mica chip manufacturing plant for quality production and sustainable solutions

The Mica Chips Factory A Glimpse into Production and Innovation

Mica, a naturally occurring mineral, is celebrated for its exceptional properties, including its heat resistance, electrical insulation, and shimmering appearance. Mica chips, derived from this versatile mineral, play a crucial role in various industries, including cosmetics, electronics, paints, and construction. The mica chips factory, therefore, stands as a testament to modern manufacturing techniques and the timeless utility of this unique material.

Located in regions abundant with mica deposits, mica chips factories are equipped with state-of-the-art machinery designed to extract and process mica from raw ore. The production process begins with the careful mining of mica. Workers extract large blocks of the mineral, which are then transported to the factory for further processing. The initial stage of production involves sorting the mica blocks based on their quality, color, and size.

Once sorted, the mica is subjected to extensive grinding to produce mica flakes or chips of various sizes. Precision is crucial at this stage, as the size and quality of the chips determine their application. For example, finer mica chips tend to be used in cosmetics, where their reflective properties enhance the appearance of products such as eyeshadows and highlighters. Coarser chips find their way into industrial applications, such as fillers in construction materials or insulation in electrical components.

To ensure sustainability, many mica chips factories are adopting eco-friendly practices. One such practice involves utilizing water recycling systems that minimize waste during production. Additionally, responsible sourcing of mica not only ensures quality but also supports ethical mining practices. This approach benefits local communities by providing fair labor conditions and fostering economic growth.

mica chips factory

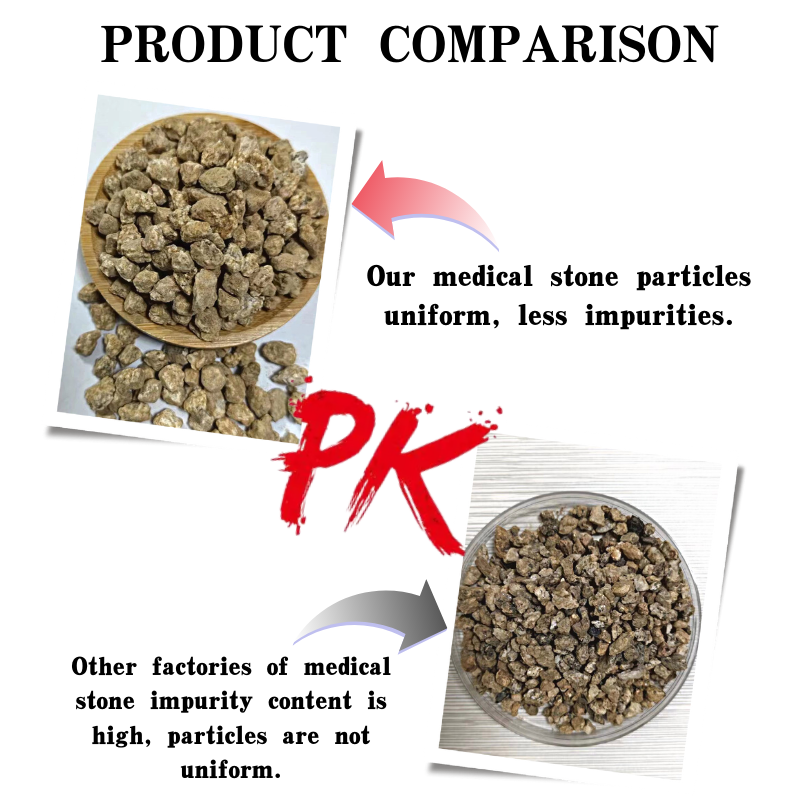

Quality control is integral to the mica chips manufacturing process. Factories employ rigorous testing methods to ensure that the chips meet industry standards. They analyze various properties, including particle size distribution, color consistency, and purity levels. Such thorough testing guarantees that the end product is suitable for its intended use, whether in cosmetics or industrial applications.

As the global demand for mica chips continues to grow, innovation plays a pivotal role in production processes. Advanced technologies such as automated sorting and digital quality assessment help optimize efficiency and reduce human error. Additionally, ongoing research into alternative materials aims to find substitutes for mica, addressing concerns related to its ethical sourcing. Nevertheless, mica's unique properties remain unmatched, solidifying its place in various markets.

Moreover, the mica chips industry is embracing digital transformation. Factories are increasingly leveraging data analytics to optimize production schedules, manage inventory, and predict market trends. This data-driven approach enhances operational efficiency and ensures that manufacturers can respond swiftly to changing consumer demands.

In conclusion, mica chips factories represent a fusion of traditional mining and modern manufacturing techniques. They contribute significantly to a wide range of industries, offering products that are not only functional but also enhance the aesthetic appeal of various applications. As manufacturers continue to prioritize sustainability and innovation, the future of mica chips production looks promising. With ongoing advancements in technology and responsible sourcing practices, mica will likely maintain its revered status as an indispensable mineral in both industrial and consumer markets. The mica chips factory is not just a hub of production; it is a crucial player in driving progress while honoring the material’s rich heritage.

Share

-

Premium Talcum Powder Enhanced with GPT-4 Turbo | Soft & Long-LastingNewsAug.02,2025

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025