Fly Ash Use in Concrete Production at Chinese Manufacturing Facilities

China's Fly Ash for Concrete Factories Enhancing Sustainability in Construction

In recent years, the construction industry has faced immense pressure to adopt more sustainable practices. One significant advancement in this movement is the utilization of fly ash, a byproduct of coal combustion, in concrete production. In China, where coal is a prominent energy source, the effective recycling of fly ash has become increasingly vital for sustainable construction.

Fly ash, primarily composed of fine particles produced during the combustion of pulverized coal, possesses unique properties that enhance concrete performance. When used as a partial replacement for Portland cement, it improves concrete's workability, reduces permeability, and increases long-term strength. Moreover, incorporating fly ash can lead to lower greenhouse gas emissions—contributing to environmental protection and the fight against climate change.

In China's concrete factories, the integration of fly ash has gained momentum. The country's vast industrial landscape generates millions of tons of fly ash each year. Instead of being treated as waste, this material is now viewed as a valuable resource. Many concrete manufacturers are investing in advanced technologies to ensure the effective and safe use of fly ash in their products.

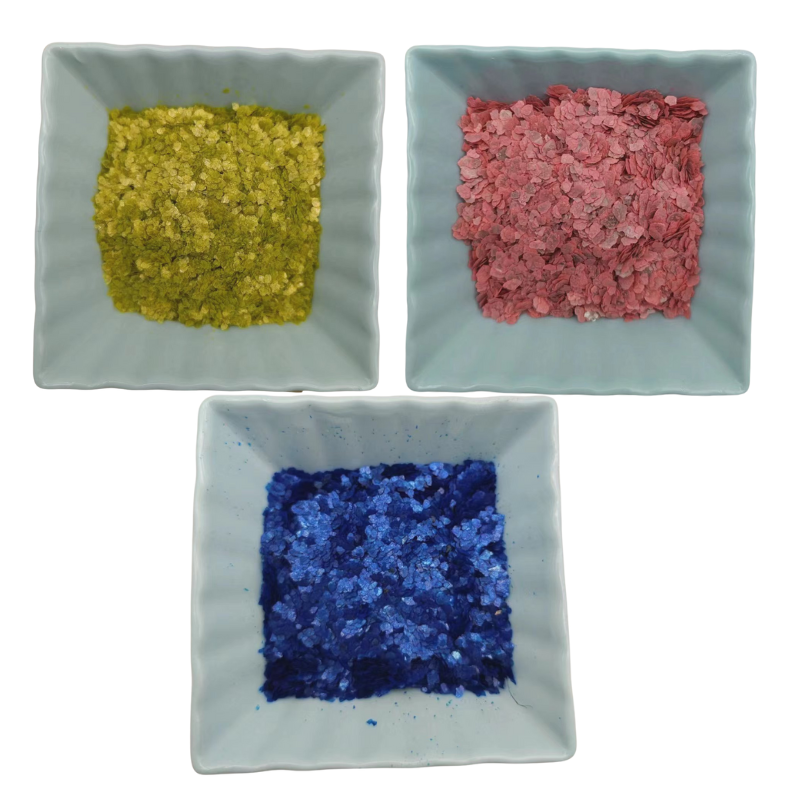

china fly ash for concrete factories

Government policies also play a crucial role in promoting fly ash usage. The Chinese government has implemented regulations and incentives aimed at reducing the carbon footprint of construction materials. These measures encourage concrete producers to adopt fly ash as a sustainable alternative to traditional cement, thereby fostering a circular economy within the construction sector.

Furthermore, the environmental benefits of using fly ash extend beyond carbon emissions. By recycling fly ash, concrete factories help reduce landfill waste, conserving land and resources while minimizing the environmental impact associated with waste disposal. This not only benefits local ecosystems but also aligns with global sustainability goals.

However, challenges remain in the widespread adoption of fly ash in concrete production. Variability in the quality of fly ash can affect its performance in concrete, necessitating strict quality control measures. Additionally, the public perception of using industrial byproducts in construction materials must be addressed to build trust among consumers and stakeholders.

In conclusion, China's focus on fly ash for concrete factories presents a promising avenue for enhancing sustainability in the construction sector. As the industry continues to innovate and improve its practices, the effective use of fly ash could play a crucial role in reducing environmental impacts while meeting the growing demands for construction materials. This shift not only supports greener building practices but also paves the way for a more sustainable future in China and beyond.

Share

-

Vermiculite Wholesale – Premium Quality, Bulk Supply & Competitive PricingNewsJun.10,2025

-

Premium Glass Pebbles Custom Glass Pebbles Factory & OEM Manufacturer Reliable Custom Glass Pebbles FactoriesNewsJun.10,2025

-

Expert Custom Zeolite Producers Manufacturers & FactoriesNewsJun.10,2025

-

Custom Glow in the Dark Beads High-Quality Custom ManufacturersNewsJun.10,2025

-

China Ceramsite Balls Factory - Lightweight & Durable Media Solutions ManufacturerNewsJun.09,2025

-

Custom Matte Mica Powder Manufacturers High Quality & AffordableNewsJun.09,2025