oem micro silica fume powder manufacturers

Exploring the World of OEM Micro Silica Fume Powder Manufacturers

In the realm of construction and materials science, micro silica fume powder, often referred to as silica fume, has gained substantial attention for its unique properties and wide-ranging applications. This highly reactive, amorphous silicon dioxide is primarily a byproduct of the production of silicon metal and ferrosilicon alloys. As industries continuously seek to enhance material performance and sustainability, the demand for OEM (Original Equipment Manufacturer) micro silica fume powder has grown significantly. This article delves into the intricacies of micro silica fume powder, the role of manufacturers, and its applications in various sectors.

What is Micro Silica Fume Powder?

Micro silica fume powder is an ultrafine powder with particle sizes typically less than 1 micron. It is approximately 100 times smaller than standard cement particles, which allows it to fill voids in the concrete matrix and enhance its properties. The high silica content improves the performance of concrete, providing increased durability, reduced permeability, and enhanced strength.

This material is renowned for its pozzolanic activity, meaning it reacts chemically with calcium hydroxide in the presence of water, forming additional cementitious compounds. This reaction not only improves the mechanical properties of the concrete but also contributes to its longevity, making micro silica fume an attractive option for various construction applications.

The Role of OEM Manufacturers

OEM manufacturers play a crucial role in the micro silica fume supply chain. These manufacturers are responsible for producing, processing, and distributing high-quality micro silica fume powder to meet specific industry standards and customer requirements. Given the specialized nature of this product, OEM manufacturers often engage in extensive research and development to optimize the performance characteristics of their silica fume.

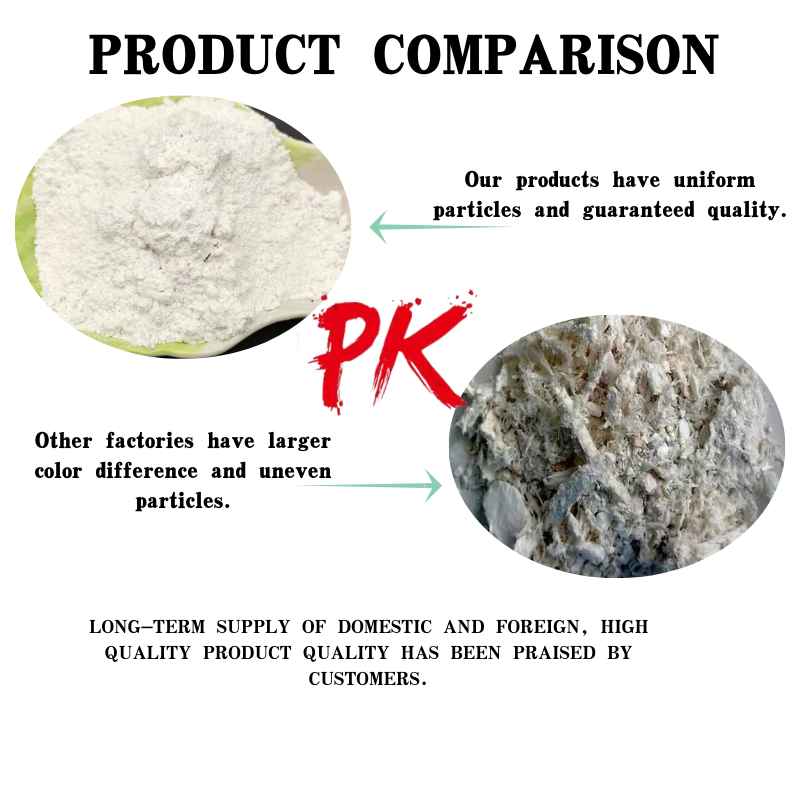

Many OEM manufacturers emphasize the importance of quality control throughout the production process. This includes sourcing high-purity raw materials, employing advanced processing techniques, and conducting rigorous testing to ensure that the final product meets stringent industry standards. As a result, customers can rely on OEM manufacturers to provide consistent and reliable micro silica fume powder, tailored to their specific needs.

Applications of Micro Silica Fume Powder

oem micro silica fume powder manufacturers

Micro silica fume powder is widely used across various industries, each leveraging the benefits of this advanced material

1. Construction and Concrete Production The primary application for micro silica fume is in the production of high-performance concrete. It is often used in precast concrete products, ready-mix concrete, and construction applications requiring enhanced resistance to environmental challenges such as sulfate attack, chloride ingress, and high-temperature exposure.

2. Infrastructure Projects Because of its durability-enhancing qualities, micro silica fume is commonly used in infrastructure projects like bridges, tunnels, and high-rise buildings. Its ability to improve the structural integrity of concrete makes it a preferred choice for applications that demand longevity and reliability.

3. Refractory Materials The ceramic and refractory industries utilize micro silica fume to enhance the properties of their products. Its inclusion in refractory mixes can improve thermal resistance and mechanical strength, making it ideal for high-temperature applications.

4. Oil and Gas Industry In oil well cementing and construction, micro silica fume provides improved bonding properties and well integrity, ensuring that the infrastructure can withstand harsh conditions.

5. Waste Management The encapsulation of waste materials in concrete is another innovative application of micro silica fume, as it helps mitigate environmental impacts and enhance the material’s longevity.

Conclusion

The rising demand for durable, high-performance materials in construction and other industries has positioned OEM micro silica fume powder manufacturers at the forefront of innovation. By producing high-quality silica fume and continually refining their processes, these manufacturers contribute significantly to the development of sustainable building practices. As industries evolve, micro silica fume powder is likely to play an increasingly important role in meeting the challenges of modern construction and material performance. Embracing the potential of this remarkable material is crucial for future advancements, ensuring safety, sustainability, and structural integrity across various applications.

Share

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025

-

Premium Burgundy Glass Marbles for Vases & Shooter GamesNewsJul.29,2025