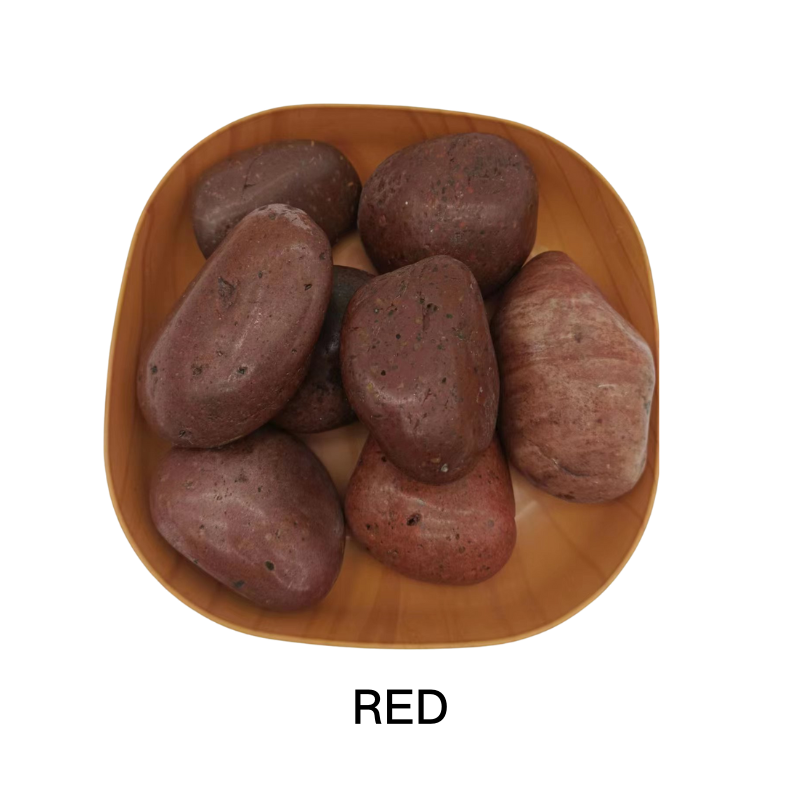

- Top Custom Ceramsite Pebbles Suppliers for Unique Landscaping and Decorative Solutions******The Rise of Custom Ceramsite Pebbles Manufacturers Ceramsite pebbles, also known as expanded clay aggregate, have become increasingly popular in various industries, particularly in construction, landscaping, and horticulture. Their lightweight nature, durability, and excellent insulation properties make them an ideal choice for many applications. As the demand for these materials continues to grow, a number of manufacturers have emerged, offering custom solutions tailored to the specific needs of clients. This article explores the significance of custom ceramsite pebbles manufacturers and the advantages they provide. Understanding Ceramsite Pebbles Ceramsite pebbles are produced by heating clay to high temperatures, resulting in a lightweight, porous material. This process creates a unique structure that offers excellent drainage and aeration properties, making it particularly suitable for gardening and landscaping. Moreover, ceramsite pebbles are fire-resistant, provide thermal insulation, and are chemically stable, all of which contribute to their widespread use. The Role of Custom Manufacturers Custom ceramsite pebbles manufacturers focus on creating tailored products to meet the unique requirements of various industries. Unlike standard products, custom solutions allow for adjustments in size, color, and composition, effectively addressing specific needs. This level of customization can be crucial for projects that require a particular aesthetic or functional characteristic. For example, in the landscaping industry, designers may seek specific sizes and colors of ceramsite pebbles to create visually appealing features in gardens or outdoor spaces. Custom manufacturers can provide pebbles that match a client’s vision, ensuring that the final product aligns with the overall design intent. Benefits of Custom Solutions custom ceramsite pebbles manufacturers 1. Tailored Applications Custom ceramsite pebbles can be designed for specific applications, whether it's for drainage systems, lightweight concrete, or insulation in construction projects. This flexibility allows architects and builders to utilize materials that best suit their project requirements. 2. Enhanced Aesthetic Appeal Customizing the color and finish of ceramsite pebbles allows for greater design flexibility. This is particularly important in landscaping, where the natural beauty of the material can significantly enhance the overall look of a space. 3. Improved Performance By working closely with manufacturers, clients can develop ceramsite pebbles that enhance performance aspects such as thermal insulation and weight distribution. Custom formulations can lead to products that outperform standard offerings in specific conditions. 4. Sustainability Preparation Many manufacturers are now focusing on sustainable practices. Custom ceramsite pebbles can be produced using eco-friendly processes and materials, aligning with the growing trend towards sustainability in construction and landscaping. Clients looking to reduce their environmental impact can benefit from engaging with manufacturers who prioritize green practices. 5. Competitive Advantage For businesses in construction and landscaping, having access to custom products can provide a competitive edge. These unique offerings can attract new clients and facilitate the execution of innovative designs and efficient construction methods. Conclusion The emergence of custom ceramsite pebbles manufacturers marks a significant development in industries that rely on expanded clay aggregate. By offering tailored solutions, these manufacturers play a crucial role in enabling architects, builders, and landscapers to optimize their projects in terms of aesthetics, functionality, and sustainability. As the demand for unique and high-performance materials continues to rise, the partnership between clients and custom ceramsite pebbles manufacturers will help shape the future of construction and landscaping, fostering innovation and excellence.>

- Top Custom Ceramsite Pebbles Suppliers for Unique Landscaping and Decorative Solutions******The Rise of Custom Ceramsite Pebbles Manufacturers Ceramsite pebbles, also known as expanded clay aggregate, have become increasingly popular in various industries, particularly in construction, landscaping, and horticulture. Their lightweight nature, durability, and excellent insulation properties make them an ideal choice for many applications. As the demand for these materials continues to grow, a number of manufacturers have emerged, offering custom solutions tailored to the specific needs of clients. This article explores the significance of custom ceramsite pebbles manufacturers and the advantages they provide. Understanding Ceramsite Pebbles Ceramsite pebbles are produced by heating clay to high temperatures, resulting in a lightweight, porous material. This process creates a unique structure that offers excellent drainage and aeration properties, making it particularly suitable for gardening and landscaping. Moreover, ceramsite pebbles are fire-resistant, provide thermal insulation, and are chemically stable, all of which contribute to their widespread use. The Role of Custom Manufacturers Custom ceramsite pebbles manufacturers focus on creating tailored products to meet the unique requirements of various industries. Unlike standard products, custom solutions allow for adjustments in size, color, and composition, effectively addressing specific needs. This level of customization can be crucial for projects that require a particular aesthetic or functional characteristic. For example, in the landscaping industry, designers may seek specific sizes and colors of ceramsite pebbles to create visually appealing features in gardens or outdoor spaces. Custom manufacturers can provide pebbles that match a client’s vision, ensuring that the final product aligns with the overall design intent. Benefits of Custom Solutions custom ceramsite pebbles manufacturers 1. Tailored Applications Custom ceramsite pebbles can be designed for specific applications, whether it's for drainage systems, lightweight concrete, or insulation in construction projects. This flexibility allows architects and builders to utilize materials that best suit their project requirements. 2. Enhanced Aesthetic Appeal Customizing the color and finish of ceramsite pebbles allows for greater design flexibility. This is particularly important in landscaping, where the natural beauty of the material can significantly enhance the overall look of a space. 3. Improved Performance By working closely with manufacturers, clients can develop ceramsite pebbles that enhance performance aspects such as thermal insulation and weight distribution. Custom formulations can lead to products that outperform standard offerings in specific conditions. 4. Sustainability Preparation Many manufacturers are now focusing on sustainable practices. Custom ceramsite pebbles can be produced using eco-friendly processes and materials, aligning with the growing trend towards sustainability in construction and landscaping. Clients looking to reduce their environmental impact can benefit from engaging with manufacturers who prioritize green practices. 5. Competitive Advantage For businesses in construction and landscaping, having access to custom products can provide a competitive edge. These unique offerings can attract new clients and facilitate the execution of innovative designs and efficient construction methods. Conclusion The emergence of custom ceramsite pebbles manufacturers marks a significant development in industries that rely on expanded clay aggregate. By offering tailored solutions, these manufacturers play a crucial role in enabling architects, builders, and landscapers to optimize their projects in terms of aesthetics, functionality, and sustainability. As the demand for unique and high-performance materials continues to rise, the partnership between clients and custom ceramsite pebbles manufacturers will help shape the future of construction and landscaping, fostering innovation and excellence._custom glass beads bulk

Top Custom Ceramsite Pebbles Suppliers for Unique Landscaping and Decorative Solutions******The Rise of Custom Ceramsite Pebbles Manufacturers Ceramsite pebbles, also known as expanded clay aggregate, have become increasingly popular in various industries, particularly in construction, landscaping, and horticulture. Their lightweight nature, durability, and excellent insulation properties make them an ideal choice for many applications. As the demand for these materials continues to grow, a number of manufacturers have emerged, offering custom solutions tailored to the specific needs of clients. This article explores the significance of custom ceramsite pebbles manufacturers and the advantages they provide. Understanding Ceramsite Pebbles Ceramsite pebbles are produced by heating clay to high temperatures, resulting in a lightweight, porous material. This process creates a unique structure that offers excellent drainage and aeration properties, making it particularly suitable for gardening and landscaping. Moreover, ceramsite pebbles are fire-resistant, provide thermal insulation, and are chemically stable, all of which contribute to their widespread use. The Role of Custom Manufacturers Custom ceramsite pebbles manufacturers focus on creating tailored products to meet the unique requirements of various industries. Unlike standard products, custom solutions allow for adjustments in size, color, and composition, effectively addressing specific needs. This level of customization can be crucial for projects that require a particular aesthetic or functional characteristic. For example, in the landscaping industry, designers may seek specific sizes and colors of ceramsite pebbles to create visually appealing features in gardens or outdoor spaces. Custom manufacturers can provide pebbles that match a client’s vision, ensuring that the final product aligns with the overall design intent. Benefits of Custom Solutions custom ceramsite pebbles manufacturers 1. Tailored Applications Custom ceramsite pebbles can be designed for specific applications, whether it's for drainage systems, lightweight concrete, or insulation in construction projects. This flexibility allows architects and builders to utilize materials that best suit their project requirements. 2. Enhanced Aesthetic Appeal Customizing the color and finish of ceramsite pebbles allows for greater design flexibility. This is particularly important in landscaping, where the natural beauty of the material can significantly enhance the overall look of a space. 3. Improved Performance By working closely with manufacturers, clients can develop ceramsite pebbles that enhance performance aspects such as thermal insulation and weight distribution. Custom formulations can lead to products that outperform standard offerings in specific conditions. 4. Sustainability Preparation Many manufacturers are now focusing on sustainable practices. Custom ceramsite pebbles can be produced using eco-friendly processes and materials, aligning with the growing trend towards sustainability in construction and landscaping. Clients looking to reduce their environmental impact can benefit from engaging with manufacturers who prioritize green practices. 5. Competitive Advantage For businesses in construction and landscaping, having access to custom products can provide a competitive edge. These unique offerings can attract new clients and facilitate the execution of innovative designs and efficient construction methods. Conclusion The emergence of custom ceramsite pebbles manufacturers marks a significant development in industries that rely on expanded clay aggregate. By offering tailored solutions, these manufacturers play a crucial role in enabling architects, builders, and landscapers to optimize their projects in terms of aesthetics, functionality, and sustainability. As the demand for unique and high-performance materials continues to rise, the partnership between clients and custom ceramsite pebbles manufacturers will help shape the future of construction and landscaping, fostering innovation and excellence._custom glass beads bulk

High-Quality Zeolite Powder Available for Purchase Online Today

Exploring Zeolite Powder for Sale Benefits and Applications Zeolite, a naturally occurring volcanic...

Read MoreTop Custom Ceramsite Pebbles Suppliers for Unique Landscaping and Decorative Solutions******The Rise of Custom Ceramsite Pebbles Manufacturers Ceramsite pebbles, also known as expanded clay aggregate, have become increasingly popular in various industries, particularly in construction, landscaping, and horticulture. Their lightweight nature, durability, and excellent insulation properties make them an ideal choice for many applications. As the demand for these materials continues to grow, a number of manufacturers have emerged, offering custom solutions tailored to the specific needs of clients. This article explores the significance of custom ceramsite pebbles manufacturers and the advantages they provide. Understanding Ceramsite Pebbles Ceramsite pebbles are produced by heating clay to high temperatures, resulting in a lightweight, porous material. This process creates a unique structure that offers excellent drainage and aeration properties, making it particularly suitable for gardening and landscaping. Moreover, ceramsite pebbles are fire-resistant, provide thermal insulation, and are chemically stable, all of which contribute to their widespread use. The Role of Custom Manufacturers Custom ceramsite pebbles manufacturers focus on creating tailored products to meet the unique requirements of various industries. Unlike standard products, custom solutions allow for adjustments in size, color, and composition, effectively addressing specific needs. This level of customization can be crucial for projects that require a particular aesthetic or functional characteristic. For example, in the landscaping industry, designers may seek specific sizes and colors of ceramsite pebbles to create visually appealing features in gardens or outdoor spaces. Custom manufacturers can provide pebbles that match a client’s vision, ensuring that the final product aligns with the overall design intent. Benefits of Custom Solutions custom ceramsite pebbles manufacturers 1. Tailored Applications Custom ceramsite pebbles can be designed for specific applications, whether it's for drainage systems, lightweight concrete, or insulation in construction projects. This flexibility allows architects and builders to utilize materials that best suit their project requirements. 2. Enhanced Aesthetic Appeal Customizing the color and finish of ceramsite pebbles allows for greater design flexibility. This is particularly important in landscaping, where the natural beauty of the material can significantly enhance the overall look of a space. 3. Improved Performance By working closely with manufacturers, clients can develop ceramsite pebbles that enhance performance aspects such as thermal insulation and weight distribution. Custom formulations can lead to products that outperform standard offerings in specific conditions. 4. Sustainability Preparation Many manufacturers are now focusing on sustainable practices. Custom ceramsite pebbles can be produced using eco-friendly processes and materials, aligning with the growing trend towards sustainability in construction and landscaping. Clients looking to reduce their environmental impact can benefit from engaging with manufacturers who prioritize green practices. 5. Competitive Advantage For businesses in construction and landscaping, having access to custom products can provide a competitive edge. These unique offerings can attract new clients and facilitate the execution of innovative designs and efficient construction methods. Conclusion The emergence of custom ceramsite pebbles manufacturers marks a significant development in industries that rely on expanded clay aggregate. By offering tailored solutions, these manufacturers play a crucial role in enabling architects, builders, and landscapers to optimize their projects in terms of aesthetics, functionality, and sustainability. As the demand for unique and high-performance materials continues to rise, the partnership between clients and custom ceramsite pebbles manufacturers will help shape the future of construction and landscaping, fostering innovation and excellence._custom glass beads bulk2025-08-17 13:04Read(2338)Custom Silica Fume for Cement Plant

Custom Silica Fume A Vital Ingredient for Cement Factories Cement factories have long been dependen...

Read MoreTop Custom Ceramsite Pebbles Suppliers for Unique Landscaping and Decorative Solutions******The Rise of Custom Ceramsite Pebbles Manufacturers Ceramsite pebbles, also known as expanded clay aggregate, have become increasingly popular in various industries, particularly in construction, landscaping, and horticulture. Their lightweight nature, durability, and excellent insulation properties make them an ideal choice for many applications. As the demand for these materials continues to grow, a number of manufacturers have emerged, offering custom solutions tailored to the specific needs of clients. This article explores the significance of custom ceramsite pebbles manufacturers and the advantages they provide. Understanding Ceramsite Pebbles Ceramsite pebbles are produced by heating clay to high temperatures, resulting in a lightweight, porous material. This process creates a unique structure that offers excellent drainage and aeration properties, making it particularly suitable for gardening and landscaping. Moreover, ceramsite pebbles are fire-resistant, provide thermal insulation, and are chemically stable, all of which contribute to their widespread use. The Role of Custom Manufacturers Custom ceramsite pebbles manufacturers focus on creating tailored products to meet the unique requirements of various industries. Unlike standard products, custom solutions allow for adjustments in size, color, and composition, effectively addressing specific needs. This level of customization can be crucial for projects that require a particular aesthetic or functional characteristic. For example, in the landscaping industry, designers may seek specific sizes and colors of ceramsite pebbles to create visually appealing features in gardens or outdoor spaces. Custom manufacturers can provide pebbles that match a client’s vision, ensuring that the final product aligns with the overall design intent. Benefits of Custom Solutions custom ceramsite pebbles manufacturers 1. Tailored Applications Custom ceramsite pebbles can be designed for specific applications, whether it's for drainage systems, lightweight concrete, or insulation in construction projects. This flexibility allows architects and builders to utilize materials that best suit their project requirements. 2. Enhanced Aesthetic Appeal Customizing the color and finish of ceramsite pebbles allows for greater design flexibility. This is particularly important in landscaping, where the natural beauty of the material can significantly enhance the overall look of a space. 3. Improved Performance By working closely with manufacturers, clients can develop ceramsite pebbles that enhance performance aspects such as thermal insulation and weight distribution. Custom formulations can lead to products that outperform standard offerings in specific conditions. 4. Sustainability Preparation Many manufacturers are now focusing on sustainable practices. Custom ceramsite pebbles can be produced using eco-friendly processes and materials, aligning with the growing trend towards sustainability in construction and landscaping. Clients looking to reduce their environmental impact can benefit from engaging with manufacturers who prioritize green practices. 5. Competitive Advantage For businesses in construction and landscaping, having access to custom products can provide a competitive edge. These unique offerings can attract new clients and facilitate the execution of innovative designs and efficient construction methods. Conclusion The emergence of custom ceramsite pebbles manufacturers marks a significant development in industries that rely on expanded clay aggregate. By offering tailored solutions, these manufacturers play a crucial role in enabling architects, builders, and landscapers to optimize their projects in terms of aesthetics, functionality, and sustainability. As the demand for unique and high-performance materials continues to rise, the partnership between clients and custom ceramsite pebbles manufacturers will help shape the future of construction and landscaping, fostering innovation and excellence._custom glass beads bulk2025-08-17 13:03Read(2512)...

Read MoreTop Custom Ceramsite Pebbles Suppliers for Unique Landscaping and Decorative Solutions******The Rise of Custom Ceramsite Pebbles Manufacturers Ceramsite pebbles, also known as expanded clay aggregate, have become increasingly popular in various industries, particularly in construction, landscaping, and horticulture. Their lightweight nature, durability, and excellent insulation properties make them an ideal choice for many applications. As the demand for these materials continues to grow, a number of manufacturers have emerged, offering custom solutions tailored to the specific needs of clients. This article explores the significance of custom ceramsite pebbles manufacturers and the advantages they provide. Understanding Ceramsite Pebbles Ceramsite pebbles are produced by heating clay to high temperatures, resulting in a lightweight, porous material. This process creates a unique structure that offers excellent drainage and aeration properties, making it particularly suitable for gardening and landscaping. Moreover, ceramsite pebbles are fire-resistant, provide thermal insulation, and are chemically stable, all of which contribute to their widespread use. The Role of Custom Manufacturers Custom ceramsite pebbles manufacturers focus on creating tailored products to meet the unique requirements of various industries. Unlike standard products, custom solutions allow for adjustments in size, color, and composition, effectively addressing specific needs. This level of customization can be crucial for projects that require a particular aesthetic or functional characteristic. For example, in the landscaping industry, designers may seek specific sizes and colors of ceramsite pebbles to create visually appealing features in gardens or outdoor spaces. Custom manufacturers can provide pebbles that match a client’s vision, ensuring that the final product aligns with the overall design intent. Benefits of Custom Solutions custom ceramsite pebbles manufacturers 1. Tailored Applications Custom ceramsite pebbles can be designed for specific applications, whether it's for drainage systems, lightweight concrete, or insulation in construction projects. This flexibility allows architects and builders to utilize materials that best suit their project requirements. 2. Enhanced Aesthetic Appeal Customizing the color and finish of ceramsite pebbles allows for greater design flexibility. This is particularly important in landscaping, where the natural beauty of the material can significantly enhance the overall look of a space. 3. Improved Performance By working closely with manufacturers, clients can develop ceramsite pebbles that enhance performance aspects such as thermal insulation and weight distribution. Custom formulations can lead to products that outperform standard offerings in specific conditions. 4. Sustainability Preparation Many manufacturers are now focusing on sustainable practices. Custom ceramsite pebbles can be produced using eco-friendly processes and materials, aligning with the growing trend towards sustainability in construction and landscaping. Clients looking to reduce their environmental impact can benefit from engaging with manufacturers who prioritize green practices. 5. Competitive Advantage For businesses in construction and landscaping, having access to custom products can provide a competitive edge. These unique offerings can attract new clients and facilitate the execution of innovative designs and efficient construction methods. Conclusion The emergence of custom ceramsite pebbles manufacturers marks a significant development in industries that rely on expanded clay aggregate. By offering tailored solutions, these manufacturers play a crucial role in enabling architects, builders, and landscapers to optimize their projects in terms of aesthetics, functionality, and sustainability. As the demand for unique and high-performance materials continues to rise, the partnership between clients and custom ceramsite pebbles manufacturers will help shape the future of construction and landscaping, fostering innovation and excellence._custom glass beads bulk2025-08-17 12:44Read(1832)4. Expertise and Innovation OEM manufacturers often have extensive experience and knowledge in the cosmetic formulations sector. They stay updated with the latest trends and regulations, providing brands with insights into what consumers want and what is permissible in formulations. This partnership can lead to innovative product offerings that set brands apart.

...

Read MoreTop Custom Ceramsite Pebbles Suppliers for Unique Landscaping and Decorative Solutions******The Rise of Custom Ceramsite Pebbles Manufacturers Ceramsite pebbles, also known as expanded clay aggregate, have become increasingly popular in various industries, particularly in construction, landscaping, and horticulture. Their lightweight nature, durability, and excellent insulation properties make them an ideal choice for many applications. As the demand for these materials continues to grow, a number of manufacturers have emerged, offering custom solutions tailored to the specific needs of clients. This article explores the significance of custom ceramsite pebbles manufacturers and the advantages they provide. Understanding Ceramsite Pebbles Ceramsite pebbles are produced by heating clay to high temperatures, resulting in a lightweight, porous material. This process creates a unique structure that offers excellent drainage and aeration properties, making it particularly suitable for gardening and landscaping. Moreover, ceramsite pebbles are fire-resistant, provide thermal insulation, and are chemically stable, all of which contribute to their widespread use. The Role of Custom Manufacturers Custom ceramsite pebbles manufacturers focus on creating tailored products to meet the unique requirements of various industries. Unlike standard products, custom solutions allow for adjustments in size, color, and composition, effectively addressing specific needs. This level of customization can be crucial for projects that require a particular aesthetic or functional characteristic. For example, in the landscaping industry, designers may seek specific sizes and colors of ceramsite pebbles to create visually appealing features in gardens or outdoor spaces. Custom manufacturers can provide pebbles that match a client’s vision, ensuring that the final product aligns with the overall design intent. Benefits of Custom Solutions custom ceramsite pebbles manufacturers 1. Tailored Applications Custom ceramsite pebbles can be designed for specific applications, whether it's for drainage systems, lightweight concrete, or insulation in construction projects. This flexibility allows architects and builders to utilize materials that best suit their project requirements. 2. Enhanced Aesthetic Appeal Customizing the color and finish of ceramsite pebbles allows for greater design flexibility. This is particularly important in landscaping, where the natural beauty of the material can significantly enhance the overall look of a space. 3. Improved Performance By working closely with manufacturers, clients can develop ceramsite pebbles that enhance performance aspects such as thermal insulation and weight distribution. Custom formulations can lead to products that outperform standard offerings in specific conditions. 4. Sustainability Preparation Many manufacturers are now focusing on sustainable practices. Custom ceramsite pebbles can be produced using eco-friendly processes and materials, aligning with the growing trend towards sustainability in construction and landscaping. Clients looking to reduce their environmental impact can benefit from engaging with manufacturers who prioritize green practices. 5. Competitive Advantage For businesses in construction and landscaping, having access to custom products can provide a competitive edge. These unique offerings can attract new clients and facilitate the execution of innovative designs and efficient construction methods. Conclusion The emergence of custom ceramsite pebbles manufacturers marks a significant development in industries that rely on expanded clay aggregate. By offering tailored solutions, these manufacturers play a crucial role in enabling architects, builders, and landscapers to optimize their projects in terms of aesthetics, functionality, and sustainability. As the demand for unique and high-performance materials continues to rise, the partnership between clients and custom ceramsite pebbles manufacturers will help shape the future of construction and landscaping, fostering innovation and excellence._custom glass beads bulk2025-08-17 12:35Read(1306)OEM Pink Mica Manufacturers for Quality Cosmetic and Craft Applications

Exploring OEM Pink Mica Factories A Vibrant Industry Insight In the ever-evolving landscape of cosme...

Read MoreTop Custom Ceramsite Pebbles Suppliers for Unique Landscaping and Decorative Solutions******The Rise of Custom Ceramsite Pebbles Manufacturers Ceramsite pebbles, also known as expanded clay aggregate, have become increasingly popular in various industries, particularly in construction, landscaping, and horticulture. Their lightweight nature, durability, and excellent insulation properties make them an ideal choice for many applications. As the demand for these materials continues to grow, a number of manufacturers have emerged, offering custom solutions tailored to the specific needs of clients. This article explores the significance of custom ceramsite pebbles manufacturers and the advantages they provide. Understanding Ceramsite Pebbles Ceramsite pebbles are produced by heating clay to high temperatures, resulting in a lightweight, porous material. This process creates a unique structure that offers excellent drainage and aeration properties, making it particularly suitable for gardening and landscaping. Moreover, ceramsite pebbles are fire-resistant, provide thermal insulation, and are chemically stable, all of which contribute to their widespread use. The Role of Custom Manufacturers Custom ceramsite pebbles manufacturers focus on creating tailored products to meet the unique requirements of various industries. Unlike standard products, custom solutions allow for adjustments in size, color, and composition, effectively addressing specific needs. This level of customization can be crucial for projects that require a particular aesthetic or functional characteristic. For example, in the landscaping industry, designers may seek specific sizes and colors of ceramsite pebbles to create visually appealing features in gardens or outdoor spaces. Custom manufacturers can provide pebbles that match a client’s vision, ensuring that the final product aligns with the overall design intent. Benefits of Custom Solutions custom ceramsite pebbles manufacturers 1. Tailored Applications Custom ceramsite pebbles can be designed for specific applications, whether it's for drainage systems, lightweight concrete, or insulation in construction projects. This flexibility allows architects and builders to utilize materials that best suit their project requirements. 2. Enhanced Aesthetic Appeal Customizing the color and finish of ceramsite pebbles allows for greater design flexibility. This is particularly important in landscaping, where the natural beauty of the material can significantly enhance the overall look of a space. 3. Improved Performance By working closely with manufacturers, clients can develop ceramsite pebbles that enhance performance aspects such as thermal insulation and weight distribution. Custom formulations can lead to products that outperform standard offerings in specific conditions. 4. Sustainability Preparation Many manufacturers are now focusing on sustainable practices. Custom ceramsite pebbles can be produced using eco-friendly processes and materials, aligning with the growing trend towards sustainability in construction and landscaping. Clients looking to reduce their environmental impact can benefit from engaging with manufacturers who prioritize green practices. 5. Competitive Advantage For businesses in construction and landscaping, having access to custom products can provide a competitive edge. These unique offerings can attract new clients and facilitate the execution of innovative designs and efficient construction methods. Conclusion The emergence of custom ceramsite pebbles manufacturers marks a significant development in industries that rely on expanded clay aggregate. By offering tailored solutions, these manufacturers play a crucial role in enabling architects, builders, and landscapers to optimize their projects in terms of aesthetics, functionality, and sustainability. As the demand for unique and high-performance materials continues to rise, the partnership between clients and custom ceramsite pebbles manufacturers will help shape the future of construction and landscaping, fostering innovation and excellence._custom glass beads bulk2025-08-17 12:31Read(1183)- " title=''>" title=''>

...

Read MoreTop Custom Ceramsite Pebbles Suppliers for Unique Landscaping and Decorative Solutions******The Rise of Custom Ceramsite Pebbles Manufacturers Ceramsite pebbles, also known as expanded clay aggregate, have become increasingly popular in various industries, particularly in construction, landscaping, and horticulture. Their lightweight nature, durability, and excellent insulation properties make them an ideal choice for many applications. As the demand for these materials continues to grow, a number of manufacturers have emerged, offering custom solutions tailored to the specific needs of clients. This article explores the significance of custom ceramsite pebbles manufacturers and the advantages they provide. Understanding Ceramsite Pebbles Ceramsite pebbles are produced by heating clay to high temperatures, resulting in a lightweight, porous material. This process creates a unique structure that offers excellent drainage and aeration properties, making it particularly suitable for gardening and landscaping. Moreover, ceramsite pebbles are fire-resistant, provide thermal insulation, and are chemically stable, all of which contribute to their widespread use. The Role of Custom Manufacturers Custom ceramsite pebbles manufacturers focus on creating tailored products to meet the unique requirements of various industries. Unlike standard products, custom solutions allow for adjustments in size, color, and composition, effectively addressing specific needs. This level of customization can be crucial for projects that require a particular aesthetic or functional characteristic. For example, in the landscaping industry, designers may seek specific sizes and colors of ceramsite pebbles to create visually appealing features in gardens or outdoor spaces. Custom manufacturers can provide pebbles that match a client’s vision, ensuring that the final product aligns with the overall design intent. Benefits of Custom Solutions custom ceramsite pebbles manufacturers 1. Tailored Applications Custom ceramsite pebbles can be designed for specific applications, whether it's for drainage systems, lightweight concrete, or insulation in construction projects. This flexibility allows architects and builders to utilize materials that best suit their project requirements. 2. Enhanced Aesthetic Appeal Customizing the color and finish of ceramsite pebbles allows for greater design flexibility. This is particularly important in landscaping, where the natural beauty of the material can significantly enhance the overall look of a space. 3. Improved Performance By working closely with manufacturers, clients can develop ceramsite pebbles that enhance performance aspects such as thermal insulation and weight distribution. Custom formulations can lead to products that outperform standard offerings in specific conditions. 4. Sustainability Preparation Many manufacturers are now focusing on sustainable practices. Custom ceramsite pebbles can be produced using eco-friendly processes and materials, aligning with the growing trend towards sustainability in construction and landscaping. Clients looking to reduce their environmental impact can benefit from engaging with manufacturers who prioritize green practices. 5. Competitive Advantage For businesses in construction and landscaping, having access to custom products can provide a competitive edge. These unique offerings can attract new clients and facilitate the execution of innovative designs and efficient construction methods. Conclusion The emergence of custom ceramsite pebbles manufacturers marks a significant development in industries that rely on expanded clay aggregate. By offering tailored solutions, these manufacturers play a crucial role in enabling architects, builders, and landscapers to optimize their projects in terms of aesthetics, functionality, and sustainability. As the demand for unique and high-performance materials continues to rise, the partnership between clients and custom ceramsite pebbles manufacturers will help shape the future of construction and landscaping, fostering innovation and excellence._custom glass beads bulk2025-08-17 12:28Read(636)Exploring Options for Purchasing Quality Marble Powder Online

The Benefits of Buying Marble Powder A Comprehensive Guide Marble powder, a byproduct of the marble...

Read MoreTop Custom Ceramsite Pebbles Suppliers for Unique Landscaping and Decorative Solutions******The Rise of Custom Ceramsite Pebbles Manufacturers Ceramsite pebbles, also known as expanded clay aggregate, have become increasingly popular in various industries, particularly in construction, landscaping, and horticulture. Their lightweight nature, durability, and excellent insulation properties make them an ideal choice for many applications. As the demand for these materials continues to grow, a number of manufacturers have emerged, offering custom solutions tailored to the specific needs of clients. This article explores the significance of custom ceramsite pebbles manufacturers and the advantages they provide. Understanding Ceramsite Pebbles Ceramsite pebbles are produced by heating clay to high temperatures, resulting in a lightweight, porous material. This process creates a unique structure that offers excellent drainage and aeration properties, making it particularly suitable for gardening and landscaping. Moreover, ceramsite pebbles are fire-resistant, provide thermal insulation, and are chemically stable, all of which contribute to their widespread use. The Role of Custom Manufacturers Custom ceramsite pebbles manufacturers focus on creating tailored products to meet the unique requirements of various industries. Unlike standard products, custom solutions allow for adjustments in size, color, and composition, effectively addressing specific needs. This level of customization can be crucial for projects that require a particular aesthetic or functional characteristic. For example, in the landscaping industry, designers may seek specific sizes and colors of ceramsite pebbles to create visually appealing features in gardens or outdoor spaces. Custom manufacturers can provide pebbles that match a client’s vision, ensuring that the final product aligns with the overall design intent. Benefits of Custom Solutions custom ceramsite pebbles manufacturers 1. Tailored Applications Custom ceramsite pebbles can be designed for specific applications, whether it's for drainage systems, lightweight concrete, or insulation in construction projects. This flexibility allows architects and builders to utilize materials that best suit their project requirements. 2. Enhanced Aesthetic Appeal Customizing the color and finish of ceramsite pebbles allows for greater design flexibility. This is particularly important in landscaping, where the natural beauty of the material can significantly enhance the overall look of a space. 3. Improved Performance By working closely with manufacturers, clients can develop ceramsite pebbles that enhance performance aspects such as thermal insulation and weight distribution. Custom formulations can lead to products that outperform standard offerings in specific conditions. 4. Sustainability Preparation Many manufacturers are now focusing on sustainable practices. Custom ceramsite pebbles can be produced using eco-friendly processes and materials, aligning with the growing trend towards sustainability in construction and landscaping. Clients looking to reduce their environmental impact can benefit from engaging with manufacturers who prioritize green practices. 5. Competitive Advantage For businesses in construction and landscaping, having access to custom products can provide a competitive edge. These unique offerings can attract new clients and facilitate the execution of innovative designs and efficient construction methods. Conclusion The emergence of custom ceramsite pebbles manufacturers marks a significant development in industries that rely on expanded clay aggregate. By offering tailored solutions, these manufacturers play a crucial role in enabling architects, builders, and landscapers to optimize their projects in terms of aesthetics, functionality, and sustainability. As the demand for unique and high-performance materials continues to rise, the partnership between clients and custom ceramsite pebbles manufacturers will help shape the future of construction and landscaping, fostering innovation and excellence._custom glass beads bulk2025-08-17 11:45Read(1364)One way of classifying coals is based on the degree of “coking” or arrangement of their carbon atoms. The less ordered, the less hard the carbon is and the more easily it can be activated.

...

Read MoreTop Custom Ceramsite Pebbles Suppliers for Unique Landscaping and Decorative Solutions******The Rise of Custom Ceramsite Pebbles Manufacturers Ceramsite pebbles, also known as expanded clay aggregate, have become increasingly popular in various industries, particularly in construction, landscaping, and horticulture. Their lightweight nature, durability, and excellent insulation properties make them an ideal choice for many applications. As the demand for these materials continues to grow, a number of manufacturers have emerged, offering custom solutions tailored to the specific needs of clients. This article explores the significance of custom ceramsite pebbles manufacturers and the advantages they provide. Understanding Ceramsite Pebbles Ceramsite pebbles are produced by heating clay to high temperatures, resulting in a lightweight, porous material. This process creates a unique structure that offers excellent drainage and aeration properties, making it particularly suitable for gardening and landscaping. Moreover, ceramsite pebbles are fire-resistant, provide thermal insulation, and are chemically stable, all of which contribute to their widespread use. The Role of Custom Manufacturers Custom ceramsite pebbles manufacturers focus on creating tailored products to meet the unique requirements of various industries. Unlike standard products, custom solutions allow for adjustments in size, color, and composition, effectively addressing specific needs. This level of customization can be crucial for projects that require a particular aesthetic or functional characteristic. For example, in the landscaping industry, designers may seek specific sizes and colors of ceramsite pebbles to create visually appealing features in gardens or outdoor spaces. Custom manufacturers can provide pebbles that match a client’s vision, ensuring that the final product aligns with the overall design intent. Benefits of Custom Solutions custom ceramsite pebbles manufacturers 1. Tailored Applications Custom ceramsite pebbles can be designed for specific applications, whether it's for drainage systems, lightweight concrete, or insulation in construction projects. This flexibility allows architects and builders to utilize materials that best suit their project requirements. 2. Enhanced Aesthetic Appeal Customizing the color and finish of ceramsite pebbles allows for greater design flexibility. This is particularly important in landscaping, where the natural beauty of the material can significantly enhance the overall look of a space. 3. Improved Performance By working closely with manufacturers, clients can develop ceramsite pebbles that enhance performance aspects such as thermal insulation and weight distribution. Custom formulations can lead to products that outperform standard offerings in specific conditions. 4. Sustainability Preparation Many manufacturers are now focusing on sustainable practices. Custom ceramsite pebbles can be produced using eco-friendly processes and materials, aligning with the growing trend towards sustainability in construction and landscaping. Clients looking to reduce their environmental impact can benefit from engaging with manufacturers who prioritize green practices. 5. Competitive Advantage For businesses in construction and landscaping, having access to custom products can provide a competitive edge. These unique offerings can attract new clients and facilitate the execution of innovative designs and efficient construction methods. Conclusion The emergence of custom ceramsite pebbles manufacturers marks a significant development in industries that rely on expanded clay aggregate. By offering tailored solutions, these manufacturers play a crucial role in enabling architects, builders, and landscapers to optimize their projects in terms of aesthetics, functionality, and sustainability. As the demand for unique and high-performance materials continues to rise, the partnership between clients and custom ceramsite pebbles manufacturers will help shape the future of construction and landscaping, fostering innovation and excellence._custom glass beads bulk2025-08-17 10:53Read(2688)Understanding the Expenses Related to Activated Carbon Production and Usage

The Cost of Activated Carbon An In-Depth Analysis Activated carbon is a versatile material widely us...

Read MoreTop Custom Ceramsite Pebbles Suppliers for Unique Landscaping and Decorative Solutions******The Rise of Custom Ceramsite Pebbles Manufacturers Ceramsite pebbles, also known as expanded clay aggregate, have become increasingly popular in various industries, particularly in construction, landscaping, and horticulture. Their lightweight nature, durability, and excellent insulation properties make them an ideal choice for many applications. As the demand for these materials continues to grow, a number of manufacturers have emerged, offering custom solutions tailored to the specific needs of clients. This article explores the significance of custom ceramsite pebbles manufacturers and the advantages they provide. Understanding Ceramsite Pebbles Ceramsite pebbles are produced by heating clay to high temperatures, resulting in a lightweight, porous material. This process creates a unique structure that offers excellent drainage and aeration properties, making it particularly suitable for gardening and landscaping. Moreover, ceramsite pebbles are fire-resistant, provide thermal insulation, and are chemically stable, all of which contribute to their widespread use. The Role of Custom Manufacturers Custom ceramsite pebbles manufacturers focus on creating tailored products to meet the unique requirements of various industries. Unlike standard products, custom solutions allow for adjustments in size, color, and composition, effectively addressing specific needs. This level of customization can be crucial for projects that require a particular aesthetic or functional characteristic. For example, in the landscaping industry, designers may seek specific sizes and colors of ceramsite pebbles to create visually appealing features in gardens or outdoor spaces. Custom manufacturers can provide pebbles that match a client’s vision, ensuring that the final product aligns with the overall design intent. Benefits of Custom Solutions custom ceramsite pebbles manufacturers 1. Tailored Applications Custom ceramsite pebbles can be designed for specific applications, whether it's for drainage systems, lightweight concrete, or insulation in construction projects. This flexibility allows architects and builders to utilize materials that best suit their project requirements. 2. Enhanced Aesthetic Appeal Customizing the color and finish of ceramsite pebbles allows for greater design flexibility. This is particularly important in landscaping, where the natural beauty of the material can significantly enhance the overall look of a space. 3. Improved Performance By working closely with manufacturers, clients can develop ceramsite pebbles that enhance performance aspects such as thermal insulation and weight distribution. Custom formulations can lead to products that outperform standard offerings in specific conditions. 4. Sustainability Preparation Many manufacturers are now focusing on sustainable practices. Custom ceramsite pebbles can be produced using eco-friendly processes and materials, aligning with the growing trend towards sustainability in construction and landscaping. Clients looking to reduce their environmental impact can benefit from engaging with manufacturers who prioritize green practices. 5. Competitive Advantage For businesses in construction and landscaping, having access to custom products can provide a competitive edge. These unique offerings can attract new clients and facilitate the execution of innovative designs and efficient construction methods. Conclusion The emergence of custom ceramsite pebbles manufacturers marks a significant development in industries that rely on expanded clay aggregate. By offering tailored solutions, these manufacturers play a crucial role in enabling architects, builders, and landscapers to optimize their projects in terms of aesthetics, functionality, and sustainability. As the demand for unique and high-performance materials continues to rise, the partnership between clients and custom ceramsite pebbles manufacturers will help shape the future of construction and landscaping, fostering innovation and excellence._custom glass beads bulk2025-08-17 10:51Read(691)In conclusion, fly ash, once seen as a disposal problem, has transformed into a valuable resource. Its use as a raw material in construction not only contributes to waste reduction but also enhances the sustainability and efficiency of the industry. As we strive for a greener future, the strategic integration of fly ash into our building practices should be a priority, turning waste into a resource and paving the way for a more circular economy.

...

Read MoreTop Custom Ceramsite Pebbles Suppliers for Unique Landscaping and Decorative Solutions******The Rise of Custom Ceramsite Pebbles Manufacturers Ceramsite pebbles, also known as expanded clay aggregate, have become increasingly popular in various industries, particularly in construction, landscaping, and horticulture. Their lightweight nature, durability, and excellent insulation properties make them an ideal choice for many applications. As the demand for these materials continues to grow, a number of manufacturers have emerged, offering custom solutions tailored to the specific needs of clients. This article explores the significance of custom ceramsite pebbles manufacturers and the advantages they provide. Understanding Ceramsite Pebbles Ceramsite pebbles are produced by heating clay to high temperatures, resulting in a lightweight, porous material. This process creates a unique structure that offers excellent drainage and aeration properties, making it particularly suitable for gardening and landscaping. Moreover, ceramsite pebbles are fire-resistant, provide thermal insulation, and are chemically stable, all of which contribute to their widespread use. The Role of Custom Manufacturers Custom ceramsite pebbles manufacturers focus on creating tailored products to meet the unique requirements of various industries. Unlike standard products, custom solutions allow for adjustments in size, color, and composition, effectively addressing specific needs. This level of customization can be crucial for projects that require a particular aesthetic or functional characteristic. For example, in the landscaping industry, designers may seek specific sizes and colors of ceramsite pebbles to create visually appealing features in gardens or outdoor spaces. Custom manufacturers can provide pebbles that match a client’s vision, ensuring that the final product aligns with the overall design intent. Benefits of Custom Solutions custom ceramsite pebbles manufacturers 1. Tailored Applications Custom ceramsite pebbles can be designed for specific applications, whether it's for drainage systems, lightweight concrete, or insulation in construction projects. This flexibility allows architects and builders to utilize materials that best suit their project requirements. 2. Enhanced Aesthetic Appeal Customizing the color and finish of ceramsite pebbles allows for greater design flexibility. This is particularly important in landscaping, where the natural beauty of the material can significantly enhance the overall look of a space. 3. Improved Performance By working closely with manufacturers, clients can develop ceramsite pebbles that enhance performance aspects such as thermal insulation and weight distribution. Custom formulations can lead to products that outperform standard offerings in specific conditions. 4. Sustainability Preparation Many manufacturers are now focusing on sustainable practices. Custom ceramsite pebbles can be produced using eco-friendly processes and materials, aligning with the growing trend towards sustainability in construction and landscaping. Clients looking to reduce their environmental impact can benefit from engaging with manufacturers who prioritize green practices. 5. Competitive Advantage For businesses in construction and landscaping, having access to custom products can provide a competitive edge. These unique offerings can attract new clients and facilitate the execution of innovative designs and efficient construction methods. Conclusion The emergence of custom ceramsite pebbles manufacturers marks a significant development in industries that rely on expanded clay aggregate. By offering tailored solutions, these manufacturers play a crucial role in enabling architects, builders, and landscapers to optimize their projects in terms of aesthetics, functionality, and sustainability. As the demand for unique and high-performance materials continues to rise, the partnership between clients and custom ceramsite pebbles manufacturers will help shape the future of construction and landscaping, fostering innovation and excellence._custom glass beads bulk2025-08-17 10:36Read(870)Netizens pay attention

Looked and looked

Latest tags

Links: