- OEM Barite Powder for Drilling Applications from Trusted Manufacturing Source******The Importance of OEM Barite Powder for Drilling A Closer Look at the Manufacturing Process and Its Applications Barite, a naturally occurring mineral composed of barium sulfate (BaSO4), plays a pivotal role in the drilling industry, particularly in oil and gas extraction. The demand for high-quality barite powder has surged over the years, leading to the emergence of various manufacturers that provide OEM (Original Equipment Manufacturer) barite powder specifically tailored for drilling purposes. This article explores the significance of OEM barite powder, the manufacturing process involved, and its diverse applications in the drilling sector. Understanding Barite Powder in Drilling In the drilling industry, barite powder serves as a crucial weighting agent in drilling mud. The high density of barite, typically ranging from 4.2 to 4.5 g/cm3, helps to counteract the pressures encountered during drilling operations, stabilizing the borehole and preventing blowouts. Additionally, barite improves the viscosity of drilling fluids, enhancing their ability to carry rock cuttings to the surface and facilitate the efficient operation of the drilling machinery. The Manufacturing Process of OEM Barite Powder The production of OEM barite powder involves several distinct steps, each crucial to ensuring the quality and suitability of the product for drilling applications 1. Mining and Extraction Barite is mined from natural deposits, typically found in sedimentary rocks. The extraction process includes crushing the ore and removing impurities to obtain high-purity barite. 2. Grinding and Milling Once the raw barite is obtained, it undergoes rigorous grinding and milling processes to achieve the desired particle size. This step is essential as the fineness of the barite powder directly influences its performance in drilling applications. 3. Quality Control OEM manufacturers typically implement stringent quality control measures to ensure that the barite powder meets industry standards. This includes testing for various physical and chemical properties, such as specific gravity, particle size distribution, and purity levels. oem barite powder for drilling factory 4. Packaging and Distribution The final step involves packaging the barite powder in bulk bags or containers, ready for distribution to drilling companies . The OEM aspect ensures that the packaging can be customized according to the specific requirements of clients. Applications of OEM Barite Powder in Drilling OEM barite powder finds extensive use in various drilling applications, including 1. Oil and Gas Exploration In the oil and gas industry, barite powder is an indispensable component of drilling mud. It helps maintain wellbore stability and controls downhole pressure, which is vital for safe and efficient drilling operations. 2. Mining Operations Apart from oil and gas, barite is also used in the mining sector, where it serves similar functions in the drilling process to extract valuable minerals. 3. Construction Industry Barite powder is utilized in cement production and as a filler in construction materials due to its density and inert properties. This application demonstrates the versatility of barite beyond the drilling industry. 4. Environmental Applications In certain environmental drilling projects, barite is employed as a tracer and as part of remediation efforts, showcasing its multifaceted utility. Conclusion The significance of OEM barite powder in the drilling industry cannot be overstated. Its ability to enhance drilling efficiency and safety makes it a vital resource for oil and gas extraction as well as other mining operations. As the demand for energy continues to grow, the role of high-quality barite powder in drilling activities will become increasingly critical. Manufacturers are tasked with producing consistent, high-purity barite powder that meets the evolving needs of the industry. Therefore, understanding the manufacturing process and applications of OEM barite powder is essential for stakeholders looking to optimize their drilling operations and maintain a competitive edge in the market.>

- OEM Barite Powder for Drilling Applications from Trusted Manufacturing Source******The Importance of OEM Barite Powder for Drilling A Closer Look at the Manufacturing Process and Its Applications Barite, a naturally occurring mineral composed of barium sulfate (BaSO4), plays a pivotal role in the drilling industry, particularly in oil and gas extraction. The demand for high-quality barite powder has surged over the years, leading to the emergence of various manufacturers that provide OEM (Original Equipment Manufacturer) barite powder specifically tailored for drilling purposes. This article explores the significance of OEM barite powder, the manufacturing process involved, and its diverse applications in the drilling sector. Understanding Barite Powder in Drilling In the drilling industry, barite powder serves as a crucial weighting agent in drilling mud. The high density of barite, typically ranging from 4.2 to 4.5 g/cm3, helps to counteract the pressures encountered during drilling operations, stabilizing the borehole and preventing blowouts. Additionally, barite improves the viscosity of drilling fluids, enhancing their ability to carry rock cuttings to the surface and facilitate the efficient operation of the drilling machinery. The Manufacturing Process of OEM Barite Powder The production of OEM barite powder involves several distinct steps, each crucial to ensuring the quality and suitability of the product for drilling applications 1. Mining and Extraction Barite is mined from natural deposits, typically found in sedimentary rocks. The extraction process includes crushing the ore and removing impurities to obtain high-purity barite. 2. Grinding and Milling Once the raw barite is obtained, it undergoes rigorous grinding and milling processes to achieve the desired particle size. This step is essential as the fineness of the barite powder directly influences its performance in drilling applications. 3. Quality Control OEM manufacturers typically implement stringent quality control measures to ensure that the barite powder meets industry standards. This includes testing for various physical and chemical properties, such as specific gravity, particle size distribution, and purity levels. oem barite powder for drilling factory 4. Packaging and Distribution The final step involves packaging the barite powder in bulk bags or containers, ready for distribution to drilling companies . The OEM aspect ensures that the packaging can be customized according to the specific requirements of clients. Applications of OEM Barite Powder in Drilling OEM barite powder finds extensive use in various drilling applications, including 1. Oil and Gas Exploration In the oil and gas industry, barite powder is an indispensable component of drilling mud. It helps maintain wellbore stability and controls downhole pressure, which is vital for safe and efficient drilling operations. 2. Mining Operations Apart from oil and gas, barite is also used in the mining sector, where it serves similar functions in the drilling process to extract valuable minerals. 3. Construction Industry Barite powder is utilized in cement production and as a filler in construction materials due to its density and inert properties. This application demonstrates the versatility of barite beyond the drilling industry. 4. Environmental Applications In certain environmental drilling projects, barite is employed as a tracer and as part of remediation efforts, showcasing its multifaceted utility. Conclusion The significance of OEM barite powder in the drilling industry cannot be overstated. Its ability to enhance drilling efficiency and safety makes it a vital resource for oil and gas extraction as well as other mining operations. As the demand for energy continues to grow, the role of high-quality barite powder in drilling activities will become increasingly critical. Manufacturers are tasked with producing consistent, high-purity barite powder that meets the evolving needs of the industry. Therefore, understanding the manufacturing process and applications of OEM barite powder is essential for stakeholders looking to optimize their drilling operations and maintain a competitive edge in the market._custom glass marbles

OEM Barite Powder for Drilling Applications from Trusted Manufacturing Source******The Importance of OEM Barite Powder for Drilling A Closer Look at the Manufacturing Process and Its Applications Barite, a naturally occurring mineral composed of barium sulfate (BaSO4), plays a pivotal role in the drilling industry, particularly in oil and gas extraction. The demand for high-quality barite powder has surged over the years, leading to the emergence of various manufacturers that provide OEM (Original Equipment Manufacturer) barite powder specifically tailored for drilling purposes. This article explores the significance of OEM barite powder, the manufacturing process involved, and its diverse applications in the drilling sector. Understanding Barite Powder in Drilling In the drilling industry, barite powder serves as a crucial weighting agent in drilling mud. The high density of barite, typically ranging from 4.2 to 4.5 g/cm3, helps to counteract the pressures encountered during drilling operations, stabilizing the borehole and preventing blowouts. Additionally, barite improves the viscosity of drilling fluids, enhancing their ability to carry rock cuttings to the surface and facilitate the efficient operation of the drilling machinery. The Manufacturing Process of OEM Barite Powder The production of OEM barite powder involves several distinct steps, each crucial to ensuring the quality and suitability of the product for drilling applications 1. Mining and Extraction Barite is mined from natural deposits, typically found in sedimentary rocks. The extraction process includes crushing the ore and removing impurities to obtain high-purity barite. 2. Grinding and Milling Once the raw barite is obtained, it undergoes rigorous grinding and milling processes to achieve the desired particle size. This step is essential as the fineness of the barite powder directly influences its performance in drilling applications. 3. Quality Control OEM manufacturers typically implement stringent quality control measures to ensure that the barite powder meets industry standards. This includes testing for various physical and chemical properties, such as specific gravity, particle size distribution, and purity levels. oem barite powder for drilling factory 4. Packaging and Distribution The final step involves packaging the barite powder in bulk bags or containers, ready for distribution to drilling companies . The OEM aspect ensures that the packaging can be customized according to the specific requirements of clients. Applications of OEM Barite Powder in Drilling OEM barite powder finds extensive use in various drilling applications, including 1. Oil and Gas Exploration In the oil and gas industry, barite powder is an indispensable component of drilling mud. It helps maintain wellbore stability and controls downhole pressure, which is vital for safe and efficient drilling operations. 2. Mining Operations Apart from oil and gas, barite is also used in the mining sector, where it serves similar functions in the drilling process to extract valuable minerals. 3. Construction Industry Barite powder is utilized in cement production and as a filler in construction materials due to its density and inert properties. This application demonstrates the versatility of barite beyond the drilling industry. 4. Environmental Applications In certain environmental drilling projects, barite is employed as a tracer and as part of remediation efforts, showcasing its multifaceted utility. Conclusion The significance of OEM barite powder in the drilling industry cannot be overstated. Its ability to enhance drilling efficiency and safety makes it a vital resource for oil and gas extraction as well as other mining operations. As the demand for energy continues to grow, the role of high-quality barite powder in drilling activities will become increasingly critical. Manufacturers are tasked with producing consistent, high-purity barite powder that meets the evolving needs of the industry. Therefore, understanding the manufacturing process and applications of OEM barite powder is essential for stakeholders looking to optimize their drilling operations and maintain a competitive edge in the market._custom glass marbles

Properties and Applications of Clay Bentonite in Various Industries

Exploring Clay Bentonite Nature's Versatile Mineral Clay bentonite is a remarkable natural material,...

Read MoreOEM Barite Powder for Drilling Applications from Trusted Manufacturing Source******The Importance of OEM Barite Powder for Drilling A Closer Look at the Manufacturing Process and Its Applications Barite, a naturally occurring mineral composed of barium sulfate (BaSO4), plays a pivotal role in the drilling industry, particularly in oil and gas extraction. The demand for high-quality barite powder has surged over the years, leading to the emergence of various manufacturers that provide OEM (Original Equipment Manufacturer) barite powder specifically tailored for drilling purposes. This article explores the significance of OEM barite powder, the manufacturing process involved, and its diverse applications in the drilling sector. Understanding Barite Powder in Drilling In the drilling industry, barite powder serves as a crucial weighting agent in drilling mud. The high density of barite, typically ranging from 4.2 to 4.5 g/cm3, helps to counteract the pressures encountered during drilling operations, stabilizing the borehole and preventing blowouts. Additionally, barite improves the viscosity of drilling fluids, enhancing their ability to carry rock cuttings to the surface and facilitate the efficient operation of the drilling machinery. The Manufacturing Process of OEM Barite Powder The production of OEM barite powder involves several distinct steps, each crucial to ensuring the quality and suitability of the product for drilling applications 1. Mining and Extraction Barite is mined from natural deposits, typically found in sedimentary rocks. The extraction process includes crushing the ore and removing impurities to obtain high-purity barite. 2. Grinding and Milling Once the raw barite is obtained, it undergoes rigorous grinding and milling processes to achieve the desired particle size. This step is essential as the fineness of the barite powder directly influences its performance in drilling applications. 3. Quality Control OEM manufacturers typically implement stringent quality control measures to ensure that the barite powder meets industry standards. This includes testing for various physical and chemical properties, such as specific gravity, particle size distribution, and purity levels. oem barite powder for drilling factory 4. Packaging and Distribution The final step involves packaging the barite powder in bulk bags or containers, ready for distribution to drilling companies . The OEM aspect ensures that the packaging can be customized according to the specific requirements of clients. Applications of OEM Barite Powder in Drilling OEM barite powder finds extensive use in various drilling applications, including 1. Oil and Gas Exploration In the oil and gas industry, barite powder is an indispensable component of drilling mud. It helps maintain wellbore stability and controls downhole pressure, which is vital for safe and efficient drilling operations. 2. Mining Operations Apart from oil and gas, barite is also used in the mining sector, where it serves similar functions in the drilling process to extract valuable minerals. 3. Construction Industry Barite powder is utilized in cement production and as a filler in construction materials due to its density and inert properties. This application demonstrates the versatility of barite beyond the drilling industry. 4. Environmental Applications In certain environmental drilling projects, barite is employed as a tracer and as part of remediation efforts, showcasing its multifaceted utility. Conclusion The significance of OEM barite powder in the drilling industry cannot be overstated. Its ability to enhance drilling efficiency and safety makes it a vital resource for oil and gas extraction as well as other mining operations. As the demand for energy continues to grow, the role of high-quality barite powder in drilling activities will become increasingly critical. Manufacturers are tasked with producing consistent, high-purity barite powder that meets the evolving needs of the industry. Therefore, understanding the manufacturing process and applications of OEM barite powder is essential for stakeholders looking to optimize their drilling operations and maintain a competitive edge in the market._custom glass marbles2025-08-17 22:09Read(2480)The Significance of Limestone in Nature and Industry

...

Read MoreOEM Barite Powder for Drilling Applications from Trusted Manufacturing Source******The Importance of OEM Barite Powder for Drilling A Closer Look at the Manufacturing Process and Its Applications Barite, a naturally occurring mineral composed of barium sulfate (BaSO4), plays a pivotal role in the drilling industry, particularly in oil and gas extraction. The demand for high-quality barite powder has surged over the years, leading to the emergence of various manufacturers that provide OEM (Original Equipment Manufacturer) barite powder specifically tailored for drilling purposes. This article explores the significance of OEM barite powder, the manufacturing process involved, and its diverse applications in the drilling sector. Understanding Barite Powder in Drilling In the drilling industry, barite powder serves as a crucial weighting agent in drilling mud. The high density of barite, typically ranging from 4.2 to 4.5 g/cm3, helps to counteract the pressures encountered during drilling operations, stabilizing the borehole and preventing blowouts. Additionally, barite improves the viscosity of drilling fluids, enhancing their ability to carry rock cuttings to the surface and facilitate the efficient operation of the drilling machinery. The Manufacturing Process of OEM Barite Powder The production of OEM barite powder involves several distinct steps, each crucial to ensuring the quality and suitability of the product for drilling applications 1. Mining and Extraction Barite is mined from natural deposits, typically found in sedimentary rocks. The extraction process includes crushing the ore and removing impurities to obtain high-purity barite. 2. Grinding and Milling Once the raw barite is obtained, it undergoes rigorous grinding and milling processes to achieve the desired particle size. This step is essential as the fineness of the barite powder directly influences its performance in drilling applications. 3. Quality Control OEM manufacturers typically implement stringent quality control measures to ensure that the barite powder meets industry standards. This includes testing for various physical and chemical properties, such as specific gravity, particle size distribution, and purity levels. oem barite powder for drilling factory 4. Packaging and Distribution The final step involves packaging the barite powder in bulk bags or containers, ready for distribution to drilling companies . The OEM aspect ensures that the packaging can be customized according to the specific requirements of clients. Applications of OEM Barite Powder in Drilling OEM barite powder finds extensive use in various drilling applications, including 1. Oil and Gas Exploration In the oil and gas industry, barite powder is an indispensable component of drilling mud. It helps maintain wellbore stability and controls downhole pressure, which is vital for safe and efficient drilling operations. 2. Mining Operations Apart from oil and gas, barite is also used in the mining sector, where it serves similar functions in the drilling process to extract valuable minerals. 3. Construction Industry Barite powder is utilized in cement production and as a filler in construction materials due to its density and inert properties. This application demonstrates the versatility of barite beyond the drilling industry. 4. Environmental Applications In certain environmental drilling projects, barite is employed as a tracer and as part of remediation efforts, showcasing its multifaceted utility. Conclusion The significance of OEM barite powder in the drilling industry cannot be overstated. Its ability to enhance drilling efficiency and safety makes it a vital resource for oil and gas extraction as well as other mining operations. As the demand for energy continues to grow, the role of high-quality barite powder in drilling activities will become increasingly critical. Manufacturers are tasked with producing consistent, high-purity barite powder that meets the evolving needs of the industry. Therefore, understanding the manufacturing process and applications of OEM barite powder is essential for stakeholders looking to optimize their drilling operations and maintain a competitive edge in the market._custom glass marbles2025-08-17 22:05Read(1696)What are OEM Glass Beads?

...

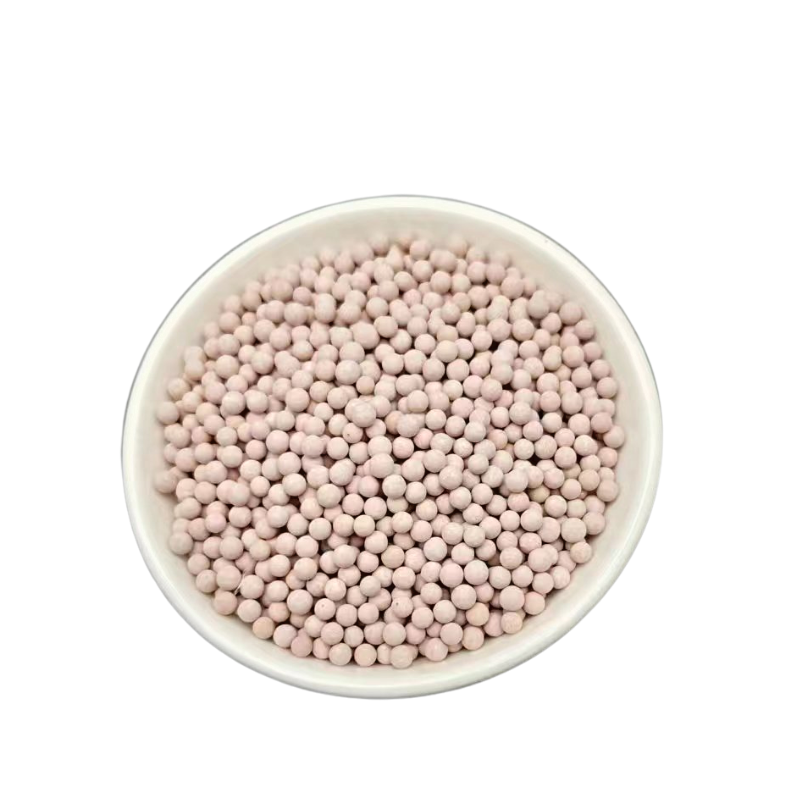

Read MoreOEM Barite Powder for Drilling Applications from Trusted Manufacturing Source******The Importance of OEM Barite Powder for Drilling A Closer Look at the Manufacturing Process and Its Applications Barite, a naturally occurring mineral composed of barium sulfate (BaSO4), plays a pivotal role in the drilling industry, particularly in oil and gas extraction. The demand for high-quality barite powder has surged over the years, leading to the emergence of various manufacturers that provide OEM (Original Equipment Manufacturer) barite powder specifically tailored for drilling purposes. This article explores the significance of OEM barite powder, the manufacturing process involved, and its diverse applications in the drilling sector. Understanding Barite Powder in Drilling In the drilling industry, barite powder serves as a crucial weighting agent in drilling mud. The high density of barite, typically ranging from 4.2 to 4.5 g/cm3, helps to counteract the pressures encountered during drilling operations, stabilizing the borehole and preventing blowouts. Additionally, barite improves the viscosity of drilling fluids, enhancing their ability to carry rock cuttings to the surface and facilitate the efficient operation of the drilling machinery. The Manufacturing Process of OEM Barite Powder The production of OEM barite powder involves several distinct steps, each crucial to ensuring the quality and suitability of the product for drilling applications 1. Mining and Extraction Barite is mined from natural deposits, typically found in sedimentary rocks. The extraction process includes crushing the ore and removing impurities to obtain high-purity barite. 2. Grinding and Milling Once the raw barite is obtained, it undergoes rigorous grinding and milling processes to achieve the desired particle size. This step is essential as the fineness of the barite powder directly influences its performance in drilling applications. 3. Quality Control OEM manufacturers typically implement stringent quality control measures to ensure that the barite powder meets industry standards. This includes testing for various physical and chemical properties, such as specific gravity, particle size distribution, and purity levels. oem barite powder for drilling factory 4. Packaging and Distribution The final step involves packaging the barite powder in bulk bags or containers, ready for distribution to drilling companies . The OEM aspect ensures that the packaging can be customized according to the specific requirements of clients. Applications of OEM Barite Powder in Drilling OEM barite powder finds extensive use in various drilling applications, including 1. Oil and Gas Exploration In the oil and gas industry, barite powder is an indispensable component of drilling mud. It helps maintain wellbore stability and controls downhole pressure, which is vital for safe and efficient drilling operations. 2. Mining Operations Apart from oil and gas, barite is also used in the mining sector, where it serves similar functions in the drilling process to extract valuable minerals. 3. Construction Industry Barite powder is utilized in cement production and as a filler in construction materials due to its density and inert properties. This application demonstrates the versatility of barite beyond the drilling industry. 4. Environmental Applications In certain environmental drilling projects, barite is employed as a tracer and as part of remediation efforts, showcasing its multifaceted utility. Conclusion The significance of OEM barite powder in the drilling industry cannot be overstated. Its ability to enhance drilling efficiency and safety makes it a vital resource for oil and gas extraction as well as other mining operations. As the demand for energy continues to grow, the role of high-quality barite powder in drilling activities will become increasingly critical. Manufacturers are tasked with producing consistent, high-purity barite powder that meets the evolving needs of the industry. Therefore, understanding the manufacturing process and applications of OEM barite powder is essential for stakeholders looking to optimize their drilling operations and maintain a competitive edge in the market._custom glass marbles2025-08-17 21:53Read(272)In addition to its practical benefits, ceramsite also has aesthetic appeal in the garden. The small, round particles of ceramsite create a decorative mulch that can add visual interest to flower beds, containers, and landscaping designs. OEM ceramsite manufacturers offer a variety of colors and sizes, allowing gardeners to customize their designs and create unique and beautiful outdoor spaces.

...

Read MoreOEM Barite Powder for Drilling Applications from Trusted Manufacturing Source******The Importance of OEM Barite Powder for Drilling A Closer Look at the Manufacturing Process and Its Applications Barite, a naturally occurring mineral composed of barium sulfate (BaSO4), plays a pivotal role in the drilling industry, particularly in oil and gas extraction. The demand for high-quality barite powder has surged over the years, leading to the emergence of various manufacturers that provide OEM (Original Equipment Manufacturer) barite powder specifically tailored for drilling purposes. This article explores the significance of OEM barite powder, the manufacturing process involved, and its diverse applications in the drilling sector. Understanding Barite Powder in Drilling In the drilling industry, barite powder serves as a crucial weighting agent in drilling mud. The high density of barite, typically ranging from 4.2 to 4.5 g/cm3, helps to counteract the pressures encountered during drilling operations, stabilizing the borehole and preventing blowouts. Additionally, barite improves the viscosity of drilling fluids, enhancing their ability to carry rock cuttings to the surface and facilitate the efficient operation of the drilling machinery. The Manufacturing Process of OEM Barite Powder The production of OEM barite powder involves several distinct steps, each crucial to ensuring the quality and suitability of the product for drilling applications 1. Mining and Extraction Barite is mined from natural deposits, typically found in sedimentary rocks. The extraction process includes crushing the ore and removing impurities to obtain high-purity barite. 2. Grinding and Milling Once the raw barite is obtained, it undergoes rigorous grinding and milling processes to achieve the desired particle size. This step is essential as the fineness of the barite powder directly influences its performance in drilling applications. 3. Quality Control OEM manufacturers typically implement stringent quality control measures to ensure that the barite powder meets industry standards. This includes testing for various physical and chemical properties, such as specific gravity, particle size distribution, and purity levels. oem barite powder for drilling factory 4. Packaging and Distribution The final step involves packaging the barite powder in bulk bags or containers, ready for distribution to drilling companies . The OEM aspect ensures that the packaging can be customized according to the specific requirements of clients. Applications of OEM Barite Powder in Drilling OEM barite powder finds extensive use in various drilling applications, including 1. Oil and Gas Exploration In the oil and gas industry, barite powder is an indispensable component of drilling mud. It helps maintain wellbore stability and controls downhole pressure, which is vital for safe and efficient drilling operations. 2. Mining Operations Apart from oil and gas, barite is also used in the mining sector, where it serves similar functions in the drilling process to extract valuable minerals. 3. Construction Industry Barite powder is utilized in cement production and as a filler in construction materials due to its density and inert properties. This application demonstrates the versatility of barite beyond the drilling industry. 4. Environmental Applications In certain environmental drilling projects, barite is employed as a tracer and as part of remediation efforts, showcasing its multifaceted utility. Conclusion The significance of OEM barite powder in the drilling industry cannot be overstated. Its ability to enhance drilling efficiency and safety makes it a vital resource for oil and gas extraction as well as other mining operations. As the demand for energy continues to grow, the role of high-quality barite powder in drilling activities will become increasingly critical. Manufacturers are tasked with producing consistent, high-purity barite powder that meets the evolving needs of the industry. Therefore, understanding the manufacturing process and applications of OEM barite powder is essential for stakeholders looking to optimize their drilling operations and maintain a competitive edge in the market._custom glass marbles2025-08-17 21:51Read(1770)Exploring Various Types of Fly Ash from Custom Manufacturing Processes

Customizing Different Types of Fly Ash A Closer Look at the Manufacturing Process Fly ash, a byprodu...

Read MoreOEM Barite Powder for Drilling Applications from Trusted Manufacturing Source******The Importance of OEM Barite Powder for Drilling A Closer Look at the Manufacturing Process and Its Applications Barite, a naturally occurring mineral composed of barium sulfate (BaSO4), plays a pivotal role in the drilling industry, particularly in oil and gas extraction. The demand for high-quality barite powder has surged over the years, leading to the emergence of various manufacturers that provide OEM (Original Equipment Manufacturer) barite powder specifically tailored for drilling purposes. This article explores the significance of OEM barite powder, the manufacturing process involved, and its diverse applications in the drilling sector. Understanding Barite Powder in Drilling In the drilling industry, barite powder serves as a crucial weighting agent in drilling mud. The high density of barite, typically ranging from 4.2 to 4.5 g/cm3, helps to counteract the pressures encountered during drilling operations, stabilizing the borehole and preventing blowouts. Additionally, barite improves the viscosity of drilling fluids, enhancing their ability to carry rock cuttings to the surface and facilitate the efficient operation of the drilling machinery. The Manufacturing Process of OEM Barite Powder The production of OEM barite powder involves several distinct steps, each crucial to ensuring the quality and suitability of the product for drilling applications 1. Mining and Extraction Barite is mined from natural deposits, typically found in sedimentary rocks. The extraction process includes crushing the ore and removing impurities to obtain high-purity barite. 2. Grinding and Milling Once the raw barite is obtained, it undergoes rigorous grinding and milling processes to achieve the desired particle size. This step is essential as the fineness of the barite powder directly influences its performance in drilling applications. 3. Quality Control OEM manufacturers typically implement stringent quality control measures to ensure that the barite powder meets industry standards. This includes testing for various physical and chemical properties, such as specific gravity, particle size distribution, and purity levels. oem barite powder for drilling factory 4. Packaging and Distribution The final step involves packaging the barite powder in bulk bags or containers, ready for distribution to drilling companies . The OEM aspect ensures that the packaging can be customized according to the specific requirements of clients. Applications of OEM Barite Powder in Drilling OEM barite powder finds extensive use in various drilling applications, including 1. Oil and Gas Exploration In the oil and gas industry, barite powder is an indispensable component of drilling mud. It helps maintain wellbore stability and controls downhole pressure, which is vital for safe and efficient drilling operations. 2. Mining Operations Apart from oil and gas, barite is also used in the mining sector, where it serves similar functions in the drilling process to extract valuable minerals. 3. Construction Industry Barite powder is utilized in cement production and as a filler in construction materials due to its density and inert properties. This application demonstrates the versatility of barite beyond the drilling industry. 4. Environmental Applications In certain environmental drilling projects, barite is employed as a tracer and as part of remediation efforts, showcasing its multifaceted utility. Conclusion The significance of OEM barite powder in the drilling industry cannot be overstated. Its ability to enhance drilling efficiency and safety makes it a vital resource for oil and gas extraction as well as other mining operations. As the demand for energy continues to grow, the role of high-quality barite powder in drilling activities will become increasingly critical. Manufacturers are tasked with producing consistent, high-purity barite powder that meets the evolving needs of the industry. Therefore, understanding the manufacturing process and applications of OEM barite powder is essential for stakeholders looking to optimize their drilling operations and maintain a competitive edge in the market._custom glass marbles2025-08-17 21:36Read(1959)While rutile titanium oxide is widely considered safe, its mining and production come with environmental considerations. The extraction processes can lead to habitat destruction and pollution if not managed responsibly. Therefore, advancements in sustainable mining practices and the development of recycling methods for titanium dioxide waste are crucial for minimizing the ecological footprint associated with this mineral. The growing demand for eco-friendly alternatives emphasizes the need for industries to adopt greener practices, ensuring that the benefits of rutile titanium oxide do not come at the expense of environmental wellbeing.

...

Read MoreOEM Barite Powder for Drilling Applications from Trusted Manufacturing Source******The Importance of OEM Barite Powder for Drilling A Closer Look at the Manufacturing Process and Its Applications Barite, a naturally occurring mineral composed of barium sulfate (BaSO4), plays a pivotal role in the drilling industry, particularly in oil and gas extraction. The demand for high-quality barite powder has surged over the years, leading to the emergence of various manufacturers that provide OEM (Original Equipment Manufacturer) barite powder specifically tailored for drilling purposes. This article explores the significance of OEM barite powder, the manufacturing process involved, and its diverse applications in the drilling sector. Understanding Barite Powder in Drilling In the drilling industry, barite powder serves as a crucial weighting agent in drilling mud. The high density of barite, typically ranging from 4.2 to 4.5 g/cm3, helps to counteract the pressures encountered during drilling operations, stabilizing the borehole and preventing blowouts. Additionally, barite improves the viscosity of drilling fluids, enhancing their ability to carry rock cuttings to the surface and facilitate the efficient operation of the drilling machinery. The Manufacturing Process of OEM Barite Powder The production of OEM barite powder involves several distinct steps, each crucial to ensuring the quality and suitability of the product for drilling applications 1. Mining and Extraction Barite is mined from natural deposits, typically found in sedimentary rocks. The extraction process includes crushing the ore and removing impurities to obtain high-purity barite. 2. Grinding and Milling Once the raw barite is obtained, it undergoes rigorous grinding and milling processes to achieve the desired particle size. This step is essential as the fineness of the barite powder directly influences its performance in drilling applications. 3. Quality Control OEM manufacturers typically implement stringent quality control measures to ensure that the barite powder meets industry standards. This includes testing for various physical and chemical properties, such as specific gravity, particle size distribution, and purity levels. oem barite powder for drilling factory 4. Packaging and Distribution The final step involves packaging the barite powder in bulk bags or containers, ready for distribution to drilling companies . The OEM aspect ensures that the packaging can be customized according to the specific requirements of clients. Applications of OEM Barite Powder in Drilling OEM barite powder finds extensive use in various drilling applications, including 1. Oil and Gas Exploration In the oil and gas industry, barite powder is an indispensable component of drilling mud. It helps maintain wellbore stability and controls downhole pressure, which is vital for safe and efficient drilling operations. 2. Mining Operations Apart from oil and gas, barite is also used in the mining sector, where it serves similar functions in the drilling process to extract valuable minerals. 3. Construction Industry Barite powder is utilized in cement production and as a filler in construction materials due to its density and inert properties. This application demonstrates the versatility of barite beyond the drilling industry. 4. Environmental Applications In certain environmental drilling projects, barite is employed as a tracer and as part of remediation efforts, showcasing its multifaceted utility. Conclusion The significance of OEM barite powder in the drilling industry cannot be overstated. Its ability to enhance drilling efficiency and safety makes it a vital resource for oil and gas extraction as well as other mining operations. As the demand for energy continues to grow, the role of high-quality barite powder in drilling activities will become increasingly critical. Manufacturers are tasked with producing consistent, high-purity barite powder that meets the evolving needs of the industry. Therefore, understanding the manufacturing process and applications of OEM barite powder is essential for stakeholders looking to optimize their drilling operations and maintain a competitive edge in the market._custom glass marbles2025-08-17 21:30Read(1299)In conclusion, the titanium dioxide rutile export sector plays a vital role in global trade, feeding various industries and contributing to economic growth. As demand continues to rise and new regulations are implemented, the industry must adapt to ensure both profitability and sustainability. Stakeholders must navigate these changes effectively to harness the full potential of titanium dioxide rutile while promoting responsible mining practices that safeguard our planet for future generations.

...

Read MoreOEM Barite Powder for Drilling Applications from Trusted Manufacturing Source******The Importance of OEM Barite Powder for Drilling A Closer Look at the Manufacturing Process and Its Applications Barite, a naturally occurring mineral composed of barium sulfate (BaSO4), plays a pivotal role in the drilling industry, particularly in oil and gas extraction. The demand for high-quality barite powder has surged over the years, leading to the emergence of various manufacturers that provide OEM (Original Equipment Manufacturer) barite powder specifically tailored for drilling purposes. This article explores the significance of OEM barite powder, the manufacturing process involved, and its diverse applications in the drilling sector. Understanding Barite Powder in Drilling In the drilling industry, barite powder serves as a crucial weighting agent in drilling mud. The high density of barite, typically ranging from 4.2 to 4.5 g/cm3, helps to counteract the pressures encountered during drilling operations, stabilizing the borehole and preventing blowouts. Additionally, barite improves the viscosity of drilling fluids, enhancing their ability to carry rock cuttings to the surface and facilitate the efficient operation of the drilling machinery. The Manufacturing Process of OEM Barite Powder The production of OEM barite powder involves several distinct steps, each crucial to ensuring the quality and suitability of the product for drilling applications 1. Mining and Extraction Barite is mined from natural deposits, typically found in sedimentary rocks. The extraction process includes crushing the ore and removing impurities to obtain high-purity barite. 2. Grinding and Milling Once the raw barite is obtained, it undergoes rigorous grinding and milling processes to achieve the desired particle size. This step is essential as the fineness of the barite powder directly influences its performance in drilling applications. 3. Quality Control OEM manufacturers typically implement stringent quality control measures to ensure that the barite powder meets industry standards. This includes testing for various physical and chemical properties, such as specific gravity, particle size distribution, and purity levels. oem barite powder for drilling factory 4. Packaging and Distribution The final step involves packaging the barite powder in bulk bags or containers, ready for distribution to drilling companies . The OEM aspect ensures that the packaging can be customized according to the specific requirements of clients. Applications of OEM Barite Powder in Drilling OEM barite powder finds extensive use in various drilling applications, including 1. Oil and Gas Exploration In the oil and gas industry, barite powder is an indispensable component of drilling mud. It helps maintain wellbore stability and controls downhole pressure, which is vital for safe and efficient drilling operations. 2. Mining Operations Apart from oil and gas, barite is also used in the mining sector, where it serves similar functions in the drilling process to extract valuable minerals. 3. Construction Industry Barite powder is utilized in cement production and as a filler in construction materials due to its density and inert properties. This application demonstrates the versatility of barite beyond the drilling industry. 4. Environmental Applications In certain environmental drilling projects, barite is employed as a tracer and as part of remediation efforts, showcasing its multifaceted utility. Conclusion The significance of OEM barite powder in the drilling industry cannot be overstated. Its ability to enhance drilling efficiency and safety makes it a vital resource for oil and gas extraction as well as other mining operations. As the demand for energy continues to grow, the role of high-quality barite powder in drilling activities will become increasingly critical. Manufacturers are tasked with producing consistent, high-purity barite powder that meets the evolving needs of the industry. Therefore, understanding the manufacturing process and applications of OEM barite powder is essential for stakeholders looking to optimize their drilling operations and maintain a competitive edge in the market._custom glass marbles2025-08-17 21:05Read(2364)In addition to environmental advantages, fly ash suppliers often focus on the economic benefits of using fly ash. Not only does it reduce the cost of construction materials by providing a less expensive alternative to conventional cement, but it also promotes the concept of recycling industrial waste. By using fly ash, construction companies can contribute to a circular economy, where waste materials are repurposed into valuable products, ultimately minimizing landfill space and promoting resource efficiency.

...

Read MoreOEM Barite Powder for Drilling Applications from Trusted Manufacturing Source******The Importance of OEM Barite Powder for Drilling A Closer Look at the Manufacturing Process and Its Applications Barite, a naturally occurring mineral composed of barium sulfate (BaSO4), plays a pivotal role in the drilling industry, particularly in oil and gas extraction. The demand for high-quality barite powder has surged over the years, leading to the emergence of various manufacturers that provide OEM (Original Equipment Manufacturer) barite powder specifically tailored for drilling purposes. This article explores the significance of OEM barite powder, the manufacturing process involved, and its diverse applications in the drilling sector. Understanding Barite Powder in Drilling In the drilling industry, barite powder serves as a crucial weighting agent in drilling mud. The high density of barite, typically ranging from 4.2 to 4.5 g/cm3, helps to counteract the pressures encountered during drilling operations, stabilizing the borehole and preventing blowouts. Additionally, barite improves the viscosity of drilling fluids, enhancing their ability to carry rock cuttings to the surface and facilitate the efficient operation of the drilling machinery. The Manufacturing Process of OEM Barite Powder The production of OEM barite powder involves several distinct steps, each crucial to ensuring the quality and suitability of the product for drilling applications 1. Mining and Extraction Barite is mined from natural deposits, typically found in sedimentary rocks. The extraction process includes crushing the ore and removing impurities to obtain high-purity barite. 2. Grinding and Milling Once the raw barite is obtained, it undergoes rigorous grinding and milling processes to achieve the desired particle size. This step is essential as the fineness of the barite powder directly influences its performance in drilling applications. 3. Quality Control OEM manufacturers typically implement stringent quality control measures to ensure that the barite powder meets industry standards. This includes testing for various physical and chemical properties, such as specific gravity, particle size distribution, and purity levels. oem barite powder for drilling factory 4. Packaging and Distribution The final step involves packaging the barite powder in bulk bags or containers, ready for distribution to drilling companies . The OEM aspect ensures that the packaging can be customized according to the specific requirements of clients. Applications of OEM Barite Powder in Drilling OEM barite powder finds extensive use in various drilling applications, including 1. Oil and Gas Exploration In the oil and gas industry, barite powder is an indispensable component of drilling mud. It helps maintain wellbore stability and controls downhole pressure, which is vital for safe and efficient drilling operations. 2. Mining Operations Apart from oil and gas, barite is also used in the mining sector, where it serves similar functions in the drilling process to extract valuable minerals. 3. Construction Industry Barite powder is utilized in cement production and as a filler in construction materials due to its density and inert properties. This application demonstrates the versatility of barite beyond the drilling industry. 4. Environmental Applications In certain environmental drilling projects, barite is employed as a tracer and as part of remediation efforts, showcasing its multifaceted utility. Conclusion The significance of OEM barite powder in the drilling industry cannot be overstated. Its ability to enhance drilling efficiency and safety makes it a vital resource for oil and gas extraction as well as other mining operations. As the demand for energy continues to grow, the role of high-quality barite powder in drilling activities will become increasingly critical. Manufacturers are tasked with producing consistent, high-purity barite powder that meets the evolving needs of the industry. Therefore, understanding the manufacturing process and applications of OEM barite powder is essential for stakeholders looking to optimize their drilling operations and maintain a competitive edge in the market._custom glass marbles2025-08-17 20:43Read(1612)виробники фарбованих склянів

Виробництво вітражних бісерів в Україні мистецтво та інновації Вітражні бісери стали невід’ємною час...

Read MoreOEM Barite Powder for Drilling Applications from Trusted Manufacturing Source******The Importance of OEM Barite Powder for Drilling A Closer Look at the Manufacturing Process and Its Applications Barite, a naturally occurring mineral composed of barium sulfate (BaSO4), plays a pivotal role in the drilling industry, particularly in oil and gas extraction. The demand for high-quality barite powder has surged over the years, leading to the emergence of various manufacturers that provide OEM (Original Equipment Manufacturer) barite powder specifically tailored for drilling purposes. This article explores the significance of OEM barite powder, the manufacturing process involved, and its diverse applications in the drilling sector. Understanding Barite Powder in Drilling In the drilling industry, barite powder serves as a crucial weighting agent in drilling mud. The high density of barite, typically ranging from 4.2 to 4.5 g/cm3, helps to counteract the pressures encountered during drilling operations, stabilizing the borehole and preventing blowouts. Additionally, barite improves the viscosity of drilling fluids, enhancing their ability to carry rock cuttings to the surface and facilitate the efficient operation of the drilling machinery. The Manufacturing Process of OEM Barite Powder The production of OEM barite powder involves several distinct steps, each crucial to ensuring the quality and suitability of the product for drilling applications 1. Mining and Extraction Barite is mined from natural deposits, typically found in sedimentary rocks. The extraction process includes crushing the ore and removing impurities to obtain high-purity barite. 2. Grinding and Milling Once the raw barite is obtained, it undergoes rigorous grinding and milling processes to achieve the desired particle size. This step is essential as the fineness of the barite powder directly influences its performance in drilling applications. 3. Quality Control OEM manufacturers typically implement stringent quality control measures to ensure that the barite powder meets industry standards. This includes testing for various physical and chemical properties, such as specific gravity, particle size distribution, and purity levels. oem barite powder for drilling factory 4. Packaging and Distribution The final step involves packaging the barite powder in bulk bags or containers, ready for distribution to drilling companies . The OEM aspect ensures that the packaging can be customized according to the specific requirements of clients. Applications of OEM Barite Powder in Drilling OEM barite powder finds extensive use in various drilling applications, including 1. Oil and Gas Exploration In the oil and gas industry, barite powder is an indispensable component of drilling mud. It helps maintain wellbore stability and controls downhole pressure, which is vital for safe and efficient drilling operations. 2. Mining Operations Apart from oil and gas, barite is also used in the mining sector, where it serves similar functions in the drilling process to extract valuable minerals. 3. Construction Industry Barite powder is utilized in cement production and as a filler in construction materials due to its density and inert properties. This application demonstrates the versatility of barite beyond the drilling industry. 4. Environmental Applications In certain environmental drilling projects, barite is employed as a tracer and as part of remediation efforts, showcasing its multifaceted utility. Conclusion The significance of OEM barite powder in the drilling industry cannot be overstated. Its ability to enhance drilling efficiency and safety makes it a vital resource for oil and gas extraction as well as other mining operations. As the demand for energy continues to grow, the role of high-quality barite powder in drilling activities will become increasingly critical. Manufacturers are tasked with producing consistent, high-purity barite powder that meets the evolving needs of the industry. Therefore, understanding the manufacturing process and applications of OEM barite powder is essential for stakeholders looking to optimize their drilling operations and maintain a competitive edge in the market._custom glass marbles2025-08-17 20:34Read(627)Custom Pumice Stone for Plants A Sustainable Solution for Modern Agriculture

...

Read MoreOEM Barite Powder for Drilling Applications from Trusted Manufacturing Source******The Importance of OEM Barite Powder for Drilling A Closer Look at the Manufacturing Process and Its Applications Barite, a naturally occurring mineral composed of barium sulfate (BaSO4), plays a pivotal role in the drilling industry, particularly in oil and gas extraction. The demand for high-quality barite powder has surged over the years, leading to the emergence of various manufacturers that provide OEM (Original Equipment Manufacturer) barite powder specifically tailored for drilling purposes. This article explores the significance of OEM barite powder, the manufacturing process involved, and its diverse applications in the drilling sector. Understanding Barite Powder in Drilling In the drilling industry, barite powder serves as a crucial weighting agent in drilling mud. The high density of barite, typically ranging from 4.2 to 4.5 g/cm3, helps to counteract the pressures encountered during drilling operations, stabilizing the borehole and preventing blowouts. Additionally, barite improves the viscosity of drilling fluids, enhancing their ability to carry rock cuttings to the surface and facilitate the efficient operation of the drilling machinery. The Manufacturing Process of OEM Barite Powder The production of OEM barite powder involves several distinct steps, each crucial to ensuring the quality and suitability of the product for drilling applications 1. Mining and Extraction Barite is mined from natural deposits, typically found in sedimentary rocks. The extraction process includes crushing the ore and removing impurities to obtain high-purity barite. 2. Grinding and Milling Once the raw barite is obtained, it undergoes rigorous grinding and milling processes to achieve the desired particle size. This step is essential as the fineness of the barite powder directly influences its performance in drilling applications. 3. Quality Control OEM manufacturers typically implement stringent quality control measures to ensure that the barite powder meets industry standards. This includes testing for various physical and chemical properties, such as specific gravity, particle size distribution, and purity levels. oem barite powder for drilling factory 4. Packaging and Distribution The final step involves packaging the barite powder in bulk bags or containers, ready for distribution to drilling companies . The OEM aspect ensures that the packaging can be customized according to the specific requirements of clients. Applications of OEM Barite Powder in Drilling OEM barite powder finds extensive use in various drilling applications, including 1. Oil and Gas Exploration In the oil and gas industry, barite powder is an indispensable component of drilling mud. It helps maintain wellbore stability and controls downhole pressure, which is vital for safe and efficient drilling operations. 2. Mining Operations Apart from oil and gas, barite is also used in the mining sector, where it serves similar functions in the drilling process to extract valuable minerals. 3. Construction Industry Barite powder is utilized in cement production and as a filler in construction materials due to its density and inert properties. This application demonstrates the versatility of barite beyond the drilling industry. 4. Environmental Applications In certain environmental drilling projects, barite is employed as a tracer and as part of remediation efforts, showcasing its multifaceted utility. Conclusion The significance of OEM barite powder in the drilling industry cannot be overstated. Its ability to enhance drilling efficiency and safety makes it a vital resource for oil and gas extraction as well as other mining operations. As the demand for energy continues to grow, the role of high-quality barite powder in drilling activities will become increasingly critical. Manufacturers are tasked with producing consistent, high-purity barite powder that meets the evolving needs of the industry. Therefore, understanding the manufacturing process and applications of OEM barite powder is essential for stakeholders looking to optimize their drilling operations and maintain a competitive edge in the market._custom glass marbles2025-08-17 20:01Read(357)