OEM Pearl Mica Powder Production Facilities for Quality Cosmetic Ingredients

The Rise of OEM Pearl Mica Powder Factories

In recent years, the cosmetic and beauty industry has witnessed a significant transformation driven by innovations in materials and manufacturing processes. One particular area experiencing rapid growth is the production of pearl mica powder. As more companies look to develop high-quality cosmetic products, the demand for OEM (Original Equipment Manufacturer) pearl mica powder factories has surged.

The Rise of OEM Pearl Mica Powder Factories

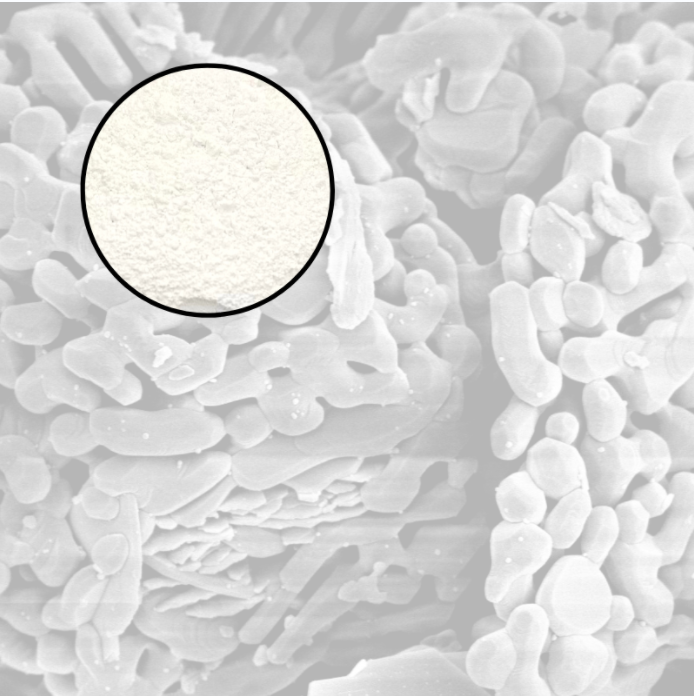

OEM pearl mica powder factories specialize in manufacturing this desired material according to the specifications set by brands and companies. These factories offer customized solutions, allowing businesses to tailor the characteristics of mica powder, such as particle size, color, and finish. This customization is critical for brands that aim to differentiate their products in a saturated market. By partnering with OEM manufacturers, cosmetic brands can focus on their formulation and branding while leaving the production of mica powder in the hands of experts.

oem pearl mica powder factories

The manufacturing process of pearl mica powder involves the careful selection of raw materials, typically sourced from natural mica deposits. Once harvested, mica is finely ground to achieve the desired particle size and purity. Next, the powder undergoes surface treatment to enhance its luster and performance characteristics. The final product is then rigorously tested for quality control to ensure it meets industry standards and customer expectations. This meticulous process is what sets OEM pearl mica powder factories apart, ensuring that the product delivered is of the highest quality.

Moreover, sustainability has become a pivotal concern in the beauty industry, prompting OEM factories to adopt environmentally friendly practices. Many manufacturers are now sourcing mica from conflict-free suppliers and implementing eco-friendly processing techniques. This shift towards sustainability not only caters to the ethical concerns of consumers but also positions brands as responsible players in the marketplace.

The increase in e-commerce and direct-to-consumer platforms has also contributed to the growth of the OEM pearl mica powder sector. Brands can now reach a wider audience with tailored products, and they increasingly rely on reliable OEM partners to scale production while maintaining product quality. This synergy between brands and OEM factories fosters innovation, leading to the development of revolutionary formulations that capture consumer interest.

In conclusion, the growing demand for pearl mica powder within the cosmetics industry has given rise to specialized OEM factories that provide tailored manufacturing solutions. With a focus on quality, customization, and sustainability, these factories play a crucial role in the success of beauty brands. As consumers continue to seek out high-quality, ethically produced cosmetics, the importance of OEM pearl mica powder factories will only continue to grow in the coming years. The future looks bright for those involved in this dynamic sector, and with it, the promise of stunning cosmetic products made with exquisite mica powder shines even brighter.

Share

-

Premium Talcum Powder Enhanced with GPT-4 Turbo | Soft & Long-LastingNewsAug.02,2025

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025