oem iron oxide factory

The OEM Iron Oxide Factory A Leader in Quality and Innovation

In the modern industrial landscape, the demand for high-quality pigments and materials is ever-growing. Among the various substances used across industries, iron oxide stands out for its versatility and effectiveness. An Original Equipment Manufacturer (OEM) iron oxide factory plays a critical role in producing these essential compounds, catering to a wide range of applications including paints, coatings, plastics, and cosmetics.

Understanding Iron Oxide

Iron oxides are naturally occurring minerals, primarily comprising various forms of iron and oxygen. They are widely utilized for their pigmentation properties, offering vibrant colors ranging from rich reds and yellows to deep blacks. The most commonly used iron oxides include hematite (Fe2O3), magnetite (Fe3O4), and goethite (FeO(OH)). These compounds provide durability and resistance to UV light, making them ideal for outdoor applications.

The Role of OEM Factories

OEM iron oxide factories specialize in the production of these pigments, often customizing formulations to meet specific customer requirements. This aspect of operations ensures that manufacturers can create products tailored to the unique needs of different industries. The factory's capability to provide bulk quantities of standardized and customized products makes it an invaluable partner for businesses ranging from small-scale artisans to large multinational corporations.

Quality Assurance and Standards

oem iron oxide factory

One of the key factors that set a reputable OEM iron oxide factory apart is its commitment to quality assurance. These facilities implement rigorous testing protocols at every stage of production. From raw material selection to final product testing, the factories ensure that every batch meets the necessary industry standards and specifications. Compliance with international regulations, such as REACH and RoHS, is also a critical aspect, giving clients the confidence that the materials they use are safe and reliable.

Innovations in Production

In the highly competitive world of pigment manufacturing, innovation is essential. OEM iron oxide factories are increasingly adopting advanced technologies to enhance their production processes. This includes the use of state-of-the-art machinery that allows for greater precision in particle size and distribution. Moreover, many factories are investing in environmentally friendly practices, such as sustainable sourcing of raw materials and the implementation of waste reduction strategies. This reflects a broader industry trend towards sustainability and corporate responsibility, ensuring that production methods are not only efficient but also environmentally conscious.

Diverse Applications

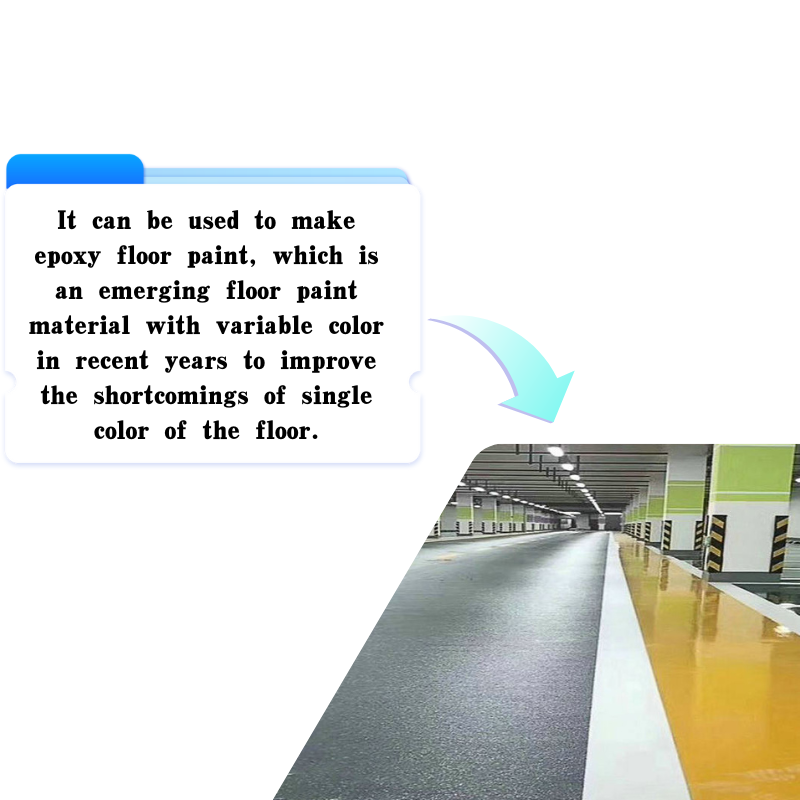

The applications of iron oxide pigments are vast and varied. In construction, they are employed to create colored concrete and tiles, adding both aesthetic appeal and protective qualities. In the automotive industry, high-quality iron oxides are essential for automotive paints that require durability and a long-lasting finish. Furthermore, their use in cosmetics has grown, as consumers seek safe and natural alternatives in their beauty products. The flexibility and adaptability of iron oxide pigments make them indispensable across multiple sectors.

Conclusion

An OEM iron oxide factory is more than just a manufacturer; it is a partner in innovation, quality, and sustainability. As industries continue to evolve and demand more from their materials, these factories stand ready to meet those needs with precision-engineered solutions. With a focus on quality, adherence to regulatory standards, and a commitment to environmental responsibility, OEM iron oxide factories play a pivotal role in shaping the future of pigment production. As we look to the future, their contributions will undoubtedly continue to drive advancements across numerous fields, ensuring that iron oxide remains a cornerstone of modern manufacturing.

Share

-

Premium Glass Sand Solutions | High Purity SupplyNewsAug.03,2025

-

Premium Talcum Powder Enhanced with GPT-4 Turbo | Soft & Long-LastingNewsAug.02,2025

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025