aluminium oxide manufacturer manufacturer

The Role of Aluminium Oxide Manufacturers in Modern Industry

Aluminium oxide, often referred to as alumina, is a critical material in various industrial applications, ranging from the production of aluminum metal to its use as an abrasive and in ceramics. Manufacturers of aluminium oxide play a vital role in supplying this essential compound, facilitating advancements across multiple sectors including aerospace, automotive, electronics, and manufacturing. In this article, we will explore the importance of aluminium oxide, the manufacturing processes involved, and the implications for various industries.

Understanding Aluminium Oxide

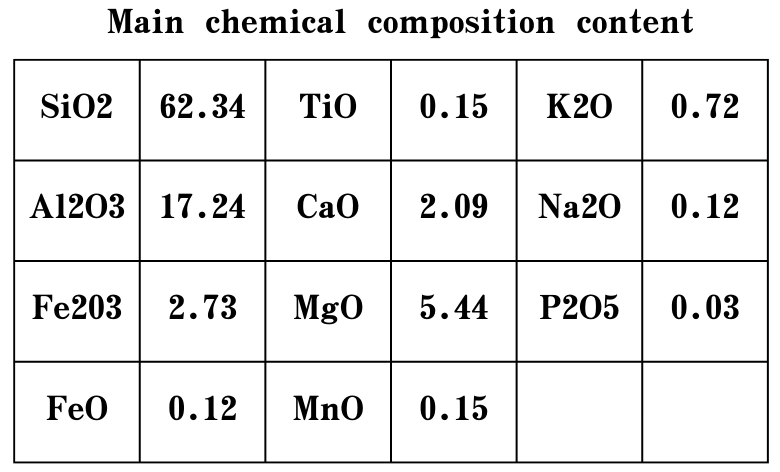

Aluminium oxide (Al2O3) is a chemical compound derived from bauxite, the primary ore of aluminum. It appears as a white, powdery substance and is known for its hardness and thermal stability. With a high melting point of about 2072°C (3762°F), aluminium oxide is suitable for applications that require materials to withstand extreme conditions.

One of the most notable properties of aluminium oxide is its ability to resist corrosion, making it ideal for use in environments where chemicals and moisture exposure could damage other materials. Additionally, alumina's hardness makes it an excellent abrasive, widely used in sandpapers, grinding wheels, and polishing agents.

Manufacturing Process

The production of aluminium oxide entails several stages. Typically, the process begins with the mining of bauxite, which undergoes refining to extract alumina. The Bayer process is the most common method, where bauxite is crushed and mixed with a hot sodium hydroxide solution to yield aluminum hydroxide. This compound is then precipitated, filtered, and calcined at high temperatures to produce pure aluminium oxide.

Alumina can also be produced through alternative methods, such as the Hall-Héroult process, which is primarily used for obtaining aluminum metal but also produces alumina as a byproduct. Manufacturers employ advanced technologies to ensure high purity and quality of the alumina produced, which is crucial for downstream applications in industries such as ceramics and electronics.

Applications of Aluminium Oxide

aluminium oxide manufacturer manufacturer

The versatility of aluminium oxide is reflected in its wide range of applications. In the aerospace and automotive sectors, it is used in lightweight structures due to its strength-to-weight ratio. The ability to withstand high temperatures and resist corrosion makes it an essential component in turbine engines and brakes.

In the electronics industry, alumina serves as an insulating material. Its excellent electrical properties make it ideal for the production of substrates for electronic components, as well as in the manufacturing of semiconductors and capacitors. Furthermore, its use in the field of optics is growing, particularly in the development of laser materials and high-durability lenses.

The ceramic industry greatly benefits from aluminium oxide as well. It is used in the production of abrasives and as a component in composite materials to enhance strength and stability. The introduction of alumina in ceramic tiles and sanitary ware has also improved the durability and aesthetic appeal of these products.

Challenges and Innovations

While aluminium oxide manufacturers contribute significantly to various industries, they also face challenges, including environmental concerns related to mining and refining processes. Bauxite mining can lead to land degradation and deforestation. Thus, manufacturers are continuously seeking sustainable practices, such as recycling alumina and improving the efficiency of production technologies to minimize their environmental footprint.

Innovations in manufacturing techniques, such as the use of nanotechnology, are pushing the boundaries of alumina applications. Researchers are exploring the potential of nanoscale aluminium oxide for use in healthcare, where it may enhance drug delivery systems or improve the performance of medical devices.

Conclusion

Aluminium oxide manufacturers hold a key position in modern industry, contributing to the development of advanced materials and technologies. As demand for alumina continues to rise, driven by its numerous applications, manufacturers are tasked with not only meeting production needs but also addressing environmental challenges. The future of aluminium oxide appears promising, with ongoing research and innovations paving the way for its enhanced utility across various high-tech domains. As industries evolve, the significance of aluminium oxide and the role of its manufacturers will undoubtedly grow, making them indispensable players in the quest for progress and sustainability.

Share

-

Premium Glass Sand Solutions | High Purity SupplyNewsAug.03,2025

-

Premium Talcum Powder Enhanced with GPT-4 Turbo | Soft & Long-LastingNewsAug.02,2025

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025