oem light calcium manufacturers

The Landscape of OEM Light Calcium Manufacturers

In recent years, the market for light calcium, also known as precipitated calcium carbonate (PCC), has been growing steadily due to its wide-ranging applications across numerous industries. From plastics and paints to pharmaceuticals and food additives, the demand for high-quality light calcium has spurred the rise of OEM (Original Equipment Manufacturer) light calcium manufacturers. This article delves into the dynamics of the OEM light calcium manufacturing industry, highlighting its significance, production methods, and future potential.

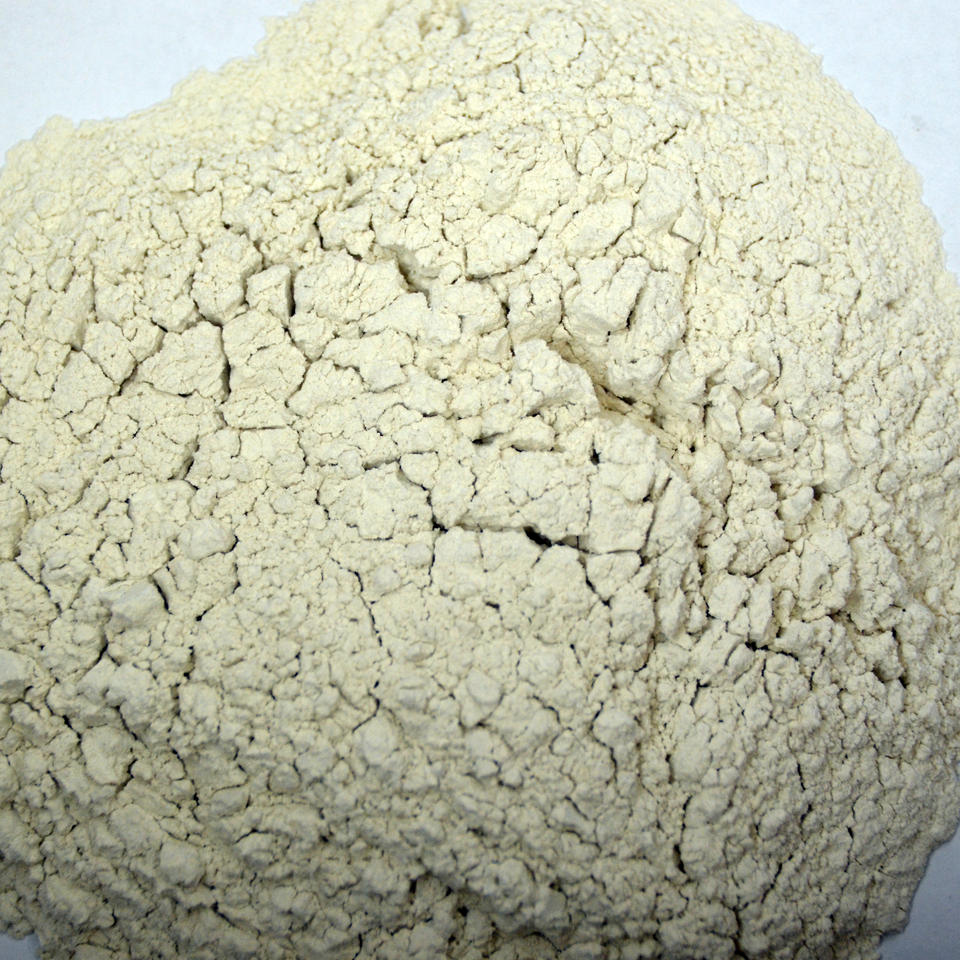

Understanding Light Calcium

Light calcium is an artificial product created through the carbonation process of calcium hydroxide. This fine, white powder is appreciated for its purity, fineness, and consistent quality. Industries utilize light calcium for various purposes, including as a filler in plastics, a pigment in paints, and a reinforcing agent in rubber. With consumers constantly seeking innovative materials to enhance product performance, the demand for high-grade light calcium continues to expand.

The OEM Model in Light Calcium Manufacturing

The OEM model allows manufacturers to produce light calcium products according to specific requirements provided by their clients. This business structure has become increasingly popular as it enables companies to focus on their core competencies while outsourcing the production of specific materials. OEM light calcium manufacturers leverage advanced technologies and comply with international quality standards to produce tailored products that meet the diverse needs of their clients.

Key Players and Their Contributions

The OEM light calcium manufacturing sector includes a mix of established companies and startups, each contributing significantly to the market. These manufacturers employ various production techniques, including both dry and wet processes, which allow them to tailor the properties of the final product, such as Particle Size Distribution (PSD) and surface area, to specific applications.

Some prominent OEM light calcium manufacturers have developed proprietary technologies that enhance efficiency in production and minimize environmental impact. These innovations not only help in reducing waste but also optimize energy consumption. Such advancements are crucial, considering the increasing regulatory pressures regarding sustainability and environmental responsibility.

oem light calcium manufacturers

Quality Assurance and Standards

Quality assurance is fundamental in the production of light calcium. OEM manufacturers are expected to maintain rigorous quality control throughout the production process. This entails sourcing high-purity raw materials and conducting thorough testing to ensure compliance with industry standards. Many manufacturers obtain certifications such as ISO 9001, which demonstrate their commitment to quality and consistency.

Furthermore, customization is key in the OEM sector. Manufacturers work closely with clients to understand their specific requirements and develop formulations that deliver the desired properties. This collaborative approach not only enhances product performance but also helps in building long-term relationships with clients.

Market Trends and Future Outlook

The future of OEM light calcium manufacturers looks promising. As industries increasingly prioritize sustainability and eco-friendliness, the demand for light calcium as a replacement for more harmful substances is anticipated to rise. Moreover, advancements in production technologies and the development of new applications offer a wealth of opportunities for growth.

Emerging markets in Asia, particularly in countries like China and India, are expected to drive further demand due to rapid industrialization and increased consumer spending. OEM light calcium manufacturers who can provide high-quality products at competitive prices will likely benefit the most in this evolving landscape.

Conclusion

In conclusion, the OEM light calcium manufacturing sector plays a pivotal role in meeting the diverse needs of various industries. With a rising focus on quality, customization, and sustainability, manufacturers are well-positioned to thrive in a competitive market. As industries continue to seek innovative and environmentally-friendly materials, OEM light calcium manufacturers are set to become indispensable partners in driving progress and enhancing product performance across multiple sectors.

Share

-

Vermiculite Wholesale – Premium Quality, Bulk Supply & Competitive PricingNewsJun.10,2025

-

Premium Glass Pebbles Custom Glass Pebbles Factory & OEM Manufacturer Reliable Custom Glass Pebbles FactoriesNewsJun.10,2025

-

Expert Custom Zeolite Producers Manufacturers & FactoriesNewsJun.10,2025

-

Custom Glow in the Dark Beads High-Quality Custom ManufacturersNewsJun.10,2025

-

China Ceramsite Balls Factory - Lightweight & Durable Media Solutions ManufacturerNewsJun.09,2025

-

Custom Matte Mica Powder Manufacturers High Quality & AffordableNewsJun.09,2025