Yan . 14, 2025 10:38

Back to list

microsilica production

Microsilica, also known as silica fume, is an ultrafine powder collected as a byproduct during the production of silicon and ferrosilicon alloys. This material has rapidly gained popularity across industries due to its exceptional properties, including high strength and durability. While many are familiar with microsilica's applications, fewer understand the intricacies of its production process. Here, we delve into the methodologies and benefits of microsilica production, providing insights from experts and real-world applications.

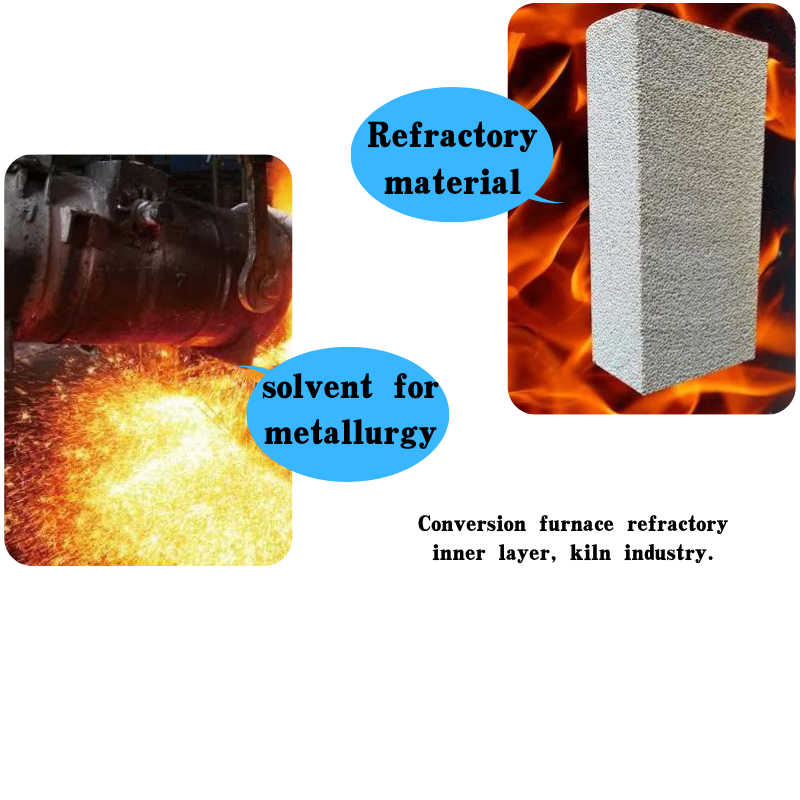

Microsilica possesses an impressive array of applications, from construction to refractory materials, thanks to its pozzolanic properties and its ability to enhance the mechanical performance of concrete. Its production requires a blend of scientific precision and industrial expertise. The expertise of chemists and engineers is paramount, as they devise and fine-tune processes that maximize yield while ensuring the quality of the microsilica. This is often achieved through ongoing research and development projects aimed at innovating and improving production techniques. Trust in the quality of produced microsilica often comes from certifications and adherence to international standards. Manufacturers who adhere to ISO guidelines and ensure thorough quality control are more likely to win contracts and repeat business, as clients are reassured of the product's reliability and effectiveness. The importance of third-party verification cannot be overstated; it establishes a reputation of trust and authority within the market. In conclusion, the production of microsilica is a complex yet rewarding process that demands technical expertise, operational excellence, and a commitment to quality. Companies engaged in its manufacture must remain agile, adapting to advancements in technology and environmental regulations. As industries continue to explore sustainable solutions, microsilica stands out as a product not just of strategic importance but also of endless potential. Its creation, worthy of mastery, represents an inspiring intersection of engineering, science, and environmental stewardship.

Microsilica possesses an impressive array of applications, from construction to refractory materials, thanks to its pozzolanic properties and its ability to enhance the mechanical performance of concrete. Its production requires a blend of scientific precision and industrial expertise. The expertise of chemists and engineers is paramount, as they devise and fine-tune processes that maximize yield while ensuring the quality of the microsilica. This is often achieved through ongoing research and development projects aimed at innovating and improving production techniques. Trust in the quality of produced microsilica often comes from certifications and adherence to international standards. Manufacturers who adhere to ISO guidelines and ensure thorough quality control are more likely to win contracts and repeat business, as clients are reassured of the product's reliability and effectiveness. The importance of third-party verification cannot be overstated; it establishes a reputation of trust and authority within the market. In conclusion, the production of microsilica is a complex yet rewarding process that demands technical expertise, operational excellence, and a commitment to quality. Companies engaged in its manufacture must remain agile, adapting to advancements in technology and environmental regulations. As industries continue to explore sustainable solutions, microsilica stands out as a product not just of strategic importance but also of endless potential. Its creation, worthy of mastery, represents an inspiring intersection of engineering, science, and environmental stewardship.

Share

Next:

Latest news

-

Vermiculite Wholesale – Premium Quality, Bulk Supply & Competitive PricingNewsJun.10,2025

-

Premium Glass Pebbles Custom Glass Pebbles Factory & OEM Manufacturer Reliable Custom Glass Pebbles FactoriesNewsJun.10,2025

-

Expert Custom Zeolite Producers Manufacturers & FactoriesNewsJun.10,2025

-

Custom Glow in the Dark Beads High-Quality Custom ManufacturersNewsJun.10,2025

-

China Ceramsite Balls Factory - Lightweight & Durable Media Solutions ManufacturerNewsJun.09,2025

-

Custom Matte Mica Powder Manufacturers High Quality & AffordableNewsJun.09,2025