custom sodium bentonite factories

Understanding Custom Sodium Bentonite Factories

Sodium bentonite, a natural clay material with unique properties, plays a pivotal role in various industries, including construction, drilling, environmental remediation, and agriculture. Custom sodium bentonite factories specialize in tailoring this versatile material to meet specific client requirements, thereby enhancing its functionality for particular applications. In this article, we will explore the significance of custom sodium bentonite production, the processes involved, and its diverse applications.

What is Sodium Bentonite?

Sodium bentonite is a type of swelling clay primarily composed of montmorillonite, a mineral that expands when hydrated. Its remarkable ability to absorb water and swell makes it ideal for various applications. It is commonly used as a sealing material for landfills, ponds, and reservoirs, thanks to its impermeability. It also serves essential functions in drilling mud, cat litter, cosmetics, and pharmaceuticals.

The Process of Custom Sodium Bentonite Production

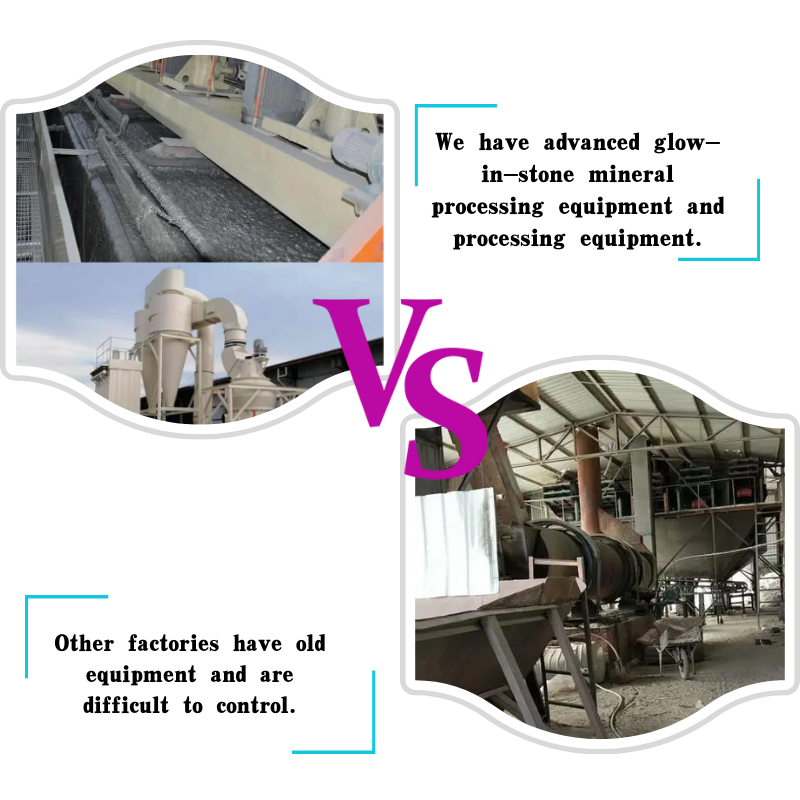

Custom sodium bentonite factories employ a series of processes to produce tailored products that meet specific industry standards. The process typically begins with the selection of high-quality bentonite ore. The raw material is then subjected to various treatments, which may include

1. Crushing and Milling The ore is crushed and milled to achieve the desired particle size. This step is crucial, as the finer the bentonite, the better its performance in applications.

2. Activation Sodium bentonite is often treated with sodium carbonate to enhance its properties. This activation process increases its swelling capacity, making it more effective in applications such as sealants and drilling fluids.

3. Blending Custom formulations may require blending sodium bentonite with other materials. Factories can customize the product by adjusting the proportions of additivities based on client specifications.

4. Quality Control Rigorous testing is conducted at each stage of production to ensure the final product meets purity and performance standards. This includes assessments of moisture content, plasticity, and swelling potential.

custom sodium bentonite factories

5. Packaging and Distribution Once the product passes quality checks, it is packaged in bulk or smaller quantities, based on customer needs. Efficient distribution channels are essential for timely delivery to various industries.

.

Applications of Custom Sodium Bentonite

The versatility of sodium bentonite allows it to be used in numerous applications across different sectors

1. Drilling Industry In oil and gas drilling, sodium bentonite is a key component of drilling mud. It helps to maintain borehole stability, provides lubrication for drill bits, and carries drill cuttings to the surface.

2. Environmental Remediation Sodium bentonite is used in landfill liners and caps to prevent leachate migration. Its impermeable nature makes it an effective barrier against pollutants, ensuring environmental protection.

3. Construction In construction, sodium bentonite is utilized in foundation sealing, waterproofing, and soil stabilization. Its ability to swell and form a gel-like substance is advantageous for enhancing ground conditions.

4. Agriculture Sodium bentonite serves as an important ingredient in animal feed and soil conditioning. It enhances nutrient retention and improves soil structure, leading to better crop yields.

5. Industrial Applications In the manufacturing sector, sodium bentonite is found in cosmetics, pharmaceuticals, and various industrial processes. Its properties contribute to thickening, stabilizing, and clarifying solutions.

Conclusion

Custom sodium bentonite factories play a key role in meeting the diverse needs of various industries. By specializing in tailored products, these factories contribute to the effective utilization of sodium bentonite across multiple applications. The processes involved in production—from raw material selection to quality control—ensure that the final product meets high standards, ultimately benefiting the clients and industries that rely on this remarkable material. As industries continue to evolve, the demand for customized solutions will likely grow, further reinforcing the importance of sodium bentonite in modern applications.

Share

-

Premium Talcum Powder Enhanced with GPT-4 Turbo | Soft & Long-LastingNewsAug.02,2025

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025