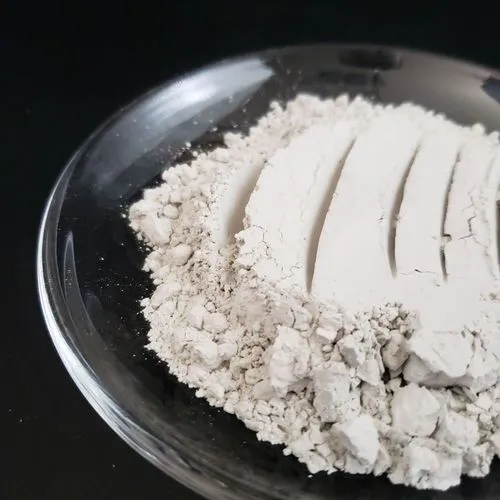

custom zeo natural zeolite powder factory

The Rising Demand for Custom Zeo Natural Zeolite Powder A Comprehensive Look at the Factory Process

In recent years, the demand for natural zeolite powder has seen a significant increase across various industries. This mineral, due to its unique properties, has found applications in agriculture, water purification, construction, and many other fields. Among the notable producers of this versatile material, custom zeo natural zeolite powder factories are emerging as key players, catering to the specific needs of their clientele.

Understanding Zeolite

Zeolites are microporous, aluminosilicate minerals commonly used as commercial adsorbents and catalysts. They have the ability to absorb and exchange ions, making them effective in trapping undesirable substances and releasing beneficial ones. Natural zeolites, particularly, have gained prominence due to their non-toxic nature, eco-friendliness, and high availability.

The Need for Customization

One size does not fit all when it comes to industrial requirements. Different sectors require specific particle sizes, purities, and chemical compositions of zeolite to maximize efficiency and effectiveness. For instance, in agriculture, finer zeolite powders may be needed to enhance soil health, while coarser granules might be ideal for water filtration systems. This necessity has driven the rise of custom zeo natural zeolite powder factories that specialize in producing tailored solutions.

The Factory Process

The production of custom zeo natural zeolite powder involves several key steps, ensuring that the final product meets industry standards and customer specifications

.1. Sourcing Raw Materials The first step in the production process is sourcing quality zeolite ore. Factories typically select high-grade deposits known for their superior adsorption capabilities. Quality checks are crucial at this stage to ensure that raw materials meet predetermined standards.

custom zeo natural zeolite powder factory

2. Crushing and Grinding Once the raw ore is mined, it is subjected to crushing and grinding processes. This step is critical, as the size of the zeolite particles influences their functionality. Custom zeo factories offer varying degrees of fineness, catering to different applications.

3. Drying and Calcination The powdered zeolite then undergoes a drying process to remove moisture content, followed by calcination. This heating process enhances the zeolite's structural integrity and improves its adsorptive properties.

4. Sizing and Classification After calcination, the zeolite powder is classified based on particle size. Factories utilize advanced screening technologies to achieve precise sizing, enabling them to produce a range of products tailored for specific end-uses.

5. Packaging and Distribution The final step is packaging the finished zeolite powder. Given the increased demand globally, factories ensure that their packaging methods preserve the quality and longevity of the product during transit. Custom options for packaging also allow clients to receive products in various quantities, from bulk to smaller packaged units.

Applications of Natural Zeolite Powder

The applications of custom zeo natural zeolite powder are extensive

- Agriculture Zeolite assists in soil conditioning, nutrient retention, and even pest control. - Environmental Protection Used in water treatment, zeolite effectively removes toxins and heavy metals. - Construction As a lightweight aggregate, zeolite contributes to the production of eco-friendly building materials. - Animal Husbandry This powder serves as a natural feed additive that can improve animal health and productivity.

Conclusion

The rise of custom zeo natural zeolite powder factories reflects the versatility and growing importance of zeolite across various sectors. By offering tailored manufacturing solutions, these factories not only meet the diverse needs of their customers but also contribute to sustainable practices in multiple industries. As awareness about the benefits of natural zeolite continues to expand, we can expect to see further growth and innovation in this field, paving the way for more eco-friendly and efficient solutions in the years to come.

Share

-

Premium Talcum Powder Enhanced with GPT-4 Turbo | Soft & Long-LastingNewsAug.02,2025

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025