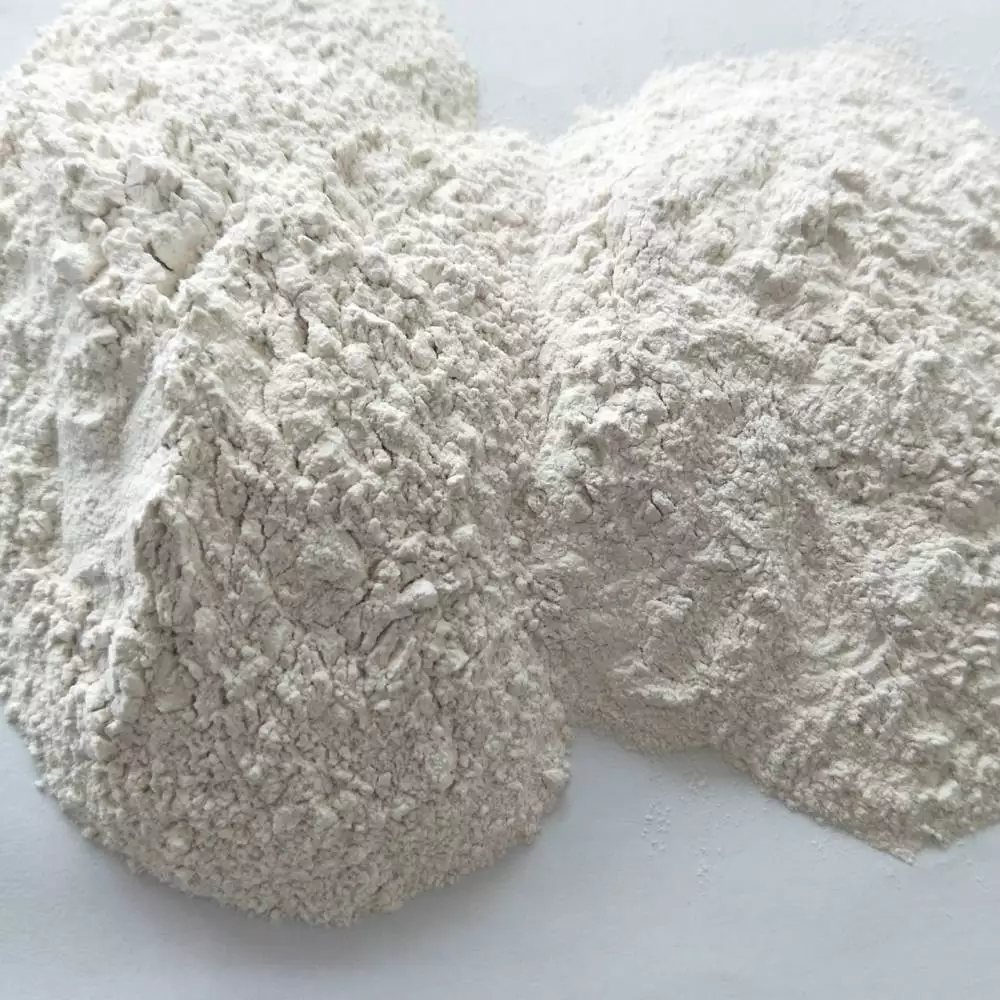

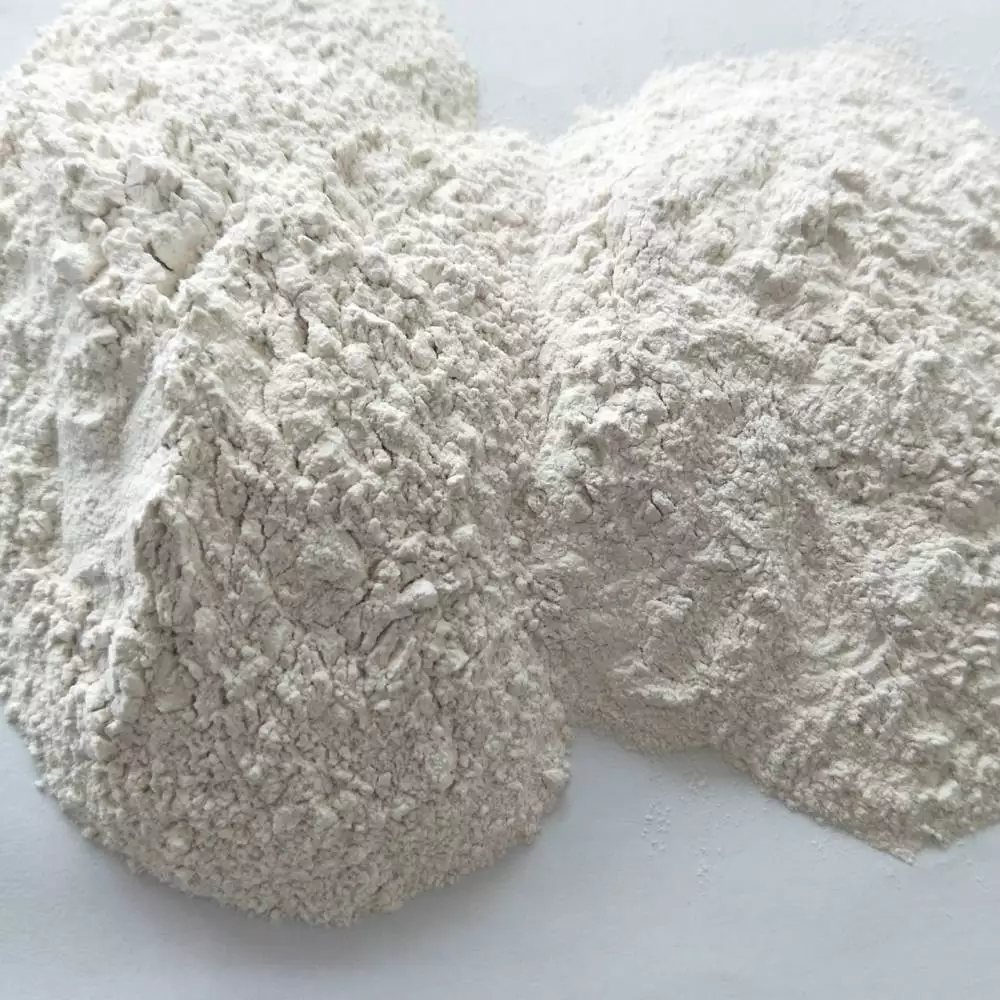

- 3. Beachside Oyster Shells******The Oyster Shell Sand A Unique and Intriguing Natural Phenomenon The oyster shell sand, a fascinating natural phenomenon, is formed from the accumulation of oyster shells over time. This unique type of sand is found in various coastal regions around the world, each with its own distinct characteristics and beauty. The process of oyster shell sand formation begins with the growth of oysters in the ocean. As they feed on plankton and other small organisms, oysters excrete calcium carbonate, which eventually hardens into shells. Over time, these shells accumulate on the ocean floor, forming a layer of oyster shell sand. One of the most striking features of oyster shell sand is its bright white color, which contrasts sharply with the surrounding environment. This color comes from the high concentration of calcium carbonate in the shells, which reflects sunlight and gives the sand its distinctive hue. Another intriguing aspect of oyster shell sand is its unique texture. Unlike regular sand, which is made up of small, angular grains, oyster shell sand has a smoother, more rounded texture. This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges oyster shell sand . Oyster shell sand also plays an important role in coastal ecosystems. As a source of calcium carbonate, it provides a vital nutrient for many marine organisms, including corals and some types of seaweed. Additionally, the rough texture of oyster shell sand creates a habitat for small marine creatures, such as crabs and shrimp, which use the shells as shelter. In recent years, oyster shell sand has gained popularity as a building material and landscaping element. Its unique appearance and natural properties make it an attractive alternative to traditional building materials like concrete and gravel. Many homeowners and landscape architects are now incorporating oyster shell sand into their projects, creating stunning outdoor spaces that blend seamlessly with their surroundings. In conclusion, the oyster shell sand is a truly remarkable natural phenomenon that showcases the beauty and complexity of our planet's ecosystems. Its bright white color, unique texture, and important role in coastal ecosystems make it a valuable resource that continues to inspire and captivate people around the world.>

- 3. Beachside Oyster Shells******The Oyster Shell Sand A Unique and Intriguing Natural Phenomenon The oyster shell sand, a fascinating natural phenomenon, is formed from the accumulation of oyster shells over time. This unique type of sand is found in various coastal regions around the world, each with its own distinct characteristics and beauty. The process of oyster shell sand formation begins with the growth of oysters in the ocean. As they feed on plankton and other small organisms, oysters excrete calcium carbonate, which eventually hardens into shells. Over time, these shells accumulate on the ocean floor, forming a layer of oyster shell sand. One of the most striking features of oyster shell sand is its bright white color, which contrasts sharply with the surrounding environment. This color comes from the high concentration of calcium carbonate in the shells, which reflects sunlight and gives the sand its distinctive hue. Another intriguing aspect of oyster shell sand is its unique texture. Unlike regular sand, which is made up of small, angular grains, oyster shell sand has a smoother, more rounded texture. This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges oyster shell sand . Oyster shell sand also plays an important role in coastal ecosystems. As a source of calcium carbonate, it provides a vital nutrient for many marine organisms, including corals and some types of seaweed. Additionally, the rough texture of oyster shell sand creates a habitat for small marine creatures, such as crabs and shrimp, which use the shells as shelter. In recent years, oyster shell sand has gained popularity as a building material and landscaping element. Its unique appearance and natural properties make it an attractive alternative to traditional building materials like concrete and gravel. Many homeowners and landscape architects are now incorporating oyster shell sand into their projects, creating stunning outdoor spaces that blend seamlessly with their surroundings. In conclusion, the oyster shell sand is a truly remarkable natural phenomenon that showcases the beauty and complexity of our planet's ecosystems. Its bright white color, unique texture, and important role in coastal ecosystems make it a valuable resource that continues to inspire and captivate people around the world._brown oxide color

3. Beachside Oyster Shells******The Oyster Shell Sand A Unique and Intriguing Natural Phenomenon The oyster shell sand, a fascinating natural phenomenon, is formed from the accumulation of oyster shells over time. This unique type of sand is found in various coastal regions around the world, each with its own distinct characteristics and beauty. The process of oyster shell sand formation begins with the growth of oysters in the ocean. As they feed on plankton and other small organisms, oysters excrete calcium carbonate, which eventually hardens into shells. Over time, these shells accumulate on the ocean floor, forming a layer of oyster shell sand. One of the most striking features of oyster shell sand is its bright white color, which contrasts sharply with the surrounding environment. This color comes from the high concentration of calcium carbonate in the shells, which reflects sunlight and gives the sand its distinctive hue. Another intriguing aspect of oyster shell sand is its unique texture. Unlike regular sand, which is made up of small, angular grains, oyster shell sand has a smoother, more rounded texture. This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges oyster shell sand . Oyster shell sand also plays an important role in coastal ecosystems. As a source of calcium carbonate, it provides a vital nutrient for many marine organisms, including corals and some types of seaweed. Additionally, the rough texture of oyster shell sand creates a habitat for small marine creatures, such as crabs and shrimp, which use the shells as shelter. In recent years, oyster shell sand has gained popularity as a building material and landscaping element. Its unique appearance and natural properties make it an attractive alternative to traditional building materials like concrete and gravel. Many homeowners and landscape architects are now incorporating oyster shell sand into their projects, creating stunning outdoor spaces that blend seamlessly with their surroundings. In conclusion, the oyster shell sand is a truly remarkable natural phenomenon that showcases the beauty and complexity of our planet's ecosystems. Its bright white color, unique texture, and important role in coastal ecosystems make it a valuable resource that continues to inspire and captivate people around the world._brown oxide color

modern cobblestone driveway

The Modern Cobblestone Driveway Blending Tradition with Contemporary Design A driveway is more than...

Read More3. Beachside Oyster Shells******The Oyster Shell Sand A Unique and Intriguing Natural Phenomenon The oyster shell sand, a fascinating natural phenomenon, is formed from the accumulation of oyster shells over time. This unique type of sand is found in various coastal regions around the world, each with its own distinct characteristics and beauty. The process of oyster shell sand formation begins with the growth of oysters in the ocean. As they feed on plankton and other small organisms, oysters excrete calcium carbonate, which eventually hardens into shells. Over time, these shells accumulate on the ocean floor, forming a layer of oyster shell sand. One of the most striking features of oyster shell sand is its bright white color, which contrasts sharply with the surrounding environment. This color comes from the high concentration of calcium carbonate in the shells, which reflects sunlight and gives the sand its distinctive hue. Another intriguing aspect of oyster shell sand is its unique texture. Unlike regular sand, which is made up of small, angular grains, oyster shell sand has a smoother, more rounded texture. This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges oyster shell sand . Oyster shell sand also plays an important role in coastal ecosystems. As a source of calcium carbonate, it provides a vital nutrient for many marine organisms, including corals and some types of seaweed. Additionally, the rough texture of oyster shell sand creates a habitat for small marine creatures, such as crabs and shrimp, which use the shells as shelter. In recent years, oyster shell sand has gained popularity as a building material and landscaping element. Its unique appearance and natural properties make it an attractive alternative to traditional building materials like concrete and gravel. Many homeowners and landscape architects are now incorporating oyster shell sand into their projects, creating stunning outdoor spaces that blend seamlessly with their surroundings. In conclusion, the oyster shell sand is a truly remarkable natural phenomenon that showcases the beauty and complexity of our planet's ecosystems. Its bright white color, unique texture, and important role in coastal ecosystems make it a valuable resource that continues to inspire and captivate people around the world._brown oxide color2025-08-17 11:45Read(2613)" title='

'>

...

Read More3. Beachside Oyster Shells******The Oyster Shell Sand A Unique and Intriguing Natural Phenomenon The oyster shell sand, a fascinating natural phenomenon, is formed from the accumulation of oyster shells over time. This unique type of sand is found in various coastal regions around the world, each with its own distinct characteristics and beauty. The process of oyster shell sand formation begins with the growth of oysters in the ocean. As they feed on plankton and other small organisms, oysters excrete calcium carbonate, which eventually hardens into shells. Over time, these shells accumulate on the ocean floor, forming a layer of oyster shell sand. One of the most striking features of oyster shell sand is its bright white color, which contrasts sharply with the surrounding environment. This color comes from the high concentration of calcium carbonate in the shells, which reflects sunlight and gives the sand its distinctive hue. Another intriguing aspect of oyster shell sand is its unique texture. Unlike regular sand, which is made up of small, angular grains, oyster shell sand has a smoother, more rounded texture. This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges oyster shell sand . Oyster shell sand also plays an important role in coastal ecosystems. As a source of calcium carbonate, it provides a vital nutrient for many marine organisms, including corals and some types of seaweed. Additionally, the rough texture of oyster shell sand creates a habitat for small marine creatures, such as crabs and shrimp, which use the shells as shelter. In recent years, oyster shell sand has gained popularity as a building material and landscaping element. Its unique appearance and natural properties make it an attractive alternative to traditional building materials like concrete and gravel. Many homeowners and landscape architects are now incorporating oyster shell sand into their projects, creating stunning outdoor spaces that blend seamlessly with their surroundings. In conclusion, the oyster shell sand is a truly remarkable natural phenomenon that showcases the beauty and complexity of our planet's ecosystems. Its bright white color, unique texture, and important role in coastal ecosystems make it a valuable resource that continues to inspire and captivate people around the world._brown oxide color2025-08-17 11:24Read(2226)One of the primary uses of custom perlite ore is in the production of lightweight aggregates. These aggregates are used in a variety of construction materials, such as concrete and plasterboard, to reduce their weight without sacrificing strength or durability. The porous nature of perlite also allows it to absorb and retain water, making it an effective moisture regulator in building materials.

...

Read More3. Beachside Oyster Shells******The Oyster Shell Sand A Unique and Intriguing Natural Phenomenon The oyster shell sand, a fascinating natural phenomenon, is formed from the accumulation of oyster shells over time. This unique type of sand is found in various coastal regions around the world, each with its own distinct characteristics and beauty. The process of oyster shell sand formation begins with the growth of oysters in the ocean. As they feed on plankton and other small organisms, oysters excrete calcium carbonate, which eventually hardens into shells. Over time, these shells accumulate on the ocean floor, forming a layer of oyster shell sand. One of the most striking features of oyster shell sand is its bright white color, which contrasts sharply with the surrounding environment. This color comes from the high concentration of calcium carbonate in the shells, which reflects sunlight and gives the sand its distinctive hue. Another intriguing aspect of oyster shell sand is its unique texture. Unlike regular sand, which is made up of small, angular grains, oyster shell sand has a smoother, more rounded texture. This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges oyster shell sand . Oyster shell sand also plays an important role in coastal ecosystems. As a source of calcium carbonate, it provides a vital nutrient for many marine organisms, including corals and some types of seaweed. Additionally, the rough texture of oyster shell sand creates a habitat for small marine creatures, such as crabs and shrimp, which use the shells as shelter. In recent years, oyster shell sand has gained popularity as a building material and landscaping element. Its unique appearance and natural properties make it an attractive alternative to traditional building materials like concrete and gravel. Many homeowners and landscape architects are now incorporating oyster shell sand into their projects, creating stunning outdoor spaces that blend seamlessly with their surroundings. In conclusion, the oyster shell sand is a truly remarkable natural phenomenon that showcases the beauty and complexity of our planet's ecosystems. Its bright white color, unique texture, and important role in coastal ecosystems make it a valuable resource that continues to inspire and captivate people around the world._brown oxide color2025-08-17 10:41Read(2250)CDC9. But bentonite clay may help where conventional medicine cannot.'>

Serious bacterial infections like MRSA—a form of staph that's resistant to many forms of antibiotics—are no joke. It can cause problems ranging from skin infections and sepsis to pneumonia to bloodstream infections, according to the CDC9. But bentonite clay may help where conventional medicine cannot.

...

Read More3. Beachside Oyster Shells******The Oyster Shell Sand A Unique and Intriguing Natural Phenomenon The oyster shell sand, a fascinating natural phenomenon, is formed from the accumulation of oyster shells over time. This unique type of sand is found in various coastal regions around the world, each with its own distinct characteristics and beauty. The process of oyster shell sand formation begins with the growth of oysters in the ocean. As they feed on plankton and other small organisms, oysters excrete calcium carbonate, which eventually hardens into shells. Over time, these shells accumulate on the ocean floor, forming a layer of oyster shell sand. One of the most striking features of oyster shell sand is its bright white color, which contrasts sharply with the surrounding environment. This color comes from the high concentration of calcium carbonate in the shells, which reflects sunlight and gives the sand its distinctive hue. Another intriguing aspect of oyster shell sand is its unique texture. Unlike regular sand, which is made up of small, angular grains, oyster shell sand has a smoother, more rounded texture. This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges oyster shell sand . Oyster shell sand also plays an important role in coastal ecosystems. As a source of calcium carbonate, it provides a vital nutrient for many marine organisms, including corals and some types of seaweed. Additionally, the rough texture of oyster shell sand creates a habitat for small marine creatures, such as crabs and shrimp, which use the shells as shelter. In recent years, oyster shell sand has gained popularity as a building material and landscaping element. Its unique appearance and natural properties make it an attractive alternative to traditional building materials like concrete and gravel. Many homeowners and landscape architects are now incorporating oyster shell sand into their projects, creating stunning outdoor spaces that blend seamlessly with their surroundings. In conclusion, the oyster shell sand is a truly remarkable natural phenomenon that showcases the beauty and complexity of our planet's ecosystems. Its bright white color, unique texture, and important role in coastal ecosystems make it a valuable resource that continues to inspire and captivate people around the world._brown oxide color2025-08-17 10:36Read(2362)oem ceramsite for orchid manufacturer

The Importance of OEM Ceramsite for Orchid Cultivation Orchids are a beloved group of flowering plan...

Read More3. Beachside Oyster Shells******The Oyster Shell Sand A Unique and Intriguing Natural Phenomenon The oyster shell sand, a fascinating natural phenomenon, is formed from the accumulation of oyster shells over time. This unique type of sand is found in various coastal regions around the world, each with its own distinct characteristics and beauty. The process of oyster shell sand formation begins with the growth of oysters in the ocean. As they feed on plankton and other small organisms, oysters excrete calcium carbonate, which eventually hardens into shells. Over time, these shells accumulate on the ocean floor, forming a layer of oyster shell sand. One of the most striking features of oyster shell sand is its bright white color, which contrasts sharply with the surrounding environment. This color comes from the high concentration of calcium carbonate in the shells, which reflects sunlight and gives the sand its distinctive hue. Another intriguing aspect of oyster shell sand is its unique texture. Unlike regular sand, which is made up of small, angular grains, oyster shell sand has a smoother, more rounded texture. This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges oyster shell sand . Oyster shell sand also plays an important role in coastal ecosystems. As a source of calcium carbonate, it provides a vital nutrient for many marine organisms, including corals and some types of seaweed. Additionally, the rough texture of oyster shell sand creates a habitat for small marine creatures, such as crabs and shrimp, which use the shells as shelter. In recent years, oyster shell sand has gained popularity as a building material and landscaping element. Its unique appearance and natural properties make it an attractive alternative to traditional building materials like concrete and gravel. Many homeowners and landscape architects are now incorporating oyster shell sand into their projects, creating stunning outdoor spaces that blend seamlessly with their surroundings. In conclusion, the oyster shell sand is a truly remarkable natural phenomenon that showcases the beauty and complexity of our planet's ecosystems. Its bright white color, unique texture, and important role in coastal ecosystems make it a valuable resource that continues to inspire and captivate people around the world._brown oxide color2025-08-17 10:21Read(580)...

Read More3. Beachside Oyster Shells******The Oyster Shell Sand A Unique and Intriguing Natural Phenomenon The oyster shell sand, a fascinating natural phenomenon, is formed from the accumulation of oyster shells over time. This unique type of sand is found in various coastal regions around the world, each with its own distinct characteristics and beauty. The process of oyster shell sand formation begins with the growth of oysters in the ocean. As they feed on plankton and other small organisms, oysters excrete calcium carbonate, which eventually hardens into shells. Over time, these shells accumulate on the ocean floor, forming a layer of oyster shell sand. One of the most striking features of oyster shell sand is its bright white color, which contrasts sharply with the surrounding environment. This color comes from the high concentration of calcium carbonate in the shells, which reflects sunlight and gives the sand its distinctive hue. Another intriguing aspect of oyster shell sand is its unique texture. Unlike regular sand, which is made up of small, angular grains, oyster shell sand has a smoother, more rounded texture. This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges oyster shell sand . Oyster shell sand also plays an important role in coastal ecosystems. As a source of calcium carbonate, it provides a vital nutrient for many marine organisms, including corals and some types of seaweed. Additionally, the rough texture of oyster shell sand creates a habitat for small marine creatures, such as crabs and shrimp, which use the shells as shelter. In recent years, oyster shell sand has gained popularity as a building material and landscaping element. Its unique appearance and natural properties make it an attractive alternative to traditional building materials like concrete and gravel. Many homeowners and landscape architects are now incorporating oyster shell sand into their projects, creating stunning outdoor spaces that blend seamlessly with their surroundings. In conclusion, the oyster shell sand is a truly remarkable natural phenomenon that showcases the beauty and complexity of our planet's ecosystems. Its bright white color, unique texture, and important role in coastal ecosystems make it a valuable resource that continues to inspire and captivate people around the world._brown oxide color2025-08-17 10:16Read(401)Optimal Perlite Use for Enhancing Citrus Tree Growth and Soil Quality

Perlite for Citrus Trees Enhancing Growth and Health Citrus trees are prized for their vibrant fruit...

Read More3. Beachside Oyster Shells******The Oyster Shell Sand A Unique and Intriguing Natural Phenomenon The oyster shell sand, a fascinating natural phenomenon, is formed from the accumulation of oyster shells over time. This unique type of sand is found in various coastal regions around the world, each with its own distinct characteristics and beauty. The process of oyster shell sand formation begins with the growth of oysters in the ocean. As they feed on plankton and other small organisms, oysters excrete calcium carbonate, which eventually hardens into shells. Over time, these shells accumulate on the ocean floor, forming a layer of oyster shell sand. One of the most striking features of oyster shell sand is its bright white color, which contrasts sharply with the surrounding environment. This color comes from the high concentration of calcium carbonate in the shells, which reflects sunlight and gives the sand its distinctive hue. Another intriguing aspect of oyster shell sand is its unique texture. Unlike regular sand, which is made up of small, angular grains, oyster shell sand has a smoother, more rounded texture. This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges oyster shell sand . Oyster shell sand also plays an important role in coastal ecosystems. As a source of calcium carbonate, it provides a vital nutrient for many marine organisms, including corals and some types of seaweed. Additionally, the rough texture of oyster shell sand creates a habitat for small marine creatures, such as crabs and shrimp, which use the shells as shelter. In recent years, oyster shell sand has gained popularity as a building material and landscaping element. Its unique appearance and natural properties make it an attractive alternative to traditional building materials like concrete and gravel. Many homeowners and landscape architects are now incorporating oyster shell sand into their projects, creating stunning outdoor spaces that blend seamlessly with their surroundings. In conclusion, the oyster shell sand is a truly remarkable natural phenomenon that showcases the beauty and complexity of our planet's ecosystems. Its bright white color, unique texture, and important role in coastal ecosystems make it a valuable resource that continues to inspire and captivate people around the world._brown oxide color2025-08-17 10:07Read(2275)Since ancient civilization, humans have applied mining techniques when mining rocks and minerals on Earth’s surface. The importance of minerals in our everyday lives can be recognized all around us. From eating nutrient-rich foods to powering smartphones with copper, almost everything we use is a mineral resource. Here are a few common ways we use minerals today.

...

Read More3. Beachside Oyster Shells******The Oyster Shell Sand A Unique and Intriguing Natural Phenomenon The oyster shell sand, a fascinating natural phenomenon, is formed from the accumulation of oyster shells over time. This unique type of sand is found in various coastal regions around the world, each with its own distinct characteristics and beauty. The process of oyster shell sand formation begins with the growth of oysters in the ocean. As they feed on plankton and other small organisms, oysters excrete calcium carbonate, which eventually hardens into shells. Over time, these shells accumulate on the ocean floor, forming a layer of oyster shell sand. One of the most striking features of oyster shell sand is its bright white color, which contrasts sharply with the surrounding environment. This color comes from the high concentration of calcium carbonate in the shells, which reflects sunlight and gives the sand its distinctive hue. Another intriguing aspect of oyster shell sand is its unique texture. Unlike regular sand, which is made up of small, angular grains, oyster shell sand has a smoother, more rounded texture. This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges oyster shell sand . Oyster shell sand also plays an important role in coastal ecosystems. As a source of calcium carbonate, it provides a vital nutrient for many marine organisms, including corals and some types of seaweed. Additionally, the rough texture of oyster shell sand creates a habitat for small marine creatures, such as crabs and shrimp, which use the shells as shelter. In recent years, oyster shell sand has gained popularity as a building material and landscaping element. Its unique appearance and natural properties make it an attractive alternative to traditional building materials like concrete and gravel. Many homeowners and landscape architects are now incorporating oyster shell sand into their projects, creating stunning outdoor spaces that blend seamlessly with their surroundings. In conclusion, the oyster shell sand is a truly remarkable natural phenomenon that showcases the beauty and complexity of our planet's ecosystems. Its bright white color, unique texture, and important role in coastal ecosystems make it a valuable resource that continues to inspire and captivate people around the world._brown oxide color2025-08-17 09:54Read(892)Exploring the Versatile Uses and Benefits of Cultured Stone in Modern Architecture and Design

The Aesthetic Appeal and Versatility of Cultured Stone Cap In the world of construction and design,...

Read More3. Beachside Oyster Shells******The Oyster Shell Sand A Unique and Intriguing Natural Phenomenon The oyster shell sand, a fascinating natural phenomenon, is formed from the accumulation of oyster shells over time. This unique type of sand is found in various coastal regions around the world, each with its own distinct characteristics and beauty. The process of oyster shell sand formation begins with the growth of oysters in the ocean. As they feed on plankton and other small organisms, oysters excrete calcium carbonate, which eventually hardens into shells. Over time, these shells accumulate on the ocean floor, forming a layer of oyster shell sand. One of the most striking features of oyster shell sand is its bright white color, which contrasts sharply with the surrounding environment. This color comes from the high concentration of calcium carbonate in the shells, which reflects sunlight and gives the sand its distinctive hue. Another intriguing aspect of oyster shell sand is its unique texture. Unlike regular sand, which is made up of small, angular grains, oyster shell sand has a smoother, more rounded texture. This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges oyster shell sand . Oyster shell sand also plays an important role in coastal ecosystems. As a source of calcium carbonate, it provides a vital nutrient for many marine organisms, including corals and some types of seaweed. Additionally, the rough texture of oyster shell sand creates a habitat for small marine creatures, such as crabs and shrimp, which use the shells as shelter. In recent years, oyster shell sand has gained popularity as a building material and landscaping element. Its unique appearance and natural properties make it an attractive alternative to traditional building materials like concrete and gravel. Many homeowners and landscape architects are now incorporating oyster shell sand into their projects, creating stunning outdoor spaces that blend seamlessly with their surroundings. In conclusion, the oyster shell sand is a truly remarkable natural phenomenon that showcases the beauty and complexity of our planet's ecosystems. Its bright white color, unique texture, and important role in coastal ecosystems make it a valuable resource that continues to inspire and captivate people around the world._brown oxide color2025-08-17 09:41Read(1934)In conclusion, the topic of corn cob price is complex and multifaceted, with numerous factors influencing its dynamics. It is essential to consider these factors when analyzing trends in corn cob prices and their implications for different stakeholders. By understanding these dynamics, we can make informed decisions about our consumption patterns and support sustainable agricultural practices that benefit both farmers and consumers alike.

...

Read More3. Beachside Oyster Shells******The Oyster Shell Sand A Unique and Intriguing Natural Phenomenon The oyster shell sand, a fascinating natural phenomenon, is formed from the accumulation of oyster shells over time. This unique type of sand is found in various coastal regions around the world, each with its own distinct characteristics and beauty. The process of oyster shell sand formation begins with the growth of oysters in the ocean. As they feed on plankton and other small organisms, oysters excrete calcium carbonate, which eventually hardens into shells. Over time, these shells accumulate on the ocean floor, forming a layer of oyster shell sand. One of the most striking features of oyster shell sand is its bright white color, which contrasts sharply with the surrounding environment. This color comes from the high concentration of calcium carbonate in the shells, which reflects sunlight and gives the sand its distinctive hue. Another intriguing aspect of oyster shell sand is its unique texture. Unlike regular sand, which is made up of small, angular grains, oyster shell sand has a smoother, more rounded texture. This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges This is because the oyster shells are worn down and polished by the action of the waves and the wind, gradually smoothing out their edges oyster shell sand . Oyster shell sand also plays an important role in coastal ecosystems. As a source of calcium carbonate, it provides a vital nutrient for many marine organisms, including corals and some types of seaweed. Additionally, the rough texture of oyster shell sand creates a habitat for small marine creatures, such as crabs and shrimp, which use the shells as shelter. In recent years, oyster shell sand has gained popularity as a building material and landscaping element. Its unique appearance and natural properties make it an attractive alternative to traditional building materials like concrete and gravel. Many homeowners and landscape architects are now incorporating oyster shell sand into their projects, creating stunning outdoor spaces that blend seamlessly with their surroundings. In conclusion, the oyster shell sand is a truly remarkable natural phenomenon that showcases the beauty and complexity of our planet's ecosystems. Its bright white color, unique texture, and important role in coastal ecosystems make it a valuable resource that continues to inspire and captivate people around the world._brown oxide color2025-08-17 09:32Read(1701)

Top Ranking

- 1Factories Producing Chinese Potting Soil Blended with Vermiculite and Perlite for Optimal Growth

- 2China's Zeolite and Bentonite Market Trends and Opportunities for Growth Analysis

- 3china fly ash in concrete mix factory

- 4

- 5oem glass block factory

- 6OEM Iron II Oxide Production Facility for High-Quality Manufacturing Solutions

- 7100 litros de vermut

- " title=''>8

Netizens pay attention

iron on powder

2025-08-17 11:52Read2924Visitors

OEM Titanium Dioxide for PAI Production from Reliable Factories Worldwide

2025-08-17 11:20Read1984Visitors

china micro silica fume manufacturer

2025-08-17 11:02Read1464Visitors

china clay pebbles for gardening factories

2025-08-17 10:59Read187Visitors

Manufacturer of Zeolite and Bentonite Products for Industrial Applications and Environmental Solutio

2025-08-17 10:15Read765Visitors

Looked and looked

- Exploring the Uses and Benefits of Kaolin Clay Powder in China

- oem sodium bentonite price

- pumice rock for sale

- alumina al203

- Unique Custom Pebbles for Plant Care and Creative Home Décor Solutions

Comparative Analysis: Silicon Carbide Vs Aluminum Oxide

- silica fume company

- कस्टम बेंटोनाइट पाउडर के लिए अनुकूलित समाधान और उपयोग विधियाँ

Links: