OEM Supplier of Fly Ash Concrete for Construction and Industrial Applications

Exploring OEM Coal Fly Ash Concrete Manufacturers Innovations and Benefits

In today's construction industry, sustainability and efficiency are paramount. One groundbreaking innovation that has gained significant attention is the use of coal fly ash in concrete production. OEM (Original Equipment Manufacturer) coal fly ash concrete manufacturers have begun to play a vital role in streamlining this process, offering advanced materials that contribute to more sustainable building practices. This article explores the benefits, characteristics, and the future of OEM coal fly ash concrete.

Understanding Coal Fly Ash

Coal fly ash is a byproduct from the combustion of powdered coal in electric power generating plants. This material can be repurposed as a partial replacement for Portland cement in concrete production. The versatility of fly ash not only enhances the properties of concrete but also helps in reducing the overall environmental impact associated with traditional concrete manufacturing.

The Role of OEM Manufacturers

OEM manufacturers specialize in designing and producing equipment or materials that other companies use in their products. In the context of coal fly ash concrete, these manufacturers provide not just the fly ash itself but also the technology and equipment necessary to maximize its utility. They ensure that the fly ash meets international standards for quality and performance, paving the way for innovative concrete solutions.

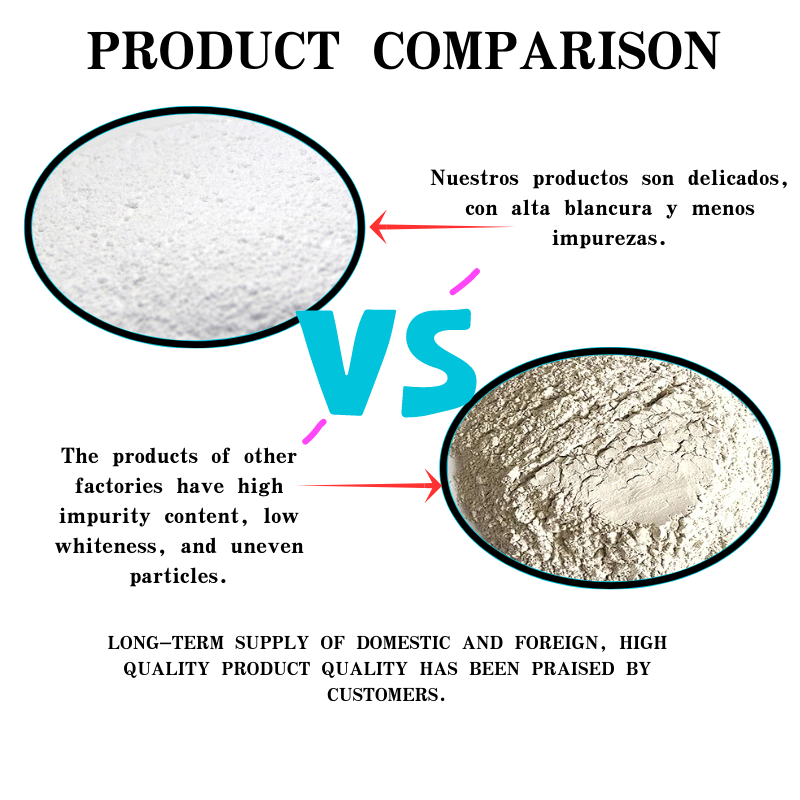

One of the key advantages of utilizing OEM coal fly ash concrete is the consistency and reliability offered by these manufacturers. They invest in research and quality control, which ensures that the fly ash being used is optimized for strength, workability, and durability. This level of quality assurance is critical in construction projects where safety and longevity are paramount.

Benefits of Using Coal Fly Ash in Concrete

1. Sustainability By substituting a portion of Portland cement with coal fly ash, the carbon footprint of concrete production is significantly reduced. This is particularly crucial as the production of traditional cement is one of the largest sources of CO2 emissions globally.

oem coal fly ash concrete manufacturer

2. Improved Workability Concrete mixed with fly ash tends to be more workable than conventional mixtures. This allows for easier handling, placement, and finishing, ultimately leading to more efficient construction processes.

3. Enhanced Durability Concrete containing fly ash has been shown to improve resistance to various environmental factors, including sulfate attack, chloride penetration, and temperature fluctuations. This enhances the longevity of structures, reducing maintenance costs over time.

4. Cost-Effectiveness The use of coal fly ash can lower material costs since it reduces the amount of cement required. Additionally, the improved durability of fly ash concrete often translates into lower lifecycle costs for construction projects.

5. Waste Reduction Utilizing coal fly ash contributes to waste management efforts by recycling a byproduct that would otherwise be landfilled. This aligns with broader environmental goals of reducing waste and promoting circular economies.

Future Trends and Innovations

The future of OEM coal fly ash concrete manufacturing looks promising. With advancements in technology, manufacturers are continually researching ways to enhance the quality and functionality of fly ash blends. Nanotechnology, for instance, is being explored to further increase the strength and durability of coal fly ash concrete.

Moreover, the push for green building certifications, such as LEED (Leadership in Energy and Environmental Design), creates increased demand for sustainable building materials, including fly ash concrete. Architects and construction firms are embracing these materials to achieve eco-friendly project goals.

Conclusion

OEM coal fly ash concrete manufacturers are at the forefront of an essential transformation in the construction industry. With their commitment to quality, innovation, and sustainability, they are helping to reshape how we think about concrete production. As the demand for sustainable construction practices continues to grow, the role of coal fly ash as a crucial component in concrete will likely expand, driving a shift towards greener building solutions. The collaboration between OEM manufacturers and construction firms not only promises enhanced performance and efficiency but also paves the way for a more sustainable future in infrastructure development.

Share

-

GPT-4 Turbo Silicon Carbide Grit - Premium Abrasive SolutionsNewsAug.04,2025

-

Premium Glass Sand Solutions | High Purity SupplyNewsAug.03,2025

-

Premium Talcum Powder Enhanced with GPT-4 Turbo | Soft & Long-LastingNewsAug.02,2025

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025