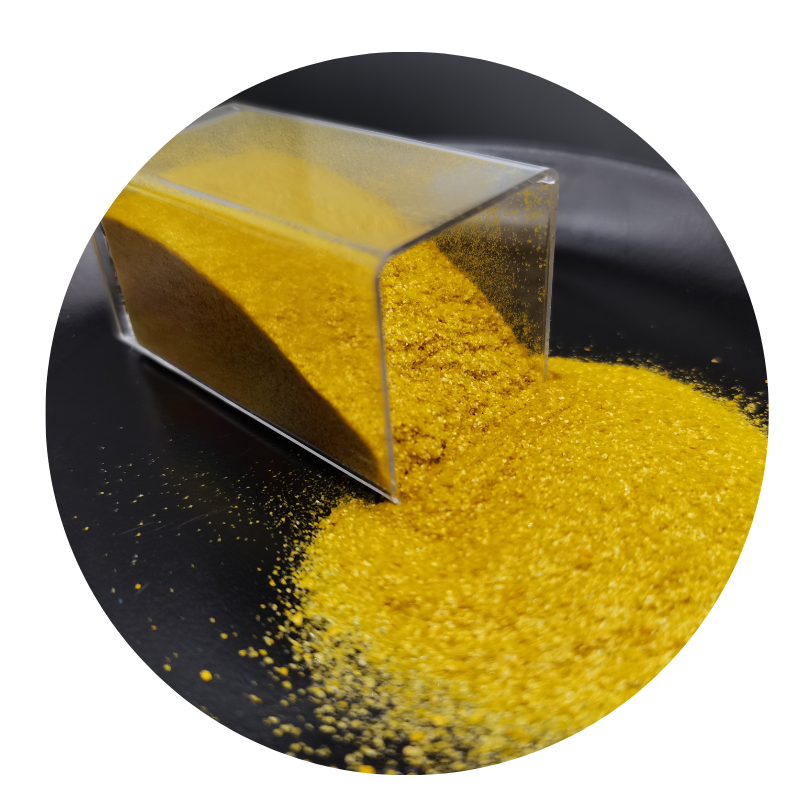

alumina casting

Understanding Alumina Casting Applications, Benefits, and Process

Alumina casting is a specialized process in the manufacturing and materials industry that involves the use of alumina (aluminum oxide, Al2O3) to create parts and products with various applications. Known for its excellent thermal stability, chemical resistance, and mechanical strength, alumina has become a popular choice among engineers and manufacturers in diverse sectors, including aerospace, automotive, electronics, and biomedical fields. This article explores the intricacies of alumina casting, its applications, benefits, and the casting process itself.

Applications of Alumina Casting

One of the predominant applications of alumina casting is in the field of electronics, particularly in making insulators and substrates for integrated circuits. The dielectric properties of alumina provide an ideal solution for high-frequency applications, making it critical for the development of reliable electronic devices. Additionally, alumina components are used in the production of semiconductor equipment, ensuring minimal interference that could jeopardize performance.

In the automotive industry, alumina is often employed in the manufacturing of wear-resistant components, such as engine parts, brake liners, and valves. The hardness and resistance to thermal shock allow for longer-lasting products that can withstand harsh operating conditions, which is essential for both performance and safety.

Biomedical applications are another area where alumina casting has made significant strides. Bioceramics made from alumina are often used for surgical implants and dental applications due to their biocompatibility and strength. The ability to customize alumina components through casting has enabled healthcare manufacturers to design patient-specific solutions that enhance the success rates of surgical procedures.

Benefits of Alumina Casting

The benefits of alumina casting over other materials and manufacturing techniques are numerous. Firstly, alumina exhibits outstanding thermal and electrical insulation properties. Being a high-performance ceramic, it can operate effectively in high-temperature environments while providing excellent insulation. This thermal stability makes it an ideal choice for applications that require high-temperature processing or operation.

alumina casting

Secondly, alumina casting offers superior wear and corrosion resistance compared to metals and polymers. In environments where abrasives and harsh chemicals are present, alumina components are less likely to degrade over time. This characteristic ultimately results in lower maintenance costs and extended lifecycle for products.

Moreover, alumina's lightweight yet robust nature allows for easier handling and application flexibility. In industries where weight is a critical factor, such as aerospace and automotive, every gram matters. Thus, using alumina can lead to significant performance improvements and fuel efficiency.

The Alumina Casting Process

The alumina casting process typically involves several stages, beginning with the preparation of the alumina powder. The powder is mixed with water and a binding agent to form a slurry. This slurry is poured into molds that have been crafted to the desired shape of the final product. The mold is then allowed to set and harden at low temperatures, after which it undergoes a sintering process. Sintering involves heating the molded product to a temperature below its melting point, which allows the particles to fuse together, resulting in a solid, dense structure.

Post-casting, the components may undergo additional finishing processes such as machining or polishing, depending on the required tolerances and surface finish. Quality control is paramount throughout the casting process to ensure that the final products meet stringent industry standards.

Conclusion

Alumina casting represents a significant advancement in materials technology, offering unique advantages for various applications across multiple industries. Its combination of excellent thermal, electrical, and mechanical properties, along with its versatility in production, makes alumina an increasingly popular choice for manufacturers looking to enhance performance and durability. As ongoing research and development continue to unlock new possibilities, the future of alumina casting appears promising, paving the way for innovative applications and solutions.

Share

-

Vermiculite Wholesale – Premium Quality, Bulk Supply & Competitive PricingNewsJun.10,2025

-

Premium Glass Pebbles Custom Glass Pebbles Factory & OEM Manufacturer Reliable Custom Glass Pebbles FactoriesNewsJun.10,2025

-

Expert Custom Zeolite Producers Manufacturers & FactoriesNewsJun.10,2025

-

Custom Glow in the Dark Beads High-Quality Custom ManufacturersNewsJun.10,2025

-

China Ceramsite Balls Factory - Lightweight & Durable Media Solutions ManufacturerNewsJun.09,2025

-

Custom Matte Mica Powder Manufacturers High Quality & AffordableNewsJun.09,2025