custom aluminium oxide grinding factories

The Rise of Custom Aluminium Oxide Grinding Factories

In the ever-evolving landscape of manufacturing, the demand for precision and quality is paramount. Among the materials that have gained significant traction in various industries is aluminium oxide. Known for its exceptional hardness and durability, aluminium oxide has become a staple in grinding applications. As a result, custom aluminium oxide grinding factories are emerging as crucial players in the manufacturing sector. This article explores the reasons behind this trend and the implications for various industries.

The Versatility of Aluminium Oxide

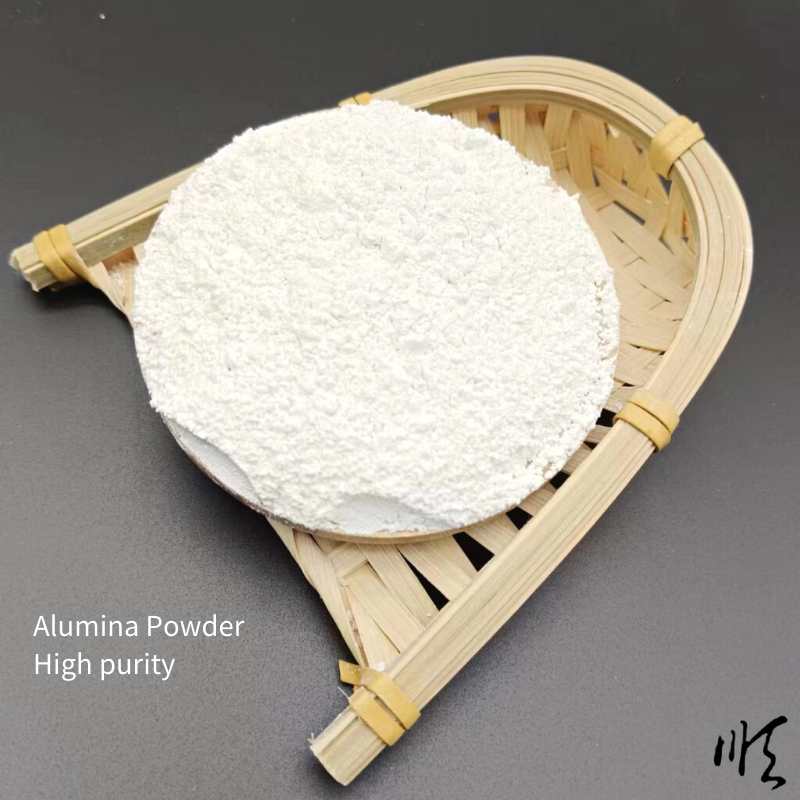

Aluminium oxide, or alumina, is a ceramic material that exhibits remarkable properties, making it suitable for a wide range of applications. Its high melting point, thermal stability, and resistance to chemical corrosion make it ideal for industries such as aerospace, automotive, and electronics. Additionally, its abrasive qualities allow it to be used effectively in grinding and polishing processes.

Custom aluminium oxide grinding factories are able to tailor their products to meet the specific needs of their clients. By adjusting parameters such as particle size, shape, and purity, these factories can produce grinding materials that are optimized for different applications. This customization not only enhances the efficiency of the grinding process but also improves the quality of the finished products.

Meeting Industry Demands

The push for more efficient manufacturing processes has led to an increase in the need for specialized grinding materials. Industries are constantly looking for ways to improve their production lines and reduce costs. Custom aluminium oxide grinding factories are stepping in to fill this gap by providing products that enhance productivity and minimize waste.

Moreover, the rise of automation and advanced manufacturing technologies has placed further emphasis on precision. Manufacturers require grinding materials that can deliver consistent results, and custom factories are uniquely positioned to fulfill these requirements. By leveraging state-of-the-art technology and expert knowledge, these facilities can produce high-quality aluminium oxide grinding products that meet the stringent standards of modern manufacturing.

custom aluminium oxide grinding factories

Sustainability and Eco-friendliness

As industries worldwide strive to become more sustainable, the role of custom aluminium oxide grinding factories is increasingly being scrutinized. These factories are making strides to ensure that their processes are environmentally friendly. By utilizing materials that have a lower environmental impact and implementing recycling practices, they are contributing to a more sustainable manufacturing landscape.

For instance, many factories are focusing on the reuse of waste materials generated during the grinding process. By recycling these materials, they not only reduce waste but also lower production costs. This sustainability initiative resonates well with companies that prioritize eco-friendliness in their supply chain, making custom aluminium oxide grinding factories even more appealing.

Technological Advancements

The advent of advanced technologies such as artificial intelligence and machine learning is revolutionizing the operations of custom aluminium oxide grinding factories. These technologies enable factories to optimize their processes, improve quality control, and reduce production timelines.

For example, AI-driven systems can analyze data from grinding processes to identify areas for improvement, helping factories to achieve greater efficiency. Predictive maintenance tools can also be employed to foresee equipment failures before they occur, resulting in lower downtime and enhancing overall productivity.

Conclusion

The emergence of custom aluminium oxide grinding factories signifies a significant advancement in manufacturing. By offering tailored grinding solutions, these facilities not only meet the specialized needs of various industries but also contribute to sustainability efforts and embrace technological innovations. As industries continue to evolve, the role of these factories will likely become even more crucial, paving the way for a more efficient and sustainable manufacturing future. In a world where precision and quality are key, custom aluminium oxide grinding factories stand out as invaluable partners in progress.

Share

-

Premium Talcum Powder Enhanced with GPT-4 Turbo | Soft & Long-LastingNewsAug.02,2025

-

Fly Ash Solutions Enhanced by GPT-4 Turbo | Sustainable InnovationNewsAug.01,2025

-

Natural Premium Bentonite Cat Litter - Superior ClumpingNewsJul.31,2025

-

Premium Resin Coated Sand - High Heat Resistance CastingNewsJul.31,2025

-

High Quality Silicon Carbide Grit for Abrasive ApplicationsNewsJul.30,2025

-

High-Quality Ceramsite for Plants & Gardening | Lightweight PebblesNewsJul.29,2025