Current location:

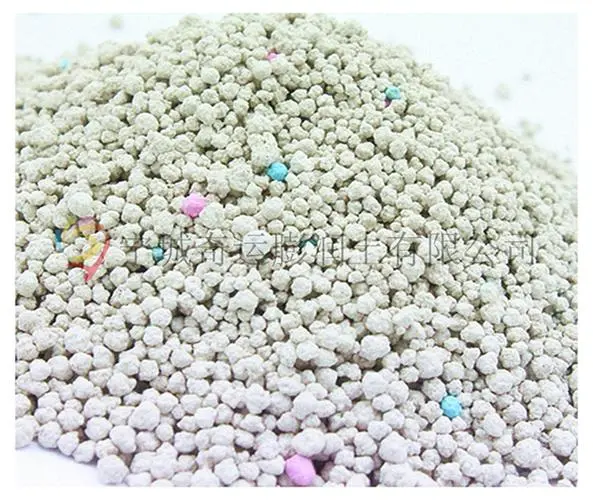

oem zeolite producers factory_oem zeolite producers factory

oem lava rock factory

OEM Lava Rock Factory A Beacon of Innovation in Natural Materials In the realm of natural materials,...

- " title=''>" title=''>

...

china bulk bentonite clay for sale

Bulk Bentonite Clay for Sale in China A Comprehensive Overview Bentonite clay, a versatile natural p...

Sustainable Solutions with Bagged Fly Ash - Eco-Friendly Building Materials

The Benefits and Applications of Bagged Fly Ash in Construction Fly ash, a byproduct from burning pu...

Black Iron Oxide Production Facilities and Their Manufacturing Processes

The Role of Black Iron Oxide Factories in Modern Industry Black iron oxide, a compound known for its...

Mineralholdige stoffer og deres betydning i moderne industri

Mineraler og deres betydning for helsen Mineraler er kjemiske forbindelser som finnes naturlig i jor...

china aluminium oxide grinding factories

The Role of Aluminium Oxide Grinding Factories in China China has become a global leader in the prod...

Links: