OEM Bentonite Clay for Efficient Well Drilling Solutions from Trusted Factory

The Advantages of OEM Bentonite Clay for Well Drilling

Bentonite clay, a natural clay consisting primarily of montmorillonite, has become a staple in various industries, particularly in well drilling. Its unique properties, including high absorbency, swelling, and adhesive qualities, make it an essential component for creating drilling mud. This article explores the advantages of OEM (Original Equipment Manufacturer) bentonite clay sourced from reputable factories, emphasizing its significance in the well drilling sector.

Understanding Bentonite Clay

Bentonite clay is formed from the weathering of volcanic ash, resulting in a fine-grained sediment. It is classified into two main types sodium bentonite and calcium bentonite. Sodium bentonite has a higher swelling capacity, making it ideal for well drilling applications. The unique qualities of bentonite allow it to serve multiple purposes, such as stabilizing boreholes, preventing fluid loss, and cooling down the drill bit during operations.

Benefits of Using Bentonite Clay in Well Drilling

1. Enhanced Hole Stability One of the foremost advantages of using bentonite clay in drilling operations is its ability to provide excellent borehole stability. When mixed with water, bentonite forms a viscous drilling fluid that helps support the walls of the drilled hole. This stability prevents collapse and minimizes the risk of cave-ins, ensuring a safer working environment.

2. Fluid Loss Control Bentonite clay acts as a filter cake when drilling fluid is pumped into a well. The clay particles accumulate along the borehole walls, forming a thin but effective barrier that reduces fluid loss into the surrounding formations. This property is crucial in maintaining the desired pressure and preventing unwanted fluid influx during drilling.

3. Cooling and Lubrication The cooling properties of bentonite are vital for drilling operations. As drill bits generate heat from friction, the drilling fluid helps cool them down, prolonging their lifespan and enhancing drilling efficiency. Additionally, the lubricating properties of bentonite minimize wear and tear on drilling equipment, further improving operational efficiency.

4. Environmental Safety Bentonite clay is an environmentally friendly solution for drilling operations. It is non-toxic, non-hazardous, and biodegradable, reducing the environmental impact associated with drilling activities. Many OEM manufacturers ensure that their bentonite products meet stringent environmental standards, making it a sustainable choice for well drilling.

oem bentonite clay for well drilling factory

5. Cost-Effectiveness Opting for OEM bentonite clay can be highly cost-effective. Manufacturers often provide bulk purchasing options, which can significantly reduce the price per unit. Furthermore, the efficient properties of bentonite reduce the need for additional chemicals or additives, leading to lower overall operational costs in drilling projects.

The Importance of OEM Sourcing

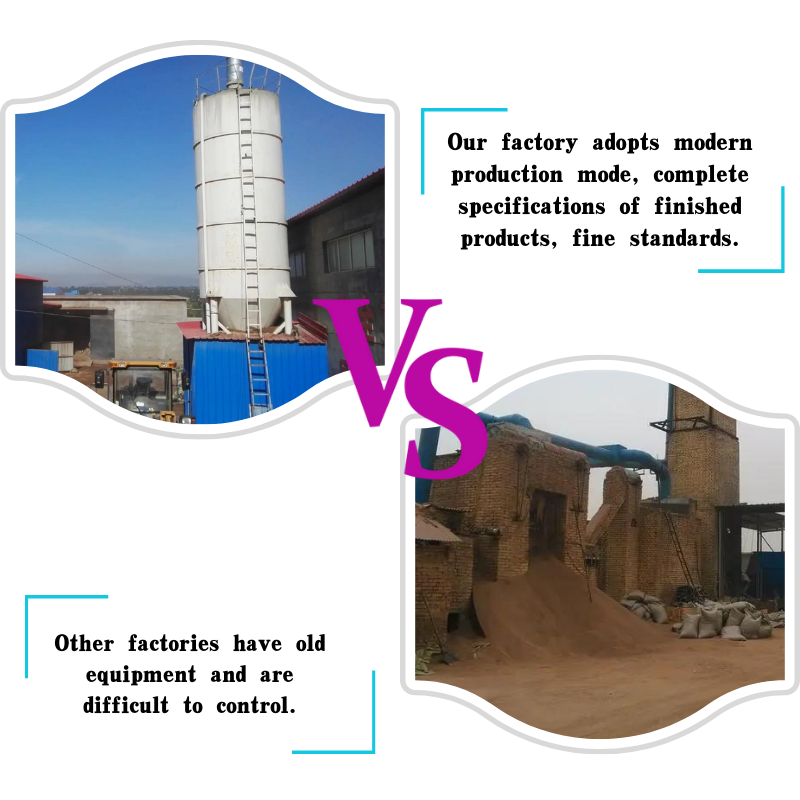

Purchasing OEM bentonite clay from reputable manufacturers ensures high quality and consistency in the product. These manufacturers adhere to strict quality control measures and produce bentonite that meets industry specifications. The benefits of utilizing OEM products include

- Consistency in Quality OEM factories maintain rigorous testing procedures to ensure their bentonite clay meets required standards. Consistent quality ensures that the drilling operations proceed smoothly without unexpected complications caused by inferior materials.

- Technical Support OEM manufacturers often provide technical support and consultation to their clients. This assistance can be invaluable in determining the most suitable grade of bentonite for specific drilling conditions, optimizing performance, and addressing any challenges that arise.

- Customization Options Many OEM providers offer customization services that allow customers to specify their unique needs. From granule size to additives, these tailored solutions can further enhance the effectiveness of bentonite clay for particular drilling applications.

Conclusion

Bentonite clay plays an indispensable role in the well drilling industry, offering numerous advantages that enhance safety, efficiency, and cost-effectiveness. Opting for OEM bentonite clay from reputable factories ensures high quality, reliability, and technical support. By leveraging the capabilities of bentonite, drilling companies can achieve better results while adhering to environmental and safety standards. As the demand for natural resources continues to grow, the use of high-quality bentonite clay will remain pivotal in the evolution of well drilling practices.

Share

-

Premium Glass Sand Solutions | High Purity SupplyNewsAug.03,2025

-

Premium Talcum Powder Enhanced with GPT-4 Turbo | Soft & Long-LastingNewsAug.02,2025

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025