custom silicon powder 325 mesh size manufacturer

The Benefits of Custom Silicon Powder with 325 Mesh Size

In the ever-evolving landscape of industrial manufacturing, the demand for specialized materials has grown significantly. One such innovative product gaining traction is custom silicon powder, particularly in the 325 mesh size. This fine-grade silicon powder offers numerous advantages across various applications, making it an essential component in many industries.

Silicon powder, known for its exceptional properties, serves as a critical material in electronics, ceramics, and even construction. The 325 mesh size, which corresponds to a particle size of approximately 44 microns, is particularly sought after due to its ideal balance between fineness and performance. This size enables manufacturers to achieve optimal reactivity and enhance the physical properties of the end products.

One of the primary benefits of custom silicon powder is its versatility. Tailored formulations can be engineered to meet specific requirements, whether the end goal is to enhance conductivity in electronic components or improve the mechanical strength of ceramic materials. By working with specialized manufacturers, companies can specify the desired particle size, morphology, and purity level, ensuring that the silicon powder aligns perfectly with their operational needs.

custom silicon powder 325 mesh size manufacturer

Moreover, the use of 325 mesh silicon powder can significantly improve product performance. In the realm of electronics, for instance, finer silicon particles facilitate better electron mobility, which can lead to enhanced efficiency in semiconductors. Similarly, in the field of ceramics, incorporating custom silicon powder can boost density and strength, thus elevating the quality and durability of finished products.

Environmental considerations also play a vital role in today’s manufacturing practices. Many manufacturers of custom silicon powder are increasingly adopting sustainable sourcing and production methods. Utilizing eco-friendly materials and reducing waste not only helps meet regulatory requirements but also appeals to the growing consumer base that prioritizes sustainability.

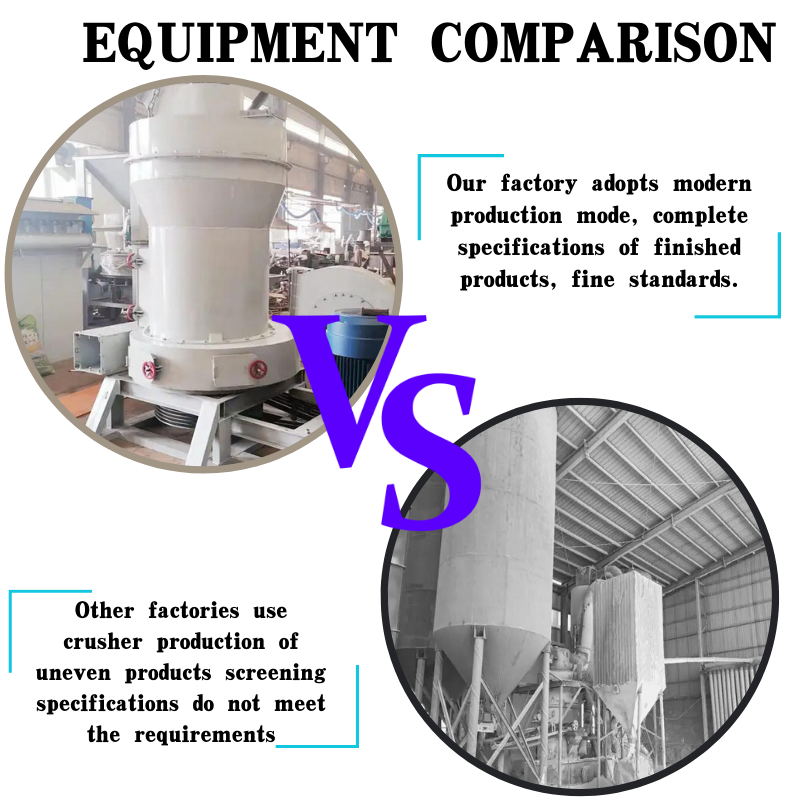

Finally, the integration of advanced technologies in manufacturing processes guarantees that custom silicon powders meet the highest industry standards. Rigorous quality control measures ensure that each batch of 325 mesh silicon powder is consistent in quality and performance, providing peace of mind for manufacturers relying on these materials in their production lines.

In conclusion, custom silicon powder with a 325 mesh size stands out as a valuable resource in modern manufacturing. Its versatility, performance enhancement capabilities, and alignment with sustainable practices make it an attractive option for industries ranging from electronics to construction. As manufacturers continue to seek specialized materials to improve their products, the demand for high-quality silicon powder is likely to rise, highlighting its importance in the future of manufacturing.

Share

-

Premium Talcum Powder Enhanced with GPT-4 Turbo | Soft & Long-LastingNewsAug.02,2025

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025