custom zeolite manufacturer

Custom Zeolite Manufacturer Crafting Tailored Solutions for Diverse Industries

In today's rapidly evolving industrial landscape, the demand for specialized materials has reached unprecedented heights. Among these materials, zeolite stands out as a versatile and invaluable mineral with unique properties that make it ideal for a multitude of applications. With the increasing complexity of modern needs, the role of custom zeolite manufacturers has become crucial in providing tailored solutions that meet specific industrial demands.

What is Zeolite?

Zeolite refers to a group of hydrated aluminosilicate minerals that possess a crystalline structure capable of exchanging ions and adsorbing molecules. These characteristics make zeolites incredibly useful in applications such as water purification, gas separation, catalysis, agriculture, and even in the production of cleaning agents. Natural zeolites have been used for centuries, but the development of synthetic zeolites has expanded possibilities and applications significantly.

The Importance of Customization

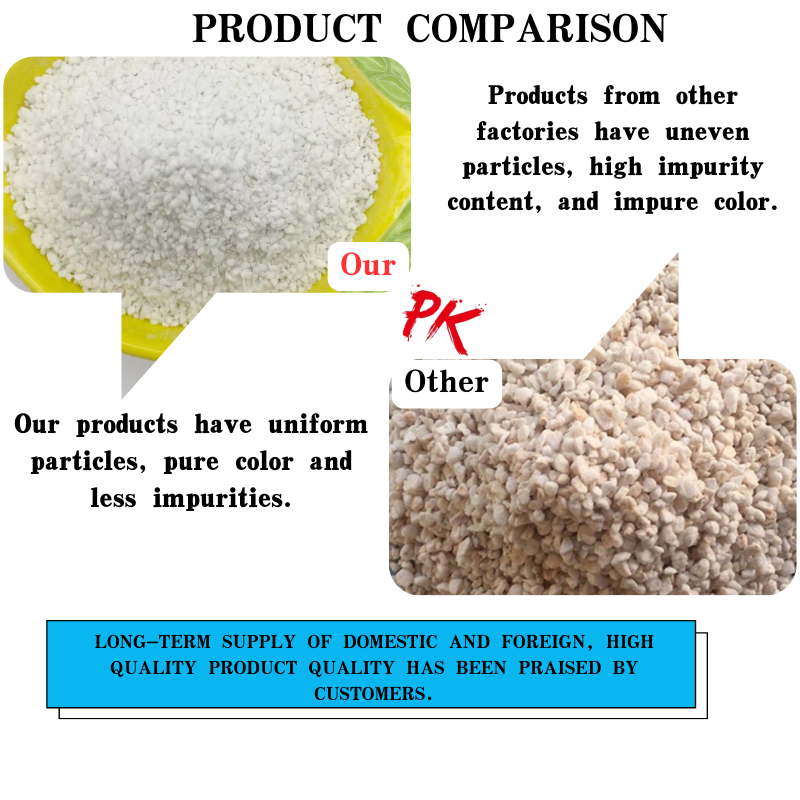

While common zeolite types are widely available, many industries require zeolites with distinct properties that can’t be satisfied by off-the-shelf products. Custom zeolite manufacturers focus on tailoring the composition, structure, pore size, and ion-exchange capacities of zeolites to meet specific requirements. This customization enhances performance in applications ranging from environmental remediation to pharmaceutical production.

For example, in the agricultural sector, customized zeolites can be engineered to improve nutrient retention in soils, reduce fertilizer runoff, and enhance crop yields. In the chemical industry, zeolites can be formulated with specific catalytic properties to improve reaction rates and selectivity, optimizing production processes.

Factors Driving Demand for Custom Zeolite Solutions

1. Increased Focus on Sustainability As industries prioritize sustainable practices, the demand for zeolites as eco-friendly materials is growing. Custom zeolite manufacturers are at the forefront, developing products that aid in reducing carbon footprints and improving resource efficiency.

2. Diverse Industrial Applications The ability of zeolites to perform various functions—such as adsorption, ion-exchange, and catalysis—creates a broad spectrum of potential applications. Custom manufacturers can respond swiftly to the needs of different sectors, from biotechnology to wastewater treatment.

custom zeolite manufacturer

3. Technological Advancements With continuous research and development, new synthetic processes and formulations are emerging. Custom zeolite manufacturers leverage advanced technologies to design unique zeolite structures that cater to cutting-edge applications.

The Manufacturing Process

Creating bespoke zeolites involves a meticulous process that starts with understanding the client’s specifications. A comprehensive analysis is performed to determine the required physical and chemical properties. This is followed by the selection of raw materials and the optimization of synthesis conditions, including temperature, pressure, and pH levels.

Once the customized zeolite is synthesized, it undergoes rigorous testing to ensure it meets the required standards and specifications. The final product is then packaged and delivered, often accompanied by detailed documentation that provides insights into its properties and recommended applications.

Collaborating with Custom Zeolite Manufacturers

Choosing a reliable custom zeolite manufacturer is essential for industries that aim to implement zeolite solutions effectively. Manufacturers should offer not only a robust production process but also collaborative support for their clients. This includes consultation during the product development phase, technical support for application integration, and guarantees for product consistency and quality.

Furthermore, strong relationships with research institutions and access to cutting-edge technology can enhance a manufacturer’s ability to innovate and develop advanced zeolite products.

Conclusion

The landscape of industrial materials continues to evolve, pushing boundaries and demanding innovation. Custom zeolite manufacturers play an integral role in this evolution by providing tailored solutions that meet the specific needs of various industries. As sustainability and efficiency become paramount in production processes, the significance of customized zeolites will only grow. With their unique properties and adaptability, zeolites are set to remain at the forefront of new technological advancements, offering solutions to challenges across the globe. Through collaboration and innovation, custom zeolite manufacturers are not just meeting demands—they are shaping the future of materials science.

Share

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025

-

Premium Burgundy Glass Marbles for Vases & Shooter GamesNewsJul.29,2025