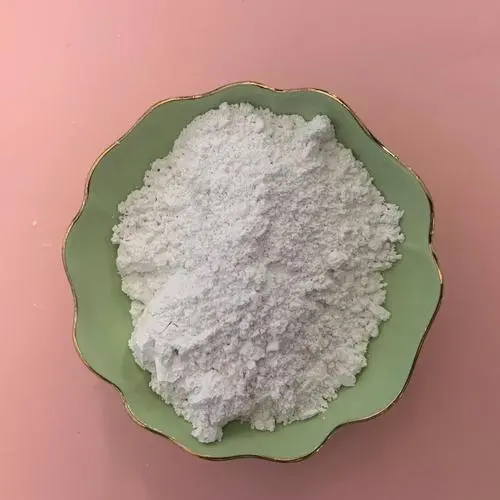

- oem calcium hydroxide powder factories******Understanding OEM Calcium Hydroxide Powder Factories An Insight into Production and Applications Calcium hydroxide, also known as hydrated lime or slack lime, is a versatile chemical compound with a wide array of industrial applications. Its uses range from water treatment and soil stabilization to being a critical component in the construction and agriculture sectors. The growing demand for calcium hydroxide has led to an increase in the number of Original Equipment Manufacturer (OEM) factories dedicated to producing this essential material. In this article, we will explore the fundamentals of calcium hydroxide powder production, the significance of OEM factories, and the various applications of this compound. Calcium Hydroxide Powder Production Process The main raw material for producing calcium hydroxide is calcium oxide, commonly derived from limestone. The production process begins with the calcination of limestone at high temperatures to produce quicklime (calcium oxide). The quicklime is then mixed with water in a process known as slaking, resulting in the formation of calcium hydroxide. This substance can be processed into a fine powder, making it suitable for various applications. OEM factories that specialize in calcium hydroxide powder production often employ advanced manufacturing techniques and technologies to ensure high-purity and finely ground products. These facilities prioritize quality control throughout the production process, with rigorous testing to meet industry standards. The scale of production varies among OEM factories, with some catering to large-scale industrial clients while others focus on smaller, specialized batches. The Role of OEM Factories OEM factories play a critical role in the supply chain of calcium hydroxide powder. They not only produce the raw material but also offer customizable solutions for various industries. The significance of OEM factories can be highlighted through several key points 1. Customization OEM factories can produce calcium hydroxide powder based on specific customer requirements, including particle size, purity, and packaging. This flexibility allows them to cater to diverse industry needs. 2. Quality Assurance Many OEM manufacturers adopt stringent quality control measures to ensure that their products meet international safety and quality standards. This is particularly important in industries like food production, where high purity levels are essential. 3. Innovation and Research Some OEM factories invest in research and development to improve product formulations and manufacturing processes. This focus on innovation can lead to enhanced performance of calcium hydroxide in various applications. oem calcium hydroxide powder factories 4. Supply Chain Efficiency By streamlining production and logistics, OEM factories help ensure a steady supply of calcium hydroxide powder, minimizing delays and disruptions for companies relying on this material. Applications of Calcium Hydroxide Powder The versatility of calcium hydroxide powder translates into numerous applications across different sectors 1. Water Treatment Calcium hydroxide is widely used in water treatment plants for pH control and as a coagulating agent to remove impurities from water. 2. Construction In the construction industry, calcium hydroxide is essential in producing calcium silicate bricks, as well as in various cement formulations. Its properties enhance the durability and stability of construction materials. 3. Agriculture Farmers use calcium hydroxide to correct soil acidity, improve nutrient availability, and promote better crop yields. It is also involved in the production of animal feed products. 4. Chemical Manufacturing Calcium hydroxide serves as a key ingredient in various chemical processes, including the production of calcium-based compounds and in the manufacturing of pharmaceuticals. 5. Food Industry In the food sector, calcium hydroxide acts as a food additive and is used in the processing of certain types of food products, such as pickles and canned vegetables. Conclusion The rise of OEM calcium hydroxide powder factories marks a significant development in the industrial landscape. As the demand for calcium hydroxide continues to grow across various sectors, these factories play an indispensable role in ensuring a reliable supply of high-quality products. Their ability to offer customized solutions, adhere to quality standards, and innovate within the production process positions them as key players in supporting industries worldwide. As we look to the future, the ongoing development of OEM factories will likely continue to enhance the efficiency and effectiveness of calcium hydroxide applications.>

- oem calcium hydroxide powder factories******Understanding OEM Calcium Hydroxide Powder Factories An Insight into Production and Applications Calcium hydroxide, also known as hydrated lime or slack lime, is a versatile chemical compound with a wide array of industrial applications. Its uses range from water treatment and soil stabilization to being a critical component in the construction and agriculture sectors. The growing demand for calcium hydroxide has led to an increase in the number of Original Equipment Manufacturer (OEM) factories dedicated to producing this essential material. In this article, we will explore the fundamentals of calcium hydroxide powder production, the significance of OEM factories, and the various applications of this compound. Calcium Hydroxide Powder Production Process The main raw material for producing calcium hydroxide is calcium oxide, commonly derived from limestone. The production process begins with the calcination of limestone at high temperatures to produce quicklime (calcium oxide). The quicklime is then mixed with water in a process known as slaking, resulting in the formation of calcium hydroxide. This substance can be processed into a fine powder, making it suitable for various applications. OEM factories that specialize in calcium hydroxide powder production often employ advanced manufacturing techniques and technologies to ensure high-purity and finely ground products. These facilities prioritize quality control throughout the production process, with rigorous testing to meet industry standards. The scale of production varies among OEM factories, with some catering to large-scale industrial clients while others focus on smaller, specialized batches. The Role of OEM Factories OEM factories play a critical role in the supply chain of calcium hydroxide powder. They not only produce the raw material but also offer customizable solutions for various industries. The significance of OEM factories can be highlighted through several key points 1. Customization OEM factories can produce calcium hydroxide powder based on specific customer requirements, including particle size, purity, and packaging. This flexibility allows them to cater to diverse industry needs. 2. Quality Assurance Many OEM manufacturers adopt stringent quality control measures to ensure that their products meet international safety and quality standards. This is particularly important in industries like food production, where high purity levels are essential. 3. Innovation and Research Some OEM factories invest in research and development to improve product formulations and manufacturing processes. This focus on innovation can lead to enhanced performance of calcium hydroxide in various applications. oem calcium hydroxide powder factories 4. Supply Chain Efficiency By streamlining production and logistics, OEM factories help ensure a steady supply of calcium hydroxide powder, minimizing delays and disruptions for companies relying on this material. Applications of Calcium Hydroxide Powder The versatility of calcium hydroxide powder translates into numerous applications across different sectors 1. Water Treatment Calcium hydroxide is widely used in water treatment plants for pH control and as a coagulating agent to remove impurities from water. 2. Construction In the construction industry, calcium hydroxide is essential in producing calcium silicate bricks, as well as in various cement formulations. Its properties enhance the durability and stability of construction materials. 3. Agriculture Farmers use calcium hydroxide to correct soil acidity, improve nutrient availability, and promote better crop yields. It is also involved in the production of animal feed products. 4. Chemical Manufacturing Calcium hydroxide serves as a key ingredient in various chemical processes, including the production of calcium-based compounds and in the manufacturing of pharmaceuticals. 5. Food Industry In the food sector, calcium hydroxide acts as a food additive and is used in the processing of certain types of food products, such as pickles and canned vegetables. Conclusion The rise of OEM calcium hydroxide powder factories marks a significant development in the industrial landscape. As the demand for calcium hydroxide continues to grow across various sectors, these factories play an indispensable role in ensuring a reliable supply of high-quality products. Their ability to offer customized solutions, adhere to quality standards, and innovate within the production process positions them as key players in supporting industries worldwide. As we look to the future, the ongoing development of OEM factories will likely continue to enhance the efficiency and effectiveness of calcium hydroxide applications._composite mica manufacturer

oem calcium hydroxide powder factories******Understanding OEM Calcium Hydroxide Powder Factories An Insight into Production and Applications Calcium hydroxide, also known as hydrated lime or slack lime, is a versatile chemical compound with a wide array of industrial applications. Its uses range from water treatment and soil stabilization to being a critical component in the construction and agriculture sectors. The growing demand for calcium hydroxide has led to an increase in the number of Original Equipment Manufacturer (OEM) factories dedicated to producing this essential material. In this article, we will explore the fundamentals of calcium hydroxide powder production, the significance of OEM factories, and the various applications of this compound. Calcium Hydroxide Powder Production Process The main raw material for producing calcium hydroxide is calcium oxide, commonly derived from limestone. The production process begins with the calcination of limestone at high temperatures to produce quicklime (calcium oxide). The quicklime is then mixed with water in a process known as slaking, resulting in the formation of calcium hydroxide. This substance can be processed into a fine powder, making it suitable for various applications. OEM factories that specialize in calcium hydroxide powder production often employ advanced manufacturing techniques and technologies to ensure high-purity and finely ground products. These facilities prioritize quality control throughout the production process, with rigorous testing to meet industry standards. The scale of production varies among OEM factories, with some catering to large-scale industrial clients while others focus on smaller, specialized batches. The Role of OEM Factories OEM factories play a critical role in the supply chain of calcium hydroxide powder. They not only produce the raw material but also offer customizable solutions for various industries. The significance of OEM factories can be highlighted through several key points 1. Customization OEM factories can produce calcium hydroxide powder based on specific customer requirements, including particle size, purity, and packaging. This flexibility allows them to cater to diverse industry needs. 2. Quality Assurance Many OEM manufacturers adopt stringent quality control measures to ensure that their products meet international safety and quality standards. This is particularly important in industries like food production, where high purity levels are essential. 3. Innovation and Research Some OEM factories invest in research and development to improve product formulations and manufacturing processes. This focus on innovation can lead to enhanced performance of calcium hydroxide in various applications. oem calcium hydroxide powder factories 4. Supply Chain Efficiency By streamlining production and logistics, OEM factories help ensure a steady supply of calcium hydroxide powder, minimizing delays and disruptions for companies relying on this material. Applications of Calcium Hydroxide Powder The versatility of calcium hydroxide powder translates into numerous applications across different sectors 1. Water Treatment Calcium hydroxide is widely used in water treatment plants for pH control and as a coagulating agent to remove impurities from water. 2. Construction In the construction industry, calcium hydroxide is essential in producing calcium silicate bricks, as well as in various cement formulations. Its properties enhance the durability and stability of construction materials. 3. Agriculture Farmers use calcium hydroxide to correct soil acidity, improve nutrient availability, and promote better crop yields. It is also involved in the production of animal feed products. 4. Chemical Manufacturing Calcium hydroxide serves as a key ingredient in various chemical processes, including the production of calcium-based compounds and in the manufacturing of pharmaceuticals. 5. Food Industry In the food sector, calcium hydroxide acts as a food additive and is used in the processing of certain types of food products, such as pickles and canned vegetables. Conclusion The rise of OEM calcium hydroxide powder factories marks a significant development in the industrial landscape. As the demand for calcium hydroxide continues to grow across various sectors, these factories play an indispensable role in ensuring a reliable supply of high-quality products. Their ability to offer customized solutions, adhere to quality standards, and innovate within the production process positions them as key players in supporting industries worldwide. As we look to the future, the ongoing development of OEM factories will likely continue to enhance the efficiency and effectiveness of calcium hydroxide applications._composite mica manufacturer

LOI Fly Ash

Exploring the Benefits and Applications of Fly Ash in Modern Construction Fly ash, a byproduct of co...

Read Moreoem calcium hydroxide powder factories******Understanding OEM Calcium Hydroxide Powder Factories An Insight into Production and Applications Calcium hydroxide, also known as hydrated lime or slack lime, is a versatile chemical compound with a wide array of industrial applications. Its uses range from water treatment and soil stabilization to being a critical component in the construction and agriculture sectors. The growing demand for calcium hydroxide has led to an increase in the number of Original Equipment Manufacturer (OEM) factories dedicated to producing this essential material. In this article, we will explore the fundamentals of calcium hydroxide powder production, the significance of OEM factories, and the various applications of this compound. Calcium Hydroxide Powder Production Process The main raw material for producing calcium hydroxide is calcium oxide, commonly derived from limestone. The production process begins with the calcination of limestone at high temperatures to produce quicklime (calcium oxide). The quicklime is then mixed with water in a process known as slaking, resulting in the formation of calcium hydroxide. This substance can be processed into a fine powder, making it suitable for various applications. OEM factories that specialize in calcium hydroxide powder production often employ advanced manufacturing techniques and technologies to ensure high-purity and finely ground products. These facilities prioritize quality control throughout the production process, with rigorous testing to meet industry standards. The scale of production varies among OEM factories, with some catering to large-scale industrial clients while others focus on smaller, specialized batches. The Role of OEM Factories OEM factories play a critical role in the supply chain of calcium hydroxide powder. They not only produce the raw material but also offer customizable solutions for various industries. The significance of OEM factories can be highlighted through several key points 1. Customization OEM factories can produce calcium hydroxide powder based on specific customer requirements, including particle size, purity, and packaging. This flexibility allows them to cater to diverse industry needs. 2. Quality Assurance Many OEM manufacturers adopt stringent quality control measures to ensure that their products meet international safety and quality standards. This is particularly important in industries like food production, where high purity levels are essential. 3. Innovation and Research Some OEM factories invest in research and development to improve product formulations and manufacturing processes. This focus on innovation can lead to enhanced performance of calcium hydroxide in various applications. oem calcium hydroxide powder factories 4. Supply Chain Efficiency By streamlining production and logistics, OEM factories help ensure a steady supply of calcium hydroxide powder, minimizing delays and disruptions for companies relying on this material. Applications of Calcium Hydroxide Powder The versatility of calcium hydroxide powder translates into numerous applications across different sectors 1. Water Treatment Calcium hydroxide is widely used in water treatment plants for pH control and as a coagulating agent to remove impurities from water. 2. Construction In the construction industry, calcium hydroxide is essential in producing calcium silicate bricks, as well as in various cement formulations. Its properties enhance the durability and stability of construction materials. 3. Agriculture Farmers use calcium hydroxide to correct soil acidity, improve nutrient availability, and promote better crop yields. It is also involved in the production of animal feed products. 4. Chemical Manufacturing Calcium hydroxide serves as a key ingredient in various chemical processes, including the production of calcium-based compounds and in the manufacturing of pharmaceuticals. 5. Food Industry In the food sector, calcium hydroxide acts as a food additive and is used in the processing of certain types of food products, such as pickles and canned vegetables. Conclusion The rise of OEM calcium hydroxide powder factories marks a significant development in the industrial landscape. As the demand for calcium hydroxide continues to grow across various sectors, these factories play an indispensable role in ensuring a reliable supply of high-quality products. Their ability to offer customized solutions, adhere to quality standards, and innovate within the production process positions them as key players in supporting industries worldwide. As we look to the future, the ongoing development of OEM factories will likely continue to enhance the efficiency and effectiveness of calcium hydroxide applications._composite mica manufacturer2025-08-17 18:44Read(661)dry fly ash

The Role of Dry Fly Ash in Modern Construction In the ever-evolving field of construction and civil...

Read Moreoem calcium hydroxide powder factories******Understanding OEM Calcium Hydroxide Powder Factories An Insight into Production and Applications Calcium hydroxide, also known as hydrated lime or slack lime, is a versatile chemical compound with a wide array of industrial applications. Its uses range from water treatment and soil stabilization to being a critical component in the construction and agriculture sectors. The growing demand for calcium hydroxide has led to an increase in the number of Original Equipment Manufacturer (OEM) factories dedicated to producing this essential material. In this article, we will explore the fundamentals of calcium hydroxide powder production, the significance of OEM factories, and the various applications of this compound. Calcium Hydroxide Powder Production Process The main raw material for producing calcium hydroxide is calcium oxide, commonly derived from limestone. The production process begins with the calcination of limestone at high temperatures to produce quicklime (calcium oxide). The quicklime is then mixed with water in a process known as slaking, resulting in the formation of calcium hydroxide. This substance can be processed into a fine powder, making it suitable for various applications. OEM factories that specialize in calcium hydroxide powder production often employ advanced manufacturing techniques and technologies to ensure high-purity and finely ground products. These facilities prioritize quality control throughout the production process, with rigorous testing to meet industry standards. The scale of production varies among OEM factories, with some catering to large-scale industrial clients while others focus on smaller, specialized batches. The Role of OEM Factories OEM factories play a critical role in the supply chain of calcium hydroxide powder. They not only produce the raw material but also offer customizable solutions for various industries. The significance of OEM factories can be highlighted through several key points 1. Customization OEM factories can produce calcium hydroxide powder based on specific customer requirements, including particle size, purity, and packaging. This flexibility allows them to cater to diverse industry needs. 2. Quality Assurance Many OEM manufacturers adopt stringent quality control measures to ensure that their products meet international safety and quality standards. This is particularly important in industries like food production, where high purity levels are essential. 3. Innovation and Research Some OEM factories invest in research and development to improve product formulations and manufacturing processes. This focus on innovation can lead to enhanced performance of calcium hydroxide in various applications. oem calcium hydroxide powder factories 4. Supply Chain Efficiency By streamlining production and logistics, OEM factories help ensure a steady supply of calcium hydroxide powder, minimizing delays and disruptions for companies relying on this material. Applications of Calcium Hydroxide Powder The versatility of calcium hydroxide powder translates into numerous applications across different sectors 1. Water Treatment Calcium hydroxide is widely used in water treatment plants for pH control and as a coagulating agent to remove impurities from water. 2. Construction In the construction industry, calcium hydroxide is essential in producing calcium silicate bricks, as well as in various cement formulations. Its properties enhance the durability and stability of construction materials. 3. Agriculture Farmers use calcium hydroxide to correct soil acidity, improve nutrient availability, and promote better crop yields. It is also involved in the production of animal feed products. 4. Chemical Manufacturing Calcium hydroxide serves as a key ingredient in various chemical processes, including the production of calcium-based compounds and in the manufacturing of pharmaceuticals. 5. Food Industry In the food sector, calcium hydroxide acts as a food additive and is used in the processing of certain types of food products, such as pickles and canned vegetables. Conclusion The rise of OEM calcium hydroxide powder factories marks a significant development in the industrial landscape. As the demand for calcium hydroxide continues to grow across various sectors, these factories play an indispensable role in ensuring a reliable supply of high-quality products. Their ability to offer customized solutions, adhere to quality standards, and innovate within the production process positions them as key players in supporting industries worldwide. As we look to the future, the ongoing development of OEM factories will likely continue to enhance the efficiency and effectiveness of calcium hydroxide applications._composite mica manufacturer2025-08-17 18:28Read(1751)kosmetický talkový prášek

Kosmetický mastek Vše, co potřebujete vědět Kosmetický mastek, známý také jako talek, je jemný miner...

Read Moreoem calcium hydroxide powder factories******Understanding OEM Calcium Hydroxide Powder Factories An Insight into Production and Applications Calcium hydroxide, also known as hydrated lime or slack lime, is a versatile chemical compound with a wide array of industrial applications. Its uses range from water treatment and soil stabilization to being a critical component in the construction and agriculture sectors. The growing demand for calcium hydroxide has led to an increase in the number of Original Equipment Manufacturer (OEM) factories dedicated to producing this essential material. In this article, we will explore the fundamentals of calcium hydroxide powder production, the significance of OEM factories, and the various applications of this compound. Calcium Hydroxide Powder Production Process The main raw material for producing calcium hydroxide is calcium oxide, commonly derived from limestone. The production process begins with the calcination of limestone at high temperatures to produce quicklime (calcium oxide). The quicklime is then mixed with water in a process known as slaking, resulting in the formation of calcium hydroxide. This substance can be processed into a fine powder, making it suitable for various applications. OEM factories that specialize in calcium hydroxide powder production often employ advanced manufacturing techniques and technologies to ensure high-purity and finely ground products. These facilities prioritize quality control throughout the production process, with rigorous testing to meet industry standards. The scale of production varies among OEM factories, with some catering to large-scale industrial clients while others focus on smaller, specialized batches. The Role of OEM Factories OEM factories play a critical role in the supply chain of calcium hydroxide powder. They not only produce the raw material but also offer customizable solutions for various industries. The significance of OEM factories can be highlighted through several key points 1. Customization OEM factories can produce calcium hydroxide powder based on specific customer requirements, including particle size, purity, and packaging. This flexibility allows them to cater to diverse industry needs. 2. Quality Assurance Many OEM manufacturers adopt stringent quality control measures to ensure that their products meet international safety and quality standards. This is particularly important in industries like food production, where high purity levels are essential. 3. Innovation and Research Some OEM factories invest in research and development to improve product formulations and manufacturing processes. This focus on innovation can lead to enhanced performance of calcium hydroxide in various applications. oem calcium hydroxide powder factories 4. Supply Chain Efficiency By streamlining production and logistics, OEM factories help ensure a steady supply of calcium hydroxide powder, minimizing delays and disruptions for companies relying on this material. Applications of Calcium Hydroxide Powder The versatility of calcium hydroxide powder translates into numerous applications across different sectors 1. Water Treatment Calcium hydroxide is widely used in water treatment plants for pH control and as a coagulating agent to remove impurities from water. 2. Construction In the construction industry, calcium hydroxide is essential in producing calcium silicate bricks, as well as in various cement formulations. Its properties enhance the durability and stability of construction materials. 3. Agriculture Farmers use calcium hydroxide to correct soil acidity, improve nutrient availability, and promote better crop yields. It is also involved in the production of animal feed products. 4. Chemical Manufacturing Calcium hydroxide serves as a key ingredient in various chemical processes, including the production of calcium-based compounds and in the manufacturing of pharmaceuticals. 5. Food Industry In the food sector, calcium hydroxide acts as a food additive and is used in the processing of certain types of food products, such as pickles and canned vegetables. Conclusion The rise of OEM calcium hydroxide powder factories marks a significant development in the industrial landscape. As the demand for calcium hydroxide continues to grow across various sectors, these factories play an indispensable role in ensuring a reliable supply of high-quality products. Their ability to offer customized solutions, adhere to quality standards, and innovate within the production process positions them as key players in supporting industries worldwide. As we look to the future, the ongoing development of OEM factories will likely continue to enhance the efficiency and effectiveness of calcium hydroxide applications._composite mica manufacturer2025-08-17 18:25Read(754)Exploring the Beauty and Origins of Purple Mica Crystals in Nature

The Enigmatic World of Purple Mica Crystals Mica is a fascinating mineral renowned for its remarkabl...

Read Moreoem calcium hydroxide powder factories******Understanding OEM Calcium Hydroxide Powder Factories An Insight into Production and Applications Calcium hydroxide, also known as hydrated lime or slack lime, is a versatile chemical compound with a wide array of industrial applications. Its uses range from water treatment and soil stabilization to being a critical component in the construction and agriculture sectors. The growing demand for calcium hydroxide has led to an increase in the number of Original Equipment Manufacturer (OEM) factories dedicated to producing this essential material. In this article, we will explore the fundamentals of calcium hydroxide powder production, the significance of OEM factories, and the various applications of this compound. Calcium Hydroxide Powder Production Process The main raw material for producing calcium hydroxide is calcium oxide, commonly derived from limestone. The production process begins with the calcination of limestone at high temperatures to produce quicklime (calcium oxide). The quicklime is then mixed with water in a process known as slaking, resulting in the formation of calcium hydroxide. This substance can be processed into a fine powder, making it suitable for various applications. OEM factories that specialize in calcium hydroxide powder production often employ advanced manufacturing techniques and technologies to ensure high-purity and finely ground products. These facilities prioritize quality control throughout the production process, with rigorous testing to meet industry standards. The scale of production varies among OEM factories, with some catering to large-scale industrial clients while others focus on smaller, specialized batches. The Role of OEM Factories OEM factories play a critical role in the supply chain of calcium hydroxide powder. They not only produce the raw material but also offer customizable solutions for various industries. The significance of OEM factories can be highlighted through several key points 1. Customization OEM factories can produce calcium hydroxide powder based on specific customer requirements, including particle size, purity, and packaging. This flexibility allows them to cater to diverse industry needs. 2. Quality Assurance Many OEM manufacturers adopt stringent quality control measures to ensure that their products meet international safety and quality standards. This is particularly important in industries like food production, where high purity levels are essential. 3. Innovation and Research Some OEM factories invest in research and development to improve product formulations and manufacturing processes. This focus on innovation can lead to enhanced performance of calcium hydroxide in various applications. oem calcium hydroxide powder factories 4. Supply Chain Efficiency By streamlining production and logistics, OEM factories help ensure a steady supply of calcium hydroxide powder, minimizing delays and disruptions for companies relying on this material. Applications of Calcium Hydroxide Powder The versatility of calcium hydroxide powder translates into numerous applications across different sectors 1. Water Treatment Calcium hydroxide is widely used in water treatment plants for pH control and as a coagulating agent to remove impurities from water. 2. Construction In the construction industry, calcium hydroxide is essential in producing calcium silicate bricks, as well as in various cement formulations. Its properties enhance the durability and stability of construction materials. 3. Agriculture Farmers use calcium hydroxide to correct soil acidity, improve nutrient availability, and promote better crop yields. It is also involved in the production of animal feed products. 4. Chemical Manufacturing Calcium hydroxide serves as a key ingredient in various chemical processes, including the production of calcium-based compounds and in the manufacturing of pharmaceuticals. 5. Food Industry In the food sector, calcium hydroxide acts as a food additive and is used in the processing of certain types of food products, such as pickles and canned vegetables. Conclusion The rise of OEM calcium hydroxide powder factories marks a significant development in the industrial landscape. As the demand for calcium hydroxide continues to grow across various sectors, these factories play an indispensable role in ensuring a reliable supply of high-quality products. Their ability to offer customized solutions, adhere to quality standards, and innovate within the production process positions them as key players in supporting industries worldwide. As we look to the future, the ongoing development of OEM factories will likely continue to enhance the efficiency and effectiveness of calcium hydroxide applications._composite mica manufacturer2025-08-17 18:18Read(1128)Картины с песочными деньгами

Санд-даллар (sand dollar) – это морское животное, принадлежащее к семейству иглокожих. Его название...

Read Moreoem calcium hydroxide powder factories******Understanding OEM Calcium Hydroxide Powder Factories An Insight into Production and Applications Calcium hydroxide, also known as hydrated lime or slack lime, is a versatile chemical compound with a wide array of industrial applications. Its uses range from water treatment and soil stabilization to being a critical component in the construction and agriculture sectors. The growing demand for calcium hydroxide has led to an increase in the number of Original Equipment Manufacturer (OEM) factories dedicated to producing this essential material. In this article, we will explore the fundamentals of calcium hydroxide powder production, the significance of OEM factories, and the various applications of this compound. Calcium Hydroxide Powder Production Process The main raw material for producing calcium hydroxide is calcium oxide, commonly derived from limestone. The production process begins with the calcination of limestone at high temperatures to produce quicklime (calcium oxide). The quicklime is then mixed with water in a process known as slaking, resulting in the formation of calcium hydroxide. This substance can be processed into a fine powder, making it suitable for various applications. OEM factories that specialize in calcium hydroxide powder production often employ advanced manufacturing techniques and technologies to ensure high-purity and finely ground products. These facilities prioritize quality control throughout the production process, with rigorous testing to meet industry standards. The scale of production varies among OEM factories, with some catering to large-scale industrial clients while others focus on smaller, specialized batches. The Role of OEM Factories OEM factories play a critical role in the supply chain of calcium hydroxide powder. They not only produce the raw material but also offer customizable solutions for various industries. The significance of OEM factories can be highlighted through several key points 1. Customization OEM factories can produce calcium hydroxide powder based on specific customer requirements, including particle size, purity, and packaging. This flexibility allows them to cater to diverse industry needs. 2. Quality Assurance Many OEM manufacturers adopt stringent quality control measures to ensure that their products meet international safety and quality standards. This is particularly important in industries like food production, where high purity levels are essential. 3. Innovation and Research Some OEM factories invest in research and development to improve product formulations and manufacturing processes. This focus on innovation can lead to enhanced performance of calcium hydroxide in various applications. oem calcium hydroxide powder factories 4. Supply Chain Efficiency By streamlining production and logistics, OEM factories help ensure a steady supply of calcium hydroxide powder, minimizing delays and disruptions for companies relying on this material. Applications of Calcium Hydroxide Powder The versatility of calcium hydroxide powder translates into numerous applications across different sectors 1. Water Treatment Calcium hydroxide is widely used in water treatment plants for pH control and as a coagulating agent to remove impurities from water. 2. Construction In the construction industry, calcium hydroxide is essential in producing calcium silicate bricks, as well as in various cement formulations. Its properties enhance the durability and stability of construction materials. 3. Agriculture Farmers use calcium hydroxide to correct soil acidity, improve nutrient availability, and promote better crop yields. It is also involved in the production of animal feed products. 4. Chemical Manufacturing Calcium hydroxide serves as a key ingredient in various chemical processes, including the production of calcium-based compounds and in the manufacturing of pharmaceuticals. 5. Food Industry In the food sector, calcium hydroxide acts as a food additive and is used in the processing of certain types of food products, such as pickles and canned vegetables. Conclusion The rise of OEM calcium hydroxide powder factories marks a significant development in the industrial landscape. As the demand for calcium hydroxide continues to grow across various sectors, these factories play an indispensable role in ensuring a reliable supply of high-quality products. Their ability to offer customized solutions, adhere to quality standards, and innovate within the production process positions them as key players in supporting industries worldwide. As we look to the future, the ongoing development of OEM factories will likely continue to enhance the efficiency and effectiveness of calcium hydroxide applications._composite mica manufacturer2025-08-17 18:03Read(1209)Exploring the Beauty and Durability of Limestone in Architectural Design and Construction

The Timeless Strength of Limestone Buildings Limestone has held a prestigious place in the world of...

Read Moreoem calcium hydroxide powder factories******Understanding OEM Calcium Hydroxide Powder Factories An Insight into Production and Applications Calcium hydroxide, also known as hydrated lime or slack lime, is a versatile chemical compound with a wide array of industrial applications. Its uses range from water treatment and soil stabilization to being a critical component in the construction and agriculture sectors. The growing demand for calcium hydroxide has led to an increase in the number of Original Equipment Manufacturer (OEM) factories dedicated to producing this essential material. In this article, we will explore the fundamentals of calcium hydroxide powder production, the significance of OEM factories, and the various applications of this compound. Calcium Hydroxide Powder Production Process The main raw material for producing calcium hydroxide is calcium oxide, commonly derived from limestone. The production process begins with the calcination of limestone at high temperatures to produce quicklime (calcium oxide). The quicklime is then mixed with water in a process known as slaking, resulting in the formation of calcium hydroxide. This substance can be processed into a fine powder, making it suitable for various applications. OEM factories that specialize in calcium hydroxide powder production often employ advanced manufacturing techniques and technologies to ensure high-purity and finely ground products. These facilities prioritize quality control throughout the production process, with rigorous testing to meet industry standards. The scale of production varies among OEM factories, with some catering to large-scale industrial clients while others focus on smaller, specialized batches. The Role of OEM Factories OEM factories play a critical role in the supply chain of calcium hydroxide powder. They not only produce the raw material but also offer customizable solutions for various industries. The significance of OEM factories can be highlighted through several key points 1. Customization OEM factories can produce calcium hydroxide powder based on specific customer requirements, including particle size, purity, and packaging. This flexibility allows them to cater to diverse industry needs. 2. Quality Assurance Many OEM manufacturers adopt stringent quality control measures to ensure that their products meet international safety and quality standards. This is particularly important in industries like food production, where high purity levels are essential. 3. Innovation and Research Some OEM factories invest in research and development to improve product formulations and manufacturing processes. This focus on innovation can lead to enhanced performance of calcium hydroxide in various applications. oem calcium hydroxide powder factories 4. Supply Chain Efficiency By streamlining production and logistics, OEM factories help ensure a steady supply of calcium hydroxide powder, minimizing delays and disruptions for companies relying on this material. Applications of Calcium Hydroxide Powder The versatility of calcium hydroxide powder translates into numerous applications across different sectors 1. Water Treatment Calcium hydroxide is widely used in water treatment plants for pH control and as a coagulating agent to remove impurities from water. 2. Construction In the construction industry, calcium hydroxide is essential in producing calcium silicate bricks, as well as in various cement formulations. Its properties enhance the durability and stability of construction materials. 3. Agriculture Farmers use calcium hydroxide to correct soil acidity, improve nutrient availability, and promote better crop yields. It is also involved in the production of animal feed products. 4. Chemical Manufacturing Calcium hydroxide serves as a key ingredient in various chemical processes, including the production of calcium-based compounds and in the manufacturing of pharmaceuticals. 5. Food Industry In the food sector, calcium hydroxide acts as a food additive and is used in the processing of certain types of food products, such as pickles and canned vegetables. Conclusion The rise of OEM calcium hydroxide powder factories marks a significant development in the industrial landscape. As the demand for calcium hydroxide continues to grow across various sectors, these factories play an indispensable role in ensuring a reliable supply of high-quality products. Their ability to offer customized solutions, adhere to quality standards, and innovate within the production process positions them as key players in supporting industries worldwide. As we look to the future, the ongoing development of OEM factories will likely continue to enhance the efficiency and effectiveness of calcium hydroxide applications._composite mica manufacturer2025-08-17 17:58Read(93)mica pearl powder factories

The Essence of Mica Pearl Powder A Deep Dive into Factories and Production Mica pearl powder, known...

Read Moreoem calcium hydroxide powder factories******Understanding OEM Calcium Hydroxide Powder Factories An Insight into Production and Applications Calcium hydroxide, also known as hydrated lime or slack lime, is a versatile chemical compound with a wide array of industrial applications. Its uses range from water treatment and soil stabilization to being a critical component in the construction and agriculture sectors. The growing demand for calcium hydroxide has led to an increase in the number of Original Equipment Manufacturer (OEM) factories dedicated to producing this essential material. In this article, we will explore the fundamentals of calcium hydroxide powder production, the significance of OEM factories, and the various applications of this compound. Calcium Hydroxide Powder Production Process The main raw material for producing calcium hydroxide is calcium oxide, commonly derived from limestone. The production process begins with the calcination of limestone at high temperatures to produce quicklime (calcium oxide). The quicklime is then mixed with water in a process known as slaking, resulting in the formation of calcium hydroxide. This substance can be processed into a fine powder, making it suitable for various applications. OEM factories that specialize in calcium hydroxide powder production often employ advanced manufacturing techniques and technologies to ensure high-purity and finely ground products. These facilities prioritize quality control throughout the production process, with rigorous testing to meet industry standards. The scale of production varies among OEM factories, with some catering to large-scale industrial clients while others focus on smaller, specialized batches. The Role of OEM Factories OEM factories play a critical role in the supply chain of calcium hydroxide powder. They not only produce the raw material but also offer customizable solutions for various industries. The significance of OEM factories can be highlighted through several key points 1. Customization OEM factories can produce calcium hydroxide powder based on specific customer requirements, including particle size, purity, and packaging. This flexibility allows them to cater to diverse industry needs. 2. Quality Assurance Many OEM manufacturers adopt stringent quality control measures to ensure that their products meet international safety and quality standards. This is particularly important in industries like food production, where high purity levels are essential. 3. Innovation and Research Some OEM factories invest in research and development to improve product formulations and manufacturing processes. This focus on innovation can lead to enhanced performance of calcium hydroxide in various applications. oem calcium hydroxide powder factories 4. Supply Chain Efficiency By streamlining production and logistics, OEM factories help ensure a steady supply of calcium hydroxide powder, minimizing delays and disruptions for companies relying on this material. Applications of Calcium Hydroxide Powder The versatility of calcium hydroxide powder translates into numerous applications across different sectors 1. Water Treatment Calcium hydroxide is widely used in water treatment plants for pH control and as a coagulating agent to remove impurities from water. 2. Construction In the construction industry, calcium hydroxide is essential in producing calcium silicate bricks, as well as in various cement formulations. Its properties enhance the durability and stability of construction materials. 3. Agriculture Farmers use calcium hydroxide to correct soil acidity, improve nutrient availability, and promote better crop yields. It is also involved in the production of animal feed products. 4. Chemical Manufacturing Calcium hydroxide serves as a key ingredient in various chemical processes, including the production of calcium-based compounds and in the manufacturing of pharmaceuticals. 5. Food Industry In the food sector, calcium hydroxide acts as a food additive and is used in the processing of certain types of food products, such as pickles and canned vegetables. Conclusion The rise of OEM calcium hydroxide powder factories marks a significant development in the industrial landscape. As the demand for calcium hydroxide continues to grow across various sectors, these factories play an indispensable role in ensuring a reliable supply of high-quality products. Their ability to offer customized solutions, adhere to quality standards, and innovate within the production process positions them as key players in supporting industries worldwide. As we look to the future, the ongoing development of OEM factories will likely continue to enhance the efficiency and effectiveness of calcium hydroxide applications._composite mica manufacturer2025-08-17 17:19Read(2474)Exploring Custom Cao Manufacturing Options and Solutions for Your Needs

The Rise of Custom Cao Factories Catering to Unique Demands in the Manufacturing Industry In recent...

Read Moreoem calcium hydroxide powder factories******Understanding OEM Calcium Hydroxide Powder Factories An Insight into Production and Applications Calcium hydroxide, also known as hydrated lime or slack lime, is a versatile chemical compound with a wide array of industrial applications. Its uses range from water treatment and soil stabilization to being a critical component in the construction and agriculture sectors. The growing demand for calcium hydroxide has led to an increase in the number of Original Equipment Manufacturer (OEM) factories dedicated to producing this essential material. In this article, we will explore the fundamentals of calcium hydroxide powder production, the significance of OEM factories, and the various applications of this compound. Calcium Hydroxide Powder Production Process The main raw material for producing calcium hydroxide is calcium oxide, commonly derived from limestone. The production process begins with the calcination of limestone at high temperatures to produce quicklime (calcium oxide). The quicklime is then mixed with water in a process known as slaking, resulting in the formation of calcium hydroxide. This substance can be processed into a fine powder, making it suitable for various applications. OEM factories that specialize in calcium hydroxide powder production often employ advanced manufacturing techniques and technologies to ensure high-purity and finely ground products. These facilities prioritize quality control throughout the production process, with rigorous testing to meet industry standards. The scale of production varies among OEM factories, with some catering to large-scale industrial clients while others focus on smaller, specialized batches. The Role of OEM Factories OEM factories play a critical role in the supply chain of calcium hydroxide powder. They not only produce the raw material but also offer customizable solutions for various industries. The significance of OEM factories can be highlighted through several key points 1. Customization OEM factories can produce calcium hydroxide powder based on specific customer requirements, including particle size, purity, and packaging. This flexibility allows them to cater to diverse industry needs. 2. Quality Assurance Many OEM manufacturers adopt stringent quality control measures to ensure that their products meet international safety and quality standards. This is particularly important in industries like food production, where high purity levels are essential. 3. Innovation and Research Some OEM factories invest in research and development to improve product formulations and manufacturing processes. This focus on innovation can lead to enhanced performance of calcium hydroxide in various applications. oem calcium hydroxide powder factories 4. Supply Chain Efficiency By streamlining production and logistics, OEM factories help ensure a steady supply of calcium hydroxide powder, minimizing delays and disruptions for companies relying on this material. Applications of Calcium Hydroxide Powder The versatility of calcium hydroxide powder translates into numerous applications across different sectors 1. Water Treatment Calcium hydroxide is widely used in water treatment plants for pH control and as a coagulating agent to remove impurities from water. 2. Construction In the construction industry, calcium hydroxide is essential in producing calcium silicate bricks, as well as in various cement formulations. Its properties enhance the durability and stability of construction materials. 3. Agriculture Farmers use calcium hydroxide to correct soil acidity, improve nutrient availability, and promote better crop yields. It is also involved in the production of animal feed products. 4. Chemical Manufacturing Calcium hydroxide serves as a key ingredient in various chemical processes, including the production of calcium-based compounds and in the manufacturing of pharmaceuticals. 5. Food Industry In the food sector, calcium hydroxide acts as a food additive and is used in the processing of certain types of food products, such as pickles and canned vegetables. Conclusion The rise of OEM calcium hydroxide powder factories marks a significant development in the industrial landscape. As the demand for calcium hydroxide continues to grow across various sectors, these factories play an indispensable role in ensuring a reliable supply of high-quality products. Their ability to offer customized solutions, adhere to quality standards, and innovate within the production process positions them as key players in supporting industries worldwide. As we look to the future, the ongoing development of OEM factories will likely continue to enhance the efficiency and effectiveness of calcium hydroxide applications._composite mica manufacturer2025-08-17 16:42Read(826)Leading Manufacturers of High-Quality Silica Fume in China for Construction and Industrial Applicati

The Significance of Silica Fume in the Construction Industry A Focus on China’s Leading Companies In...

Read Moreoem calcium hydroxide powder factories******Understanding OEM Calcium Hydroxide Powder Factories An Insight into Production and Applications Calcium hydroxide, also known as hydrated lime or slack lime, is a versatile chemical compound with a wide array of industrial applications. Its uses range from water treatment and soil stabilization to being a critical component in the construction and agriculture sectors. The growing demand for calcium hydroxide has led to an increase in the number of Original Equipment Manufacturer (OEM) factories dedicated to producing this essential material. In this article, we will explore the fundamentals of calcium hydroxide powder production, the significance of OEM factories, and the various applications of this compound. Calcium Hydroxide Powder Production Process The main raw material for producing calcium hydroxide is calcium oxide, commonly derived from limestone. The production process begins with the calcination of limestone at high temperatures to produce quicklime (calcium oxide). The quicklime is then mixed with water in a process known as slaking, resulting in the formation of calcium hydroxide. This substance can be processed into a fine powder, making it suitable for various applications. OEM factories that specialize in calcium hydroxide powder production often employ advanced manufacturing techniques and technologies to ensure high-purity and finely ground products. These facilities prioritize quality control throughout the production process, with rigorous testing to meet industry standards. The scale of production varies among OEM factories, with some catering to large-scale industrial clients while others focus on smaller, specialized batches. The Role of OEM Factories OEM factories play a critical role in the supply chain of calcium hydroxide powder. They not only produce the raw material but also offer customizable solutions for various industries. The significance of OEM factories can be highlighted through several key points 1. Customization OEM factories can produce calcium hydroxide powder based on specific customer requirements, including particle size, purity, and packaging. This flexibility allows them to cater to diverse industry needs. 2. Quality Assurance Many OEM manufacturers adopt stringent quality control measures to ensure that their products meet international safety and quality standards. This is particularly important in industries like food production, where high purity levels are essential. 3. Innovation and Research Some OEM factories invest in research and development to improve product formulations and manufacturing processes. This focus on innovation can lead to enhanced performance of calcium hydroxide in various applications. oem calcium hydroxide powder factories 4. Supply Chain Efficiency By streamlining production and logistics, OEM factories help ensure a steady supply of calcium hydroxide powder, minimizing delays and disruptions for companies relying on this material. Applications of Calcium Hydroxide Powder The versatility of calcium hydroxide powder translates into numerous applications across different sectors 1. Water Treatment Calcium hydroxide is widely used in water treatment plants for pH control and as a coagulating agent to remove impurities from water. 2. Construction In the construction industry, calcium hydroxide is essential in producing calcium silicate bricks, as well as in various cement formulations. Its properties enhance the durability and stability of construction materials. 3. Agriculture Farmers use calcium hydroxide to correct soil acidity, improve nutrient availability, and promote better crop yields. It is also involved in the production of animal feed products. 4. Chemical Manufacturing Calcium hydroxide serves as a key ingredient in various chemical processes, including the production of calcium-based compounds and in the manufacturing of pharmaceuticals. 5. Food Industry In the food sector, calcium hydroxide acts as a food additive and is used in the processing of certain types of food products, such as pickles and canned vegetables. Conclusion The rise of OEM calcium hydroxide powder factories marks a significant development in the industrial landscape. As the demand for calcium hydroxide continues to grow across various sectors, these factories play an indispensable role in ensuring a reliable supply of high-quality products. Their ability to offer customized solutions, adhere to quality standards, and innovate within the production process positions them as key players in supporting industries worldwide. As we look to the future, the ongoing development of OEM factories will likely continue to enhance the efficiency and effectiveness of calcium hydroxide applications._composite mica manufacturer2025-08-17 16:25Read(681)- Iron oxides: Matches your skin type and color

...

Read Moreoem calcium hydroxide powder factories******Understanding OEM Calcium Hydroxide Powder Factories An Insight into Production and Applications Calcium hydroxide, also known as hydrated lime or slack lime, is a versatile chemical compound with a wide array of industrial applications. Its uses range from water treatment and soil stabilization to being a critical component in the construction and agriculture sectors. The growing demand for calcium hydroxide has led to an increase in the number of Original Equipment Manufacturer (OEM) factories dedicated to producing this essential material. In this article, we will explore the fundamentals of calcium hydroxide powder production, the significance of OEM factories, and the various applications of this compound. Calcium Hydroxide Powder Production Process The main raw material for producing calcium hydroxide is calcium oxide, commonly derived from limestone. The production process begins with the calcination of limestone at high temperatures to produce quicklime (calcium oxide). The quicklime is then mixed with water in a process known as slaking, resulting in the formation of calcium hydroxide. This substance can be processed into a fine powder, making it suitable for various applications. OEM factories that specialize in calcium hydroxide powder production often employ advanced manufacturing techniques and technologies to ensure high-purity and finely ground products. These facilities prioritize quality control throughout the production process, with rigorous testing to meet industry standards. The scale of production varies among OEM factories, with some catering to large-scale industrial clients while others focus on smaller, specialized batches. The Role of OEM Factories OEM factories play a critical role in the supply chain of calcium hydroxide powder. They not only produce the raw material but also offer customizable solutions for various industries. The significance of OEM factories can be highlighted through several key points 1. Customization OEM factories can produce calcium hydroxide powder based on specific customer requirements, including particle size, purity, and packaging. This flexibility allows them to cater to diverse industry needs. 2. Quality Assurance Many OEM manufacturers adopt stringent quality control measures to ensure that their products meet international safety and quality standards. This is particularly important in industries like food production, where high purity levels are essential. 3. Innovation and Research Some OEM factories invest in research and development to improve product formulations and manufacturing processes. This focus on innovation can lead to enhanced performance of calcium hydroxide in various applications. oem calcium hydroxide powder factories 4. Supply Chain Efficiency By streamlining production and logistics, OEM factories help ensure a steady supply of calcium hydroxide powder, minimizing delays and disruptions for companies relying on this material. Applications of Calcium Hydroxide Powder The versatility of calcium hydroxide powder translates into numerous applications across different sectors 1. Water Treatment Calcium hydroxide is widely used in water treatment plants for pH control and as a coagulating agent to remove impurities from water. 2. Construction In the construction industry, calcium hydroxide is essential in producing calcium silicate bricks, as well as in various cement formulations. Its properties enhance the durability and stability of construction materials. 3. Agriculture Farmers use calcium hydroxide to correct soil acidity, improve nutrient availability, and promote better crop yields. It is also involved in the production of animal feed products. 4. Chemical Manufacturing Calcium hydroxide serves as a key ingredient in various chemical processes, including the production of calcium-based compounds and in the manufacturing of pharmaceuticals. 5. Food Industry In the food sector, calcium hydroxide acts as a food additive and is used in the processing of certain types of food products, such as pickles and canned vegetables. Conclusion The rise of OEM calcium hydroxide powder factories marks a significant development in the industrial landscape. As the demand for calcium hydroxide continues to grow across various sectors, these factories play an indispensable role in ensuring a reliable supply of high-quality products. Their ability to offer customized solutions, adhere to quality standards, and innovate within the production process positions them as key players in supporting industries worldwide. As we look to the future, the ongoing development of OEM factories will likely continue to enhance the efficiency and effectiveness of calcium hydroxide applications._composite mica manufacturer2025-08-17 16:18Read(2236)