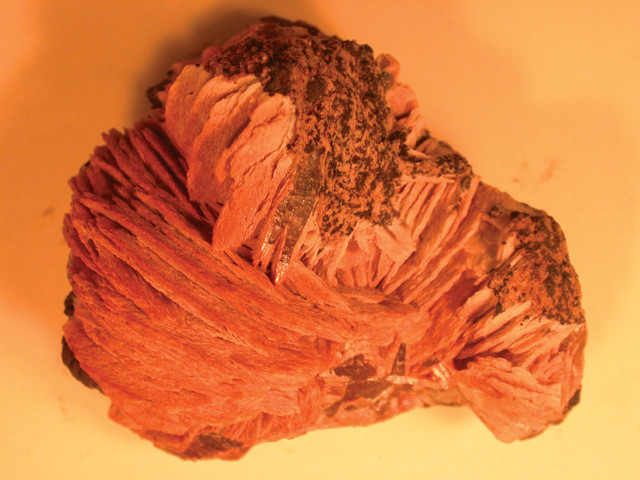

- garden soil perlite******The Role of Perlite in Garden Soil Enhancing Growth and Drainage Gardening enthusiasts and professionals alike understand that soil is the lifeblood of any garden. It serves as the foundation for plant health, influencing everything from nutrient availability to water retention. One key ingredient that has gained popularity in soil mixtures is perlite. This article will explore the importance of perlite in garden soil, its physical properties, and how it can enhance plant growth. What is Perlite? Perlite is a naturally occurring volcanic glass that expands when heated to high temperatures, resulting in a lightweight, white, and porous material. This transformation creates a structure that is not only beneficial for soil but also environmentally sustainable. Perlite is often used as a soil amendment and serves various purposes due to its unique characteristics. Benefits of Using Perlite in Garden Soil 1. Improved Drainage One of the most significant benefits of incorporating perlite into garden soil is its ability to improve drainage. Many plants, especially those in containers, can suffer from root rot and other issues related to overwatering. Perlite's porous structure allows excess water to drain away freely, preventing the soil from becoming waterlogged. This ensures that the roots have access to the moisture and oxygen they need to thrive. 2. Aeration In addition to improving drainage, perlite also enhances the aeration of soil. Good aeration is crucial for root development as it allows oxygen to reach the roots. Compacted soil can inhibit root growth, leading to stunted plants. By adding perlite to garden soil, you create a looser, more friable mix that encourages healthy root systems and promotes overall plant vigor. 3. Lightweight Composition For container gardening, the weight of the soil can be a concern, especially if you have larger pots or plan to move them around. Perlite is extremely lightweight, making it an ideal choice for potting mixes. This characteristic not only eases the burden of lifting but also minimizes the risk of container tipping over due to excess weight. garden soil perlite 4. pH Neutrality Perlite is pH neutral, which means it won’t alter the acidity or alkalinity of the soil mix. This makes it suitable for a wide variety of plants, ensuring that it won't interfere with their nutrient uptake. For gardeners looking to create specific pH environments for particular plant species, this is a significant advantage. 5. Encourages Microbiome Health The porous nature of perlite also encourages beneficial microbial activity in the soil. Healthy microbial communities play essential roles in nutrient cycling and the overall health of the garden ecosystem. By adding perlite, you create an environment conducive to these beneficial microorganisms, which can improve soil fertility and plant growth. How to Use Perlite in Your Garden Incorporating perlite into your garden soil is relatively straightforward - For Garden Beds When preparing garden beds, particularly for vegetables and flowers that prefer well-drained soil, mix about 20-30% perlite into your existing soil. This ratio can vary based on the type of plants you intend to grow; more water-sensitive plants may benefit from a higher perlite content. - For Container Gardening For potting mixes, aim for a blend that includes 30-50% perlite. This will ensure adequate drainage and aeration, helping to prevent overwatering-related issues. - For Seed Starting Perlite can also be used in seed starting mixes. Its lightweight and airy nature helps ensure that seeds have the right environment to germinate and root successfully. A mix of 50% perlite and 50% peat moss is a popular choice for this purpose. Conclusion In conclusion, perlite is a versatile and beneficial addition to garden soil. Its ability to improve drainage, aeration, and soil structure makes it a favorite among gardeners aiming for healthy, thriving plants. Whether you're tending to a small container garden or a large landscape, incorporating perlite can significantly enhance the quality of your soil and promote optimal plant growth. As gardening continues to evolve, the use of innovative and sustainable materials like perlite will play a key role in nurturing our green spaces.>

- garden soil perlite******The Role of Perlite in Garden Soil Enhancing Growth and Drainage Gardening enthusiasts and professionals alike understand that soil is the lifeblood of any garden. It serves as the foundation for plant health, influencing everything from nutrient availability to water retention. One key ingredient that has gained popularity in soil mixtures is perlite. This article will explore the importance of perlite in garden soil, its physical properties, and how it can enhance plant growth. What is Perlite? Perlite is a naturally occurring volcanic glass that expands when heated to high temperatures, resulting in a lightweight, white, and porous material. This transformation creates a structure that is not only beneficial for soil but also environmentally sustainable. Perlite is often used as a soil amendment and serves various purposes due to its unique characteristics. Benefits of Using Perlite in Garden Soil 1. Improved Drainage One of the most significant benefits of incorporating perlite into garden soil is its ability to improve drainage. Many plants, especially those in containers, can suffer from root rot and other issues related to overwatering. Perlite's porous structure allows excess water to drain away freely, preventing the soil from becoming waterlogged. This ensures that the roots have access to the moisture and oxygen they need to thrive. 2. Aeration In addition to improving drainage, perlite also enhances the aeration of soil. Good aeration is crucial for root development as it allows oxygen to reach the roots. Compacted soil can inhibit root growth, leading to stunted plants. By adding perlite to garden soil, you create a looser, more friable mix that encourages healthy root systems and promotes overall plant vigor. 3. Lightweight Composition For container gardening, the weight of the soil can be a concern, especially if you have larger pots or plan to move them around. Perlite is extremely lightweight, making it an ideal choice for potting mixes. This characteristic not only eases the burden of lifting but also minimizes the risk of container tipping over due to excess weight. garden soil perlite 4. pH Neutrality Perlite is pH neutral, which means it won’t alter the acidity or alkalinity of the soil mix. This makes it suitable for a wide variety of plants, ensuring that it won't interfere with their nutrient uptake. For gardeners looking to create specific pH environments for particular plant species, this is a significant advantage. 5. Encourages Microbiome Health The porous nature of perlite also encourages beneficial microbial activity in the soil. Healthy microbial communities play essential roles in nutrient cycling and the overall health of the garden ecosystem. By adding perlite, you create an environment conducive to these beneficial microorganisms, which can improve soil fertility and plant growth. How to Use Perlite in Your Garden Incorporating perlite into your garden soil is relatively straightforward - For Garden Beds When preparing garden beds, particularly for vegetables and flowers that prefer well-drained soil, mix about 20-30% perlite into your existing soil. This ratio can vary based on the type of plants you intend to grow; more water-sensitive plants may benefit from a higher perlite content. - For Container Gardening For potting mixes, aim for a blend that includes 30-50% perlite. This will ensure adequate drainage and aeration, helping to prevent overwatering-related issues. - For Seed Starting Perlite can also be used in seed starting mixes. Its lightweight and airy nature helps ensure that seeds have the right environment to germinate and root successfully. A mix of 50% perlite and 50% peat moss is a popular choice for this purpose. Conclusion In conclusion, perlite is a versatile and beneficial addition to garden soil. Its ability to improve drainage, aeration, and soil structure makes it a favorite among gardeners aiming for healthy, thriving plants. Whether you're tending to a small container garden or a large landscape, incorporating perlite can significantly enhance the quality of your soil and promote optimal plant growth. As gardening continues to evolve, the use of innovative and sustainable materials like perlite will play a key role in nurturing our green spaces._perlite bulk price

garden soil perlite******The Role of Perlite in Garden Soil Enhancing Growth and Drainage Gardening enthusiasts and professionals alike understand that soil is the lifeblood of any garden. It serves as the foundation for plant health, influencing everything from nutrient availability to water retention. One key ingredient that has gained popularity in soil mixtures is perlite. This article will explore the importance of perlite in garden soil, its physical properties, and how it can enhance plant growth. What is Perlite? Perlite is a naturally occurring volcanic glass that expands when heated to high temperatures, resulting in a lightweight, white, and porous material. This transformation creates a structure that is not only beneficial for soil but also environmentally sustainable. Perlite is often used as a soil amendment and serves various purposes due to its unique characteristics. Benefits of Using Perlite in Garden Soil 1. Improved Drainage One of the most significant benefits of incorporating perlite into garden soil is its ability to improve drainage. Many plants, especially those in containers, can suffer from root rot and other issues related to overwatering. Perlite's porous structure allows excess water to drain away freely, preventing the soil from becoming waterlogged. This ensures that the roots have access to the moisture and oxygen they need to thrive. 2. Aeration In addition to improving drainage, perlite also enhances the aeration of soil. Good aeration is crucial for root development as it allows oxygen to reach the roots. Compacted soil can inhibit root growth, leading to stunted plants. By adding perlite to garden soil, you create a looser, more friable mix that encourages healthy root systems and promotes overall plant vigor. 3. Lightweight Composition For container gardening, the weight of the soil can be a concern, especially if you have larger pots or plan to move them around. Perlite is extremely lightweight, making it an ideal choice for potting mixes. This characteristic not only eases the burden of lifting but also minimizes the risk of container tipping over due to excess weight. garden soil perlite 4. pH Neutrality Perlite is pH neutral, which means it won’t alter the acidity or alkalinity of the soil mix. This makes it suitable for a wide variety of plants, ensuring that it won't interfere with their nutrient uptake. For gardeners looking to create specific pH environments for particular plant species, this is a significant advantage. 5. Encourages Microbiome Health The porous nature of perlite also encourages beneficial microbial activity in the soil. Healthy microbial communities play essential roles in nutrient cycling and the overall health of the garden ecosystem. By adding perlite, you create an environment conducive to these beneficial microorganisms, which can improve soil fertility and plant growth. How to Use Perlite in Your Garden Incorporating perlite into your garden soil is relatively straightforward - For Garden Beds When preparing garden beds, particularly for vegetables and flowers that prefer well-drained soil, mix about 20-30% perlite into your existing soil. This ratio can vary based on the type of plants you intend to grow; more water-sensitive plants may benefit from a higher perlite content. - For Container Gardening For potting mixes, aim for a blend that includes 30-50% perlite. This will ensure adequate drainage and aeration, helping to prevent overwatering-related issues. - For Seed Starting Perlite can also be used in seed starting mixes. Its lightweight and airy nature helps ensure that seeds have the right environment to germinate and root successfully. A mix of 50% perlite and 50% peat moss is a popular choice for this purpose. Conclusion In conclusion, perlite is a versatile and beneficial addition to garden soil. Its ability to improve drainage, aeration, and soil structure makes it a favorite among gardeners aiming for healthy, thriving plants. Whether you're tending to a small container garden or a large landscape, incorporating perlite can significantly enhance the quality of your soil and promote optimal plant growth. As gardening continues to evolve, the use of innovative and sustainable materials like perlite will play a key role in nurturing our green spaces._perlite bulk price

zeolite pure

Zeolite Pure is rapidly becoming the focus of health enthusiasts and experts due to its versatile ap...

Read Moregarden soil perlite******The Role of Perlite in Garden Soil Enhancing Growth and Drainage Gardening enthusiasts and professionals alike understand that soil is the lifeblood of any garden. It serves as the foundation for plant health, influencing everything from nutrient availability to water retention. One key ingredient that has gained popularity in soil mixtures is perlite. This article will explore the importance of perlite in garden soil, its physical properties, and how it can enhance plant growth. What is Perlite? Perlite is a naturally occurring volcanic glass that expands when heated to high temperatures, resulting in a lightweight, white, and porous material. This transformation creates a structure that is not only beneficial for soil but also environmentally sustainable. Perlite is often used as a soil amendment and serves various purposes due to its unique characteristics. Benefits of Using Perlite in Garden Soil 1. Improved Drainage One of the most significant benefits of incorporating perlite into garden soil is its ability to improve drainage. Many plants, especially those in containers, can suffer from root rot and other issues related to overwatering. Perlite's porous structure allows excess water to drain away freely, preventing the soil from becoming waterlogged. This ensures that the roots have access to the moisture and oxygen they need to thrive. 2. Aeration In addition to improving drainage, perlite also enhances the aeration of soil. Good aeration is crucial for root development as it allows oxygen to reach the roots. Compacted soil can inhibit root growth, leading to stunted plants. By adding perlite to garden soil, you create a looser, more friable mix that encourages healthy root systems and promotes overall plant vigor. 3. Lightweight Composition For container gardening, the weight of the soil can be a concern, especially if you have larger pots or plan to move them around. Perlite is extremely lightweight, making it an ideal choice for potting mixes. This characteristic not only eases the burden of lifting but also minimizes the risk of container tipping over due to excess weight. garden soil perlite 4. pH Neutrality Perlite is pH neutral, which means it won’t alter the acidity or alkalinity of the soil mix. This makes it suitable for a wide variety of plants, ensuring that it won't interfere with their nutrient uptake. For gardeners looking to create specific pH environments for particular plant species, this is a significant advantage. 5. Encourages Microbiome Health The porous nature of perlite also encourages beneficial microbial activity in the soil. Healthy microbial communities play essential roles in nutrient cycling and the overall health of the garden ecosystem. By adding perlite, you create an environment conducive to these beneficial microorganisms, which can improve soil fertility and plant growth. How to Use Perlite in Your Garden Incorporating perlite into your garden soil is relatively straightforward - For Garden Beds When preparing garden beds, particularly for vegetables and flowers that prefer well-drained soil, mix about 20-30% perlite into your existing soil. This ratio can vary based on the type of plants you intend to grow; more water-sensitive plants may benefit from a higher perlite content. - For Container Gardening For potting mixes, aim for a blend that includes 30-50% perlite. This will ensure adequate drainage and aeration, helping to prevent overwatering-related issues. - For Seed Starting Perlite can also be used in seed starting mixes. Its lightweight and airy nature helps ensure that seeds have the right environment to germinate and root successfully. A mix of 50% perlite and 50% peat moss is a popular choice for this purpose. Conclusion In conclusion, perlite is a versatile and beneficial addition to garden soil. Its ability to improve drainage, aeration, and soil structure makes it a favorite among gardeners aiming for healthy, thriving plants. Whether you're tending to a small container garden or a large landscape, incorporating perlite can significantly enhance the quality of your soil and promote optimal plant growth. As gardening continues to evolve, the use of innovative and sustainable materials like perlite will play a key role in nurturing our green spaces._perlite bulk price2025-08-17 19:20Read(1792)Fly ash, a byproduct of coal combustion in power plants, has become an essential material in the construction industry. Among the different types of fly ash, Class F fly ash is particularly valued for its pozzolanic properties, which enable it to react with calcium hydroxide in the presence of water to form compounds that have cementitious properties. This transformative quality makes Class F fly ash a sustainable and cost-effective alternative to traditional cement. As the demand for this material grows, the role of OEM (Original Equipment Manufacturer) Class F fly ash suppliers has become increasingly significant.

...

Read Moregarden soil perlite******The Role of Perlite in Garden Soil Enhancing Growth and Drainage Gardening enthusiasts and professionals alike understand that soil is the lifeblood of any garden. It serves as the foundation for plant health, influencing everything from nutrient availability to water retention. One key ingredient that has gained popularity in soil mixtures is perlite. This article will explore the importance of perlite in garden soil, its physical properties, and how it can enhance plant growth. What is Perlite? Perlite is a naturally occurring volcanic glass that expands when heated to high temperatures, resulting in a lightweight, white, and porous material. This transformation creates a structure that is not only beneficial for soil but also environmentally sustainable. Perlite is often used as a soil amendment and serves various purposes due to its unique characteristics. Benefits of Using Perlite in Garden Soil 1. Improved Drainage One of the most significant benefits of incorporating perlite into garden soil is its ability to improve drainage. Many plants, especially those in containers, can suffer from root rot and other issues related to overwatering. Perlite's porous structure allows excess water to drain away freely, preventing the soil from becoming waterlogged. This ensures that the roots have access to the moisture and oxygen they need to thrive. 2. Aeration In addition to improving drainage, perlite also enhances the aeration of soil. Good aeration is crucial for root development as it allows oxygen to reach the roots. Compacted soil can inhibit root growth, leading to stunted plants. By adding perlite to garden soil, you create a looser, more friable mix that encourages healthy root systems and promotes overall plant vigor. 3. Lightweight Composition For container gardening, the weight of the soil can be a concern, especially if you have larger pots or plan to move them around. Perlite is extremely lightweight, making it an ideal choice for potting mixes. This characteristic not only eases the burden of lifting but also minimizes the risk of container tipping over due to excess weight. garden soil perlite 4. pH Neutrality Perlite is pH neutral, which means it won’t alter the acidity or alkalinity of the soil mix. This makes it suitable for a wide variety of plants, ensuring that it won't interfere with their nutrient uptake. For gardeners looking to create specific pH environments for particular plant species, this is a significant advantage. 5. Encourages Microbiome Health The porous nature of perlite also encourages beneficial microbial activity in the soil. Healthy microbial communities play essential roles in nutrient cycling and the overall health of the garden ecosystem. By adding perlite, you create an environment conducive to these beneficial microorganisms, which can improve soil fertility and plant growth. How to Use Perlite in Your Garden Incorporating perlite into your garden soil is relatively straightforward - For Garden Beds When preparing garden beds, particularly for vegetables and flowers that prefer well-drained soil, mix about 20-30% perlite into your existing soil. This ratio can vary based on the type of plants you intend to grow; more water-sensitive plants may benefit from a higher perlite content. - For Container Gardening For potting mixes, aim for a blend that includes 30-50% perlite. This will ensure adequate drainage and aeration, helping to prevent overwatering-related issues. - For Seed Starting Perlite can also be used in seed starting mixes. Its lightweight and airy nature helps ensure that seeds have the right environment to germinate and root successfully. A mix of 50% perlite and 50% peat moss is a popular choice for this purpose. Conclusion In conclusion, perlite is a versatile and beneficial addition to garden soil. Its ability to improve drainage, aeration, and soil structure makes it a favorite among gardeners aiming for healthy, thriving plants. Whether you're tending to a small container garden or a large landscape, incorporating perlite can significantly enhance the quality of your soil and promote optimal plant growth. As gardening continues to evolve, the use of innovative and sustainable materials like perlite will play a key role in nurturing our green spaces._perlite bulk price2025-08-17 19:08Read(1684)...

Read Moregarden soil perlite******The Role of Perlite in Garden Soil Enhancing Growth and Drainage Gardening enthusiasts and professionals alike understand that soil is the lifeblood of any garden. It serves as the foundation for plant health, influencing everything from nutrient availability to water retention. One key ingredient that has gained popularity in soil mixtures is perlite. This article will explore the importance of perlite in garden soil, its physical properties, and how it can enhance plant growth. What is Perlite? Perlite is a naturally occurring volcanic glass that expands when heated to high temperatures, resulting in a lightweight, white, and porous material. This transformation creates a structure that is not only beneficial for soil but also environmentally sustainable. Perlite is often used as a soil amendment and serves various purposes due to its unique characteristics. Benefits of Using Perlite in Garden Soil 1. Improved Drainage One of the most significant benefits of incorporating perlite into garden soil is its ability to improve drainage. Many plants, especially those in containers, can suffer from root rot and other issues related to overwatering. Perlite's porous structure allows excess water to drain away freely, preventing the soil from becoming waterlogged. This ensures that the roots have access to the moisture and oxygen they need to thrive. 2. Aeration In addition to improving drainage, perlite also enhances the aeration of soil. Good aeration is crucial for root development as it allows oxygen to reach the roots. Compacted soil can inhibit root growth, leading to stunted plants. By adding perlite to garden soil, you create a looser, more friable mix that encourages healthy root systems and promotes overall plant vigor. 3. Lightweight Composition For container gardening, the weight of the soil can be a concern, especially if you have larger pots or plan to move them around. Perlite is extremely lightweight, making it an ideal choice for potting mixes. This characteristic not only eases the burden of lifting but also minimizes the risk of container tipping over due to excess weight. garden soil perlite 4. pH Neutrality Perlite is pH neutral, which means it won’t alter the acidity or alkalinity of the soil mix. This makes it suitable for a wide variety of plants, ensuring that it won't interfere with their nutrient uptake. For gardeners looking to create specific pH environments for particular plant species, this is a significant advantage. 5. Encourages Microbiome Health The porous nature of perlite also encourages beneficial microbial activity in the soil. Healthy microbial communities play essential roles in nutrient cycling and the overall health of the garden ecosystem. By adding perlite, you create an environment conducive to these beneficial microorganisms, which can improve soil fertility and plant growth. How to Use Perlite in Your Garden Incorporating perlite into your garden soil is relatively straightforward - For Garden Beds When preparing garden beds, particularly for vegetables and flowers that prefer well-drained soil, mix about 20-30% perlite into your existing soil. This ratio can vary based on the type of plants you intend to grow; more water-sensitive plants may benefit from a higher perlite content. - For Container Gardening For potting mixes, aim for a blend that includes 30-50% perlite. This will ensure adequate drainage and aeration, helping to prevent overwatering-related issues. - For Seed Starting Perlite can also be used in seed starting mixes. Its lightweight and airy nature helps ensure that seeds have the right environment to germinate and root successfully. A mix of 50% perlite and 50% peat moss is a popular choice for this purpose. Conclusion In conclusion, perlite is a versatile and beneficial addition to garden soil. Its ability to improve drainage, aeration, and soil structure makes it a favorite among gardeners aiming for healthy, thriving plants. Whether you're tending to a small container garden or a large landscape, incorporating perlite can significantly enhance the quality of your soil and promote optimal plant growth. As gardening continues to evolve, the use of innovative and sustainable materials like perlite will play a key role in nurturing our green spaces._perlite bulk price2025-08-17 19:03Read(54)Sustainability and Environmental Considerations

...

Read Moregarden soil perlite******The Role of Perlite in Garden Soil Enhancing Growth and Drainage Gardening enthusiasts and professionals alike understand that soil is the lifeblood of any garden. It serves as the foundation for plant health, influencing everything from nutrient availability to water retention. One key ingredient that has gained popularity in soil mixtures is perlite. This article will explore the importance of perlite in garden soil, its physical properties, and how it can enhance plant growth. What is Perlite? Perlite is a naturally occurring volcanic glass that expands when heated to high temperatures, resulting in a lightweight, white, and porous material. This transformation creates a structure that is not only beneficial for soil but also environmentally sustainable. Perlite is often used as a soil amendment and serves various purposes due to its unique characteristics. Benefits of Using Perlite in Garden Soil 1. Improved Drainage One of the most significant benefits of incorporating perlite into garden soil is its ability to improve drainage. Many plants, especially those in containers, can suffer from root rot and other issues related to overwatering. Perlite's porous structure allows excess water to drain away freely, preventing the soil from becoming waterlogged. This ensures that the roots have access to the moisture and oxygen they need to thrive. 2. Aeration In addition to improving drainage, perlite also enhances the aeration of soil. Good aeration is crucial for root development as it allows oxygen to reach the roots. Compacted soil can inhibit root growth, leading to stunted plants. By adding perlite to garden soil, you create a looser, more friable mix that encourages healthy root systems and promotes overall plant vigor. 3. Lightweight Composition For container gardening, the weight of the soil can be a concern, especially if you have larger pots or plan to move them around. Perlite is extremely lightweight, making it an ideal choice for potting mixes. This characteristic not only eases the burden of lifting but also minimizes the risk of container tipping over due to excess weight. garden soil perlite 4. pH Neutrality Perlite is pH neutral, which means it won’t alter the acidity or alkalinity of the soil mix. This makes it suitable for a wide variety of plants, ensuring that it won't interfere with their nutrient uptake. For gardeners looking to create specific pH environments for particular plant species, this is a significant advantage. 5. Encourages Microbiome Health The porous nature of perlite also encourages beneficial microbial activity in the soil. Healthy microbial communities play essential roles in nutrient cycling and the overall health of the garden ecosystem. By adding perlite, you create an environment conducive to these beneficial microorganisms, which can improve soil fertility and plant growth. How to Use Perlite in Your Garden Incorporating perlite into your garden soil is relatively straightforward - For Garden Beds When preparing garden beds, particularly for vegetables and flowers that prefer well-drained soil, mix about 20-30% perlite into your existing soil. This ratio can vary based on the type of plants you intend to grow; more water-sensitive plants may benefit from a higher perlite content. - For Container Gardening For potting mixes, aim for a blend that includes 30-50% perlite. This will ensure adequate drainage and aeration, helping to prevent overwatering-related issues. - For Seed Starting Perlite can also be used in seed starting mixes. Its lightweight and airy nature helps ensure that seeds have the right environment to germinate and root successfully. A mix of 50% perlite and 50% peat moss is a popular choice for this purpose. Conclusion In conclusion, perlite is a versatile and beneficial addition to garden soil. Its ability to improve drainage, aeration, and soil structure makes it a favorite among gardeners aiming for healthy, thriving plants. Whether you're tending to a small container garden or a large landscape, incorporating perlite can significantly enhance the quality of your soil and promote optimal plant growth. As gardening continues to evolve, the use of innovative and sustainable materials like perlite will play a key role in nurturing our green spaces._perlite bulk price2025-08-17 18:47Read(825)炭酸カルシウム水酸化カルシウム。

カルシウムカーボネートとカルシウムヒドロキシドについて カルシウムカーボネート(CaCO3)とカルシウムヒドロキシド(Ca(OH)2)は、化学的性質が異なる重要なカルシウム化合物です。これらの化合物は...

Read Moregarden soil perlite******The Role of Perlite in Garden Soil Enhancing Growth and Drainage Gardening enthusiasts and professionals alike understand that soil is the lifeblood of any garden. It serves as the foundation for plant health, influencing everything from nutrient availability to water retention. One key ingredient that has gained popularity in soil mixtures is perlite. This article will explore the importance of perlite in garden soil, its physical properties, and how it can enhance plant growth. What is Perlite? Perlite is a naturally occurring volcanic glass that expands when heated to high temperatures, resulting in a lightweight, white, and porous material. This transformation creates a structure that is not only beneficial for soil but also environmentally sustainable. Perlite is often used as a soil amendment and serves various purposes due to its unique characteristics. Benefits of Using Perlite in Garden Soil 1. Improved Drainage One of the most significant benefits of incorporating perlite into garden soil is its ability to improve drainage. Many plants, especially those in containers, can suffer from root rot and other issues related to overwatering. Perlite's porous structure allows excess water to drain away freely, preventing the soil from becoming waterlogged. This ensures that the roots have access to the moisture and oxygen they need to thrive. 2. Aeration In addition to improving drainage, perlite also enhances the aeration of soil. Good aeration is crucial for root development as it allows oxygen to reach the roots. Compacted soil can inhibit root growth, leading to stunted plants. By adding perlite to garden soil, you create a looser, more friable mix that encourages healthy root systems and promotes overall plant vigor. 3. Lightweight Composition For container gardening, the weight of the soil can be a concern, especially if you have larger pots or plan to move them around. Perlite is extremely lightweight, making it an ideal choice for potting mixes. This characteristic not only eases the burden of lifting but also minimizes the risk of container tipping over due to excess weight. garden soil perlite 4. pH Neutrality Perlite is pH neutral, which means it won’t alter the acidity or alkalinity of the soil mix. This makes it suitable for a wide variety of plants, ensuring that it won't interfere with their nutrient uptake. For gardeners looking to create specific pH environments for particular plant species, this is a significant advantage. 5. Encourages Microbiome Health The porous nature of perlite also encourages beneficial microbial activity in the soil. Healthy microbial communities play essential roles in nutrient cycling and the overall health of the garden ecosystem. By adding perlite, you create an environment conducive to these beneficial microorganisms, which can improve soil fertility and plant growth. How to Use Perlite in Your Garden Incorporating perlite into your garden soil is relatively straightforward - For Garden Beds When preparing garden beds, particularly for vegetables and flowers that prefer well-drained soil, mix about 20-30% perlite into your existing soil. This ratio can vary based on the type of plants you intend to grow; more water-sensitive plants may benefit from a higher perlite content. - For Container Gardening For potting mixes, aim for a blend that includes 30-50% perlite. This will ensure adequate drainage and aeration, helping to prevent overwatering-related issues. - For Seed Starting Perlite can also be used in seed starting mixes. Its lightweight and airy nature helps ensure that seeds have the right environment to germinate and root successfully. A mix of 50% perlite and 50% peat moss is a popular choice for this purpose. Conclusion In conclusion, perlite is a versatile and beneficial addition to garden soil. Its ability to improve drainage, aeration, and soil structure makes it a favorite among gardeners aiming for healthy, thriving plants. Whether you're tending to a small container garden or a large landscape, incorporating perlite can significantly enhance the quality of your soil and promote optimal plant growth. As gardening continues to evolve, the use of innovative and sustainable materials like perlite will play a key role in nurturing our green spaces._perlite bulk price2025-08-17 18:36Read(1133)“In laying the walls after getting out of reach from the ground there were poles set about 6 or 8 feet from the wall and about as high as the walls were to be, then long poles were lashed to them with hickory withes an inch or an inch and a quarter in diameter and six to eight inches long and then scantling laid across them to the wall and planks laid on them making scaffolding all around the house. Then a crane and tackles and rope were fastened to the northeast post. Buckets a little larger than a molasses cask cut in two would be filled with either mortar or stones and hoisted up, using a horse, to the scaffold and their contents distributed with a wheelbarrow. When they were above reach from a scaffold the staging would be raised again. . . “

...

Read Moregarden soil perlite******The Role of Perlite in Garden Soil Enhancing Growth and Drainage Gardening enthusiasts and professionals alike understand that soil is the lifeblood of any garden. It serves as the foundation for plant health, influencing everything from nutrient availability to water retention. One key ingredient that has gained popularity in soil mixtures is perlite. This article will explore the importance of perlite in garden soil, its physical properties, and how it can enhance plant growth. What is Perlite? Perlite is a naturally occurring volcanic glass that expands when heated to high temperatures, resulting in a lightweight, white, and porous material. This transformation creates a structure that is not only beneficial for soil but also environmentally sustainable. Perlite is often used as a soil amendment and serves various purposes due to its unique characteristics. Benefits of Using Perlite in Garden Soil 1. Improved Drainage One of the most significant benefits of incorporating perlite into garden soil is its ability to improve drainage. Many plants, especially those in containers, can suffer from root rot and other issues related to overwatering. Perlite's porous structure allows excess water to drain away freely, preventing the soil from becoming waterlogged. This ensures that the roots have access to the moisture and oxygen they need to thrive. 2. Aeration In addition to improving drainage, perlite also enhances the aeration of soil. Good aeration is crucial for root development as it allows oxygen to reach the roots. Compacted soil can inhibit root growth, leading to stunted plants. By adding perlite to garden soil, you create a looser, more friable mix that encourages healthy root systems and promotes overall plant vigor. 3. Lightweight Composition For container gardening, the weight of the soil can be a concern, especially if you have larger pots or plan to move them around. Perlite is extremely lightweight, making it an ideal choice for potting mixes. This characteristic not only eases the burden of lifting but also minimizes the risk of container tipping over due to excess weight. garden soil perlite 4. pH Neutrality Perlite is pH neutral, which means it won’t alter the acidity or alkalinity of the soil mix. This makes it suitable for a wide variety of plants, ensuring that it won't interfere with their nutrient uptake. For gardeners looking to create specific pH environments for particular plant species, this is a significant advantage. 5. Encourages Microbiome Health The porous nature of perlite also encourages beneficial microbial activity in the soil. Healthy microbial communities play essential roles in nutrient cycling and the overall health of the garden ecosystem. By adding perlite, you create an environment conducive to these beneficial microorganisms, which can improve soil fertility and plant growth. How to Use Perlite in Your Garden Incorporating perlite into your garden soil is relatively straightforward - For Garden Beds When preparing garden beds, particularly for vegetables and flowers that prefer well-drained soil, mix about 20-30% perlite into your existing soil. This ratio can vary based on the type of plants you intend to grow; more water-sensitive plants may benefit from a higher perlite content. - For Container Gardening For potting mixes, aim for a blend that includes 30-50% perlite. This will ensure adequate drainage and aeration, helping to prevent overwatering-related issues. - For Seed Starting Perlite can also be used in seed starting mixes. Its lightweight and airy nature helps ensure that seeds have the right environment to germinate and root successfully. A mix of 50% perlite and 50% peat moss is a popular choice for this purpose. Conclusion In conclusion, perlite is a versatile and beneficial addition to garden soil. Its ability to improve drainage, aeration, and soil structure makes it a favorite among gardeners aiming for healthy, thriving plants. Whether you're tending to a small container garden or a large landscape, incorporating perlite can significantly enhance the quality of your soil and promote optimal plant growth. As gardening continues to evolve, the use of innovative and sustainable materials like perlite will play a key role in nurturing our green spaces._perlite bulk price2025-08-17 18:17Read(694)- " title=''>" title=''>

...

Read Moregarden soil perlite******The Role of Perlite in Garden Soil Enhancing Growth and Drainage Gardening enthusiasts and professionals alike understand that soil is the lifeblood of any garden. It serves as the foundation for plant health, influencing everything from nutrient availability to water retention. One key ingredient that has gained popularity in soil mixtures is perlite. This article will explore the importance of perlite in garden soil, its physical properties, and how it can enhance plant growth. What is Perlite? Perlite is a naturally occurring volcanic glass that expands when heated to high temperatures, resulting in a lightweight, white, and porous material. This transformation creates a structure that is not only beneficial for soil but also environmentally sustainable. Perlite is often used as a soil amendment and serves various purposes due to its unique characteristics. Benefits of Using Perlite in Garden Soil 1. Improved Drainage One of the most significant benefits of incorporating perlite into garden soil is its ability to improve drainage. Many plants, especially those in containers, can suffer from root rot and other issues related to overwatering. Perlite's porous structure allows excess water to drain away freely, preventing the soil from becoming waterlogged. This ensures that the roots have access to the moisture and oxygen they need to thrive. 2. Aeration In addition to improving drainage, perlite also enhances the aeration of soil. Good aeration is crucial for root development as it allows oxygen to reach the roots. Compacted soil can inhibit root growth, leading to stunted plants. By adding perlite to garden soil, you create a looser, more friable mix that encourages healthy root systems and promotes overall plant vigor. 3. Lightweight Composition For container gardening, the weight of the soil can be a concern, especially if you have larger pots or plan to move them around. Perlite is extremely lightweight, making it an ideal choice for potting mixes. This characteristic not only eases the burden of lifting but also minimizes the risk of container tipping over due to excess weight. garden soil perlite 4. pH Neutrality Perlite is pH neutral, which means it won’t alter the acidity or alkalinity of the soil mix. This makes it suitable for a wide variety of plants, ensuring that it won't interfere with their nutrient uptake. For gardeners looking to create specific pH environments for particular plant species, this is a significant advantage. 5. Encourages Microbiome Health The porous nature of perlite also encourages beneficial microbial activity in the soil. Healthy microbial communities play essential roles in nutrient cycling and the overall health of the garden ecosystem. By adding perlite, you create an environment conducive to these beneficial microorganisms, which can improve soil fertility and plant growth. How to Use Perlite in Your Garden Incorporating perlite into your garden soil is relatively straightforward - For Garden Beds When preparing garden beds, particularly for vegetables and flowers that prefer well-drained soil, mix about 20-30% perlite into your existing soil. This ratio can vary based on the type of plants you intend to grow; more water-sensitive plants may benefit from a higher perlite content. - For Container Gardening For potting mixes, aim for a blend that includes 30-50% perlite. This will ensure adequate drainage and aeration, helping to prevent overwatering-related issues. - For Seed Starting Perlite can also be used in seed starting mixes. Its lightweight and airy nature helps ensure that seeds have the right environment to germinate and root successfully. A mix of 50% perlite and 50% peat moss is a popular choice for this purpose. Conclusion In conclusion, perlite is a versatile and beneficial addition to garden soil. Its ability to improve drainage, aeration, and soil structure makes it a favorite among gardeners aiming for healthy, thriving plants. Whether you're tending to a small container garden or a large landscape, incorporating perlite can significantly enhance the quality of your soil and promote optimal plant growth. As gardening continues to evolve, the use of innovative and sustainable materials like perlite will play a key role in nurturing our green spaces._perlite bulk price2025-08-17 17:58Read(1894)The Role of Perlite in Agriculture A Focus on Manufacturers

...

Read Moregarden soil perlite******The Role of Perlite in Garden Soil Enhancing Growth and Drainage Gardening enthusiasts and professionals alike understand that soil is the lifeblood of any garden. It serves as the foundation for plant health, influencing everything from nutrient availability to water retention. One key ingredient that has gained popularity in soil mixtures is perlite. This article will explore the importance of perlite in garden soil, its physical properties, and how it can enhance plant growth. What is Perlite? Perlite is a naturally occurring volcanic glass that expands when heated to high temperatures, resulting in a lightweight, white, and porous material. This transformation creates a structure that is not only beneficial for soil but also environmentally sustainable. Perlite is often used as a soil amendment and serves various purposes due to its unique characteristics. Benefits of Using Perlite in Garden Soil 1. Improved Drainage One of the most significant benefits of incorporating perlite into garden soil is its ability to improve drainage. Many plants, especially those in containers, can suffer from root rot and other issues related to overwatering. Perlite's porous structure allows excess water to drain away freely, preventing the soil from becoming waterlogged. This ensures that the roots have access to the moisture and oxygen they need to thrive. 2. Aeration In addition to improving drainage, perlite also enhances the aeration of soil. Good aeration is crucial for root development as it allows oxygen to reach the roots. Compacted soil can inhibit root growth, leading to stunted plants. By adding perlite to garden soil, you create a looser, more friable mix that encourages healthy root systems and promotes overall plant vigor. 3. Lightweight Composition For container gardening, the weight of the soil can be a concern, especially if you have larger pots or plan to move them around. Perlite is extremely lightweight, making it an ideal choice for potting mixes. This characteristic not only eases the burden of lifting but also minimizes the risk of container tipping over due to excess weight. garden soil perlite 4. pH Neutrality Perlite is pH neutral, which means it won’t alter the acidity or alkalinity of the soil mix. This makes it suitable for a wide variety of plants, ensuring that it won't interfere with their nutrient uptake. For gardeners looking to create specific pH environments for particular plant species, this is a significant advantage. 5. Encourages Microbiome Health The porous nature of perlite also encourages beneficial microbial activity in the soil. Healthy microbial communities play essential roles in nutrient cycling and the overall health of the garden ecosystem. By adding perlite, you create an environment conducive to these beneficial microorganisms, which can improve soil fertility and plant growth. How to Use Perlite in Your Garden Incorporating perlite into your garden soil is relatively straightforward - For Garden Beds When preparing garden beds, particularly for vegetables and flowers that prefer well-drained soil, mix about 20-30% perlite into your existing soil. This ratio can vary based on the type of plants you intend to grow; more water-sensitive plants may benefit from a higher perlite content. - For Container Gardening For potting mixes, aim for a blend that includes 30-50% perlite. This will ensure adequate drainage and aeration, helping to prevent overwatering-related issues. - For Seed Starting Perlite can also be used in seed starting mixes. Its lightweight and airy nature helps ensure that seeds have the right environment to germinate and root successfully. A mix of 50% perlite and 50% peat moss is a popular choice for this purpose. Conclusion In conclusion, perlite is a versatile and beneficial addition to garden soil. Its ability to improve drainage, aeration, and soil structure makes it a favorite among gardeners aiming for healthy, thriving plants. Whether you're tending to a small container garden or a large landscape, incorporating perlite can significantly enhance the quality of your soil and promote optimal plant growth. As gardening continues to evolve, the use of innovative and sustainable materials like perlite will play a key role in nurturing our green spaces._perlite bulk price2025-08-17 17:50Read(1865)Manufacturers of Stacked Pebbles in China for Creative Landscaping Solutions

The Art of Crafting Stacked Pebbles Insights into China's Manufacturing Landscape In recent years, t...

Read Moregarden soil perlite******The Role of Perlite in Garden Soil Enhancing Growth and Drainage Gardening enthusiasts and professionals alike understand that soil is the lifeblood of any garden. It serves as the foundation for plant health, influencing everything from nutrient availability to water retention. One key ingredient that has gained popularity in soil mixtures is perlite. This article will explore the importance of perlite in garden soil, its physical properties, and how it can enhance plant growth. What is Perlite? Perlite is a naturally occurring volcanic glass that expands when heated to high temperatures, resulting in a lightweight, white, and porous material. This transformation creates a structure that is not only beneficial for soil but also environmentally sustainable. Perlite is often used as a soil amendment and serves various purposes due to its unique characteristics. Benefits of Using Perlite in Garden Soil 1. Improved Drainage One of the most significant benefits of incorporating perlite into garden soil is its ability to improve drainage. Many plants, especially those in containers, can suffer from root rot and other issues related to overwatering. Perlite's porous structure allows excess water to drain away freely, preventing the soil from becoming waterlogged. This ensures that the roots have access to the moisture and oxygen they need to thrive. 2. Aeration In addition to improving drainage, perlite also enhances the aeration of soil. Good aeration is crucial for root development as it allows oxygen to reach the roots. Compacted soil can inhibit root growth, leading to stunted plants. By adding perlite to garden soil, you create a looser, more friable mix that encourages healthy root systems and promotes overall plant vigor. 3. Lightweight Composition For container gardening, the weight of the soil can be a concern, especially if you have larger pots or plan to move them around. Perlite is extremely lightweight, making it an ideal choice for potting mixes. This characteristic not only eases the burden of lifting but also minimizes the risk of container tipping over due to excess weight. garden soil perlite 4. pH Neutrality Perlite is pH neutral, which means it won’t alter the acidity or alkalinity of the soil mix. This makes it suitable for a wide variety of plants, ensuring that it won't interfere with their nutrient uptake. For gardeners looking to create specific pH environments for particular plant species, this is a significant advantage. 5. Encourages Microbiome Health The porous nature of perlite also encourages beneficial microbial activity in the soil. Healthy microbial communities play essential roles in nutrient cycling and the overall health of the garden ecosystem. By adding perlite, you create an environment conducive to these beneficial microorganisms, which can improve soil fertility and plant growth. How to Use Perlite in Your Garden Incorporating perlite into your garden soil is relatively straightforward - For Garden Beds When preparing garden beds, particularly for vegetables and flowers that prefer well-drained soil, mix about 20-30% perlite into your existing soil. This ratio can vary based on the type of plants you intend to grow; more water-sensitive plants may benefit from a higher perlite content. - For Container Gardening For potting mixes, aim for a blend that includes 30-50% perlite. This will ensure adequate drainage and aeration, helping to prevent overwatering-related issues. - For Seed Starting Perlite can also be used in seed starting mixes. Its lightweight and airy nature helps ensure that seeds have the right environment to germinate and root successfully. A mix of 50% perlite and 50% peat moss is a popular choice for this purpose. Conclusion In conclusion, perlite is a versatile and beneficial addition to garden soil. Its ability to improve drainage, aeration, and soil structure makes it a favorite among gardeners aiming for healthy, thriving plants. Whether you're tending to a small container garden or a large landscape, incorporating perlite can significantly enhance the quality of your soil and promote optimal plant growth. As gardening continues to evolve, the use of innovative and sustainable materials like perlite will play a key role in nurturing our green spaces._perlite bulk price2025-08-17 17:34Read(936)One of the primary benefits of using vermiculite in chimneys is its excellent thermal insulation properties. Chimneys are exposed to high temperatures due to the combustion of fuels, and proper insulation is essential to prevent heat loss. By incorporating vermiculite into chimney construction, builders can enhance energy efficiency and ensure that heat remains contained within the flue. This not only reduces heating costs but also helps maintain a consistent temperature within the chimney, preventing excessive heat from accumulating, which could lead to structural damage or hazards.

...

Read Moregarden soil perlite******The Role of Perlite in Garden Soil Enhancing Growth and Drainage Gardening enthusiasts and professionals alike understand that soil is the lifeblood of any garden. It serves as the foundation for plant health, influencing everything from nutrient availability to water retention. One key ingredient that has gained popularity in soil mixtures is perlite. This article will explore the importance of perlite in garden soil, its physical properties, and how it can enhance plant growth. What is Perlite? Perlite is a naturally occurring volcanic glass that expands when heated to high temperatures, resulting in a lightweight, white, and porous material. This transformation creates a structure that is not only beneficial for soil but also environmentally sustainable. Perlite is often used as a soil amendment and serves various purposes due to its unique characteristics. Benefits of Using Perlite in Garden Soil 1. Improved Drainage One of the most significant benefits of incorporating perlite into garden soil is its ability to improve drainage. Many plants, especially those in containers, can suffer from root rot and other issues related to overwatering. Perlite's porous structure allows excess water to drain away freely, preventing the soil from becoming waterlogged. This ensures that the roots have access to the moisture and oxygen they need to thrive. 2. Aeration In addition to improving drainage, perlite also enhances the aeration of soil. Good aeration is crucial for root development as it allows oxygen to reach the roots. Compacted soil can inhibit root growth, leading to stunted plants. By adding perlite to garden soil, you create a looser, more friable mix that encourages healthy root systems and promotes overall plant vigor. 3. Lightweight Composition For container gardening, the weight of the soil can be a concern, especially if you have larger pots or plan to move them around. Perlite is extremely lightweight, making it an ideal choice for potting mixes. This characteristic not only eases the burden of lifting but also minimizes the risk of container tipping over due to excess weight. garden soil perlite 4. pH Neutrality Perlite is pH neutral, which means it won’t alter the acidity or alkalinity of the soil mix. This makes it suitable for a wide variety of plants, ensuring that it won't interfere with their nutrient uptake. For gardeners looking to create specific pH environments for particular plant species, this is a significant advantage. 5. Encourages Microbiome Health The porous nature of perlite also encourages beneficial microbial activity in the soil. Healthy microbial communities play essential roles in nutrient cycling and the overall health of the garden ecosystem. By adding perlite, you create an environment conducive to these beneficial microorganisms, which can improve soil fertility and plant growth. How to Use Perlite in Your Garden Incorporating perlite into your garden soil is relatively straightforward - For Garden Beds When preparing garden beds, particularly for vegetables and flowers that prefer well-drained soil, mix about 20-30% perlite into your existing soil. This ratio can vary based on the type of plants you intend to grow; more water-sensitive plants may benefit from a higher perlite content. - For Container Gardening For potting mixes, aim for a blend that includes 30-50% perlite. This will ensure adequate drainage and aeration, helping to prevent overwatering-related issues. - For Seed Starting Perlite can also be used in seed starting mixes. Its lightweight and airy nature helps ensure that seeds have the right environment to germinate and root successfully. A mix of 50% perlite and 50% peat moss is a popular choice for this purpose. Conclusion In conclusion, perlite is a versatile and beneficial addition to garden soil. Its ability to improve drainage, aeration, and soil structure makes it a favorite among gardeners aiming for healthy, thriving plants. Whether you're tending to a small container garden or a large landscape, incorporating perlite can significantly enhance the quality of your soil and promote optimal plant growth. As gardening continues to evolve, the use of innovative and sustainable materials like perlite will play a key role in nurturing our green spaces._perlite bulk price2025-08-17 17:03Read(2080)Latest tags

Links: