Custom Calcium Carbonate Lime Powder Supplier and Manufacturer for Various Applications

Custom CaCO3 Lime Powder Manufacturer Meeting Diverse Industrial Needs

In the dynamic world of industrial minerals, calcium carbonate (CaCO3) stands out as one of the most versatile and widely used compounds. It comes in various forms, with lime powder being one of the most important applications. The demand for custom CaCO3 lime powder has surged, driven by its essential role across multiple industries, including construction, agriculture, plastics, and pharmaceuticals. As a result, the importance of choosing a reliable manufacturer who can produce high-quality, tailored lime powder is paramount.

Understanding Calcium Carbonate and Lime Powder

Calcium carbonate exists in three primary forms ground calcium carbonate (GCC), precipitated calcium carbonate (PCC), and lime (calcium oxide or calcium hydroxide). Each form has distinct characteristics and applications. Lime powder, in particular, has gained significant traction due to its effectiveness in various applications, such as pH regulation in soil, a filler in plastics, a colorant in paints, and an essential ingredient in the construction industry for producing mortar and cement.

Lime powder is typically produced by calcining limestone, which is primarily composed of CaCO3. This process involves heating limestone to a temperature where it decomposes into quicklime (CaO) and carbon dioxide (CO2). The quicklime can then be hydrated to produce hydrated lime or can be used directly in its powdered form.

The Growing Demand for Custom Solutions

As industries evolve, the need for tailored solutions becomes increasingly evident. Companies are seeking custom formulations of lime powder that meet specific particle size distributions, purity levels, and chemical compositions. This customization is critical to ensuring optimal performance in various applications. For instance, in the agricultural sector, lime powder can be formulated to enhance the calcium content of soil, thus supporting plant growth. In the plastics industry, a specific grade of lime powder can provide the desired opacity and texture.

The growing demand for customization has propelled the creation of a niche market for specialized CaCO3 lime powder manufacturers. Companies that can offer bespoke solutions are becoming indispensable partners for businesses seeking to enhance their product quality and performance.

Quality Control and Assurance

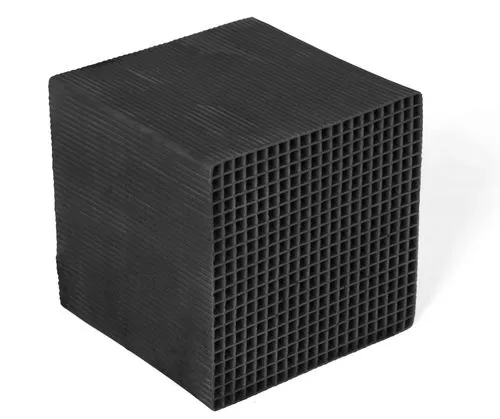

custom caco3 lime powder manufacturer

When selecting a custom CaCO3 lime powder manufacturer, quality is a non-negotiable factor. Manufacturers should adhere to stringent quality control processes throughout the production cycle. This includes sourcing high-quality limestone, maintaining consistent production parameters, and conducting thorough testing on the final product.

Testing for factors such as purity, brightness, particle size, and moisture content is crucial to ensure that the lime powder meets the intended application requirements. A reputable manufacturer should be able to provide certifications and documentation confirming their product's quality and compliance with industry standards.

Sustainability and Environmental Responsibility

With increasing attention on sustainability, manufacturers are also focusing on environmentally friendly practices. This includes adopting methods that reduce carbon emissions during the calcination process, utilizing waste materials, and implementing recycling processes. Manufacturers that prioritize sustainability not only enhance their brand reputation but also contribute positively to the environment, making them attractive partners for eco-conscious companies.

The Path Forward

As industries continue to develop and innovate, the need for custom CaCO3 lime powder will undoubtedly grow. Manufacturers capable of adapting to changing market demands and providing high-quality, customizable products will secure their position within the industry.

Moreover, strategic partnerships between manufacturers and their clients can foster innovation and efficiency. By working closely with customers, manufacturers can better understand their specific needs and develop solutions that enhance product performance.

In conclusion, the role of a custom CaCO3 lime powder manufacturer is crucial in supporting a variety of industrial applications. Companies that leverage quality, customization, and sustainability will not only meet today’s demands but will also be well-prepared for the future. The journey of finding the right manufacturer may involve thorough research and evaluation, but the rewards of high-quality, tailored lime powder are well worth the effort.

Share

-

Vermiculite Wholesale – Premium Quality, Bulk Supply & Competitive PricingNewsJun.10,2025

-

Premium Glass Pebbles Custom Glass Pebbles Factory & OEM Manufacturer Reliable Custom Glass Pebbles FactoriesNewsJun.10,2025

-

Expert Custom Zeolite Producers Manufacturers & FactoriesNewsJun.10,2025

-

Custom Glow in the Dark Beads High-Quality Custom ManufacturersNewsJun.10,2025

-

China Ceramsite Balls Factory - Lightweight & Durable Media Solutions ManufacturerNewsJun.09,2025

-

Custom Matte Mica Powder Manufacturers High Quality & AffordableNewsJun.09,2025