oem aluminium oxide grains factories

The Significance of OEM Aluminium Oxide Grains Factories in Modern Manufacturing

In the rapidly evolving landscape of manufacturing, the demand for high-quality materials is paramount. One such material that has garnered immense attention is aluminium oxide grains, commonly utilized in various abrasive applications. The production of these grains, particularly in OEM (Original Equipment Manufacturer) factories, plays a crucial role in ensuring that industries can meet their operational demands effectively.

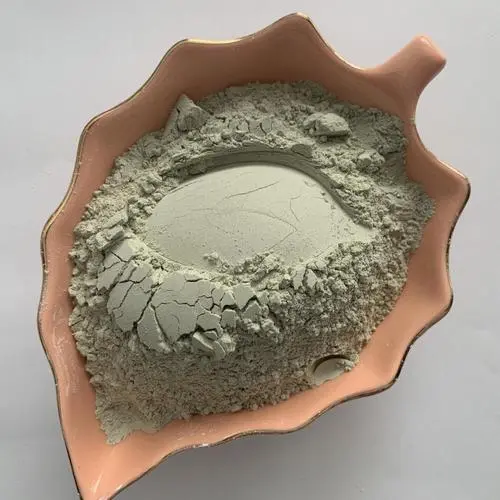

Aluminium oxide, also known as alumina, is a compound of aluminium and oxygen. It is well-regarded for its hardness and durability, making it an ideal choice for abrasive materials used in grinding, polishing, and surface preparation. The versatility of aluminium oxide grains spans multiple applications, including metalworking, woodworking, glass production, and even in electronic component manufacturing.

OEM aluminium oxide grains factories specialize in producing these grains to meet specific industry requirements. These factories leverage advanced technological processes and extensive research to manufacture grains that exhibit precise size, shape, and performance characteristics. The ability to customize the properties of aluminium oxide grains is essential, as different applications require varying levels of abrasiveness, particle size distribution, and thermal stability.

One of the key advantages of sourcing aluminium oxide grains from OEM factories is the assurance of consistent quality. These manufacturers adhere to strict quality control measures, ensuring that each batch of grains meets predetermined standards. This consistency is vital for industries that rely on precision in their processes, as variations in the quality of raw materials can lead to suboptimal results and increased production costs.

oem aluminium oxide grains factories

Moreover, OEM factories often implement sustainable practices in their production processes. The growing emphasis on environmental responsibility in manufacturing has led many OEMs to adopt methods that minimize waste and reduce energy consumption. By optimizing their production techniques, these factories not only contribute to sustainability but also enhance the overall value of their products. Manufacturers and consumers alike are increasingly aware of the importance of sustainable sourcing, making OEM aluminium oxide grains an attractive option.

In addition to quality and sustainability, innovation is a driving force within the realm of OEM aluminium oxide grains production. Research and development efforts are continually focused on creating new formulations and applications for aluminium oxide. For instance, recent advancements have led to the introduction of hybrid grains that combine aluminium oxide with other materials to enhance performance, such as increasing wear resistance or improving thermal conductivity. These innovations enable manufacturers to stay competitive in a constantly changing marketplace.

The global market for aluminium oxide grains is robust, with steady demand from various sectors. Industries such as automotive, aerospace, and electronics are increasingly relying on high-performance abrasives to maintain their competitive edge. As such, OEM factories are crucial in supporting these industries by providing the necessary materials that meet their stringent specifications.

Furthermore, the rise of e-commerce and global supply chains has transformed how OEM aluminium oxide grains are distributed. Manufacturers can now reach customers worldwide, allowing for greater flexibility in sourcing materials. This development also encourages competition among OEM factories, which can lead to improved pricing and better service for end-users.

In conclusion, OEM aluminium oxide grains factories are vital players in the manufacturing ecosystem. They provide high-quality, customized materials that are essential for various applications across multiple industries. Through consistent quality, sustainable practices, and innovation, these factories help manufacturers optimize their processes and products. As the demand for aluminium oxide grains continues to grow, the role of OEM factories will undoubtedly remain pivotal in shaping the future of manufacturing.

Share

-

Vermiculite Wholesale – Premium Quality, Bulk Supply & Competitive PricingNewsJun.10,2025

-

Premium Glass Pebbles Custom Glass Pebbles Factory & OEM Manufacturer Reliable Custom Glass Pebbles FactoriesNewsJun.10,2025

-

Expert Custom Zeolite Producers Manufacturers & FactoriesNewsJun.10,2025

-

Custom Glow in the Dark Beads High-Quality Custom ManufacturersNewsJun.10,2025

-

China Ceramsite Balls Factory - Lightweight & Durable Media Solutions ManufacturerNewsJun.09,2025

-

Custom Matte Mica Powder Manufacturers High Quality & AffordableNewsJun.09,2025