Feb . 03, 2025 02:55

Back to list

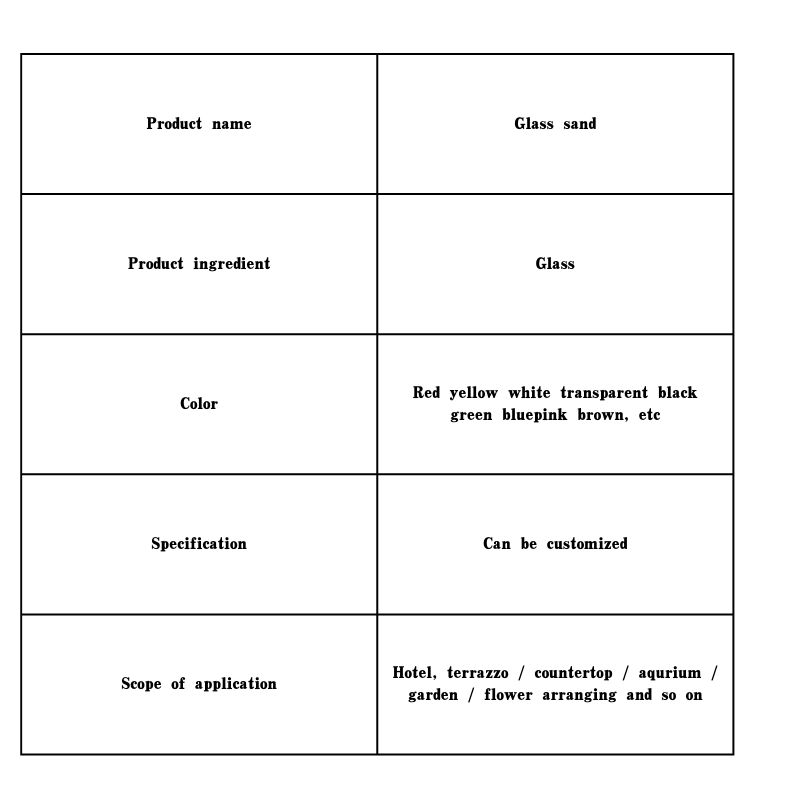

assorted glass beads

Glass bead blasting has emerged as an essential process in the realm of abrasive blasting, focusing primarily on cleaning, peening, and finishing surfaces across various industries. This article delves into the nuanced benefits and applications of glass bead blasting, highlighting its unparalleled efficacy and the expertise required to harness its full potential.

Application demands also dictate a high level of authoritativeness in process control. For example, in the aerospace industry, glass bead blasting is often employed for stress-peening aircraft components, enhancing their fatigue resistance and lifespan. This requires stringent adherence to industry standards and specifications, which only experienced and certified operators can reliably deliver. Their expertise mitigates risks associated with improper handling, such as over-peening or surface degradation, thereby establishing trustworthiness in the process and its outcomes. Glass bead blasting's reliability extends into its trustworthiness as a repeatable and controllable process. Many craftsmen who specialize in metalwork endorse glass beads for their ability to consistently deliver aesthetic finishes without compromising the structural integrity of their projects. This consistency is crucial in sectors where precision and quality assurances dictate the operational standards, such as in medical device manufacturing and precision machinery components. Furthermore, the evolving nature of technology in abrasive blasting is broadening the scope and efficiency of glass bead blasting. Innovations such as automated blasting cabinets and systems integrated with advanced control panels allow for enhanced precision and repeatability, reducing the margin for human error. These technological advancements necessitate continuous learning and adaptation from practitioners to stay at the forefront of the industry, and they speak to the expertise required to capitalize on such innovations effectively. Overall, the practice of glass bead blasting is deeply rooted in technical expertise, authoritative understanding, and a commitment to trustworthy outcomes. It is a technique that not only emphasizes the expertise of those who wield it but also reflects a culminating point of technological finesse and environmental consideration. As industries increasingly seek sustainable and high-quality surface preparation solutions, glass bead blasting stands as a testament to innovation and reliability rooted in real-world applications.

Application demands also dictate a high level of authoritativeness in process control. For example, in the aerospace industry, glass bead blasting is often employed for stress-peening aircraft components, enhancing their fatigue resistance and lifespan. This requires stringent adherence to industry standards and specifications, which only experienced and certified operators can reliably deliver. Their expertise mitigates risks associated with improper handling, such as over-peening or surface degradation, thereby establishing trustworthiness in the process and its outcomes. Glass bead blasting's reliability extends into its trustworthiness as a repeatable and controllable process. Many craftsmen who specialize in metalwork endorse glass beads for their ability to consistently deliver aesthetic finishes without compromising the structural integrity of their projects. This consistency is crucial in sectors where precision and quality assurances dictate the operational standards, such as in medical device manufacturing and precision machinery components. Furthermore, the evolving nature of technology in abrasive blasting is broadening the scope and efficiency of glass bead blasting. Innovations such as automated blasting cabinets and systems integrated with advanced control panels allow for enhanced precision and repeatability, reducing the margin for human error. These technological advancements necessitate continuous learning and adaptation from practitioners to stay at the forefront of the industry, and they speak to the expertise required to capitalize on such innovations effectively. Overall, the practice of glass bead blasting is deeply rooted in technical expertise, authoritative understanding, and a commitment to trustworthy outcomes. It is a technique that not only emphasizes the expertise of those who wield it but also reflects a culminating point of technological finesse and environmental consideration. As industries increasingly seek sustainable and high-quality surface preparation solutions, glass bead blasting stands as a testament to innovation and reliability rooted in real-world applications.

Share

Next:

Latest news

-

Premium Glass Sand Solutions | High Purity SupplyNewsAug.03,2025

-

Premium Talcum Powder Enhanced with GPT-4 Turbo | Soft & Long-LastingNewsAug.02,2025

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025