Th1 . 22, 2025 01:12

Back to list

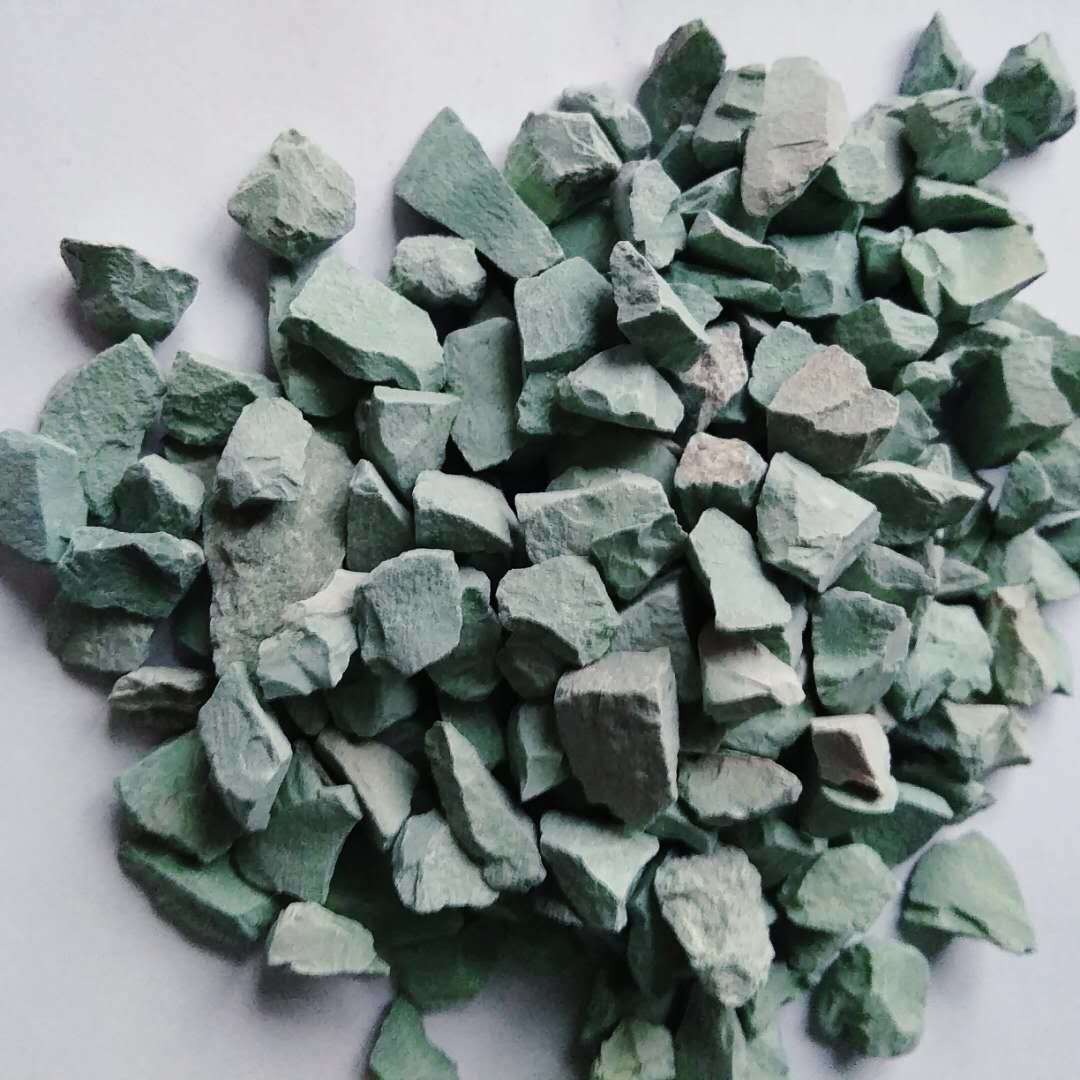

silica fume in concrete mix

Silica fume is an exceptional material used in the concrete mix that significantly enhances durability, resilience, and sustainability. Recognized for its minute particle size and potent pozzolanic properties, silica fume is a byproduct generated during the production of silicon metal or ferrosilicon alloys. Its unique characteristics make it a game-changer in the construction industry, reflecting the prowess of modern engineering in tackling some of the age-old challenges associated with traditional concrete.

Regarding the application expertise, proper handling and dosing of silica fume are critical. It's typically added to the concrete mix at a proportion of 5-10% of the cement weight. Its high surface area and fine nature demand meticulous mixing procedures to prevent dispersion-related issues. Additionally, because silica fume modifies the rheology of the concrete, offering a stickier and less fluid mix, admixtures are often employed to ensure workability isn't compromised during placement. To leverage the full potential of silica fume, it's pivotal to consider the specific requirements of the construction project. Performance objectives such as enhanced durability, resistance to chloride ion penetration, and exceptional structural integrity guide the choice to incorporate silica fume. Collective experience from large scale projects like the Confederation Bridge in Canada, which employed silica fume to combat the abrasive marine environment, underscores its efficacy in delivering beyond anticipated project requirements. In terms of trustworthiness and authoritativeness, documented case studies and ongoing field evaluations provide indisputable evidence of the benefits associated with silica fume in concrete mixes. Engineers and construction professionals worldwide continue to validate its application, citing improved service life and structural stability of building elements. This is particularly useful when proposing modifications in construction practices to clients or stakeholders less familiar with novel materials. It's apparent from decades of industry use and experience that the benefits associated with silica fume in concrete mixes are substantial. For construction professionals keen on delivering quality, reducing long-term costs, and embracing sustainable materials, silica fume provides a reliable and scientifically-validated solution. Its capacity to enhance critical performance parameters of concrete positions it as a crucial component in modern construction endeavors.

Regarding the application expertise, proper handling and dosing of silica fume are critical. It's typically added to the concrete mix at a proportion of 5-10% of the cement weight. Its high surface area and fine nature demand meticulous mixing procedures to prevent dispersion-related issues. Additionally, because silica fume modifies the rheology of the concrete, offering a stickier and less fluid mix, admixtures are often employed to ensure workability isn't compromised during placement. To leverage the full potential of silica fume, it's pivotal to consider the specific requirements of the construction project. Performance objectives such as enhanced durability, resistance to chloride ion penetration, and exceptional structural integrity guide the choice to incorporate silica fume. Collective experience from large scale projects like the Confederation Bridge in Canada, which employed silica fume to combat the abrasive marine environment, underscores its efficacy in delivering beyond anticipated project requirements. In terms of trustworthiness and authoritativeness, documented case studies and ongoing field evaluations provide indisputable evidence of the benefits associated with silica fume in concrete mixes. Engineers and construction professionals worldwide continue to validate its application, citing improved service life and structural stability of building elements. This is particularly useful when proposing modifications in construction practices to clients or stakeholders less familiar with novel materials. It's apparent from decades of industry use and experience that the benefits associated with silica fume in concrete mixes are substantial. For construction professionals keen on delivering quality, reducing long-term costs, and embracing sustainable materials, silica fume provides a reliable and scientifically-validated solution. Its capacity to enhance critical performance parameters of concrete positions it as a crucial component in modern construction endeavors.

Share

Latest news

-

Vermiculite Wholesale – Premium Quality, Bulk Supply & Competitive PricingNewsJun.10,2025

-

Premium Glass Pebbles Custom Glass Pebbles Factory & OEM Manufacturer Reliable Custom Glass Pebbles FactoriesNewsJun.10,2025

-

Expert Custom Zeolite Producers Manufacturers & FactoriesNewsJun.10,2025

-

Custom Glow in the Dark Beads High-Quality Custom ManufacturersNewsJun.10,2025

-

China Ceramsite Balls Factory - Lightweight & Durable Media Solutions ManufacturerNewsJun.09,2025

-

Custom Matte Mica Powder Manufacturers High Quality & AffordableNewsJun.09,2025