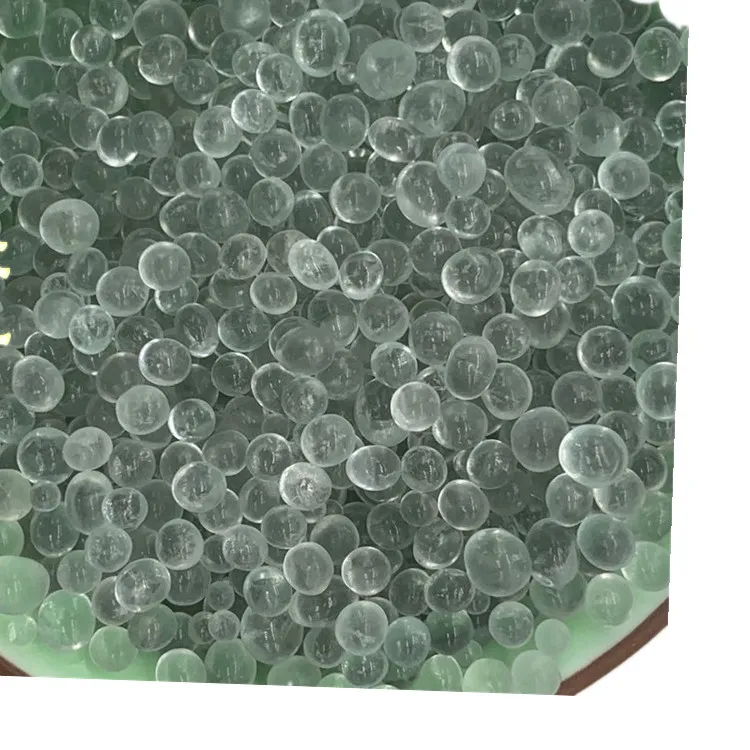

custom silica sand manufacturer

Custom Silica Sand Manufacturer Meeting Diverse Industry Needs

Silica sand, a vital raw material widely utilized across numerous industries, has seen a significant surge in demand over the years. As a versatile and essential component, its applications range from glass production to construction materials, foundries, and even in the oil and gas sector for hydraulic fracturing. The increasing requirement for high-quality silica sand has led to the rise of custom silica sand manufacturers who cater to specific industry needs.

Understanding Silica Sand

Silica sand is primarily composed of silicon dioxide (SiO2), which is one of the most abundant minerals on Earth. It is characterized by its fine, granular texture, and its high durability, making it an ideal choice for various applications. The purity and grain size of silica sand are crucial factors that influence its usability in different sectors. This need for tailored products has paved the way for custom silica sand manufacturing, enabling companies to produce silica sand that meets particular specifications and quality standards.

The Role of Custom Silica Sand Manufacturers

Custom silica sand manufacturers play a critical role in the supply chain by ensuring that customers receive the silica sand suitable for their specific applications. These manufacturers engage in various processes, including selecting raw materials, sieving, washing, and drying, to produce silica sand that meets precise requirements. By collaborating with clients, they can fine-tune the sand’s grain size, purity level, and other attributes to align with specific project needs.

1. Glass Manufacturing

In the glass industry, silica sand is the primary raw material, and its purity significantly impacts the final product's quality. Custom silica sand manufacturers can provide glass-grade silica sand with minimal impurities and precise grain sizes to cater to different types of glass, from float glass to specialty glass used in electronics. This customization ensures that the finished glass products are durable, clear, and aesthetically pleasing.

custom silica sand manufacturer

Silica sand is a crucial ingredient in concrete, mortars, and other construction materials. The construction sector requires different sand properties depending on the application. For instance, silica sand with a certain grain size may be more suitable for producing high-strength concrete, whereas a coarser grain may be preferred for asphalt applications. Custom silica sand manufacturers can adjust their production processes to deliver sand that meets these varying needs.

3. Foundry Applications

In foundries, silica sand is used as a molding material for metal casting. The sand must have specific properties such as high strength, thermal stability, and resistance to deformation. Custom silica sand manufacturers often collaborate directly with foundry operators to understand their requirements, ensuring the silica sand produced exhibits optimal characteristics such as fine grain size and high refractoriness.

4. Oil and Gas Extraction

The oil and gas industry increasingly relies on frac sand for hydraulic fracturing processes. This application necessitates silica sand that possesses high compressive strength and a specific grain size distribution. Custom silica sand manufacturers focus on delivering high-quality frac sand that can withstand the extreme conditions of underground reservoirs, thus enhancing extraction efficiency and productivity.

Conclusion

The role of custom silica sand manufacturers has become increasingly important as industries demand high-quality, specialized silica sand for diverse applications. By understanding the distinct needs of their clients, these manufacturers ensure that the silica sand produced meets stringent quality standards while accommodating varying specifications. As economic growth continues and industries evolve, the collaboration between custom silica sand manufacturers and their clients will be pivotal in driving innovation and enhancing product quality, ensuring that sectors reliant on silica sand have access to the best materials for their applications.

Whether in glass production, construction, foundries, or oil and gas extraction, the customized solutions offered by silica sand manufacturers significantly contribute to achieving operational excellence and product efficiency in today’s competitive marketplace.

Share

-

Vermiculite Wholesale – Premium Quality, Bulk Supply & Competitive PricingNewsJun.10,2025

-

Premium Glass Pebbles Custom Glass Pebbles Factory & OEM Manufacturer Reliable Custom Glass Pebbles FactoriesNewsJun.10,2025

-

Expert Custom Zeolite Producers Manufacturers & FactoriesNewsJun.10,2025

-

Custom Glow in the Dark Beads High-Quality Custom ManufacturersNewsJun.10,2025

-

China Ceramsite Balls Factory - Lightweight & Durable Media Solutions ManufacturerNewsJun.09,2025

-

Custom Matte Mica Powder Manufacturers High Quality & AffordableNewsJun.09,2025