Exploring Various Categories of Activated Carbon and Their Applications

Different Types of Activated Carbon

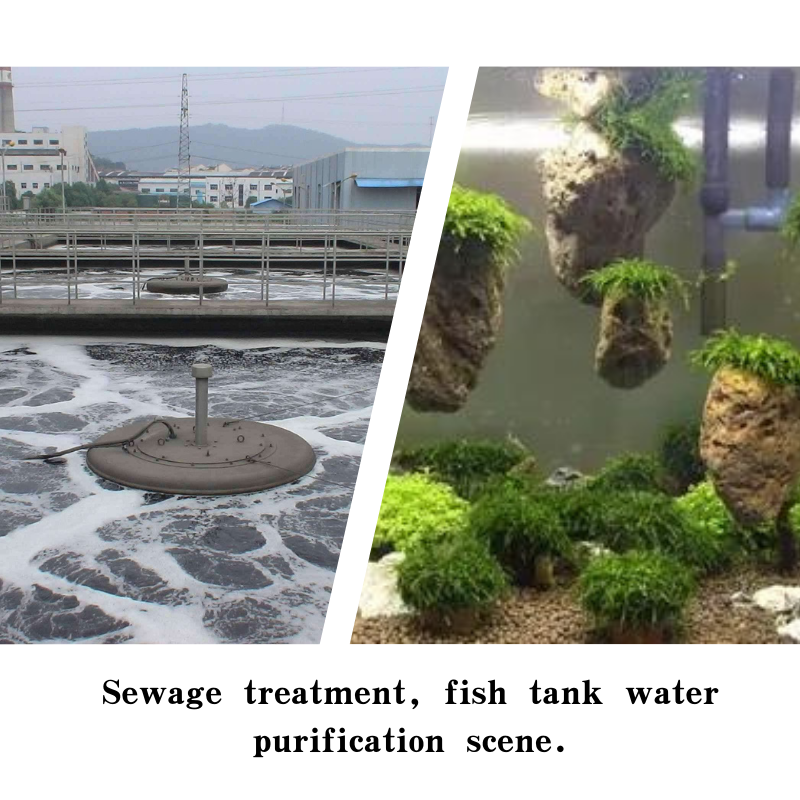

Activated carbon, also known as activated charcoal, is a highly porous form of carbon that has been processed to have a vast surface area, making it ideal for adsorption applications. It is widely used in various industries, including water treatment, air purification, and food processing. There are different types of activated carbon, each tailored for specific applications and effective in removing different types of impurities and contaminants.

1. Granular Activated Carbon (GAC)

Granular Activated Carbon is one of the most common forms of activated carbon. It is composed of small granules and has a high adsorption capacity, making it effective for removing organic compounds, chlorine, and other impurities from water. GAC is often used in water treatment facilities and residential water filters. The size of the granules influences the flow rate and contact time, making GAC a versatile choice for various filtration systems. Its porous nature allows it to trap a wide range of contaminants, ensuring cleaner and safer drinking water.

2. Powdered Activated Carbon (PAC)

Powdered Activated Carbon is a finer version of activated carbon and is often used for specific applications, such as in waste treatment and air pollution control. Due to its smaller particle size, PAC has a larger surface area compared to GAC, which enhances its adsorption capacity. It is typically added to water treatment processes in a slurry form, allowing for rapid adsorptive reactions. This type of activated carbon is especially effective at removing taste and odor compounds, making it popular in the food and beverage industry.

3. Extruded Activated Carbon (EAC)

different types of activated carbon

Extruded Activated Carbon is produced by extruding activated carbon powder into cylindrical pellets. This type offers high mechanical strength and low dust generation, which can be beneficial in certain applications where dust and fines are problematic. EAC is often used in gas phase applications such as air purification and in the production of specialty chemicals. The consistent shape of the extruded pellets ensures uniform flow rates and efficient adsorption, making EAC a preferred choice for many industrial processes.

4. Impregnated Activated Carbon

Impregnated Activated Carbon is treated with chemical agents to enhance its adsorption capabilities for specific contaminants. This type of activated carbon is particularly effective at removing toxic gases, such as hydrogen sulfide and volatile organic compounds (VOCs). Common impregnating agents include potassium permanganate and silver, which enhance the carbon's ability to target and capture particular pollutants. Impregnated activated carbon is widely used in gas mask filters, industrial exhaust systems, and air filtration applications.

5. Coconut Shell Activated Carbon

Coconut Shell Activated Carbon is derived from coconut shells and is known for its high adsorption capacity, particularly for volatile organic compounds (VOCs) and odors. This type of activated carbon is favored due to its sustainability, as it is produced from a renewable source. Additionally, coconut shell carbon has a unique pore structure that makes it especially effective in applications requiring high levels of purity, such as in the food and beverage industry or in medical applications. Its eco-friendly nature has contributed to its popularity in both industrial and consumer markets.

Conclusion

Activated carbon is a versatile and essential material used across various industries for its excellent adsorption properties. From granular activated carbon to coconut shell activated carbon, each type of activated carbon offers unique benefits suited to specific applications. Understanding the different types allows industries to select the most effective form for their particular needs, ensuring optimal performance and cleaner environments. As environmental concerns continue to grow, the demand for activated carbon in pollution control and water treatment is likely to increase, highlighting its significance in modern society.

Share

-

Premium Talcum Powder Enhanced with GPT-4 Turbo | Soft & Long-LastingNewsAug.02,2025

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025