Understanding the Impact of Alumina Percentage on Bulk Material Properties and Performance

Understanding Alumina Content in Bulk Materials

Alumina, or aluminum oxide (Al2O3), is a versatile and widely used material across various industries, primarily due to its exceptional properties. In its bulk form, alumina is a key component in a variety of applications ranging from ceramics to abrasives and even in the production of aluminum metal itself. This article explores the importance of alumina content in bulk materials, its applications, and the methods used to measure and analyze its concentration.

The Role of Alumina in Bulk Materials

Alumina is primarily derived from bauxite ore and is known for its hardness, high melting point, and resistance to chemical erosion. When present in bulk, alumina exhibits unique characteristics that make it suitable for multiple applications. For instance, the high thermal stability of alumina makes it an ideal material for refractory applications where high temperatures are common. Additionally, in the ceramic industry, alumina is used to enhance the strength and durability of ceramic products, making them suitable for demanding applications such as electronic substrates and dental prosthetics.

In the abrasive sector, alumina's hardness allows it to be used in grinding wheels and cutting tools. Its effectiveness in these applications is heavily influenced by the alumina percentage present in the bulk material, as higher alumina content typically translates to better performance.

Measuring Alumina Content

To optimize the performance of materials that contain alumina, accurate measurement of its content in bulk is essential. Various techniques are employed to determine alumina concentration, including X-ray fluorescence (XRF), inductively coupled plasma (ICP) spectroscopy, and chemical titration. XRF is particularly efficient for bulk samples as it allows for quick, non-destructive analysis, providing instant feedback on the elemental composition of the material.

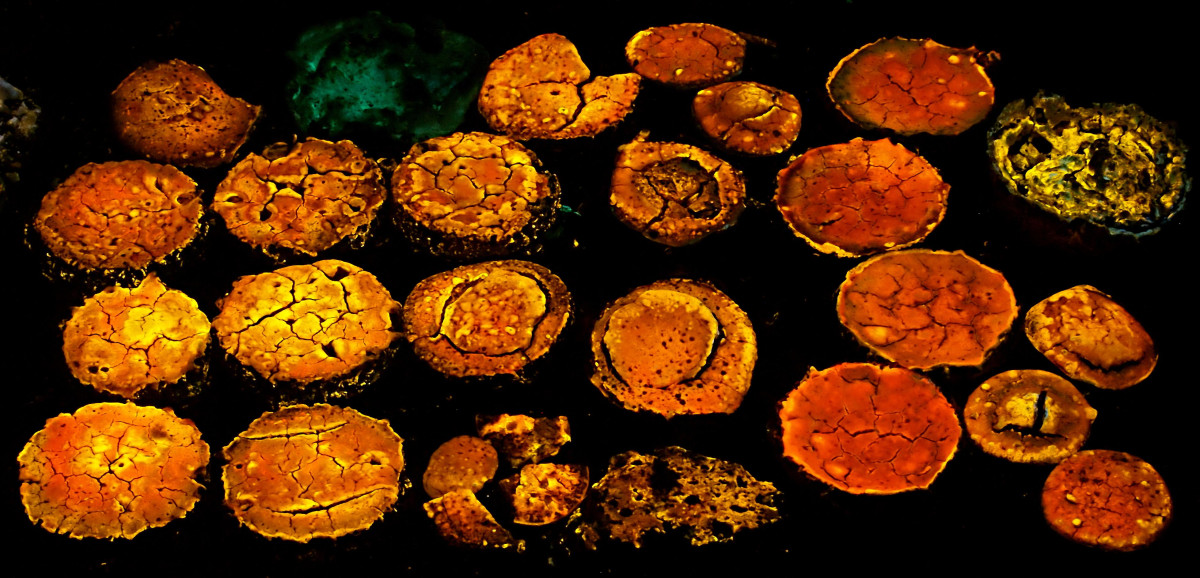

alumina in bulk

On the other hand, ICP spectroscopy offers high sensitivity and specificity for detecting trace elements, making it suitable for detailed analysis when the alumina content is low. Chemical titration is another method used, although it is more time-consuming and often reserved for laboratory settings where precise quantities are necessary.

Applications of Alumina in Bulk Material

The presence of alumina in bulk material significantly influences the final product’s properties. For instance, in the aluminum smelting process, alumina serves as the primary source of aluminum. The Bayer process, which extracts alumina from bauxite, showcases the critical nature of alumina content. A higher alumina concentration in the extracted material not only increases the efficiency of the smelting process but also reduces the energy consumption.

In the field of electronics, alumina's dielectric properties enable its use in substrates and packaging for electronic components. Its ability to withstand high temperatures and harsh environments makes it ideal for use in aerospace and automotive applications, as well.

Conclusion

The significance of alumina content in bulk materials cannot be overstated. It influences the material's characteristics, processing efficiency, and end-use applications. From manufacturing ceramics and abrasives to facilitating aluminum production, alumina's unique properties enable it to play a pivotal role in various industrial processes. As techniques for measuring and analyzing alumina content continue to evolve, industries will benefit from enhanced control over quality and performance, ultimately leading to improved products and processes. Understanding and optimizing alumina content in bulk materials remain critical for manufacturers, ensuring that they meet the demands of their respective markets effectively.

Share

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025

-

Premium Burgundy Glass Marbles for Vases & Shooter GamesNewsJul.29,2025