'>8

Netizens pay attention

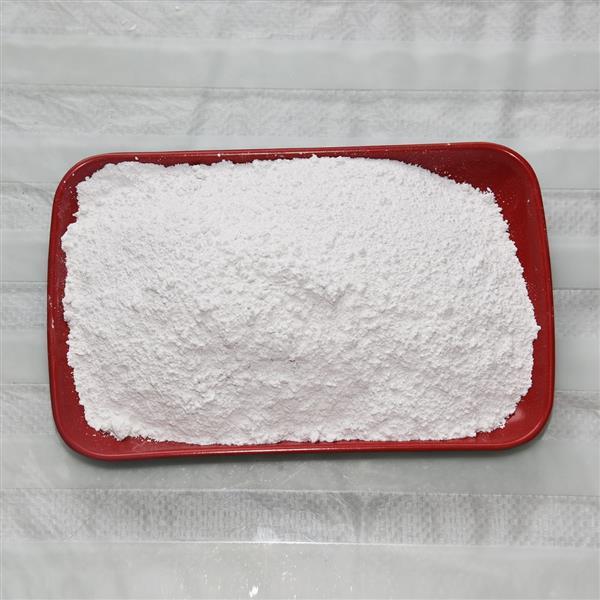

Top Manufacturers for Bulk OEM Perlite Supply and Production Solutions

2025-08-17 12:20Read1886Visitors

Decorative Glass Beads Manufacturing and Design Services for Unique Home and Fashion Accessories

2025-08-17 12:16Read2372Visitors

Exploring Sepiolite Production in China's Leading Factories and Their Global Impact

2025-08-17 11:29Read2960Visitors

zeochem zeolite manufacturer

2025-08-17 10:52Read967Visitors

Looked and looked

- تولیدکننده گیاهان پرلیت با کیفیت بالا و راه حل های نوآورانه برای کشت بهینه

- The Benefits and Applications of OEM Pulverised Fly Ash in Construction Industry

- custom natural zeolite powder manufacturer

- " title=''>

Links: