suppliers for Construction and Industrial Applications******Understanding Crushed Limestone Powder A Key Ingredient in Various Industries Crushed limestone powder has become an essential material across multiple industries, primarily due to its versatility and fundamental properties . Manufactured through the crushing of limestone, a sedimentary rock primarily composed of calcium carbonate, this fine powder offers a range of applications that contribute to construction, agriculture, and environmental management. One of the primary uses of crushed limestone powder is in the construction industry. It serves as a key ingredient in cement production, which is fundamental to creating concrete. The high calcium content in limestone provides the necessary chemical reaction when mixed with water and other materials, resulting in a durable and strong building material. Furthermore, crushed limestone powder is utilized as a base material for roads, highways, and foundations, providing stability and support. Its natural properties enhance drainage capabilities, making it an excellent choice for landscaping projects and erosion control. In agriculture, crushed limestone powder plays a crucial role in soil management. It is often used to amend acidic soils, improving pH levels for optimal crop growth. By adding calcium to the soil, it promotes the healthy development of plants and helps to enhance nutrient availability, ultimately leading to improved yields. Additionally, farmers utilize limestone powder as a feed supplement for livestock, ensuring adequate calcium intake for the animals’ bone health and productivity. crushed limestone powder manufacturer Another significant application of crushed limestone powder is in environmental management. It is frequently employed in water treatment processes, where it acts as a neutralizing agent for acidic waters, helping to restore ecological balance in aquatic systems. Moreover, limestone powder assists in the reduction of greenhouse gas emissions, as it can be used in flue gas desulfurization systems. This process captures sulfur dioxide produced from industrial processes, converting it into a solid waste product through a chemical reaction, thus minimizing air pollution. As awareness of sustainable practices increases, the demand for crushed limestone powder continues to grow. Manufacturers are now focused on optimizing their production processes to enhance efficiency while minimizing environmental impact. Utilizing advanced technologies, they aim to produce high-quality limestone powder that meets the stringent requirements of various sectors. In conclusion, crushed limestone powder is a vital ingredient that underpins numerous industries, enhancing construction practices, agricultural productivity, and environmental sustainability. Its multifaceted applications and essential properties make it an indispensable material that contributes significantly to economic growth and ecological balance. As the industries evolve, the importance of this natural resource is likely to expand, underscoring the need for responsible sourcing and innovative manufacturing methods._china pumice stone manufacturer2025-08-17 12:41Read(1268)

What does calabachop taste like?

...

Calcium provides bones and teeth with stability and endurance. It also aids in blood coagulation, enzyme regulation, nervous system processing of signals, etc. In transporting oxygen from the lungs to other parts of the body, iron is needed.

...

Wapń naturalny - Właściwości, Zastosowanie i Korzyści

Oto artykuł na temat A limestone Wapienie to grupa skał osadowych składających się głównie z węglanu...

colored sand for crafts

The Versatility of Colored Sand for Crafts Colored sand has emerged as a vibrant and versatile mediu...

Application of Calcium Carbonate in Plastic Industry

...

custom diatomite stone manufacturer

The Rise of Custom Diatomite Stone Manufacturers In recent years, the demand for diatomite stone has...

Wholesale Options for Custom Pumice Stones Tailored to Your Needs

Custom Pumice Stone Wholesale The Ultimate Guide to Sourcing Quality Products The beauty and persona...

//skinpharm.com/cdn/shop/articles/skinpharm02.09xhtp_27_new_400x.jpg?v=1686022075 400w,

...

Top Ranking

- 1Fabriken für farbigen Epoxidharzsand und deren Anwendungen

- 2Exploring the Benefits of Custom Volcanic Rock Dust for Sustainable Agriculture

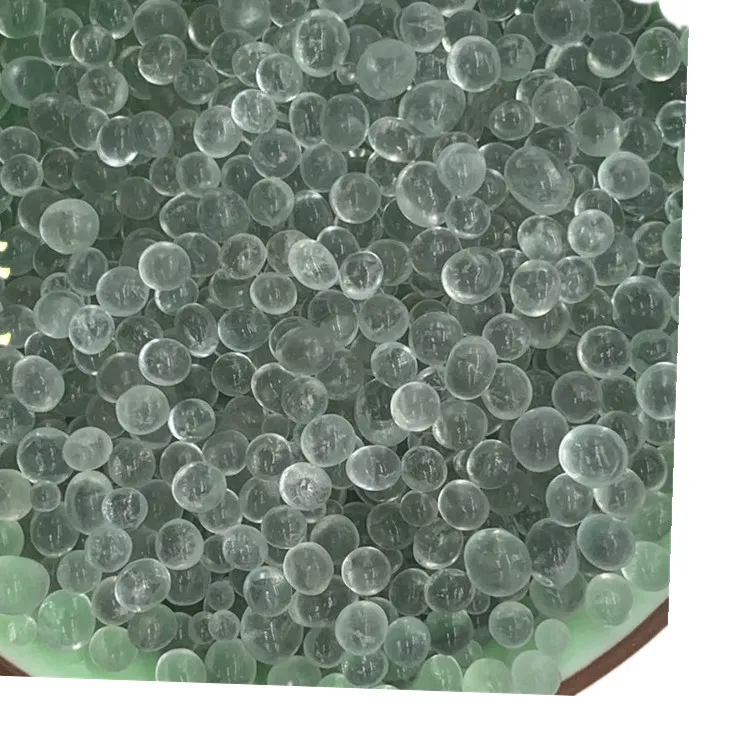

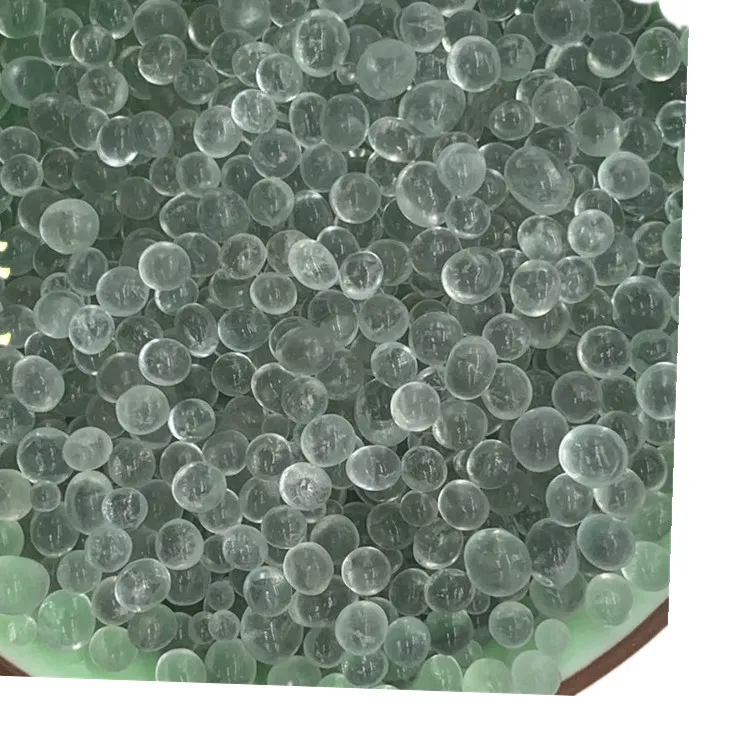

· Low oil absorption. The particle of the ball determines that it has the smallest specific surface area and low oil absorption rate, which can greatly reduce the amount of resin in the process of use, and the viscosity will not increase much even under the premise of high addition amount, which greatly improves the production operating conditions and can increase the production efficiency by 10% to 20%. " title='

· Low oil absorption. The particle of the ball determines that it has the smallest specific surface area and low oil absorption rate, which can greatly reduce the amount of resin in the process of use, and the viscosity will not increase much even under the premise of high addition amount, which greatly improves the production operating conditions and can increase the production efficiency by 10% to 20%. '>3

· Low oil absorption. The particle of the ball determines that it has the smallest specific surface area and low oil absorption rate, which can greatly reduce the amount of resin in the process of use, and the viscosity will not increase much even under the premise of high addition amount, which greatly improves the production operating conditions and can increase the production efficiency by 10% to 20%.- 4Exploring the Benefits of Custom Volcanic Rock Dust for Sustainable Agriculture

- 5High-Quality Custom Talc Powder for Makeup Applications from Leading Manufacturers

- 6Custom High-Quality Calcium Carbonate Powder Suppliers for Various Applications

- 7custom limestone powder meaning manufacturers

- " title=''>8

Netizens pay attention

Mixing vermiculite and cement for a strong and lightweight construction material.

2025-08-17 12:56Read1662Visitors

Creating a Luminous Pathway for Safe and Enchanting Nighttime Walks Outdoors

2025-08-17 12:35Read1280Visitors

custom mica sand manufacturers

2025-08-17 11:27Read1197Visitors

Exploring Innovative Applications of Custom Drilling Bentonite in Modern Construction and Environmen

2025-08-17 11:07Read2156Visitors

OEM Perlite and Vermiculite for Vegetables _ Quality Growing Solutions

2025-08-17 10:57Read1054Visitors

Looked and looked

- Perlite Mining Facilities in China and Their Industrial Applications

- custom barite powder manufacturer

- '>

If you have two cats, you can put two litter boxes next to each other but only if your space is limited. It's generally better to have them in separate areas and thus prevent conflict over the toilet. Cats like to have their own designated spots for elimination and having separate boxes helps prevent any potential issues or accidents.

- The Main Application Areas of Alumina

- Custom Dolomite Powder Production by Leading Manufacturer for Various Industrial Applications

- custom caco3 lime powder manufacturers

- custom white glass beads

- Top Quality OEM Talcum Powder Manufacturers for Your Business Needs and Custom Solutions

Links: