Th2 . 17, 2025 13:25

Back to list

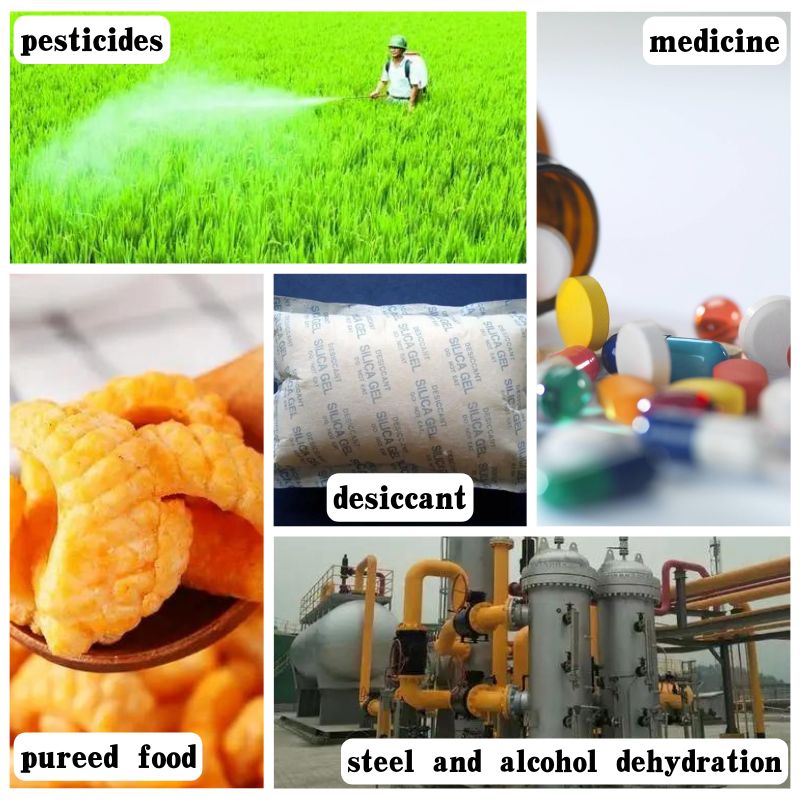

Manufacturers supply micro silica powder construction chemical electronic medicine special

China's micro silica fume powder has been steadily gaining recognition across various industries worldwide due to its unique properties and versatile applications. Its increasing demand is supported by its ability to enhance the quality and durability of concrete and other construction materials. Below, we delve into the critical aspects that make China micro silica fume powder stand out as a superior additive choice for construction projects.

Trustworthiness of Chinese micro silica fume suppliers is bolstered by numerous international case studies and testimonials from leading construction firms that have successfully used the product in critical projects. These companies underline the product’s reliability in enhancing concrete performance and prolonging the lifespan of infrastructure, which is critical for reducing maintenance costs and enhancing structural sustainability. In terms of market adaptability, China's micro silica fume is available in various grades and packaging options to cater to diverse project needs, whether it be high-performance concrete, shotcrete applications, or use as a refractory material. Chinese manufacturers have refined their logistics and export capabilities to ensure timely delivery and consistent supply, even in large quantities. The environmental implications are also compelling. Utilizing micro silica fume helps reduce the overall carbon footprint of a construction project since it allows for the reduction of Portland cement, which is energy-intensive to produce. The recycling of industrial byproducts into a valuable construction material aligns with broader sustainability goals in the industry. In conclusion, China's micro silica fume powder is a superior additive for construction and various other applications. With rigorous production standards, proven functional benefits, and strong endorsements from global industry leaders, it offers immense value to those seeking to enhance the performance and durability of their concrete structures while simultaneously supporting sustainable practices in construction. As the building and manufacturing sectors continue to evolve, the role of innovative materials like micro silica fume in shaping the future of infrastructure and environmental responsibility will undoubtedly expand.

Trustworthiness of Chinese micro silica fume suppliers is bolstered by numerous international case studies and testimonials from leading construction firms that have successfully used the product in critical projects. These companies underline the product’s reliability in enhancing concrete performance and prolonging the lifespan of infrastructure, which is critical for reducing maintenance costs and enhancing structural sustainability. In terms of market adaptability, China's micro silica fume is available in various grades and packaging options to cater to diverse project needs, whether it be high-performance concrete, shotcrete applications, or use as a refractory material. Chinese manufacturers have refined their logistics and export capabilities to ensure timely delivery and consistent supply, even in large quantities. The environmental implications are also compelling. Utilizing micro silica fume helps reduce the overall carbon footprint of a construction project since it allows for the reduction of Portland cement, which is energy-intensive to produce. The recycling of industrial byproducts into a valuable construction material aligns with broader sustainability goals in the industry. In conclusion, China's micro silica fume powder is a superior additive for construction and various other applications. With rigorous production standards, proven functional benefits, and strong endorsements from global industry leaders, it offers immense value to those seeking to enhance the performance and durability of their concrete structures while simultaneously supporting sustainable practices in construction. As the building and manufacturing sectors continue to evolve, the role of innovative materials like micro silica fume in shaping the future of infrastructure and environmental responsibility will undoubtedly expand.

Share

Next:

Latest news

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025

-

Premium Burgundy Glass Marbles for Vases & Shooter GamesNewsJul.29,2025