Understanding OEM Limestone Powder and Its Factory Production Process

Understanding OEM Limestone Powder Significance and Applications

Limestone powder, derived from the grinding and processing of limestone, has found extensive applications across various industries. The term OEM stands for Original Equipment Manufacturer, and when coupled with limestone powder, it creates a milieu of possibilities in manufacturing, construction, and other applications. This article delves into the meaning of OEM limestone powder, its significance, and its diverse applications in various industries.

What is Limestone Powder?

Limestone is a sedimentary rock composed primarily of calcium carbonate (CaCO3). When limestone is crushed and milled, it becomes limestone powder, a fine white or off-white powder that is highly versatile. This powder can vary in particle size and purity, depending on the source of limestone and the method of processing. It is commonly used in construction materials, plastics, rubber, and various chemical processes.

The Role of OEM in Limestone Powder Production

OEM limestone powder refers to limestone powder that is produced and supplied by manufacturers who cater specifically to the needs of other companies. These manufacturers create customized products that meet the specifications and quality standards required by their clients. The OEM approach allows companies to focus on their core competencies, such as product development and marketing, while outsourcing the production process to specialized manufacturers.

OEM partnerships in limestone powder production can lead to several advantages, including

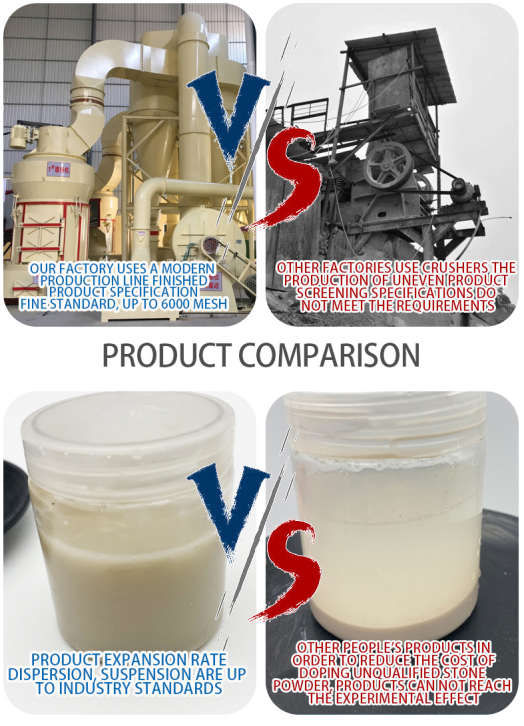

1. Cost-Effectiveness Outsourcing production helps companies save on manufacturing costs while focusing on brand development and sales strategy. 2. Quality Assurance Reputable OEM partners often have stringent quality control processes in place. This ensures that the limestone powder produced meets the required standards, thus minimizing defects and returning non-compliant materials.

3. Flexibility and Scalability OEM manufacturers can scale production up or down based on real-time demand, allowing their partners to remain responsive to market changes without the risk of overproduction or underutilization of resources.

4. Access to Technology and Expertise Partnering with an OEM allows companies to leverage advanced technologies and the expertise of reputed manufacturers, often leading to improved product quality and innovation.

oem limestone powder meaning factory

Applications of OEM Limestone Powder

The applications of OEM limestone powder are vast, reflecting the diverse nature of industries that utilize this product. Below are several key sectors where OEM limestone powder plays a crucial role

1. Construction Industry Limestone powder is widely used as an additive in cement and concrete production, improving workability and reducing water consumption. Its properties help create stronger and more durable materials, making it a preferred choice for construction projects.

2. Agriculture In agricultural applications, limestone powder is used to improve soil quality. It acts as a soil conditioner, adjusting pH levels and providing essential calcium to crops, thereby enhancing yield and productivity.

3. Plastic and Rubber Manufacturing Limestone powder serves as a filler in the production of plastics and rubber products. By incorporating limestone powder, manufacturers can reduce production costs, enhance product strength, and improve durability.

4. Chemical Industry Limestone powder is employed in the manufacture of various chemicals, including calcium carbide, calcium sulfate, and quicklime. It serves as a crucial ingredient in many chemical processes, contributing to the production of fertilizers and other essential compounds.

5. Environmental Applications As an environmentally-friendly alternative, limestone powder can be used in water treatment processes to reduce acidity and remove impurities. It can also be utilized in flue gas desulfurization, helping industries comply with environmental regulations.

Conclusion

OEM limestone powder is a vital product that advances the capabilities of numerous industries, thanks to its accessibility and versatility. By understanding the multifaceted applications and advantages of partnering with OEM manufacturers, businesses can leverage high-quality limestone powder to enhance their product offerings while benefiting from cost savings and efficiency improvements.

As demand for limestone powder continues to grow, particularly in environmentally-sensitive industries and applications, the role of OEM partnerships will remain significant, fostering innovation and sustainability across the market. In the ever-evolving landscape of manufacturing, the collaboration with OEMs will play a crucial role in shaping the future of limestone powder applications.

Share

-

Premium Kaolin Powder | High-Purity Mineral SolutionNewsAug.05,2025

-

GPT-4 Turbo Silicon Carbide Grit - Premium Abrasive SolutionsNewsAug.04,2025

-

Premium Glass Sand Solutions | High Purity SupplyNewsAug.03,2025

-

Premium Talcum Powder Enhanced with GPT-4 Turbo | Soft & Long-LastingNewsAug.02,2025

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025