glass ball factories

The Fascinating World of Glass Ball Factories

In the realm of manufacturing, few products capture the imagination quite like glass balls. Whether they are used for decorative purposes, in scientific applications, or as toys, glass balls are a testament to the intricate artistry and skill involved in glassmaking. Glass ball factories, with their unique blend of tradition and modern technology, play a crucial role in producing these mesmerizing items.

Glass production is an ancient craft, dating back thousands of years. The journey begins with raw materials, primarily silica sand, soda ash, and limestone. These components are mixed in specific proportions and then melted at extremely high temperatures to create a molten glass. The process is both an art and a science, where precision is key. In glass ball factories, artisans and technicians work in tandem to ensure that each batch meets the desired specifications in terms of color, clarity, and consistency.

Once the glass reaches a molten state, it is shaped into balls using various techniques. One popular method involves blowing, where a skilled glassblower uses a blowpipe to gather molten glass and inflate it into a sphere. This technique requires years of practice to master, as the glass must be manipulated quickly before it cools and solidifies. Other methods include molding, where the molten glass is poured into a pre-formed mold, and marvering, which involves rolling the glass on a smooth surface to shape it.

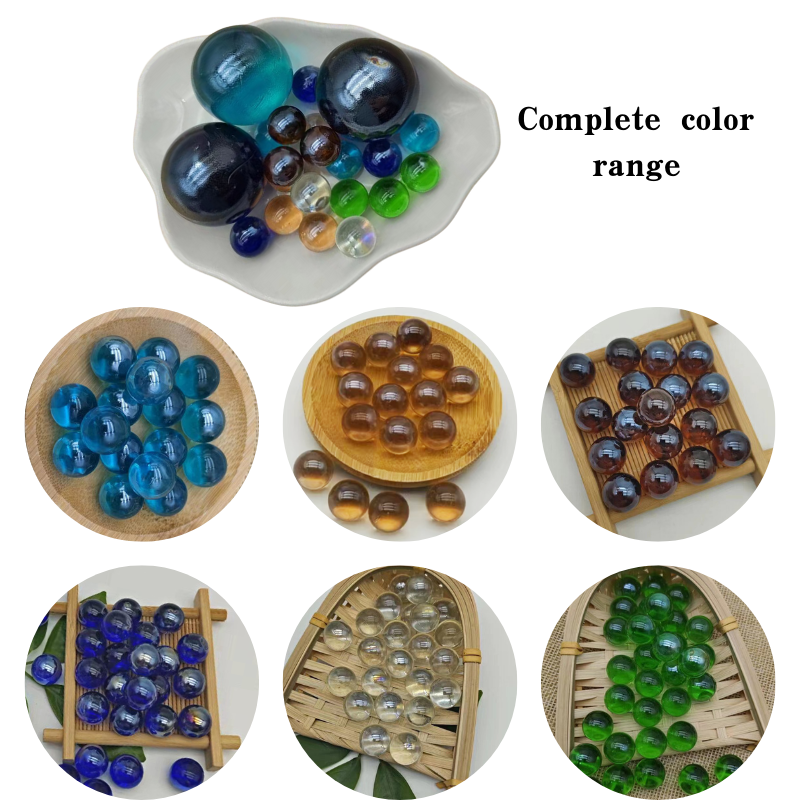

Color is another fascinating aspect of glass ball production. Factories often incorporate metal oxides and other additives during the melting process to achieve vibrant hues. For example, cobalt oxide produces a deep blue, while manganese can create a rich purple. This use of color enables factories to produce a diverse range of glass balls for various markets, from festive decorations to scientific apparatus.

glass ball factories

Quality control is paramount in glass ball factories. Each ball is meticulously inspected for imperfections, such as bubbles or surface flaws. Advanced technology now aids in this process, with machines that can detect minute defects at high speed. This ensures that only the highest quality products reach consumers, maintaining the factory's reputation for excellence.

As sustainability becomes a critical concern in manufacturing, glass ball factories are also adapting their practices. Many now utilize recycled glass, known as cullet, which significantly reduces energy consumption during production. By incorporating cullet, factories can melt glass at lower temperatures, thereby consuming less fuel and emitting fewer greenhouse gases. This shift not only improves the environmental footprint of glass production but also brings about cost savings.

The market for glass balls is diverse, ranging from artistic creations to everyday items. Collectors often seek unique pieces from specialized artists or factories, while manufacturers supply glass balls for a variety of industries, including toys, horticulture, and engineering. The versatility of glass allows it to be used in applications as varied as reflective surfaces in optics to decorative ornaments for home décor.

In conclusion, glass ball factories represent a unique intersection of art and technology. The skillful craftsmanship involved in glass production, combined with modern innovations aimed at sustainability and quality control, ensures that these simple yet beautiful objects continue to captivate and serve diverse functions in our world. As consumers become more aware of the importance of sustainable practices, the evolution of glass ball production reflects a commitment to both artistry and environmental responsibility, paving the way for a bright future in this enchanting industry.

Share

-

GPT-4 Turbo Silicon Carbide Grit - Premium Abrasive SolutionsNewsAug.04,2025

-

Premium Glass Sand Solutions | High Purity SupplyNewsAug.03,2025

-

Premium Talcum Powder Enhanced with GPT-4 Turbo | Soft & Long-LastingNewsAug.02,2025

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025