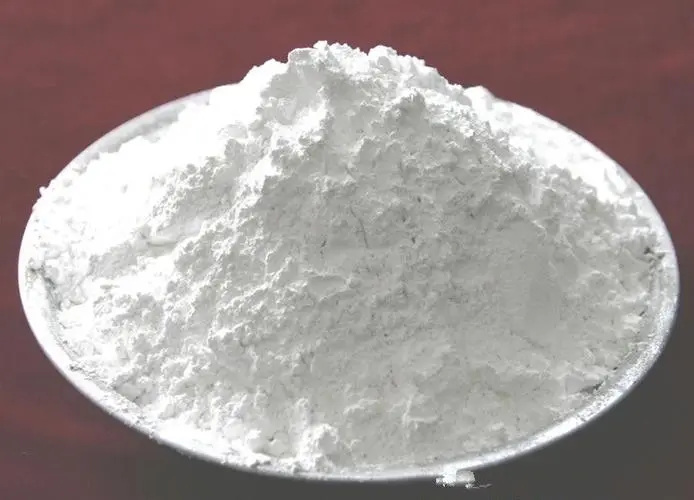

- china titanium dioxide rutile and anatase factory******The Landscape of Titanium Dioxide Production in China Rutile and Anatase China has emerged as a global powerhouse in the production of titanium dioxide (TiO₂), primarily in its two main forms rutile and anatase. This mineral has become indispensable in various industrial applications due to its unique chemical and physical properties, which include high refractive index, strong ultraviolet resistance, and stability in harsh conditions. Understanding Titanium Dioxide Titanium dioxide is a naturally occurring mineral that can be found primarily in two crystalline forms—rutile and anatase. Rutile is known for its high pigment strength and is primarily used in the production of white pigments for paints, coatings, plastics, and paper. It is also utilized in the manufacturing of high-performance products such as cosmetics and food items. In contrast, anatase, although possessing a lower refractive index and less pigmentary strength than rutile, is favored in specific applications, including photocatalysis and solar energy conversion. China's Dominance in TiO₂ Production The scale of titanium dioxide production in China is astounding. The country has established a vast network of factories dedicated to producing this mineral, making it the largest producer globally. The production methods used in these facilities vary between wet and dry techniques, with the former being more common for rutile production and the latter predominantly used for anatase. China's dominance in the titanium dioxide market is attributed to various factors, including the availability of abundant raw materials, such as ilmenite and rutile ores. Additionally, the country's continuous investments in technology and infrastructure have led to increased production efficiency and capacity. Chinese manufacturers have also emphasized eco-friendly production processes to meet international environmental standards, which enhances their competitiveness in the global market. china titanium dioxide rutile and anatase factory Quality and Applications Chinese titanium dioxide producers have made significant strides in improving the quality of their products to meet the needs of varying industries. Rutile-grade titanium dioxide is often utilized in high-end applications due to its superior opacity and durability. On the other hand, while anatase TiO₂ is less expensive, it is still highly sought after for countless applications such as in self-cleaning surfaces, water treatment, and as a pigment in various products. Moreover, the demand for titanium dioxide has skyrocketed in recent years due to the burgeoning construction and automotive industries. The ongoing urbanization in China and the increasing use of high-performance coatings contribute to this demand surge. Furthermore, with advancements in technology, the scope of application for TiO₂ continues to expand, including emerging fields such as photovoltaics and environmental remediation. The Future of Titanium Dioxide Production in China As the global economy evolves, so do the challenges and opportunities for titanium dioxide producers in China. While the demand for TiO₂ is expected to remain strong, manufacturers must navigate regulatory scrutiny and environmental concerns. The shift towards sustainability is prompting many factories to abandon harmful chemicals and adopt greener alternatives which can foster innovation. Additionally, competition in the global market is growing, with producers from other regions seeking to increase their share. This competitive landscape necessitates continuous improvement in production practices and product quality from Chinese manufacturers. In conclusion, the titanium dioxide rutile and anatase market in China stands at a pivotal point. As a leader in production, China must balance the competing demands of quality, sustainability, and market expansion. With a focus on innovation and adherence to environmental standards, the future looks promising for China’s titanium dioxide industry. The trajectory of TiO₂ production in China will undoubtedly shape global trends and provide impetus for further advancements in technology and manufacturing processes.>

- china titanium dioxide rutile and anatase factory******The Landscape of Titanium Dioxide Production in China Rutile and Anatase China has emerged as a global powerhouse in the production of titanium dioxide (TiO₂), primarily in its two main forms rutile and anatase. This mineral has become indispensable in various industrial applications due to its unique chemical and physical properties, which include high refractive index, strong ultraviolet resistance, and stability in harsh conditions. Understanding Titanium Dioxide Titanium dioxide is a naturally occurring mineral that can be found primarily in two crystalline forms—rutile and anatase. Rutile is known for its high pigment strength and is primarily used in the production of white pigments for paints, coatings, plastics, and paper. It is also utilized in the manufacturing of high-performance products such as cosmetics and food items. In contrast, anatase, although possessing a lower refractive index and less pigmentary strength than rutile, is favored in specific applications, including photocatalysis and solar energy conversion. China's Dominance in TiO₂ Production The scale of titanium dioxide production in China is astounding. The country has established a vast network of factories dedicated to producing this mineral, making it the largest producer globally. The production methods used in these facilities vary between wet and dry techniques, with the former being more common for rutile production and the latter predominantly used for anatase. China's dominance in the titanium dioxide market is attributed to various factors, including the availability of abundant raw materials, such as ilmenite and rutile ores. Additionally, the country's continuous investments in technology and infrastructure have led to increased production efficiency and capacity. Chinese manufacturers have also emphasized eco-friendly production processes to meet international environmental standards, which enhances their competitiveness in the global market. china titanium dioxide rutile and anatase factory Quality and Applications Chinese titanium dioxide producers have made significant strides in improving the quality of their products to meet the needs of varying industries. Rutile-grade titanium dioxide is often utilized in high-end applications due to its superior opacity and durability. On the other hand, while anatase TiO₂ is less expensive, it is still highly sought after for countless applications such as in self-cleaning surfaces, water treatment, and as a pigment in various products. Moreover, the demand for titanium dioxide has skyrocketed in recent years due to the burgeoning construction and automotive industries. The ongoing urbanization in China and the increasing use of high-performance coatings contribute to this demand surge. Furthermore, with advancements in technology, the scope of application for TiO₂ continues to expand, including emerging fields such as photovoltaics and environmental remediation. The Future of Titanium Dioxide Production in China As the global economy evolves, so do the challenges and opportunities for titanium dioxide producers in China. While the demand for TiO₂ is expected to remain strong, manufacturers must navigate regulatory scrutiny and environmental concerns. The shift towards sustainability is prompting many factories to abandon harmful chemicals and adopt greener alternatives which can foster innovation. Additionally, competition in the global market is growing, with producers from other regions seeking to increase their share. This competitive landscape necessitates continuous improvement in production practices and product quality from Chinese manufacturers. In conclusion, the titanium dioxide rutile and anatase market in China stands at a pivotal point. As a leader in production, China must balance the competing demands of quality, sustainability, and market expansion. With a focus on innovation and adherence to environmental standards, the future looks promising for China’s titanium dioxide industry. The trajectory of TiO₂ production in China will undoubtedly shape global trends and provide impetus for further advancements in technology and manufacturing processes._zeolit powder price

china titanium dioxide rutile and anatase factory******The Landscape of Titanium Dioxide Production in China Rutile and Anatase China has emerged as a global powerhouse in the production of titanium dioxide (TiO₂), primarily in its two main forms rutile and anatase. This mineral has become indispensable in various industrial applications due to its unique chemical and physical properties, which include high refractive index, strong ultraviolet resistance, and stability in harsh conditions. Understanding Titanium Dioxide Titanium dioxide is a naturally occurring mineral that can be found primarily in two crystalline forms—rutile and anatase. Rutile is known for its high pigment strength and is primarily used in the production of white pigments for paints, coatings, plastics, and paper. It is also utilized in the manufacturing of high-performance products such as cosmetics and food items. In contrast, anatase, although possessing a lower refractive index and less pigmentary strength than rutile, is favored in specific applications, including photocatalysis and solar energy conversion. China's Dominance in TiO₂ Production The scale of titanium dioxide production in China is astounding. The country has established a vast network of factories dedicated to producing this mineral, making it the largest producer globally. The production methods used in these facilities vary between wet and dry techniques, with the former being more common for rutile production and the latter predominantly used for anatase. China's dominance in the titanium dioxide market is attributed to various factors, including the availability of abundant raw materials, such as ilmenite and rutile ores. Additionally, the country's continuous investments in technology and infrastructure have led to increased production efficiency and capacity. Chinese manufacturers have also emphasized eco-friendly production processes to meet international environmental standards, which enhances their competitiveness in the global market. china titanium dioxide rutile and anatase factory Quality and Applications Chinese titanium dioxide producers have made significant strides in improving the quality of their products to meet the needs of varying industries. Rutile-grade titanium dioxide is often utilized in high-end applications due to its superior opacity and durability. On the other hand, while anatase TiO₂ is less expensive, it is still highly sought after for countless applications such as in self-cleaning surfaces, water treatment, and as a pigment in various products. Moreover, the demand for titanium dioxide has skyrocketed in recent years due to the burgeoning construction and automotive industries. The ongoing urbanization in China and the increasing use of high-performance coatings contribute to this demand surge. Furthermore, with advancements in technology, the scope of application for TiO₂ continues to expand, including emerging fields such as photovoltaics and environmental remediation. The Future of Titanium Dioxide Production in China As the global economy evolves, so do the challenges and opportunities for titanium dioxide producers in China. While the demand for TiO₂ is expected to remain strong, manufacturers must navigate regulatory scrutiny and environmental concerns. The shift towards sustainability is prompting many factories to abandon harmful chemicals and adopt greener alternatives which can foster innovation. Additionally, competition in the global market is growing, with producers from other regions seeking to increase their share. This competitive landscape necessitates continuous improvement in production practices and product quality from Chinese manufacturers. In conclusion, the titanium dioxide rutile and anatase market in China stands at a pivotal point. As a leader in production, China must balance the competing demands of quality, sustainability, and market expansion. With a focus on innovation and adherence to environmental standards, the future looks promising for China’s titanium dioxide industry. The trajectory of TiO₂ production in China will undoubtedly shape global trends and provide impetus for further advancements in technology and manufacturing processes._zeolit powder price

The price of a corn cob is reasonable.

The topic of corn cob price is a multifaceted issue that encompasses various aspects of the agricult...

Read Morechina titanium dioxide rutile and anatase factory******The Landscape of Titanium Dioxide Production in China Rutile and Anatase China has emerged as a global powerhouse in the production of titanium dioxide (TiO₂), primarily in its two main forms rutile and anatase. This mineral has become indispensable in various industrial applications due to its unique chemical and physical properties, which include high refractive index, strong ultraviolet resistance, and stability in harsh conditions. Understanding Titanium Dioxide Titanium dioxide is a naturally occurring mineral that can be found primarily in two crystalline forms—rutile and anatase. Rutile is known for its high pigment strength and is primarily used in the production of white pigments for paints, coatings, plastics, and paper. It is also utilized in the manufacturing of high-performance products such as cosmetics and food items. In contrast, anatase, although possessing a lower refractive index and less pigmentary strength than rutile, is favored in specific applications, including photocatalysis and solar energy conversion. China's Dominance in TiO₂ Production The scale of titanium dioxide production in China is astounding. The country has established a vast network of factories dedicated to producing this mineral, making it the largest producer globally. The production methods used in these facilities vary between wet and dry techniques, with the former being more common for rutile production and the latter predominantly used for anatase. China's dominance in the titanium dioxide market is attributed to various factors, including the availability of abundant raw materials, such as ilmenite and rutile ores. Additionally, the country's continuous investments in technology and infrastructure have led to increased production efficiency and capacity. Chinese manufacturers have also emphasized eco-friendly production processes to meet international environmental standards, which enhances their competitiveness in the global market. china titanium dioxide rutile and anatase factory Quality and Applications Chinese titanium dioxide producers have made significant strides in improving the quality of their products to meet the needs of varying industries. Rutile-grade titanium dioxide is often utilized in high-end applications due to its superior opacity and durability. On the other hand, while anatase TiO₂ is less expensive, it is still highly sought after for countless applications such as in self-cleaning surfaces, water treatment, and as a pigment in various products. Moreover, the demand for titanium dioxide has skyrocketed in recent years due to the burgeoning construction and automotive industries. The ongoing urbanization in China and the increasing use of high-performance coatings contribute to this demand surge. Furthermore, with advancements in technology, the scope of application for TiO₂ continues to expand, including emerging fields such as photovoltaics and environmental remediation. The Future of Titanium Dioxide Production in China As the global economy evolves, so do the challenges and opportunities for titanium dioxide producers in China. While the demand for TiO₂ is expected to remain strong, manufacturers must navigate regulatory scrutiny and environmental concerns. The shift towards sustainability is prompting many factories to abandon harmful chemicals and adopt greener alternatives which can foster innovation. Additionally, competition in the global market is growing, with producers from other regions seeking to increase their share. This competitive landscape necessitates continuous improvement in production practices and product quality from Chinese manufacturers. In conclusion, the titanium dioxide rutile and anatase market in China stands at a pivotal point. As a leader in production, China must balance the competing demands of quality, sustainability, and market expansion. With a focus on innovation and adherence to environmental standards, the future looks promising for China’s titanium dioxide industry. The trajectory of TiO₂ production in China will undoubtedly shape global trends and provide impetus for further advancements in technology and manufacturing processes._zeolit powder price2025-08-17 21:36Read(2866)Sustainability is also becoming a crucial element in the manufacturing landscape. Many Chinese glass bead manufacturers are increasingly adopting eco-friendly practices. They are modernizing their operations to minimize environmental impact, with several opting for recycled materials in the production process. Additionally, by ensuring responsible sourcing and implementing waste-reduction strategies, these manufacturers are not only appealing to environmentally-conscious consumers but also positioning themselves as responsible players in the global market.

...

Read Morechina titanium dioxide rutile and anatase factory******The Landscape of Titanium Dioxide Production in China Rutile and Anatase China has emerged as a global powerhouse in the production of titanium dioxide (TiO₂), primarily in its two main forms rutile and anatase. This mineral has become indispensable in various industrial applications due to its unique chemical and physical properties, which include high refractive index, strong ultraviolet resistance, and stability in harsh conditions. Understanding Titanium Dioxide Titanium dioxide is a naturally occurring mineral that can be found primarily in two crystalline forms—rutile and anatase. Rutile is known for its high pigment strength and is primarily used in the production of white pigments for paints, coatings, plastics, and paper. It is also utilized in the manufacturing of high-performance products such as cosmetics and food items. In contrast, anatase, although possessing a lower refractive index and less pigmentary strength than rutile, is favored in specific applications, including photocatalysis and solar energy conversion. China's Dominance in TiO₂ Production The scale of titanium dioxide production in China is astounding. The country has established a vast network of factories dedicated to producing this mineral, making it the largest producer globally. The production methods used in these facilities vary between wet and dry techniques, with the former being more common for rutile production and the latter predominantly used for anatase. China's dominance in the titanium dioxide market is attributed to various factors, including the availability of abundant raw materials, such as ilmenite and rutile ores. Additionally, the country's continuous investments in technology and infrastructure have led to increased production efficiency and capacity. Chinese manufacturers have also emphasized eco-friendly production processes to meet international environmental standards, which enhances their competitiveness in the global market. china titanium dioxide rutile and anatase factory Quality and Applications Chinese titanium dioxide producers have made significant strides in improving the quality of their products to meet the needs of varying industries. Rutile-grade titanium dioxide is often utilized in high-end applications due to its superior opacity and durability. On the other hand, while anatase TiO₂ is less expensive, it is still highly sought after for countless applications such as in self-cleaning surfaces, water treatment, and as a pigment in various products. Moreover, the demand for titanium dioxide has skyrocketed in recent years due to the burgeoning construction and automotive industries. The ongoing urbanization in China and the increasing use of high-performance coatings contribute to this demand surge. Furthermore, with advancements in technology, the scope of application for TiO₂ continues to expand, including emerging fields such as photovoltaics and environmental remediation. The Future of Titanium Dioxide Production in China As the global economy evolves, so do the challenges and opportunities for titanium dioxide producers in China. While the demand for TiO₂ is expected to remain strong, manufacturers must navigate regulatory scrutiny and environmental concerns. The shift towards sustainability is prompting many factories to abandon harmful chemicals and adopt greener alternatives which can foster innovation. Additionally, competition in the global market is growing, with producers from other regions seeking to increase their share. This competitive landscape necessitates continuous improvement in production practices and product quality from Chinese manufacturers. In conclusion, the titanium dioxide rutile and anatase market in China stands at a pivotal point. As a leader in production, China must balance the competing demands of quality, sustainability, and market expansion. With a focus on innovation and adherence to environmental standards, the future looks promising for China’s titanium dioxide industry. The trajectory of TiO₂ production in China will undoubtedly shape global trends and provide impetus for further advancements in technology and manufacturing processes._zeolit powder price2025-08-17 20:27Read(898)custom silica fume manufacturer

The Importance of Custom Silica Fume Manufacturers In the realm of construction and materials engine...

Read Morechina titanium dioxide rutile and anatase factory******The Landscape of Titanium Dioxide Production in China Rutile and Anatase China has emerged as a global powerhouse in the production of titanium dioxide (TiO₂), primarily in its two main forms rutile and anatase. This mineral has become indispensable in various industrial applications due to its unique chemical and physical properties, which include high refractive index, strong ultraviolet resistance, and stability in harsh conditions. Understanding Titanium Dioxide Titanium dioxide is a naturally occurring mineral that can be found primarily in two crystalline forms—rutile and anatase. Rutile is known for its high pigment strength and is primarily used in the production of white pigments for paints, coatings, plastics, and paper. It is also utilized in the manufacturing of high-performance products such as cosmetics and food items. In contrast, anatase, although possessing a lower refractive index and less pigmentary strength than rutile, is favored in specific applications, including photocatalysis and solar energy conversion. China's Dominance in TiO₂ Production The scale of titanium dioxide production in China is astounding. The country has established a vast network of factories dedicated to producing this mineral, making it the largest producer globally. The production methods used in these facilities vary between wet and dry techniques, with the former being more common for rutile production and the latter predominantly used for anatase. China's dominance in the titanium dioxide market is attributed to various factors, including the availability of abundant raw materials, such as ilmenite and rutile ores. Additionally, the country's continuous investments in technology and infrastructure have led to increased production efficiency and capacity. Chinese manufacturers have also emphasized eco-friendly production processes to meet international environmental standards, which enhances their competitiveness in the global market. china titanium dioxide rutile and anatase factory Quality and Applications Chinese titanium dioxide producers have made significant strides in improving the quality of their products to meet the needs of varying industries. Rutile-grade titanium dioxide is often utilized in high-end applications due to its superior opacity and durability. On the other hand, while anatase TiO₂ is less expensive, it is still highly sought after for countless applications such as in self-cleaning surfaces, water treatment, and as a pigment in various products. Moreover, the demand for titanium dioxide has skyrocketed in recent years due to the burgeoning construction and automotive industries. The ongoing urbanization in China and the increasing use of high-performance coatings contribute to this demand surge. Furthermore, with advancements in technology, the scope of application for TiO₂ continues to expand, including emerging fields such as photovoltaics and environmental remediation. The Future of Titanium Dioxide Production in China As the global economy evolves, so do the challenges and opportunities for titanium dioxide producers in China. While the demand for TiO₂ is expected to remain strong, manufacturers must navigate regulatory scrutiny and environmental concerns. The shift towards sustainability is prompting many factories to abandon harmful chemicals and adopt greener alternatives which can foster innovation. Additionally, competition in the global market is growing, with producers from other regions seeking to increase their share. This competitive landscape necessitates continuous improvement in production practices and product quality from Chinese manufacturers. In conclusion, the titanium dioxide rutile and anatase market in China stands at a pivotal point. As a leader in production, China must balance the competing demands of quality, sustainability, and market expansion. With a focus on innovation and adherence to environmental standards, the future looks promising for China’s titanium dioxide industry. The trajectory of TiO₂ production in China will undoubtedly shape global trends and provide impetus for further advancements in technology and manufacturing processes._zeolit powder price2025-08-17 20:21Read(2651)Custom Clear Glass Beads Manufacturer for Unique Designs and Quality Craftsmanship

custom white glass beads factory ....

Read Morechina titanium dioxide rutile and anatase factory******The Landscape of Titanium Dioxide Production in China Rutile and Anatase China has emerged as a global powerhouse in the production of titanium dioxide (TiO₂), primarily in its two main forms rutile and anatase. This mineral has become indispensable in various industrial applications due to its unique chemical and physical properties, which include high refractive index, strong ultraviolet resistance, and stability in harsh conditions. Understanding Titanium Dioxide Titanium dioxide is a naturally occurring mineral that can be found primarily in two crystalline forms—rutile and anatase. Rutile is known for its high pigment strength and is primarily used in the production of white pigments for paints, coatings, plastics, and paper. It is also utilized in the manufacturing of high-performance products such as cosmetics and food items. In contrast, anatase, although possessing a lower refractive index and less pigmentary strength than rutile, is favored in specific applications, including photocatalysis and solar energy conversion. China's Dominance in TiO₂ Production The scale of titanium dioxide production in China is astounding. The country has established a vast network of factories dedicated to producing this mineral, making it the largest producer globally. The production methods used in these facilities vary between wet and dry techniques, with the former being more common for rutile production and the latter predominantly used for anatase. China's dominance in the titanium dioxide market is attributed to various factors, including the availability of abundant raw materials, such as ilmenite and rutile ores. Additionally, the country's continuous investments in technology and infrastructure have led to increased production efficiency and capacity. Chinese manufacturers have also emphasized eco-friendly production processes to meet international environmental standards, which enhances their competitiveness in the global market. china titanium dioxide rutile and anatase factory Quality and Applications Chinese titanium dioxide producers have made significant strides in improving the quality of their products to meet the needs of varying industries. Rutile-grade titanium dioxide is often utilized in high-end applications due to its superior opacity and durability. On the other hand, while anatase TiO₂ is less expensive, it is still highly sought after for countless applications such as in self-cleaning surfaces, water treatment, and as a pigment in various products. Moreover, the demand for titanium dioxide has skyrocketed in recent years due to the burgeoning construction and automotive industries. The ongoing urbanization in China and the increasing use of high-performance coatings contribute to this demand surge. Furthermore, with advancements in technology, the scope of application for TiO₂ continues to expand, including emerging fields such as photovoltaics and environmental remediation. The Future of Titanium Dioxide Production in China As the global economy evolves, so do the challenges and opportunities for titanium dioxide producers in China. While the demand for TiO₂ is expected to remain strong, manufacturers must navigate regulatory scrutiny and environmental concerns. The shift towards sustainability is prompting many factories to abandon harmful chemicals and adopt greener alternatives which can foster innovation. Additionally, competition in the global market is growing, with producers from other regions seeking to increase their share. This competitive landscape necessitates continuous improvement in production practices and product quality from Chinese manufacturers. In conclusion, the titanium dioxide rutile and anatase market in China stands at a pivotal point. As a leader in production, China must balance the competing demands of quality, sustainability, and market expansion. With a focus on innovation and adherence to environmental standards, the future looks promising for China’s titanium dioxide industry. The trajectory of TiO₂ production in China will undoubtedly shape global trends and provide impetus for further advancements in technology and manufacturing processes._zeolit powder price2025-08-17 20:12Read(2504)oem perlite in weed factories

The Role of OEM Perlite in Cannabis Cultivation In the rapidly evolving world of cannabis cultivatio...

Read Morechina titanium dioxide rutile and anatase factory******The Landscape of Titanium Dioxide Production in China Rutile and Anatase China has emerged as a global powerhouse in the production of titanium dioxide (TiO₂), primarily in its two main forms rutile and anatase. This mineral has become indispensable in various industrial applications due to its unique chemical and physical properties, which include high refractive index, strong ultraviolet resistance, and stability in harsh conditions. Understanding Titanium Dioxide Titanium dioxide is a naturally occurring mineral that can be found primarily in two crystalline forms—rutile and anatase. Rutile is known for its high pigment strength and is primarily used in the production of white pigments for paints, coatings, plastics, and paper. It is also utilized in the manufacturing of high-performance products such as cosmetics and food items. In contrast, anatase, although possessing a lower refractive index and less pigmentary strength than rutile, is favored in specific applications, including photocatalysis and solar energy conversion. China's Dominance in TiO₂ Production The scale of titanium dioxide production in China is astounding. The country has established a vast network of factories dedicated to producing this mineral, making it the largest producer globally. The production methods used in these facilities vary between wet and dry techniques, with the former being more common for rutile production and the latter predominantly used for anatase. China's dominance in the titanium dioxide market is attributed to various factors, including the availability of abundant raw materials, such as ilmenite and rutile ores. Additionally, the country's continuous investments in technology and infrastructure have led to increased production efficiency and capacity. Chinese manufacturers have also emphasized eco-friendly production processes to meet international environmental standards, which enhances their competitiveness in the global market. china titanium dioxide rutile and anatase factory Quality and Applications Chinese titanium dioxide producers have made significant strides in improving the quality of their products to meet the needs of varying industries. Rutile-grade titanium dioxide is often utilized in high-end applications due to its superior opacity and durability. On the other hand, while anatase TiO₂ is less expensive, it is still highly sought after for countless applications such as in self-cleaning surfaces, water treatment, and as a pigment in various products. Moreover, the demand for titanium dioxide has skyrocketed in recent years due to the burgeoning construction and automotive industries. The ongoing urbanization in China and the increasing use of high-performance coatings contribute to this demand surge. Furthermore, with advancements in technology, the scope of application for TiO₂ continues to expand, including emerging fields such as photovoltaics and environmental remediation. The Future of Titanium Dioxide Production in China As the global economy evolves, so do the challenges and opportunities for titanium dioxide producers in China. While the demand for TiO₂ is expected to remain strong, manufacturers must navigate regulatory scrutiny and environmental concerns. The shift towards sustainability is prompting many factories to abandon harmful chemicals and adopt greener alternatives which can foster innovation. Additionally, competition in the global market is growing, with producers from other regions seeking to increase their share. This competitive landscape necessitates continuous improvement in production practices and product quality from Chinese manufacturers. In conclusion, the titanium dioxide rutile and anatase market in China stands at a pivotal point. As a leader in production, China must balance the competing demands of quality, sustainability, and market expansion. With a focus on innovation and adherence to environmental standards, the future looks promising for China’s titanium dioxide industry. The trajectory of TiO₂ production in China will undoubtedly shape global trends and provide impetus for further advancements in technology and manufacturing processes._zeolit powder price2025-08-17 20:06Read(966)lime prime

The Marvel of Lime Prime A Juicy Exploration of Flavor and Health Lime prime is not just a delightfu...

Read Morechina titanium dioxide rutile and anatase factory******The Landscape of Titanium Dioxide Production in China Rutile and Anatase China has emerged as a global powerhouse in the production of titanium dioxide (TiO₂), primarily in its two main forms rutile and anatase. This mineral has become indispensable in various industrial applications due to its unique chemical and physical properties, which include high refractive index, strong ultraviolet resistance, and stability in harsh conditions. Understanding Titanium Dioxide Titanium dioxide is a naturally occurring mineral that can be found primarily in two crystalline forms—rutile and anatase. Rutile is known for its high pigment strength and is primarily used in the production of white pigments for paints, coatings, plastics, and paper. It is also utilized in the manufacturing of high-performance products such as cosmetics and food items. In contrast, anatase, although possessing a lower refractive index and less pigmentary strength than rutile, is favored in specific applications, including photocatalysis and solar energy conversion. China's Dominance in TiO₂ Production The scale of titanium dioxide production in China is astounding. The country has established a vast network of factories dedicated to producing this mineral, making it the largest producer globally. The production methods used in these facilities vary between wet and dry techniques, with the former being more common for rutile production and the latter predominantly used for anatase. China's dominance in the titanium dioxide market is attributed to various factors, including the availability of abundant raw materials, such as ilmenite and rutile ores. Additionally, the country's continuous investments in technology and infrastructure have led to increased production efficiency and capacity. Chinese manufacturers have also emphasized eco-friendly production processes to meet international environmental standards, which enhances their competitiveness in the global market. china titanium dioxide rutile and anatase factory Quality and Applications Chinese titanium dioxide producers have made significant strides in improving the quality of their products to meet the needs of varying industries. Rutile-grade titanium dioxide is often utilized in high-end applications due to its superior opacity and durability. On the other hand, while anatase TiO₂ is less expensive, it is still highly sought after for countless applications such as in self-cleaning surfaces, water treatment, and as a pigment in various products. Moreover, the demand for titanium dioxide has skyrocketed in recent years due to the burgeoning construction and automotive industries. The ongoing urbanization in China and the increasing use of high-performance coatings contribute to this demand surge. Furthermore, with advancements in technology, the scope of application for TiO₂ continues to expand, including emerging fields such as photovoltaics and environmental remediation. The Future of Titanium Dioxide Production in China As the global economy evolves, so do the challenges and opportunities for titanium dioxide producers in China. While the demand for TiO₂ is expected to remain strong, manufacturers must navigate regulatory scrutiny and environmental concerns. The shift towards sustainability is prompting many factories to abandon harmful chemicals and adopt greener alternatives which can foster innovation. Additionally, competition in the global market is growing, with producers from other regions seeking to increase their share. This competitive landscape necessitates continuous improvement in production practices and product quality from Chinese manufacturers. In conclusion, the titanium dioxide rutile and anatase market in China stands at a pivotal point. As a leader in production, China must balance the competing demands of quality, sustainability, and market expansion. With a focus on innovation and adherence to environmental standards, the future looks promising for China’s titanium dioxide industry. The trajectory of TiO₂ production in China will undoubtedly shape global trends and provide impetus for further advancements in technology and manufacturing processes._zeolit powder price2025-08-17 19:28Read(1898)Matte mica powder for crafts.

The Evolution and Significance of Matte Mica Powder Factories In the realm of industrial materials,...

Read Morechina titanium dioxide rutile and anatase factory******The Landscape of Titanium Dioxide Production in China Rutile and Anatase China has emerged as a global powerhouse in the production of titanium dioxide (TiO₂), primarily in its two main forms rutile and anatase. This mineral has become indispensable in various industrial applications due to its unique chemical and physical properties, which include high refractive index, strong ultraviolet resistance, and stability in harsh conditions. Understanding Titanium Dioxide Titanium dioxide is a naturally occurring mineral that can be found primarily in two crystalline forms—rutile and anatase. Rutile is known for its high pigment strength and is primarily used in the production of white pigments for paints, coatings, plastics, and paper. It is also utilized in the manufacturing of high-performance products such as cosmetics and food items. In contrast, anatase, although possessing a lower refractive index and less pigmentary strength than rutile, is favored in specific applications, including photocatalysis and solar energy conversion. China's Dominance in TiO₂ Production The scale of titanium dioxide production in China is astounding. The country has established a vast network of factories dedicated to producing this mineral, making it the largest producer globally. The production methods used in these facilities vary between wet and dry techniques, with the former being more common for rutile production and the latter predominantly used for anatase. China's dominance in the titanium dioxide market is attributed to various factors, including the availability of abundant raw materials, such as ilmenite and rutile ores. Additionally, the country's continuous investments in technology and infrastructure have led to increased production efficiency and capacity. Chinese manufacturers have also emphasized eco-friendly production processes to meet international environmental standards, which enhances their competitiveness in the global market. china titanium dioxide rutile and anatase factory Quality and Applications Chinese titanium dioxide producers have made significant strides in improving the quality of their products to meet the needs of varying industries. Rutile-grade titanium dioxide is often utilized in high-end applications due to its superior opacity and durability. On the other hand, while anatase TiO₂ is less expensive, it is still highly sought after for countless applications such as in self-cleaning surfaces, water treatment, and as a pigment in various products. Moreover, the demand for titanium dioxide has skyrocketed in recent years due to the burgeoning construction and automotive industries. The ongoing urbanization in China and the increasing use of high-performance coatings contribute to this demand surge. Furthermore, with advancements in technology, the scope of application for TiO₂ continues to expand, including emerging fields such as photovoltaics and environmental remediation. The Future of Titanium Dioxide Production in China As the global economy evolves, so do the challenges and opportunities for titanium dioxide producers in China. While the demand for TiO₂ is expected to remain strong, manufacturers must navigate regulatory scrutiny and environmental concerns. The shift towards sustainability is prompting many factories to abandon harmful chemicals and adopt greener alternatives which can foster innovation. Additionally, competition in the global market is growing, with producers from other regions seeking to increase their share. This competitive landscape necessitates continuous improvement in production practices and product quality from Chinese manufacturers. In conclusion, the titanium dioxide rutile and anatase market in China stands at a pivotal point. As a leader in production, China must balance the competing demands of quality, sustainability, and market expansion. With a focus on innovation and adherence to environmental standards, the future looks promising for China’s titanium dioxide industry. The trajectory of TiO₂ production in China will undoubtedly shape global trends and provide impetus for further advancements in technology and manufacturing processes._zeolit powder price2025-08-17 19:20Read(1214)Craftsman Quality Colored Sand from China for Creative Projects and Artistic Endeavors

The Vibrant World of Colored Sand A Look at Chinese Manufacturers In recent years, the crafting comm...

Read Morechina titanium dioxide rutile and anatase factory******The Landscape of Titanium Dioxide Production in China Rutile and Anatase China has emerged as a global powerhouse in the production of titanium dioxide (TiO₂), primarily in its two main forms rutile and anatase. This mineral has become indispensable in various industrial applications due to its unique chemical and physical properties, which include high refractive index, strong ultraviolet resistance, and stability in harsh conditions. Understanding Titanium Dioxide Titanium dioxide is a naturally occurring mineral that can be found primarily in two crystalline forms—rutile and anatase. Rutile is known for its high pigment strength and is primarily used in the production of white pigments for paints, coatings, plastics, and paper. It is also utilized in the manufacturing of high-performance products such as cosmetics and food items. In contrast, anatase, although possessing a lower refractive index and less pigmentary strength than rutile, is favored in specific applications, including photocatalysis and solar energy conversion. China's Dominance in TiO₂ Production The scale of titanium dioxide production in China is astounding. The country has established a vast network of factories dedicated to producing this mineral, making it the largest producer globally. The production methods used in these facilities vary between wet and dry techniques, with the former being more common for rutile production and the latter predominantly used for anatase. China's dominance in the titanium dioxide market is attributed to various factors, including the availability of abundant raw materials, such as ilmenite and rutile ores. Additionally, the country's continuous investments in technology and infrastructure have led to increased production efficiency and capacity. Chinese manufacturers have also emphasized eco-friendly production processes to meet international environmental standards, which enhances their competitiveness in the global market. china titanium dioxide rutile and anatase factory Quality and Applications Chinese titanium dioxide producers have made significant strides in improving the quality of their products to meet the needs of varying industries. Rutile-grade titanium dioxide is often utilized in high-end applications due to its superior opacity and durability. On the other hand, while anatase TiO₂ is less expensive, it is still highly sought after for countless applications such as in self-cleaning surfaces, water treatment, and as a pigment in various products. Moreover, the demand for titanium dioxide has skyrocketed in recent years due to the burgeoning construction and automotive industries. The ongoing urbanization in China and the increasing use of high-performance coatings contribute to this demand surge. Furthermore, with advancements in technology, the scope of application for TiO₂ continues to expand, including emerging fields such as photovoltaics and environmental remediation. The Future of Titanium Dioxide Production in China As the global economy evolves, so do the challenges and opportunities for titanium dioxide producers in China. While the demand for TiO₂ is expected to remain strong, manufacturers must navigate regulatory scrutiny and environmental concerns. The shift towards sustainability is prompting many factories to abandon harmful chemicals and adopt greener alternatives which can foster innovation. Additionally, competition in the global market is growing, with producers from other regions seeking to increase their share. This competitive landscape necessitates continuous improvement in production practices and product quality from Chinese manufacturers. In conclusion, the titanium dioxide rutile and anatase market in China stands at a pivotal point. As a leader in production, China must balance the competing demands of quality, sustainability, and market expansion. With a focus on innovation and adherence to environmental standards, the future looks promising for China’s titanium dioxide industry. The trajectory of TiO₂ production in China will undoubtedly shape global trends and provide impetus for further advancements in technology and manufacturing processes._zeolit powder price2025-08-17 19:13Read(1728)Exploring the Production Processes and Environmental Impact of Mica Sand Manufacturing Industries

The Role of Mica Sand Factories in Modern Industry Mica is a naturally occurring mineral largely der...

Read Morechina titanium dioxide rutile and anatase factory******The Landscape of Titanium Dioxide Production in China Rutile and Anatase China has emerged as a global powerhouse in the production of titanium dioxide (TiO₂), primarily in its two main forms rutile and anatase. This mineral has become indispensable in various industrial applications due to its unique chemical and physical properties, which include high refractive index, strong ultraviolet resistance, and stability in harsh conditions. Understanding Titanium Dioxide Titanium dioxide is a naturally occurring mineral that can be found primarily in two crystalline forms—rutile and anatase. Rutile is known for its high pigment strength and is primarily used in the production of white pigments for paints, coatings, plastics, and paper. It is also utilized in the manufacturing of high-performance products such as cosmetics and food items. In contrast, anatase, although possessing a lower refractive index and less pigmentary strength than rutile, is favored in specific applications, including photocatalysis and solar energy conversion. China's Dominance in TiO₂ Production The scale of titanium dioxide production in China is astounding. The country has established a vast network of factories dedicated to producing this mineral, making it the largest producer globally. The production methods used in these facilities vary between wet and dry techniques, with the former being more common for rutile production and the latter predominantly used for anatase. China's dominance in the titanium dioxide market is attributed to various factors, including the availability of abundant raw materials, such as ilmenite and rutile ores. Additionally, the country's continuous investments in technology and infrastructure have led to increased production efficiency and capacity. Chinese manufacturers have also emphasized eco-friendly production processes to meet international environmental standards, which enhances their competitiveness in the global market. china titanium dioxide rutile and anatase factory Quality and Applications Chinese titanium dioxide producers have made significant strides in improving the quality of their products to meet the needs of varying industries. Rutile-grade titanium dioxide is often utilized in high-end applications due to its superior opacity and durability. On the other hand, while anatase TiO₂ is less expensive, it is still highly sought after for countless applications such as in self-cleaning surfaces, water treatment, and as a pigment in various products. Moreover, the demand for titanium dioxide has skyrocketed in recent years due to the burgeoning construction and automotive industries. The ongoing urbanization in China and the increasing use of high-performance coatings contribute to this demand surge. Furthermore, with advancements in technology, the scope of application for TiO₂ continues to expand, including emerging fields such as photovoltaics and environmental remediation. The Future of Titanium Dioxide Production in China As the global economy evolves, so do the challenges and opportunities for titanium dioxide producers in China. While the demand for TiO₂ is expected to remain strong, manufacturers must navigate regulatory scrutiny and environmental concerns. The shift towards sustainability is prompting many factories to abandon harmful chemicals and adopt greener alternatives which can foster innovation. Additionally, competition in the global market is growing, with producers from other regions seeking to increase their share. This competitive landscape necessitates continuous improvement in production practices and product quality from Chinese manufacturers. In conclusion, the titanium dioxide rutile and anatase market in China stands at a pivotal point. As a leader in production, China must balance the competing demands of quality, sustainability, and market expansion. With a focus on innovation and adherence to environmental standards, the future looks promising for China’s titanium dioxide industry. The trajectory of TiO₂ production in China will undoubtedly shape global trends and provide impetus for further advancements in technology and manufacturing processes._zeolit powder price2025-08-17 19:11Read(2519)In recent years, the demand for unique and visually appealing design elements has surged, leading to the rise of custom luminous stone factories. These innovative facilities specialize in creating bespoke luminous stones that not only serve decorative purposes but also integrate functionality and sustainability. This article will explore the significance of custom luminous stone factories, their production processes, applications, and the benefits they bring to various industries.

...

Read Morechina titanium dioxide rutile and anatase factory******The Landscape of Titanium Dioxide Production in China Rutile and Anatase China has emerged as a global powerhouse in the production of titanium dioxide (TiO₂), primarily in its two main forms rutile and anatase. This mineral has become indispensable in various industrial applications due to its unique chemical and physical properties, which include high refractive index, strong ultraviolet resistance, and stability in harsh conditions. Understanding Titanium Dioxide Titanium dioxide is a naturally occurring mineral that can be found primarily in two crystalline forms—rutile and anatase. Rutile is known for its high pigment strength and is primarily used in the production of white pigments for paints, coatings, plastics, and paper. It is also utilized in the manufacturing of high-performance products such as cosmetics and food items. In contrast, anatase, although possessing a lower refractive index and less pigmentary strength than rutile, is favored in specific applications, including photocatalysis and solar energy conversion. China's Dominance in TiO₂ Production The scale of titanium dioxide production in China is astounding. The country has established a vast network of factories dedicated to producing this mineral, making it the largest producer globally. The production methods used in these facilities vary between wet and dry techniques, with the former being more common for rutile production and the latter predominantly used for anatase. China's dominance in the titanium dioxide market is attributed to various factors, including the availability of abundant raw materials, such as ilmenite and rutile ores. Additionally, the country's continuous investments in technology and infrastructure have led to increased production efficiency and capacity. Chinese manufacturers have also emphasized eco-friendly production processes to meet international environmental standards, which enhances their competitiveness in the global market. china titanium dioxide rutile and anatase factory Quality and Applications Chinese titanium dioxide producers have made significant strides in improving the quality of their products to meet the needs of varying industries. Rutile-grade titanium dioxide is often utilized in high-end applications due to its superior opacity and durability. On the other hand, while anatase TiO₂ is less expensive, it is still highly sought after for countless applications such as in self-cleaning surfaces, water treatment, and as a pigment in various products. Moreover, the demand for titanium dioxide has skyrocketed in recent years due to the burgeoning construction and automotive industries. The ongoing urbanization in China and the increasing use of high-performance coatings contribute to this demand surge. Furthermore, with advancements in technology, the scope of application for TiO₂ continues to expand, including emerging fields such as photovoltaics and environmental remediation. The Future of Titanium Dioxide Production in China As the global economy evolves, so do the challenges and opportunities for titanium dioxide producers in China. While the demand for TiO₂ is expected to remain strong, manufacturers must navigate regulatory scrutiny and environmental concerns. The shift towards sustainability is prompting many factories to abandon harmful chemicals and adopt greener alternatives which can foster innovation. Additionally, competition in the global market is growing, with producers from other regions seeking to increase their share. This competitive landscape necessitates continuous improvement in production practices and product quality from Chinese manufacturers. In conclusion, the titanium dioxide rutile and anatase market in China stands at a pivotal point. As a leader in production, China must balance the competing demands of quality, sustainability, and market expansion. With a focus on innovation and adherence to environmental standards, the future looks promising for China’s titanium dioxide industry. The trajectory of TiO₂ production in China will undoubtedly shape global trends and provide impetus for further advancements in technology and manufacturing processes._zeolit powder price2025-08-17 18:58Read(675)